Pull box assembly for replacing battery and method for replacing the battery

A battery replacement and pull-out box technology, which is applied to battery components, electrical components, circuits, etc., can solve the problems of increasing labor intensity and burden of staff, cumbersome battery replacement steps, and unfavorable time saving, etc., and achieves simple structure, Easy installation and disassembly, simple and convenient operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

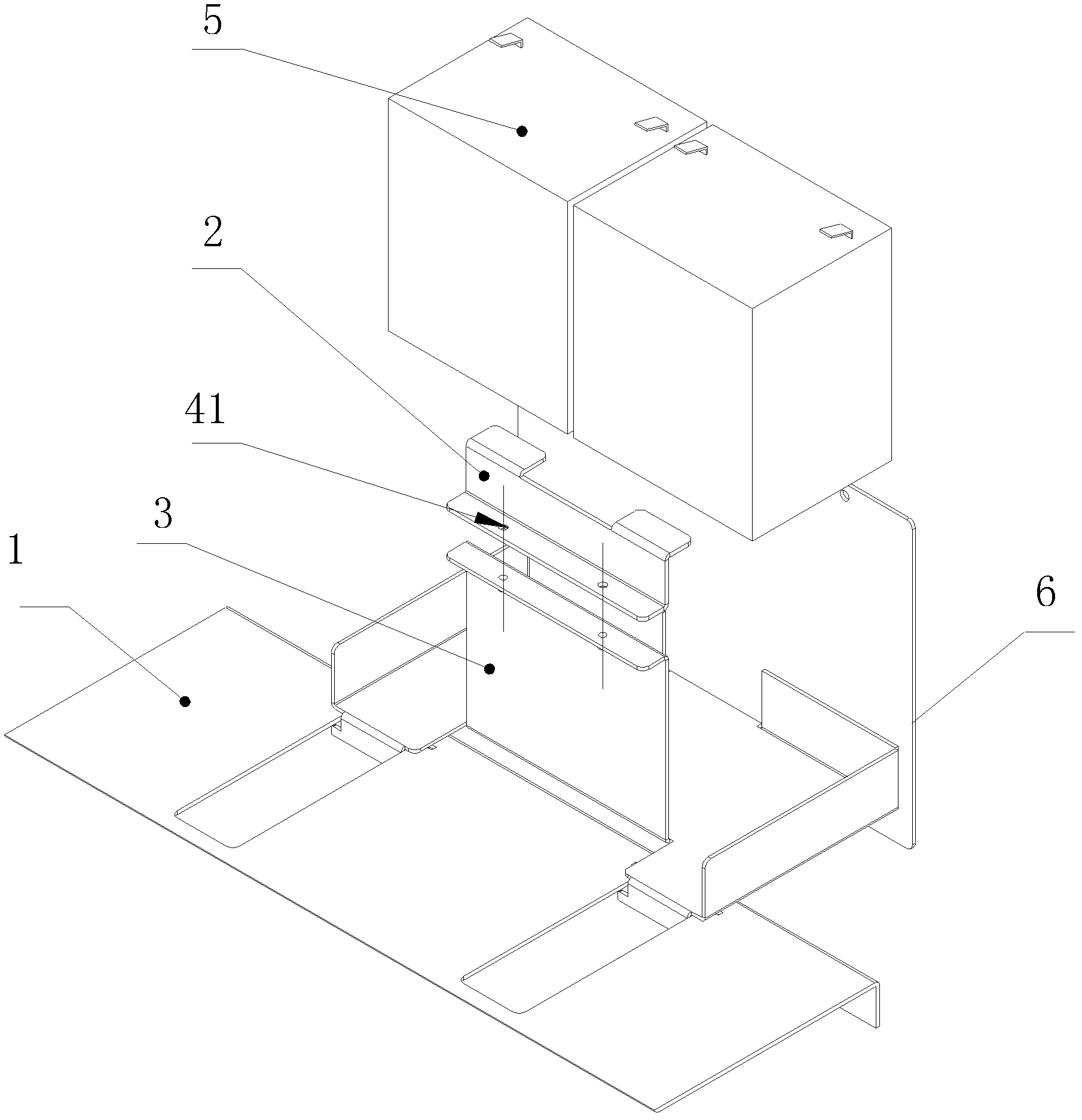

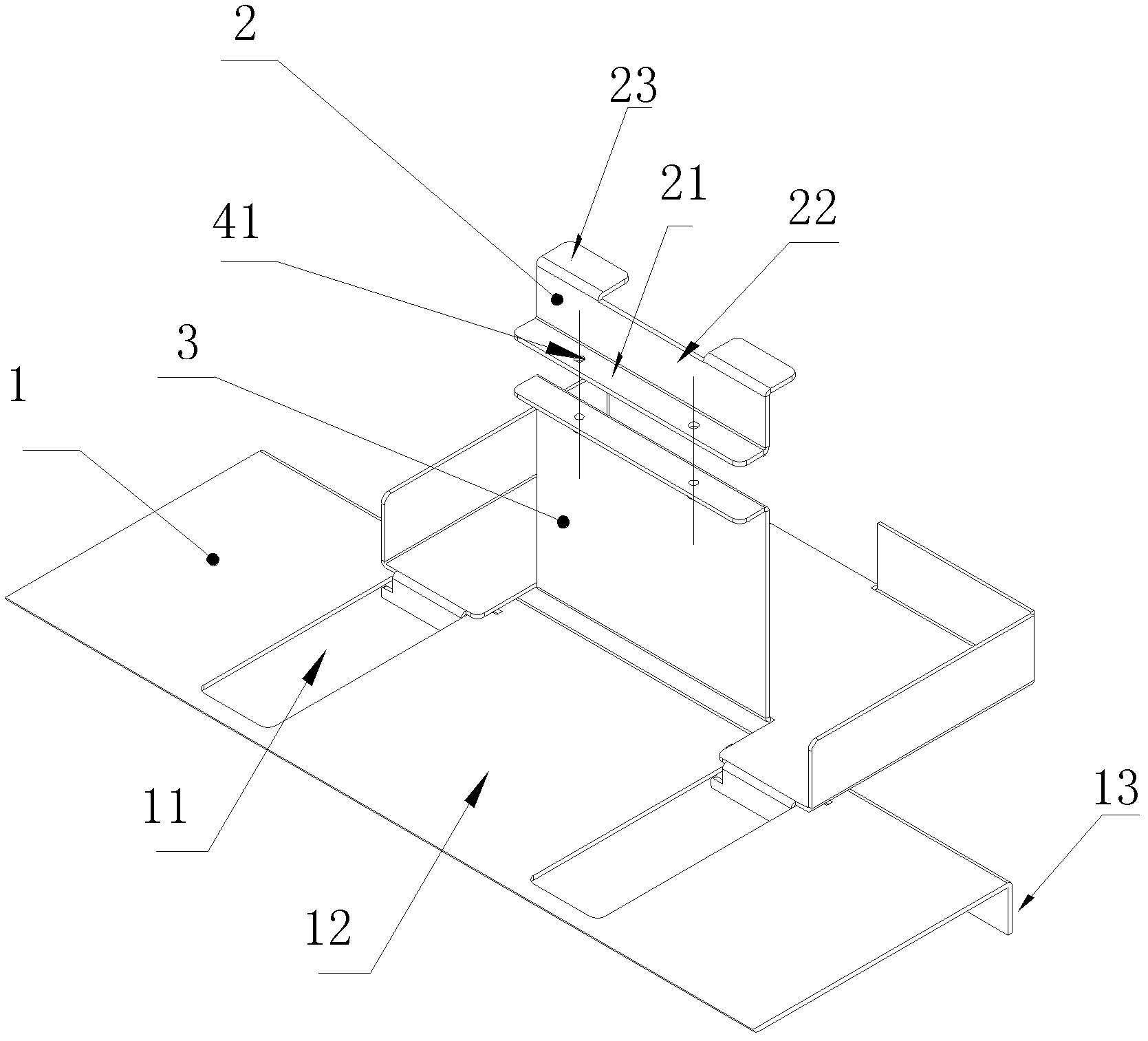

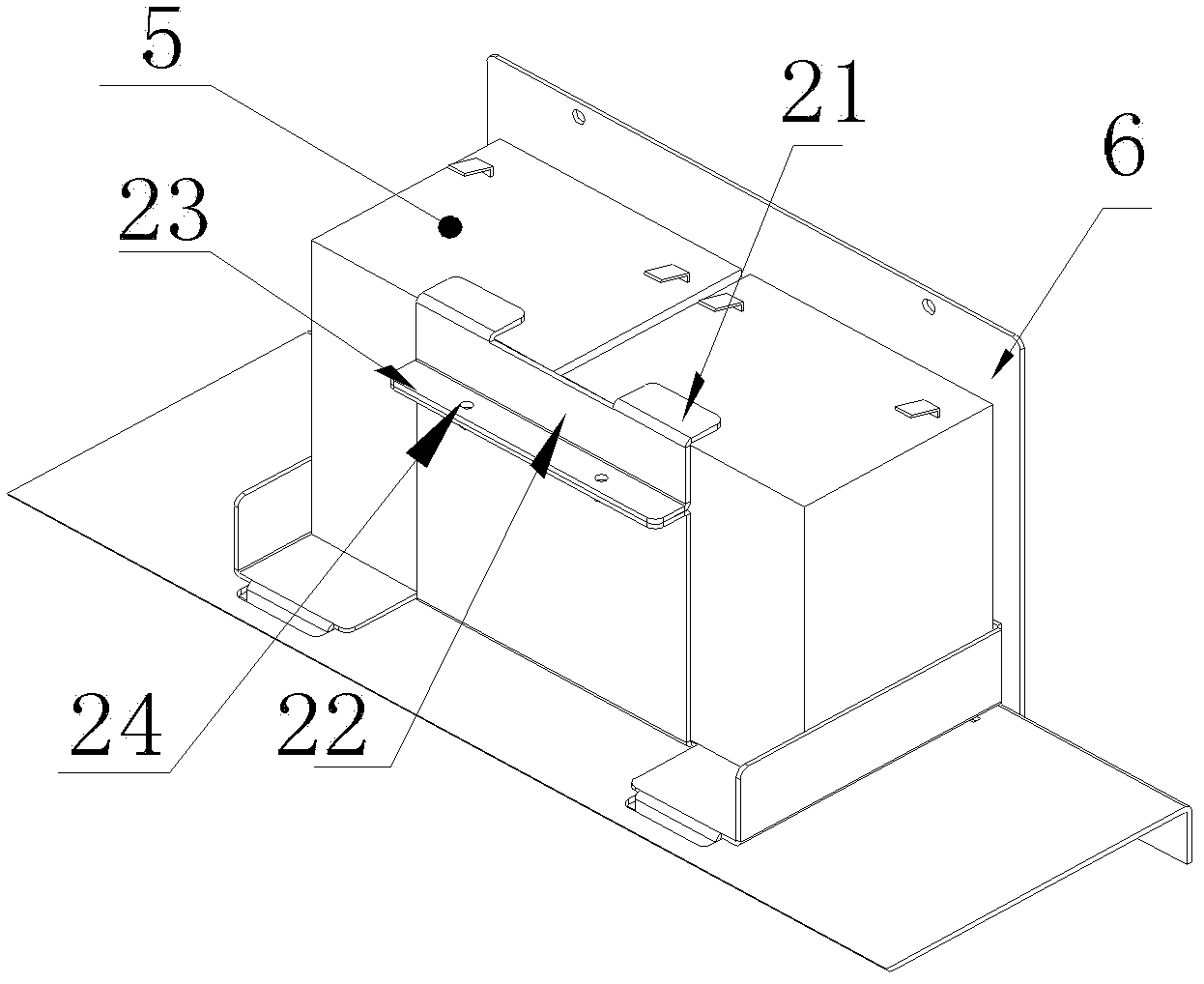

[0077] The technical solution in this embodiment provides a battery installation structural assembly, which includes a battery drawer box 3, a drawer box fixing plate 1, a battery fixing plate 2, and a rear cover plate 6, in which the battery drawer box is suitable for Install two batteries5.

[0078] Wherein, the battery pull-out box 3 is provided with a sliding structure 31, a pull-out limit structure 32, a battery limit structure 33, and a pull-out handle 34; wherein the battery limit mechanism 33 includes a first side limit surface 33-1 , The second side limiting surface 33-2, the third side limiting surface 33-3, the fourth side limiting surface 33-4, the bottom limiting surface 33-5.

[0079] The drawer box fixing plate 1 is provided with a bottom supporting plate 12 and a side fixing plate 13, both of which are folded at right angles, at least one chute structure 11 is arranged on the bottom supporting plate 12, and on the side fixing plate 13 There is at least one sid...

no. 2 example

[0097] See details Figure 2-3 , this embodiment provides a method for replacing a battery according to the battery installation assembly in the first embodiment.

[0098] The method for initial installation of the installation component includes the following steps:

[0099] Step A: The battery drawer box 3 is loaded into the chute structure 11 of the drawer box fixing plate 1 through the sliding structure 31, so that it can be pushed and pulled back and forth; the drawer limit structure 32 of the battery drawer box 3 can control the battery drawer The draw box 3 cannot be disengaged from the draw box fixing plate 1. This step A enables the battery drawer 3 to slide from the initial zero displacement position to the maximum displacement draw limit position along the chute structure 11 of the drawer fixing plate 1;

[0100] Step B: Use the pull handle 34 to pull the battery pull box 3 to the pull limit position of the maximum displacement;

[0101] Step C: Put the battery 5...

no. 3 example

[0117] Such as Figure 9 As shown, the technical solution in this embodiment provides a battery installation structural assembly, which includes a battery drawer box 103, a drawer box fixing plate 101, and a battery fixing plate 102, and is suitable for installing in the battery drawer box At least one battery 105 .

[0118] Wherein, the battery pulling box 103 is provided with a sliding structure 131, a pulling limiting structure 132, a battery limiting structure 133, and a pulling handle 134; wherein the battery limiting mechanism 133 includes a first side limiting surface 133-1 , the second side limiting surface 133-2, the third side limiting surface 133-3, the fourth side limiting surface 133-4, and the bottom limiting surface 133-5. The battery drawer box 103 has a battery limiting structure 133, the limiting structure 33 can be, for example, a bottom limiting surface and four side limiting surfaces, the bottom limiting surface 133-5 limits the downward displacement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com