Tool special for reactor heat shield adjustment and centering

A special tool and heat shielding technology, which is applied in the direction of reactors, reactor fuel elements, nuclear engineering, etc., can solve problems such as alignment difficulties, achieve long working hours, save critical path time, and shorten the time occupied by overhaul critical paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

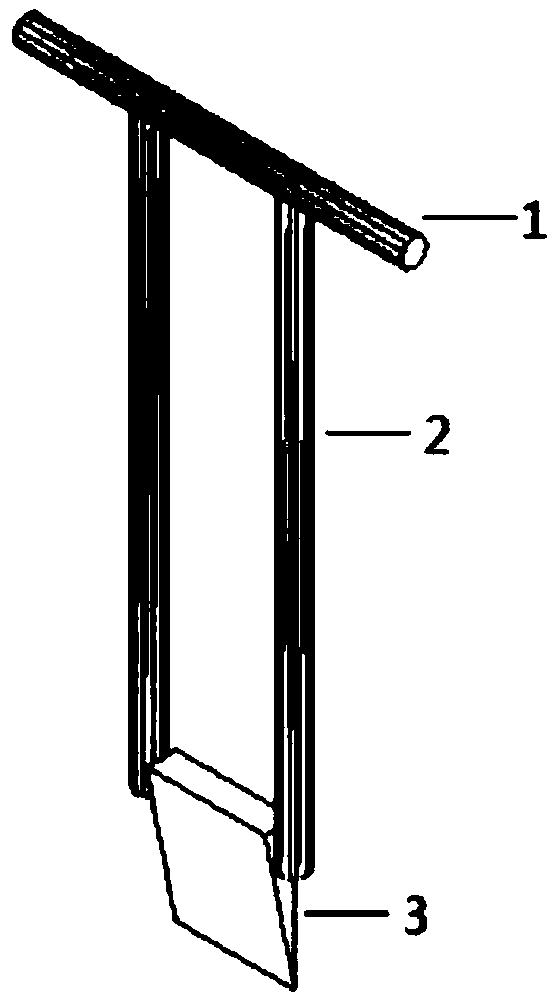

[0018] The production of special tools for heat shielding is a special tool for adjusting the center of the nuclear power plant reactor when reinstalling the heat shield. The special tool for heat shielding is designed as a single-layer inclined plane with an "open" shape. The special tools for heat shielding are divided into two parts. One half is the handle device, one diameter Φ14 carbon steel brace is connected to two Φ14 carbon steel braces, the lower half is an 80x100 carbon steel oblique iron and two Φ14 carbon steel braces are connected for inserting heat shield Adjust the gap in the guide on both sides.

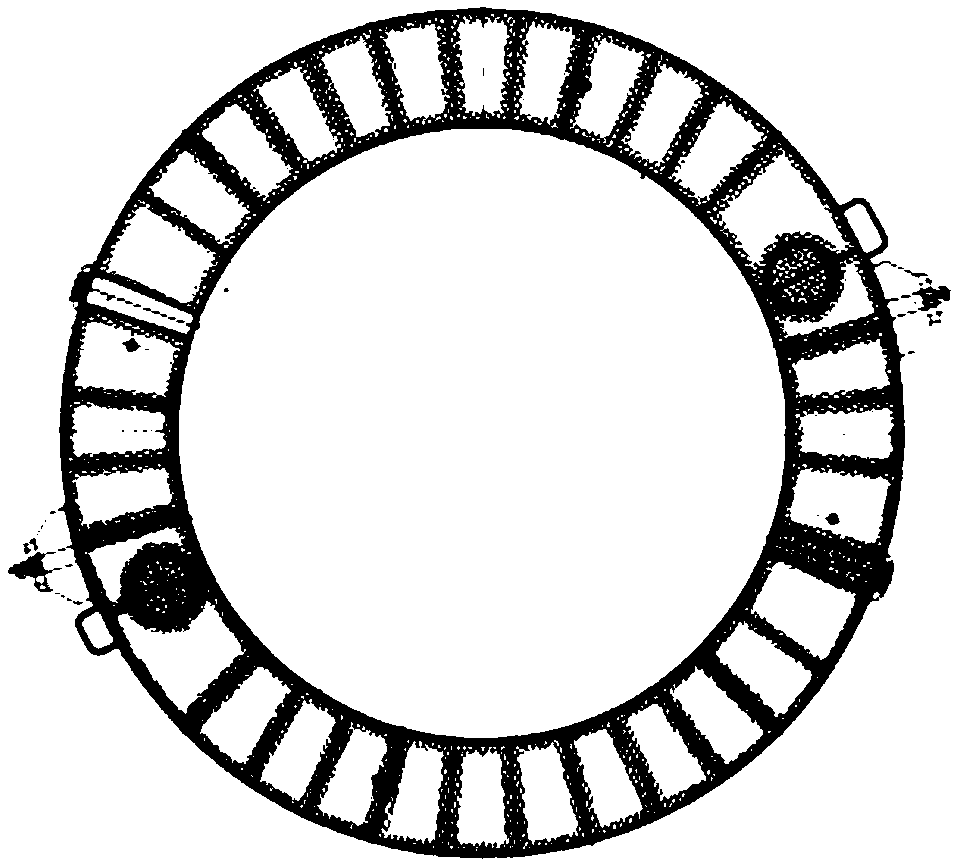

[0019] There are two slideways on both sides of the core shaft of the nuclear power plant reactor, which are used for the centering and guiding effect of large parts. When the thermal shielding of the upper component is reinstalled, the slideway beside the core shaft and the thermal shielding of the upper component are used on both sides The guide slideway is combined t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com