Large steel bridge deck and manufacture method thereof

A technology for steel bridge decks and steel bridge decks, applied in bridges, manufacturing tools, bridge parts, etc., can solve the problems of bridge deck damage, lateral shrinkage and angular deformation, and the amount of welding filling is not fixed, so as to reduce labor intensity, Ensure welding quality and save welding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

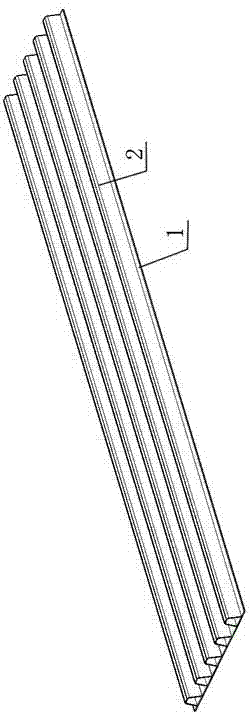

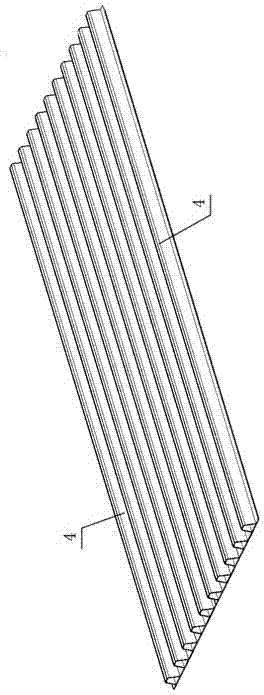

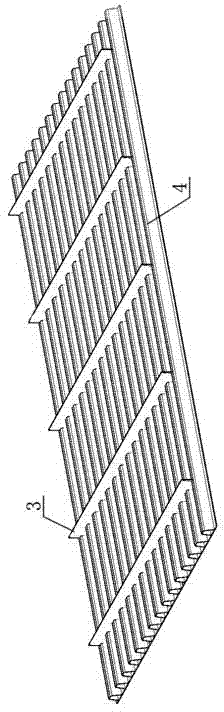

[0015] Embodiment 1: with reference to attached figure 1 ~ attached Figure 4 and Figure 7 . A large steel bridge deck, the steel bridge deck is welded by multiple steel bridge deck blocks, the steel bridge deck block is welded by two or more steel bridge deck units (1+2), the steel bridge deck unit (1 +2) It is composed of several U-shaped ribs 2 and panel 1, several U-shaped ribs 2 are welded on the panel 1 at equal intervals, and the diaphragm connecting plate 3 is welded with U-shaped ribs 2 and panel 1. The shape of the U-shaped rib 2 is a trapezoidal U-shaped rib.

Embodiment 2

[0016] Example 2: On the basis of Example 1, a large-scale steel bridge deck forming method, the prepared steel bridge deck unit (1+2) is laid on the wide tire frame, and the joints are adjusted to be even Positioning welding, using the submerged arc automatic welding process to weld the weld seam on one side of the seam, connecting 2 to 4 steel bridge deck units (1+2) at a time, and then assembling the transverse diaphragm plate 3 according to the position, using the MAG welding process to weld the transverse Partition plate 3 is welded with panel 1 and U-shaped rib 2, and then large-scale lifting equipment is used to turn the plate over 180°, and then the seam 5 between the plate units is welded by submerged arc automatic welding process on the front to form a large plate. During the welding process, design a reasonable groove form (I-type or Y-type groove) at the joint, set a reasonable amount of anti-deformation (0°~2°) to ensure that the flatness meets the requirements; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com