Temperature monitoring system and method for main circuit equipment in nsss cold state functional test room

A monitoring system and main loop technology, applied in the field of nuclear safety, can solve problems such as stability impact, achieve the effects of protecting safety, improving test accuracy, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

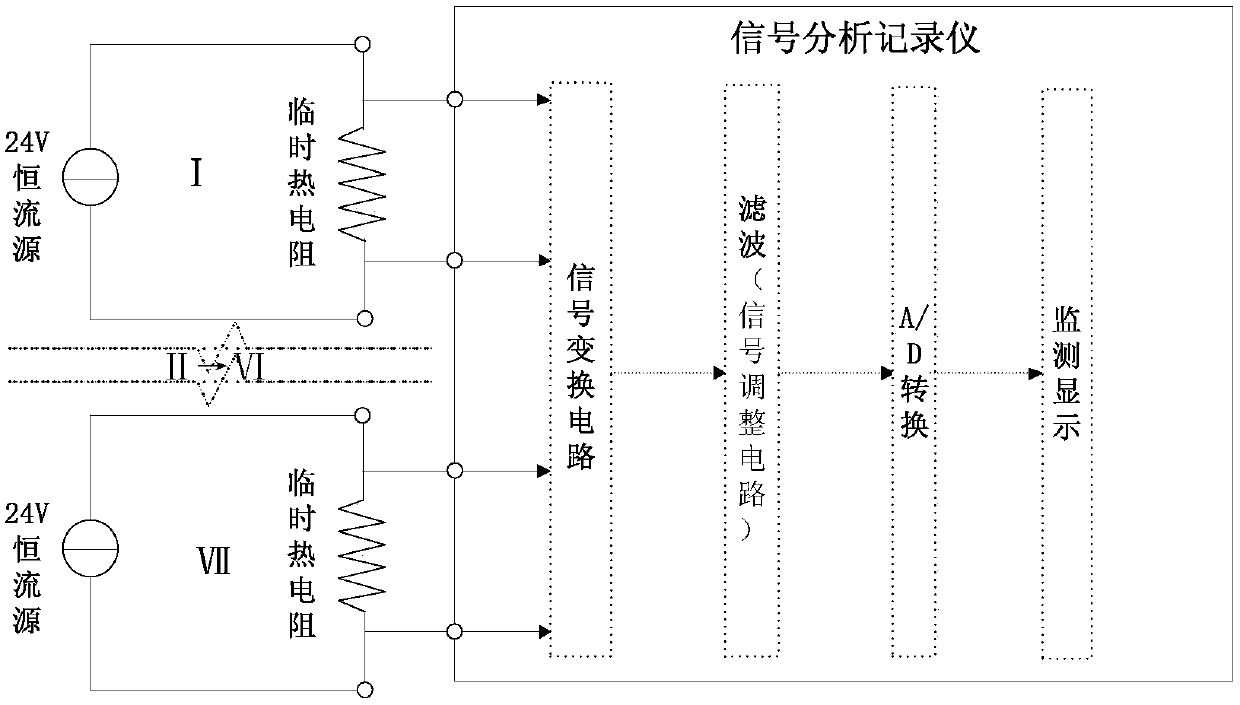

Method used

Image

Examples

Embodiment 1

[0056] An embodiment of the present invention provides a temperature monitoring system for main circuit equipment in an NSSS cold state functional test room.

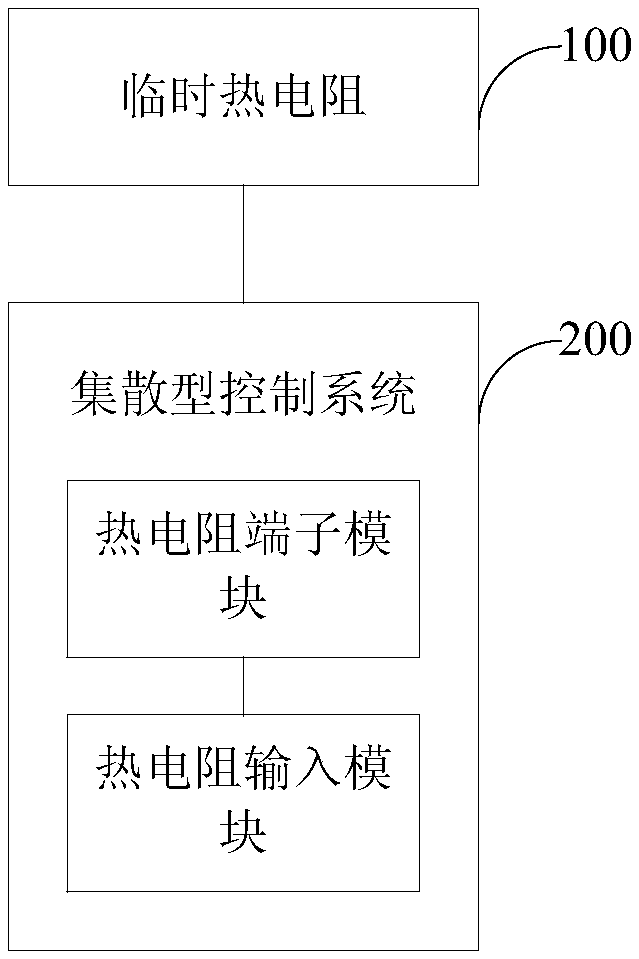

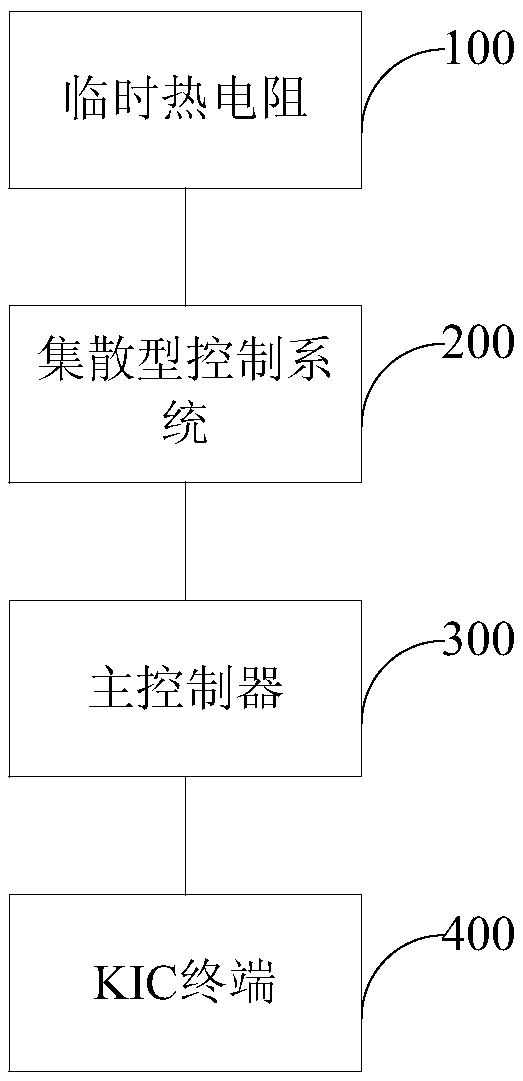

[0057] like figure 2 As shown, the system includes:

[0058] The temporary thermal resistance 100 is arranged on the outer surface of the main circuit equipment, and is used for collecting temporary temperature signals of the main circuit equipment.

[0059] The distributed control system 200 includes a thermal resistance terminal module and a thermal resistance input module, the thermal resistance terminal module is connected to the temporary thermal resistance 100 for receiving and forwarding the temporary temperature signal, and the thermal resistance input module is connected to the The thermal resistance terminal module is used for receiving and processing the temporary temperature signal to obtain temporary temperature data.

[0060] Specifically, the temporary thermal resistance 100 is a four-wire thermal resi...

Embodiment 2

[0096] The embodiment of the present invention provides a method for monitoring the temperature of the main circuit equipment in the NSSS cold-state functional test room, which corresponds to the temperature monitoring system in the first embodiment. For details that are not detailed, please refer to the first embodiment.

[0097] like Figure 7 As shown, the method includes the following steps:

[0098]S101. Collect temporary temperature signals of main circuit equipment.

[0099] S102. Receive the temporary temperature signal.

[0100] S103. Process the temporary temperature signal to obtain temporary temperature data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com