Radioactive environment large-scale shield main pump integral dismantling device and dismantling process

A dismantling device and radioactive technology, which is applied to parts, pumps, pump components, etc. of the pumping device used for elastic fluids, can solve the problem of narrow space in the hoisting channel of the shielded main pump, limited space in the chamber of the shielded main pump, and environmental dose Advanced problems, to achieve the effect of shortening the maintenance critical path time, shortening the critical path time, and reducing the total radiation dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0076] An overall disassembly device for a large shielded main pump in a radioactive environment, including a main bolt pneumatic disassembly tool, an upper C-ring residual liquid drainage tool, an upper C-ring cutting tool, a pump casing shielding protection tool, an impeller shielding and a rotor lock tight tool. in:

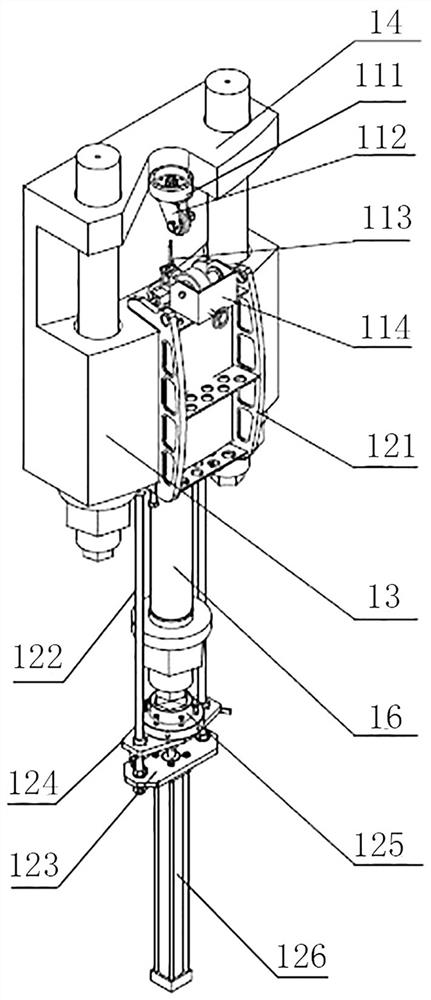

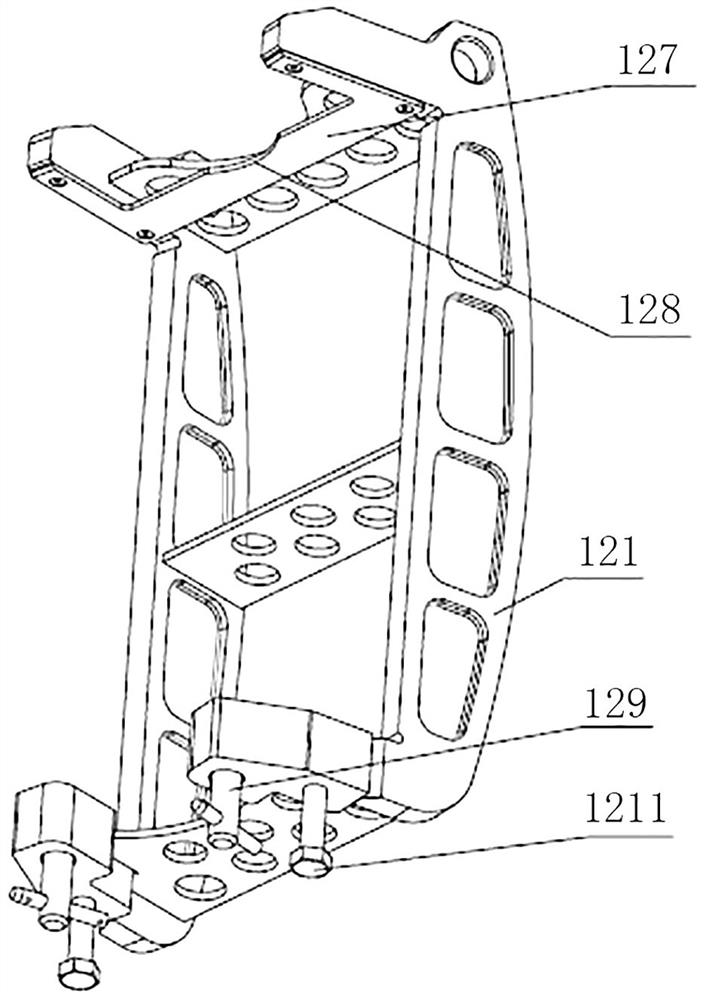

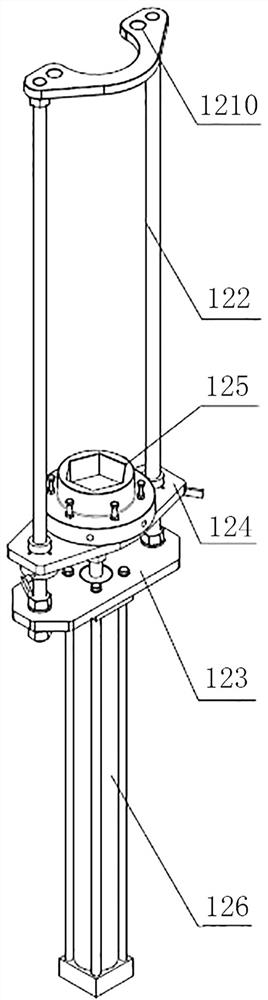

[0077] like Figure 1-5As shown, the main bolt pneumatic dismounting tool includes a main bolt lifting assembly and a main bolt lifting assembly, and the main bolt lifting assembly includes a lifting lug 111, a pulley 112 located at the lower end of the lifting lug 111, a universal lifting eyebolt 113, The winch 114, the steel wire rope connecting the universal eyebolt 113 and the winch 114 through the pulley 112, the upper end of the lifting lug 111 is provided with an external thread matching the threaded hole of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com