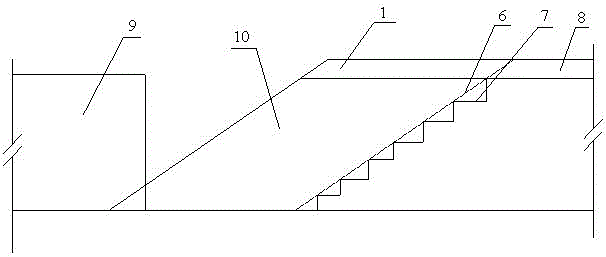

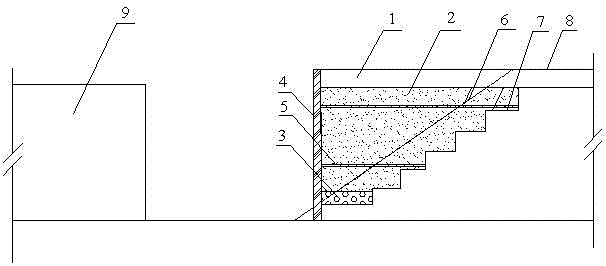

Roadbed structure applied to road widening and construction method

A construction method and roadbed technology, which is applied in the direction of infrastructure engineering, roads, roads, etc., can solve the problems of complicated process, compactness not up to the design standard, and uneven settlement of the joint parts at the junction of old and new roadbeds. The effect of inaccurate bulk density, good fluidity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The filling material described in the present invention is made of the following components by weight: 180 parts of cement, 20 parts of silica fume powder, 50 parts of diatomaceous earth, 30 parts of expanded perlite, 160 parts of water, 5 parts of water reducing agent, 10 parts of rubber powder, 25 parts of plant fiber, 12 parts of foaming agent, and 6 parts of microfoaming agent.

[0073] Cement described in the present invention is P.O42.5 cement.

[0074] The water reducer in the present invention is a polycarboxylate water reducer.

[0075] The foaming agent described in the present invention is a HT composite foaming agent.

[0076] The microfoaming agent described in the present invention is prepared by diluting the foaming agent with water at a ratio of 1:2000, and microfoaming by a plunger pump.

Embodiment 2

[0078] The filling material described in the present invention is made of the following components by weight: 350 parts of cement, 5 parts of silica fume powder, 1 part of diatomaceous earth, 20 parts of expanded perlite, 200 parts of water, 3 parts of water reducing agent, 1 part rubber powder, 15 parts plant fiber, 8 parts foaming agent, 10 parts microfoaming agent.

[0079] The cement described in the present invention is preferably P.O52.5 cement.

[0080] The water reducer in the present invention is a polycarboxylate water reducer.

[0081] The foaming agent described in the present invention is a HT composite foaming agent.

[0082] The microfoaming agent described in the present invention is prepared by diluting the foaming agent with water at a ratio of 1:2000, and microfoaming by a plunger pump.

Embodiment 3

[0084] The filling material described in the present invention is made of the following components by weight: 260 parts of cement, 30 parts of silica fume powder, 20 parts of diatomaceous earth, 70 parts of expanded perlite, 120 parts of water, 1 part of water reducing agent, 8 parts of rubber powder, 5 parts of plant fiber, 5 parts of foaming agent, and 2 parts of microfoaming agent.

[0085] The cement described in the present invention is preferably P.O42.5R cement.

[0086] The water reducer in the present invention is a polycarboxylate water reducer.

[0087] The foaming agent described in the present invention is a HT composite foaming agent.

[0088] The microfoaming agent described in the present invention is prepared by diluting the foaming agent with water at a ratio of 1:2000, and microfoaming by a plunger pump.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com