Method for positioning liquid tank quickly and accurately during building of liquefied ship

A positioning method and liquid tank technology, which are applied in ship construction, ship design, ship parts, etc., can solve problems such as large loss of bulk ship materials, sticking or disengagement of guide rods and guide grooves, and complex structure and use of positioning devices. , to achieve the effect of fast and accurate tank positioning, convenient installation and removal, and improved one-time success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The fast and accurate positioning method of the liquid tank during the construction of the liquefaction ship of the present invention will be further described in detail in the following examples and in conjunction with the accompanying drawings, in order to more clearly describe the process flow of the patented method of the present invention, as well as details related to special tooling. Structural composition and usage, but this cannot be used to limit the protection scope of the patent of the present invention.

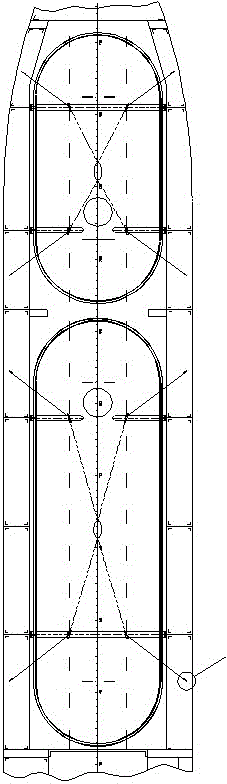

[0027] The invention relates to a quick and accurate positioning method for a liquid tank during the construction of a liquefaction ship, and the liquid tank is a large liquid tank larger than 10,000 cubic meters.

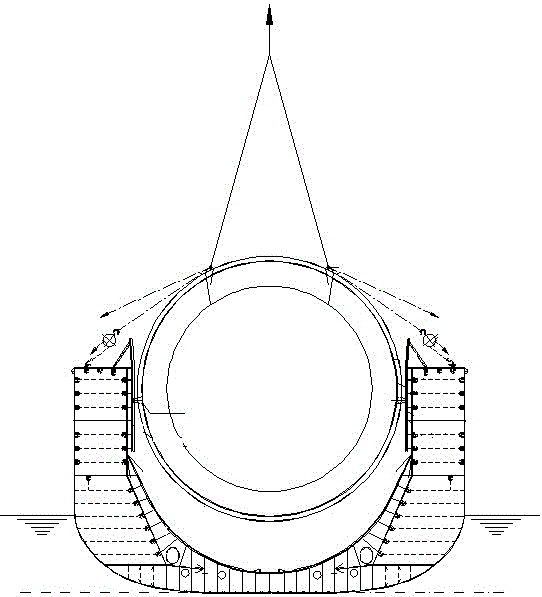

[0028] Such as figure 2 As shown, the positioning method of the liquid tank of the present invention includes the following steps:

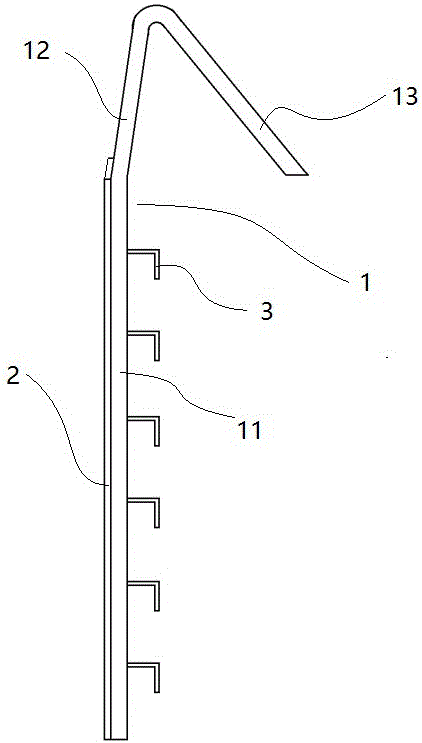

[0029] (1) Guide plates are arranged on both sides of the liquid tank with a circular cross section. The guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com