Patents

Literature

81results about How to "Small construction area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

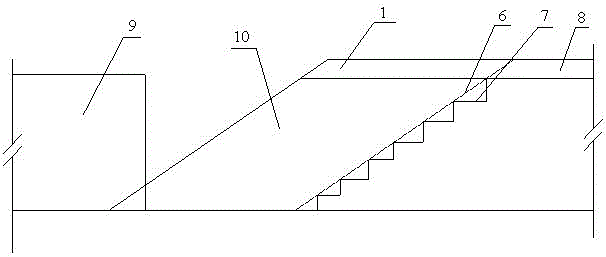

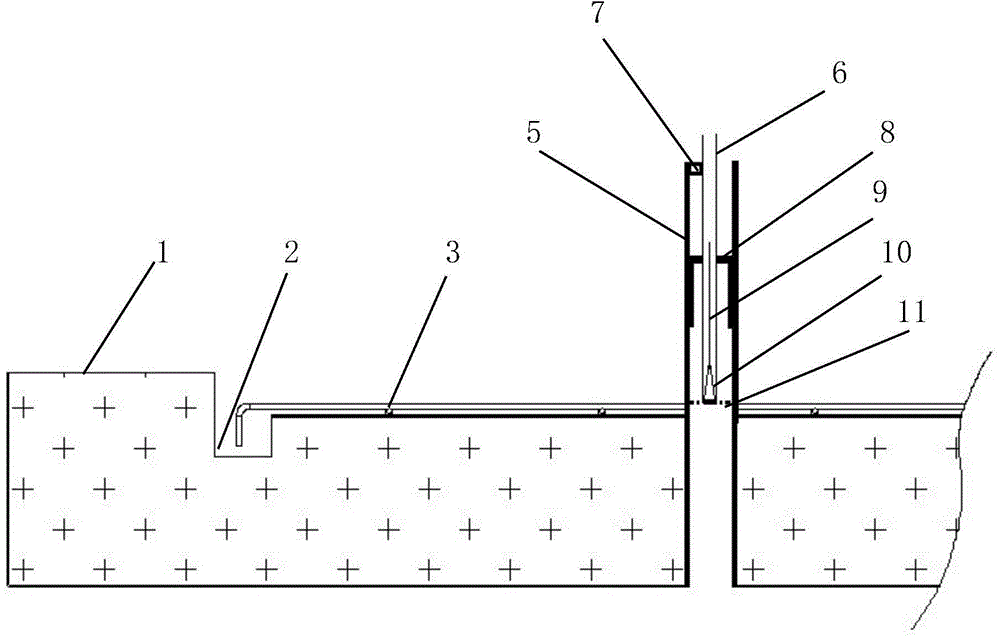

Roadbed structure applied to road widening and construction method

The invention relates to a road building structure and a construction method field. A roadbed structure applied to road widening comprises a new road layer, a filling material layer, a broken stone cushion layer, a concrete retaining wall and an original roadbed slope, wherein the original roadbed slope is finished as a step shape; the concrete retaining wall is arranged on the reciprocal nth step of the step-shaped roadbed slope; the surface of the reciprocal n-1th step of the step-shaped roadbed slope is an inclined surface; the broken stone cushion layer is laid on the surface of the bottom layer of the step-shaped roadbed slope; the filling material layer and the new road layer are arranged at the upper part of the broken stone cushion layer in sequence; and the filling material layer is prepared by cement, silicon fume powder, kieselguhr, expanded perlite, water, a water reducing agent, rubber powder, planet fibers, a foaming agent and a micro foam agent. The roadbed structure can be applied to the road widening, can perform the vertical filling to save the land and to reduce the demolition, can largely reduce the filling load to reduce the differential settlement of new and old roadbeds in soft-foundation road sections, and is short in construction period.

Owner:河南华泰新材科技股份有限公司

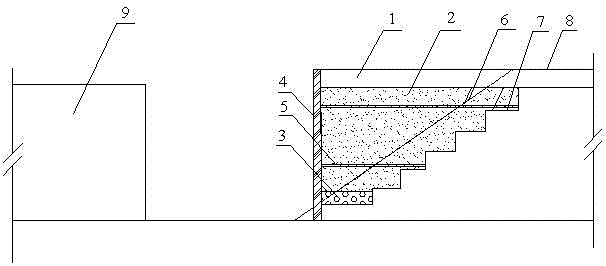

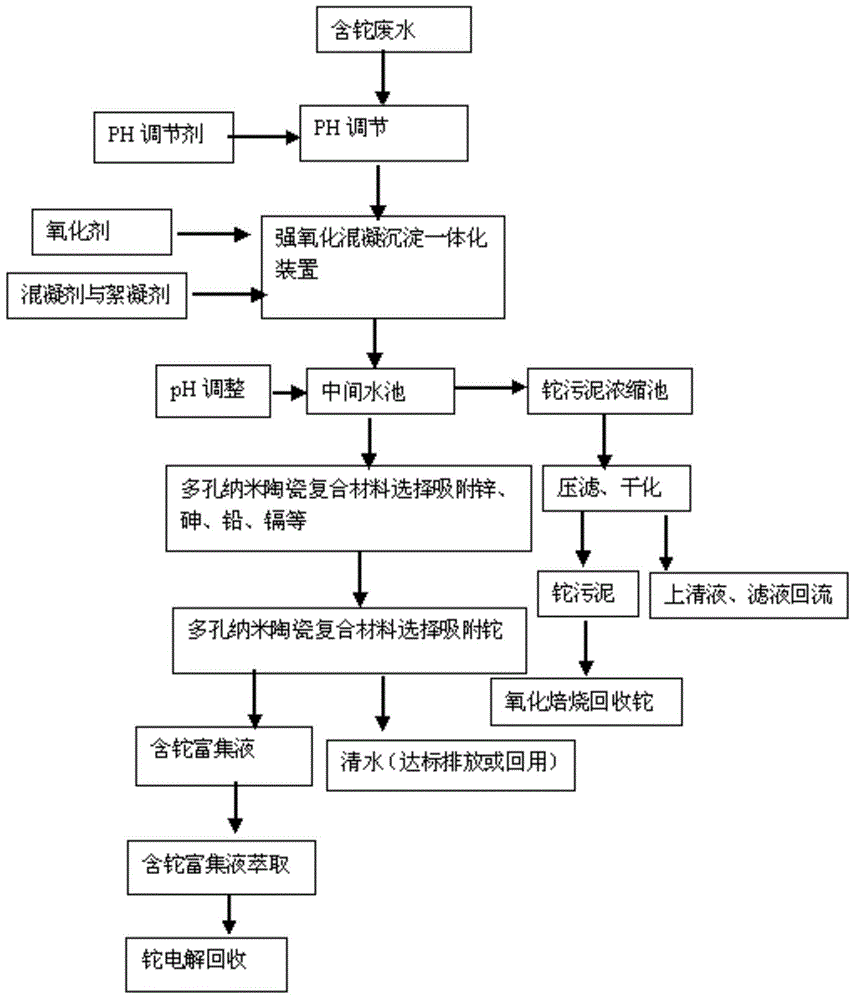

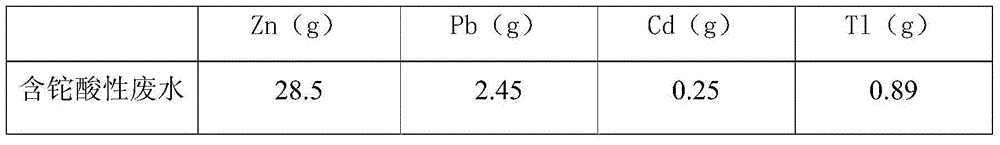

Thallium-containing wastewater strongly oxidizing, coagulating, adsorbing and recovering process

ActiveCN104310672AHighly selective adsorptionLarge specific surface areaWater treatment parameter controlSludge treatmentFiltrationSludge

The invention provides a thallium-containing wastewater strongly oxidizing, coagulating, adsorbing and recovering process. The process includes the following procedures: thallium-containing wastewater concentration, pH regulation, strong oxidization, coagulation, flocculation, precipitated sludge treatment, pH regulation, solid impurity filtration, removal of Zn, Pb, Cd and Tl, and the like. The process has the beneficial effects that the process has the advantages of advanced technology, maturity, good effluent quality, stability in operation, conciseness in process, strong practicability, easiness in start and stop, convenience in maintenance and management, small investment, low operating cost, small floor area for construction, short construction period and large application ranges of projects; treatment of heavy metal ion polluted sewage is not limited by temperatures; the limitation that a biological method can not be used in cold regions in the north can be overcome.

Owner:HUNAN JINGYUAN ENVIRONMENTAL ENG

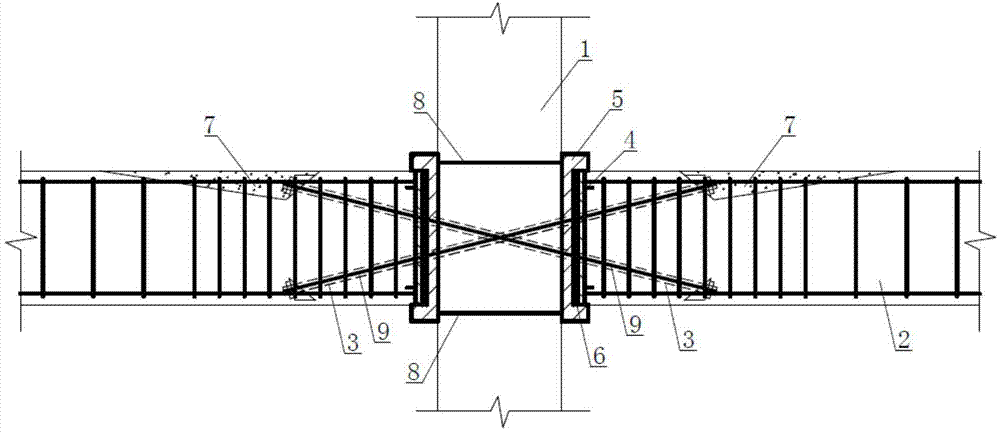

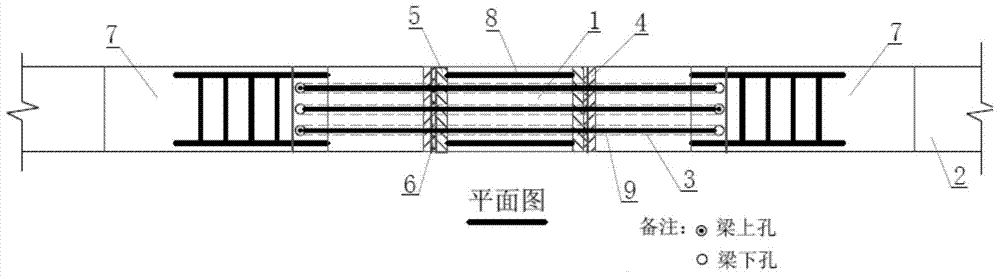

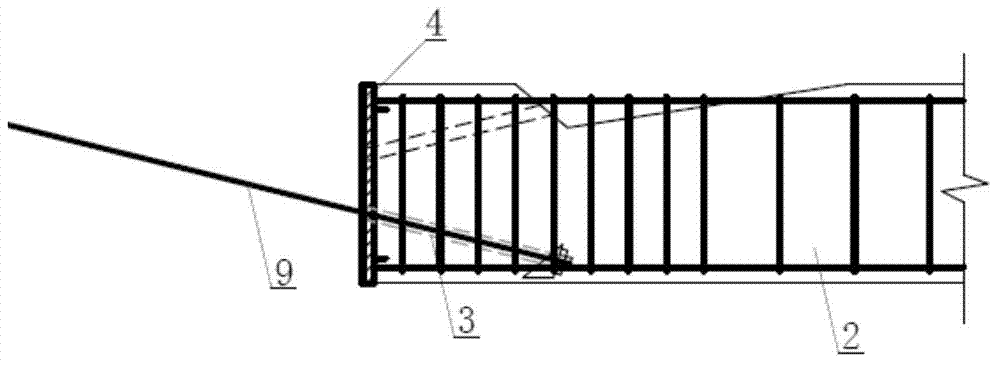

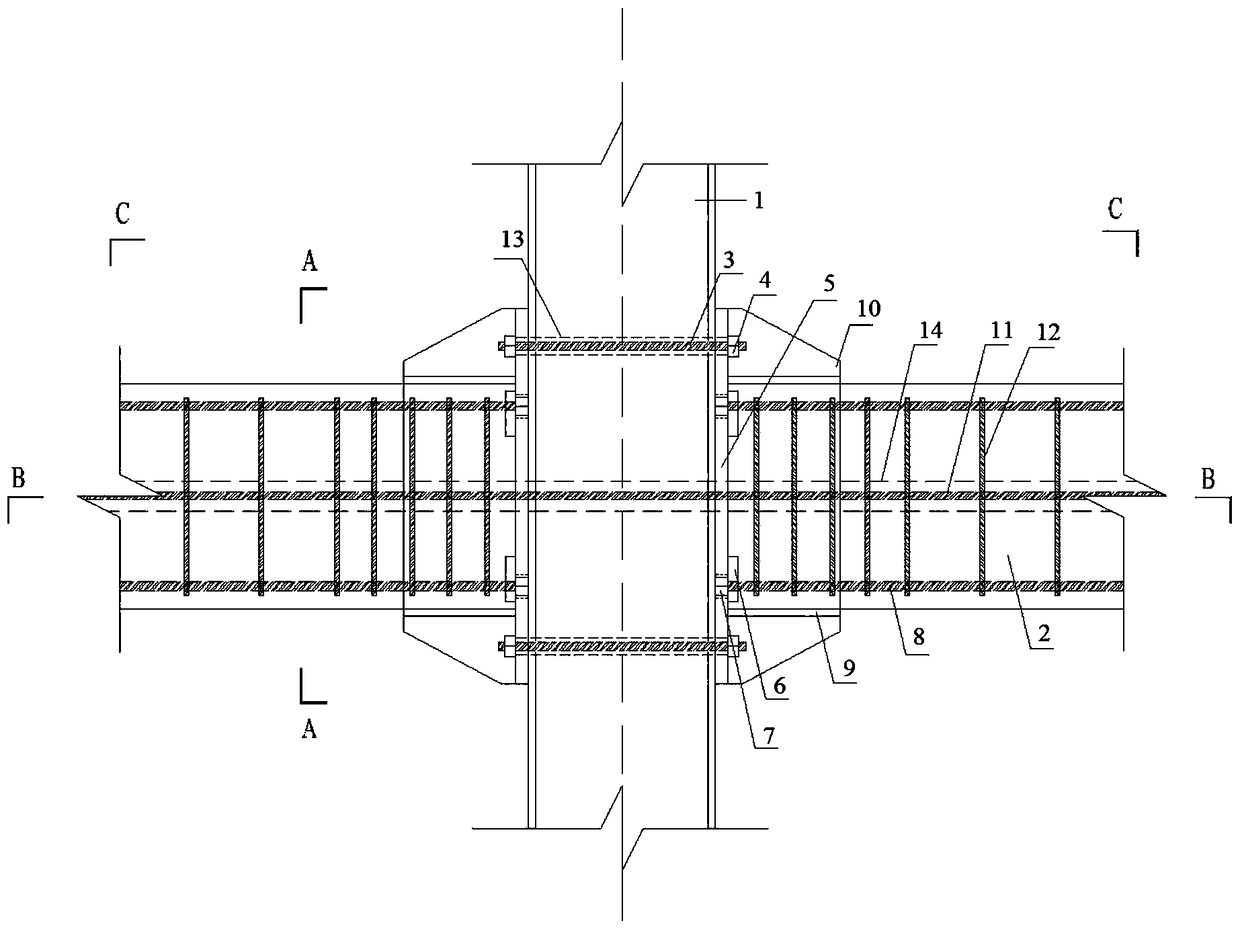

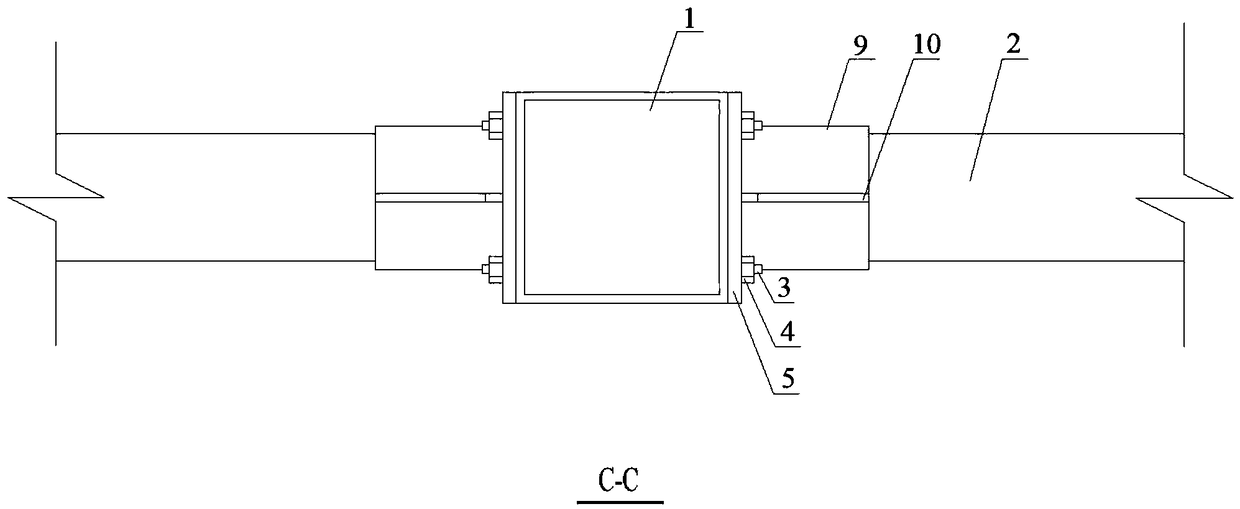

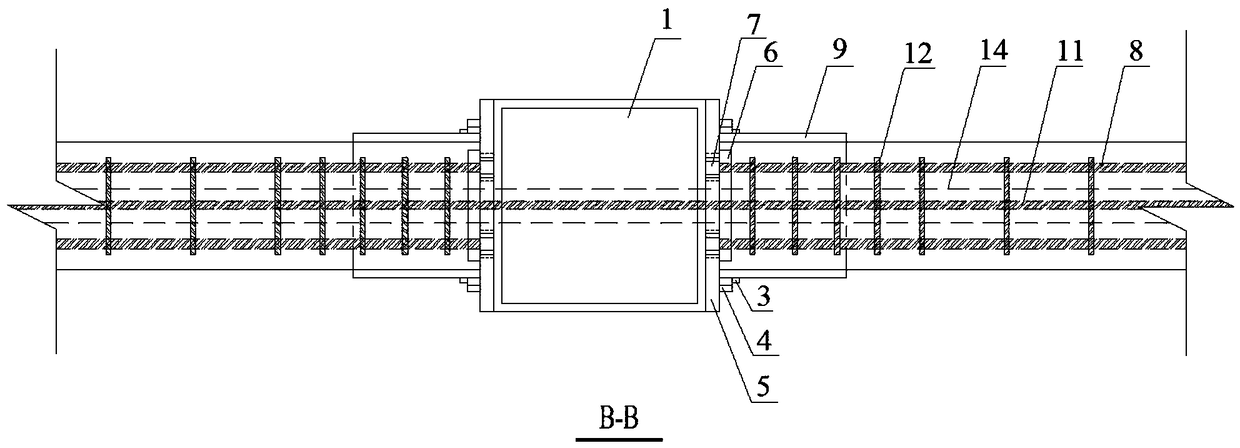

Prestress assembled concrete beam column joint structure and construction method thereof

InactiveCN104727441AArrangement length is shortSmall loss of prestressBuilding constructionsPre stressConcrete beams

The invention relates to a prestress assembled concrete beam column joint structure and a construction method thereof. The prestress assembled concrete beam column joint structure comprises a prefabricated column and a prefabricated beam. The prefabricated beam and the prefabricated column are in prepressing connection through the prestress formed by tensioning prestressed reinforced steel bars. The bottom of the beam end on one side of a joint is connected with the top of the beam end on the other side of the joint through the prestressed reinforced steel bars, and the prestressed reinforced steel bars are symmetrically crossed on a vertical face. When the prefabricated beam is manufactured, the prestressed reinforced steel bars and anchoring parts of the prestressed reinforced steel bars are pre-buried at the bottom of the beam end, prestressed reinforced steel bar pore channels and an anchoring area are reserved in the top of the beam end, and open type stirrups are adopted in the anchoring area. A force transmission steel plate is arranged on the cross section part of the beam end by the way that the cross section part of the beam end is welded with longitudinal bars. Slant prestressed reinforced steel bar pore channels are reserved in a prefabricated column joint area, groove-shaped steel plates are pre-buried on the two sides of the joint of the column, and high damping rubber layers are attached to the insides of the groove-shaped steel plates. In the connecting process, the beam is clamped into channel steel, and the prestressed reinforced steel bars penetrate through a joint core area to the top of the beam end on the other side of the joint and are anchored after being tensioned to be at the designed stress. According to the prestress assembled concrete beam column joint structure and the construction method thereof, assembling construction is convenient, and high shear-bearing capacity, energy-dissipating capacity and self-resetting capacity of the connecting joint can be achieved.

Owner:WUHAN UNIV OF TECH

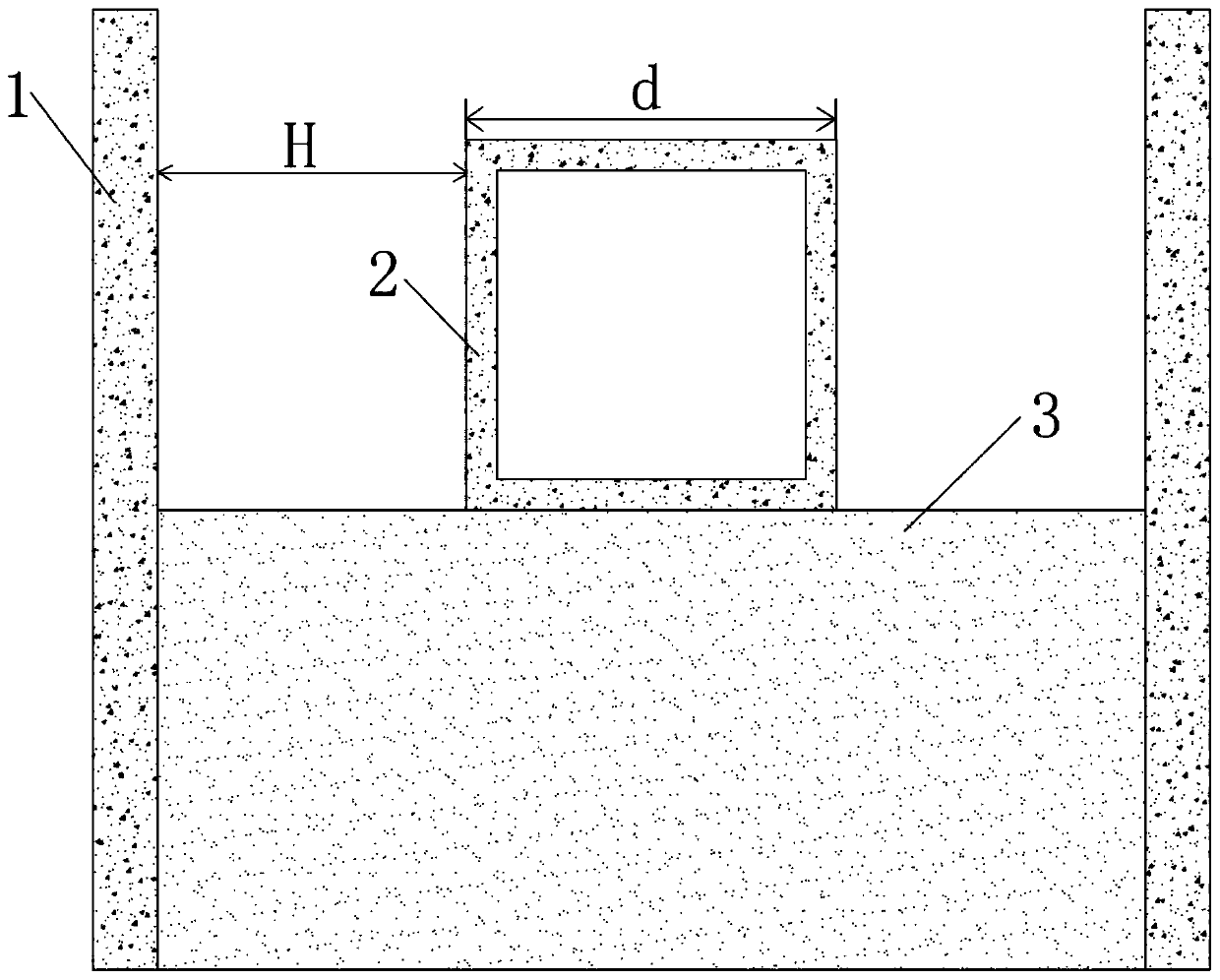

Construction method for controlling two-dimension jacking of large-scale case

ActiveCN101538832ASmall construction areaLow costBridge erection/assemblySystem constructionRailway line

The invention discloses a construction method for controlling the two-dimension jacking of a large-scale case. The method comprises the following steps: all the large-scale cases are previously arranged in a foundation pit at one side of a railway which needs to be paved with a frame bridge under a condition that the underway existing railway normally runs; after a first section of the large-scale case is jacked, all the remaining large-scale cases are transversely moved behind the first section of the large-scale case on by one; and then all the large-scale cases are jacked with the previously jacked large-scale case. In such a way, original buildings near a railway line do not need to be demolished, therefore, the invention not only has small construction occupied area and low cost but also greatly reduces interference to the surrounding environment and the existing railway cause by construction operation, reduces the demolishing quantities of the adjacent buildings caused by the construction, and effectively guarantees the normal running of the existing railway.

Owner:CHINA RAILWAY SIXTH GROUP +1

Vertical shaft construction device and method

The invention provides a vertical shaft construction device and a method, and belongs to the field of foundation engineering construction. The device comprises a ring beam, supports, a support system and floating prevention structures, wherein the ring beam is arranged in a soil body above a tunnel; the supports are applied to the side walls of a vertical shaft; the support system is a multilayer structure, and comprises a steel support structure and a middle separation plate structure arranged in the vertical direction; the support system is perpendicular to the length direction of the vertical shaft, and is fixedly connected with the supports at the two sides of the vertical shaft; and the floating prevention structures are positioned at the upper side and the left and right sides of the tunnel. The span of the vertical shaft is small, the device is provided with the multilayer support system, and the vertical shaft construction device is strong in structure, so that the pressure of soil bodies at the two sides of the tunnel can be preferably transferred, the interference on the soil bodies around the subway tunnel is little, and the swell quantity of the tunnel can be effectively controlled to satisfy the design requirement. In addition, the symmetric parallel operation can be adopted to synchronously construct and install the device on multiple working surfaces, so that the construction period is reduced.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

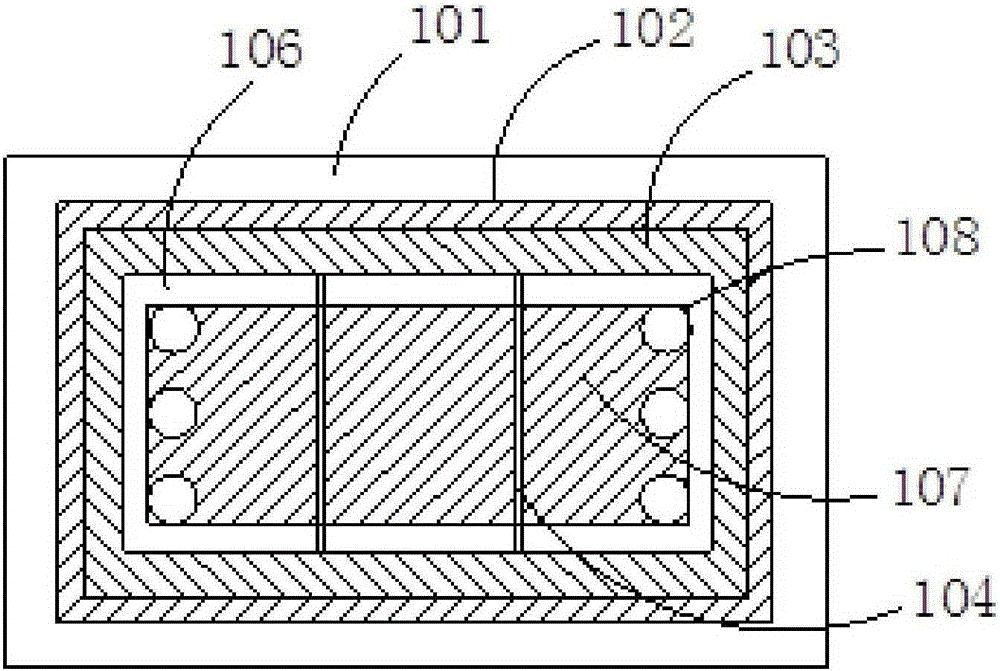

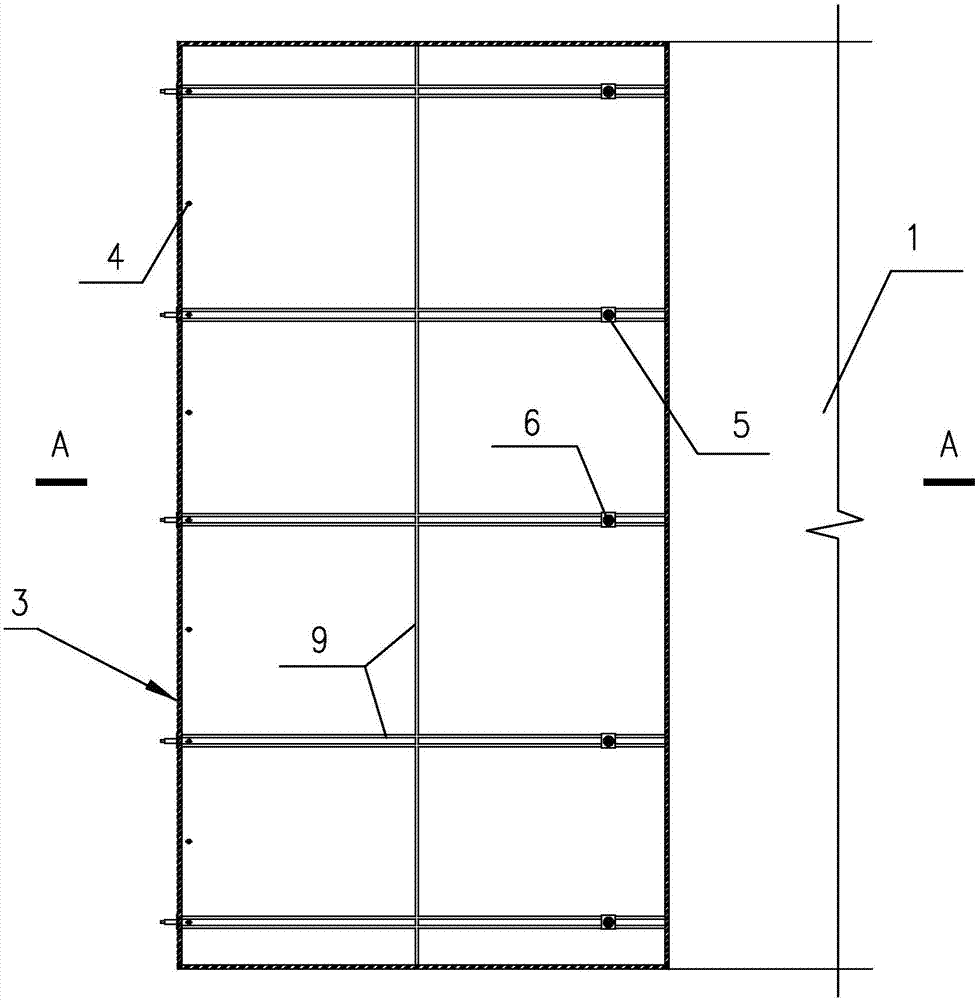

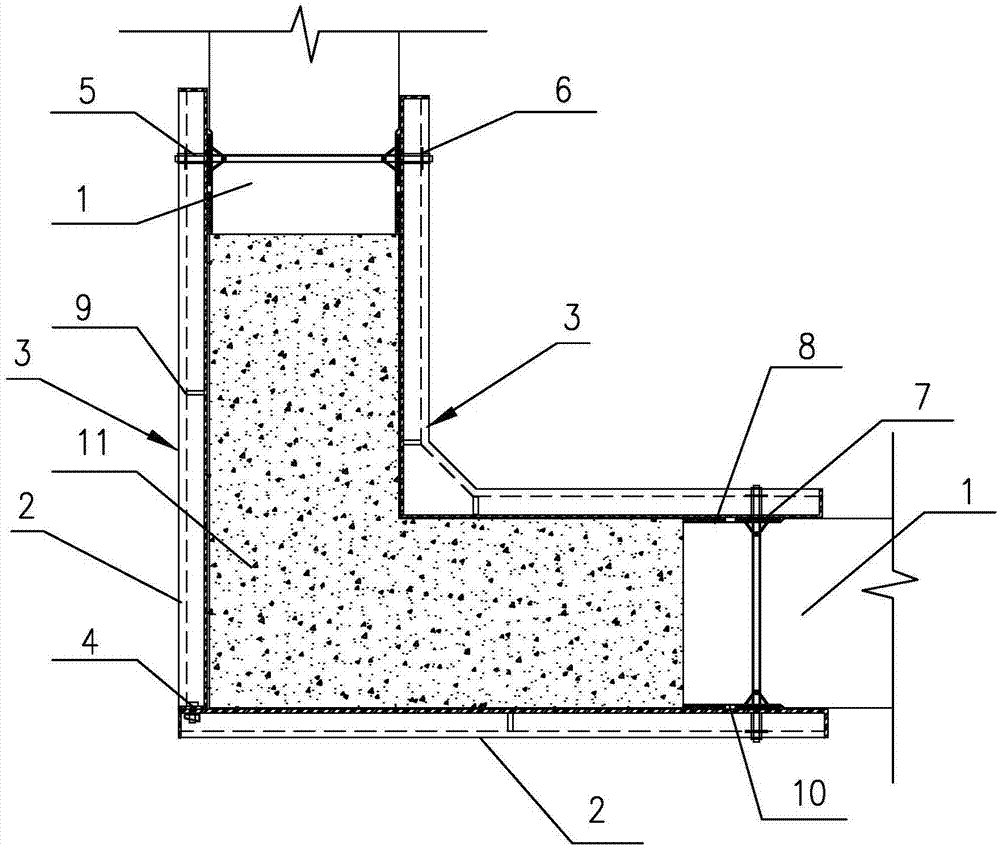

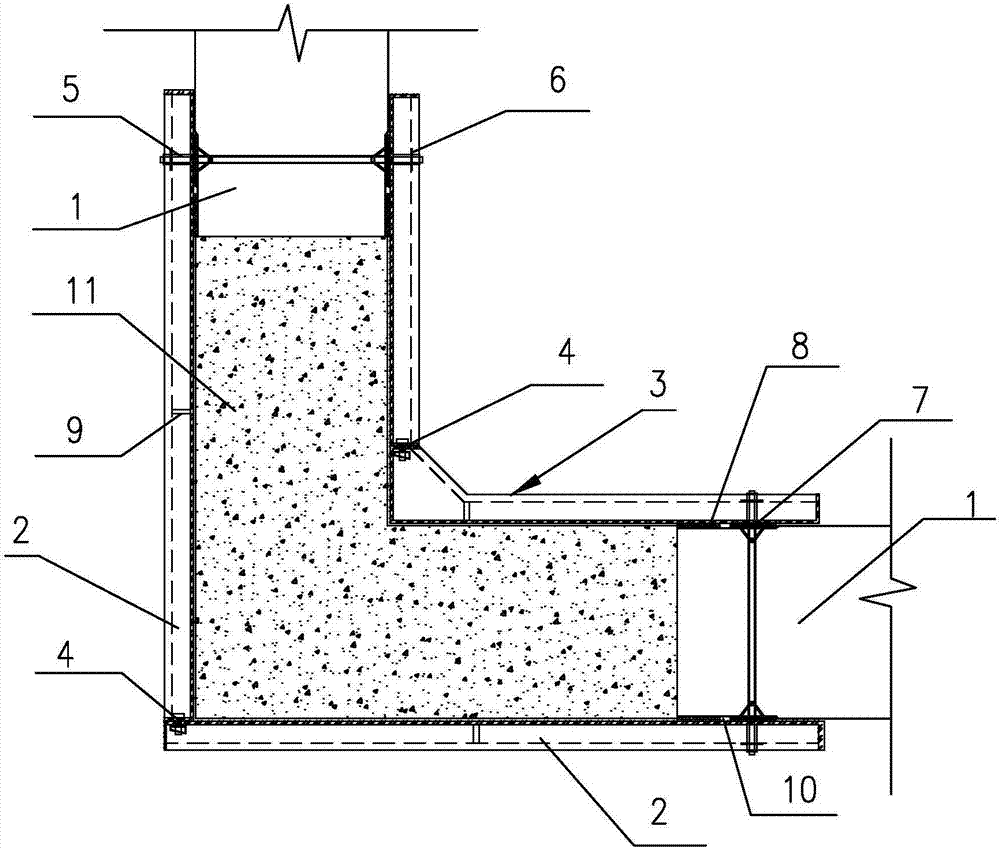

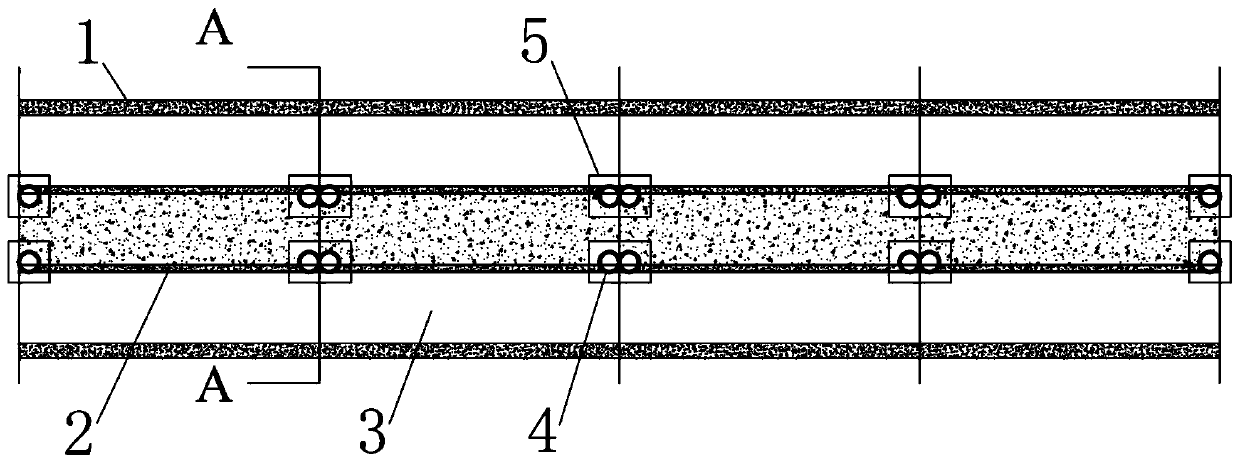

Aluminum alloy formwork special for fabricated concrete shearing wall structure

PendingCN107023160AImprove bearing capacityImprove stabilityForms/shuttering/falseworksMaterials scienceShear wall

The invention discloses an aluminum alloy formwork special for a fabricated concrete shearing wall structure. The aluminum alloy formwork comprises at least one vertical plate. When the number of the vertical plates is two or more, all the vertical plates are used for forming a cast-in-place area with a structure prefabricated component in an enclosed mode so that a concrete component can be formed, and the opening-shaped end formed by combining the vertical plates is used for being fixed to the structure prefabricated component; when one vertical plate is arranged, the vertical plate is used for forming a cast-in-place area with the structure prefabricated component and a non-structure prefabricated component in an enclosed mode so that a concrete component can be formed, and the opening-shaped end formed by combining the vertical plate and the non-structure prefabricated component is used for being fixed to the structure prefabricated component and the non-structure prefabricated component; and each vertical plate is an integral plate body or is formed by splicing a plurality of plate body units. According to the aluminum alloy formwork special for the fabricated concrete shearing wall structure, the construction efficiency is improved, the construction quality is ensured, construction is convenient, universality is high, the aluminum alloy formwork can be recycled, and energy saving and environmental friendliness are achieved, the bearing capacity is high, and stability is good. The construction finished surface of a cast-in-place concrete structure poured through the aluminum alloy formwork is smooth and beautiful, the rendering working procedure is omitted, and the construction period is shortened.

Owner:广东省建科建筑设计院有限公司 +1

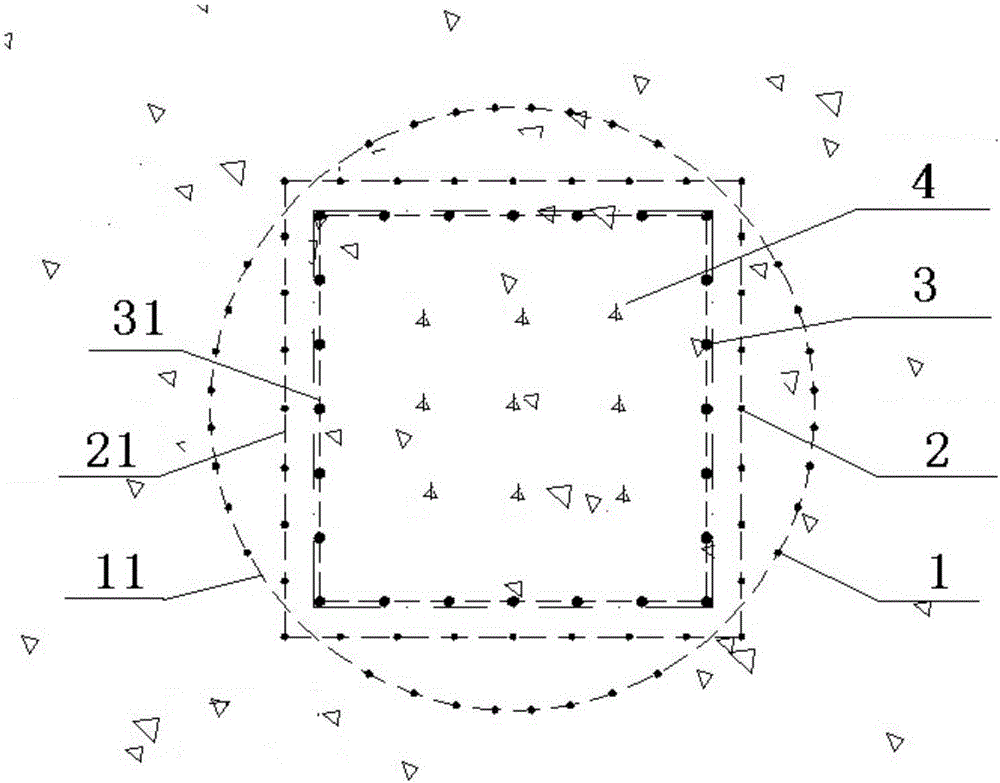

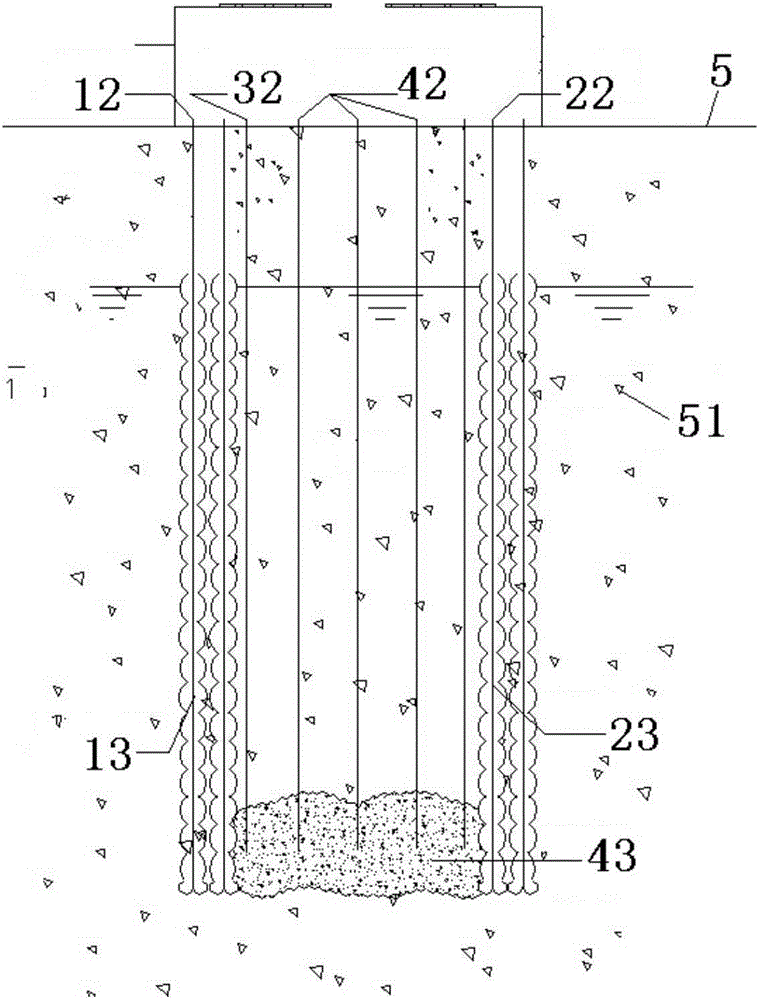

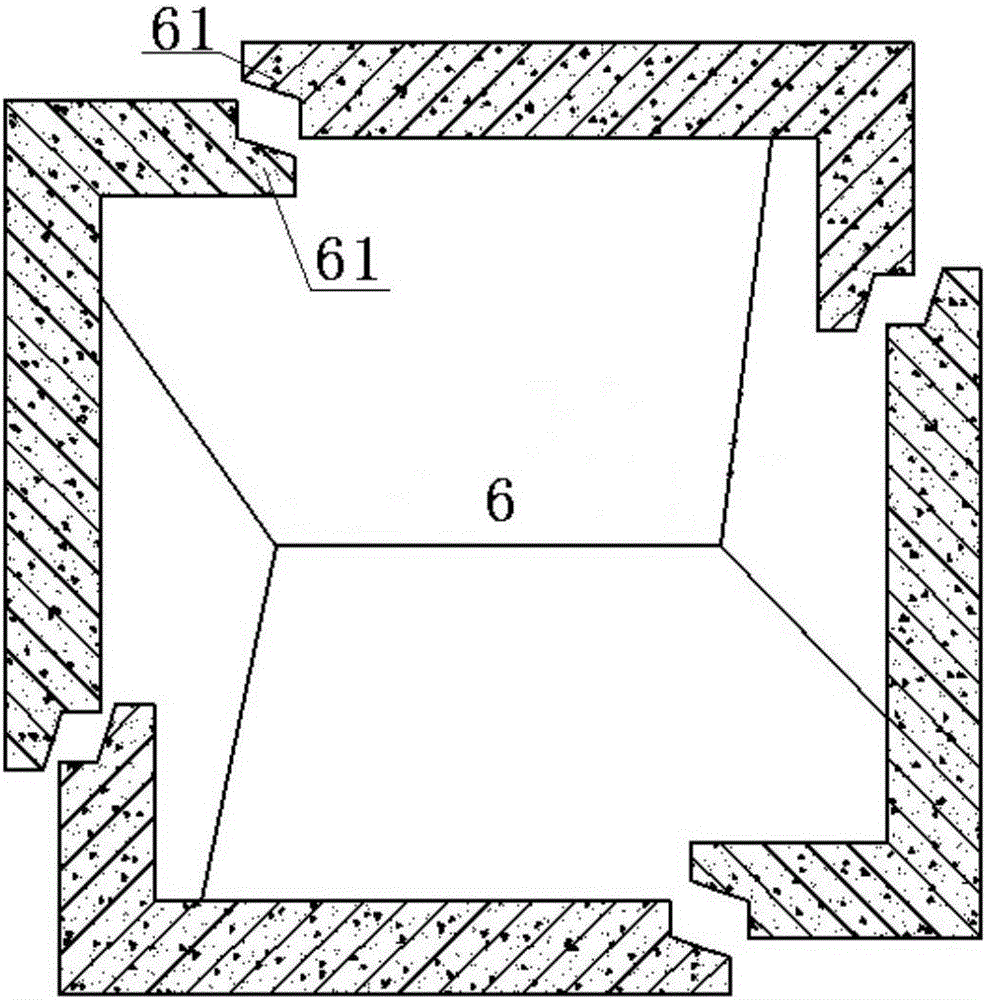

Prefabricated underground silo compound shaft construction method and silo structure

ActiveCN106088154AReduce the internal force of the rectangular sectionReduce settlementArtificial islandsUnderwater structuresEngineeringSilo

The invention relates to the field of underground silo facilities, in particular to a prefabricated underground silo compound shaft construction method and a silo structure which effectively improve the underground silo construction efficiency and greatly reduce the construction cost. The prefabricated underground silo compound shaft construction method comprises the following steps that a, paying off is firstly carried out in a silo building site to locate and arrange drill holes; b, freezing operation and bottom grouting are carried out; c, splicing assembly is carried out to form shaft structures; d, shoe leg heating pipes in shoe leg structures are used for hydrothermal circulation; e, structure shaft components are assembled step by step to form new shaft structures till the preset depth is achieved; f, bottom plates and supporting plates are mounted; g, all drill hole openings in the ground are closed; and h, debugging and running are completed, and construction is finally completed. The prefabricated underground silo compound shaft construction method and the silo structure are high in construction reliability and construction speed and especially suitable for being used in fields with the short construction period and limited construction space.

Owner:黄竟强

Core-grouting reinforcing construction method for prestressed concrete pipe piles with post-grouting method

The invention provides a core-grouting reinforcing construction method for prestressed concrete pipe piles with a post-grouting method. The method comprises the following construction steps: determining the depth of the defect position of a pile body, and then cleaning holes with compressed air or high-pressure water until the required hole cleaning depth; setting the number of steel strands or reinforcing bars according to the computing requirement, putting down the steel strands or the reinforcing bars to the computed core grouting length, exposing more than 2m out of a pile top for putting-down control or a bearing capacity test for the steel strands or the reinforcing bars, and then using a 6-8mm steel plate as the bottoming thickness; adopting two welded steel pipes as grouting pipes, namely a primary grouting pipe and a secondary grouting pipe; selecting powder-free gravel with the uniform grain sizes Phi being 10-20mm and the compressive strength larger than M30 as a gravel material, and backfilling the gravel material to orifices; before grouting, cleaning holes with pressed water for the primary grouting pipe until backwater is clean; then respectively carrying out primary grouting and secondary grouting. The method has the advantages of being convenient to operate, low in cost and high in construction speed, can improve the quality of the pile body and the bearing capacity of a single pile, and ensures the whole project quality.

Owner:CHINA FIRST METALLURGICAL GROUP

Replaceable self-resetting fabricated connecting joint and construction method

ActiveCN108755975ANo brittle failureReduce stress concentrationStrutsProtective buildings/sheltersEarthquake resistancePre stress

The invention relates to the technical field of steel-concrete composite structure in construction engineering, in particular to a replaceable self-resetting fabricated connecting joint and a construction method. The connecting joint comprises a prefabricated steel pipe concrete column and two prefabricated beams. The prefabricated beams are positioned on two sides of the prefabricated steel pipeconcrete column. Terminal plates are in contact with the prefabricated steel pipe concrete column. The prefabricated beams are provided with the terminal plates, steel sleeves and reinforced ribs. Rigidity of the beam ends of the prefabricated beams is improved; the condition of brittle fracture caused by plastic hinge generating at the beam end joint position under the action of an earthquake iseffectively prevented; beam columns adopt energy consumption rebars and prestressing tendons for connection, the energy consumption rebars can consume and dissipate energy during the earthquake, quickreplacement can be achieved after the earthquake; and repairing efficiency is improved; the prestressing tendons keep elasticity in the rare earthquake, and play a role of self-resetting after the earthquake. The replaceable self-resetting fabricated connecting joint and construction method achieve building industrialization, is free of welding and wet work on the construction site, and has the advantages of being excellent in earthquake resistance, environmentally friendly, excellent in component quality, convenient to construct, little in damage after the earthquake, replaceable and self-resetting.

Owner:DALIAN UNIV OF TECH

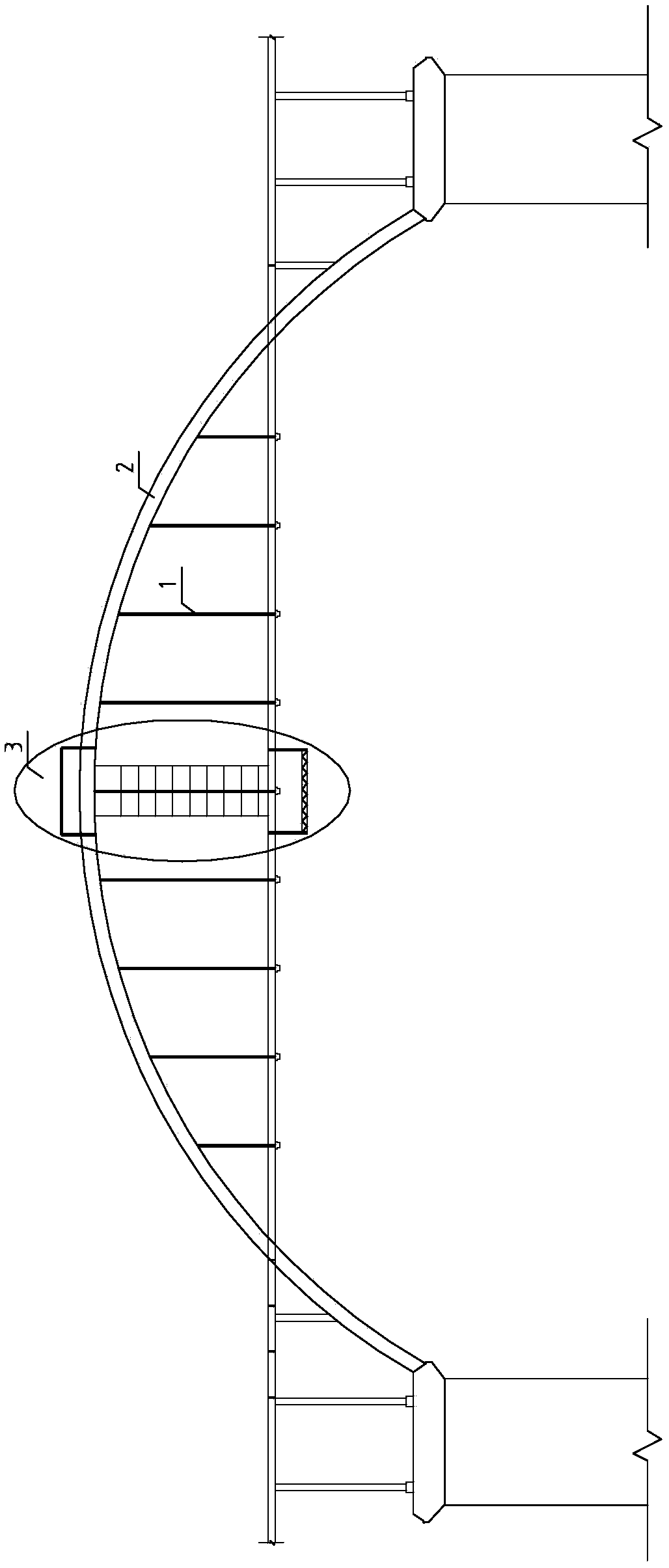

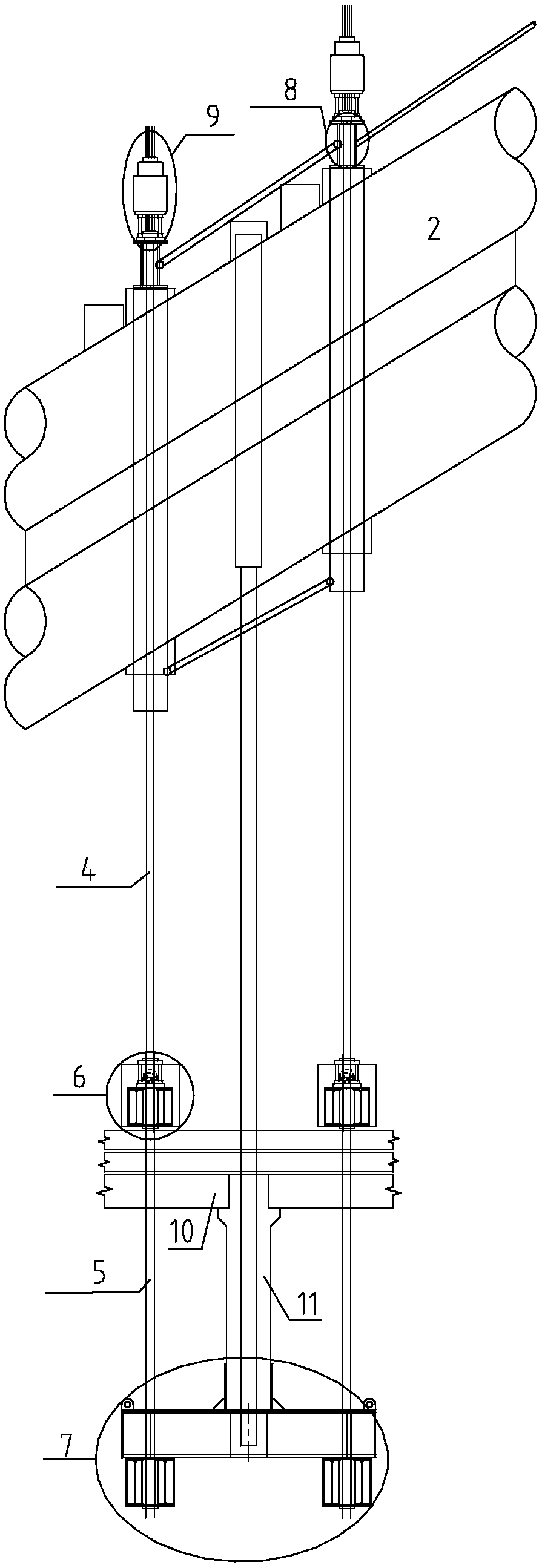

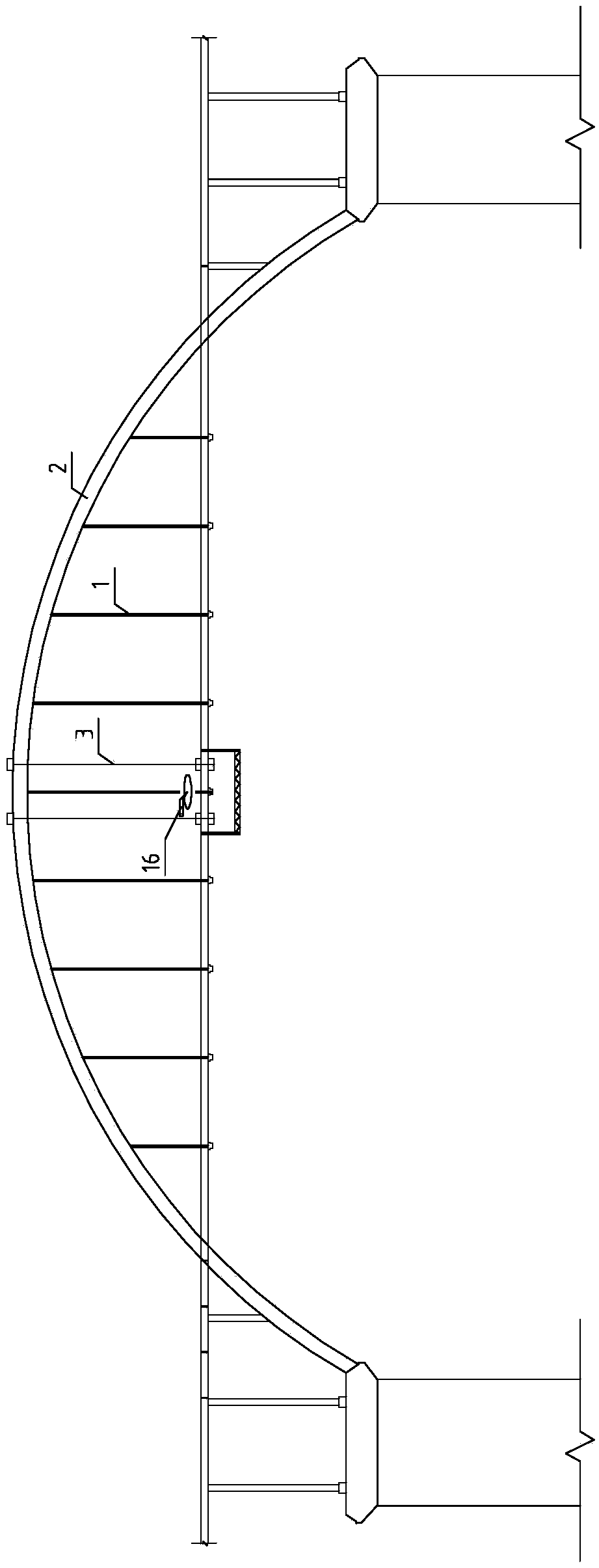

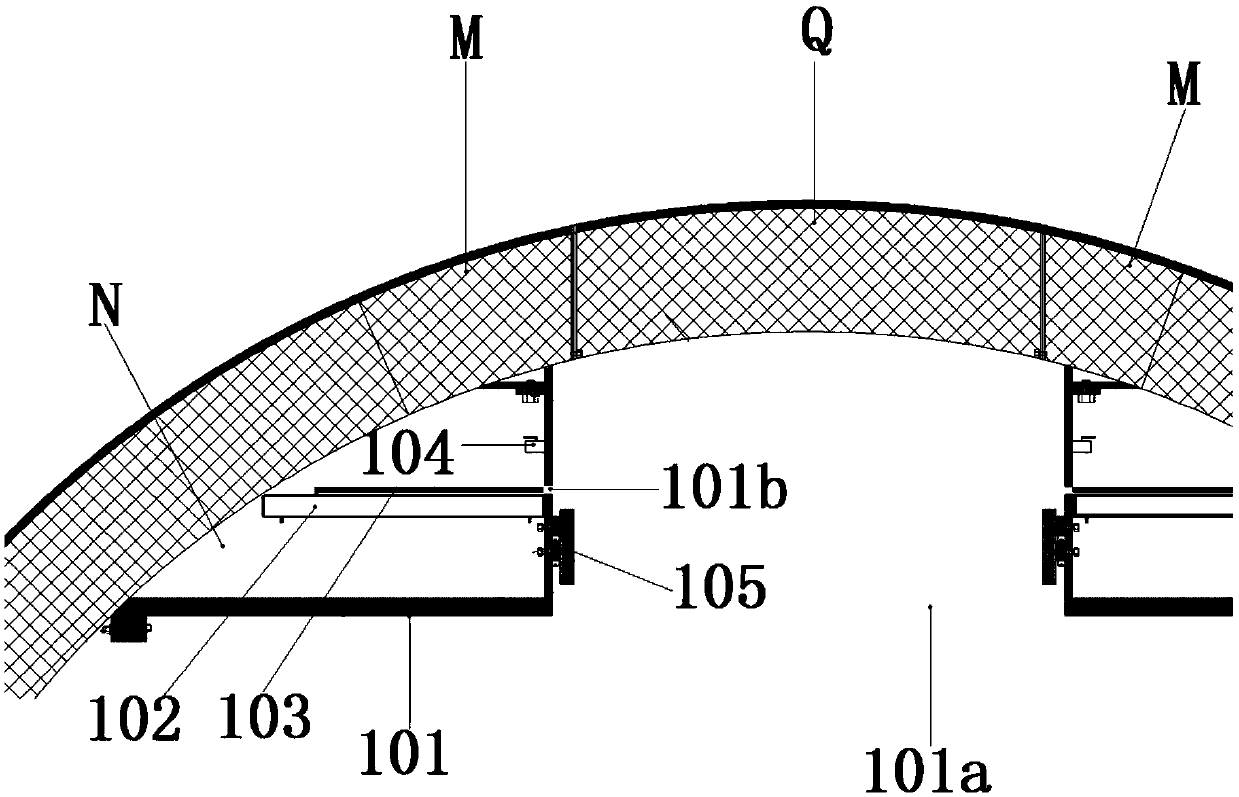

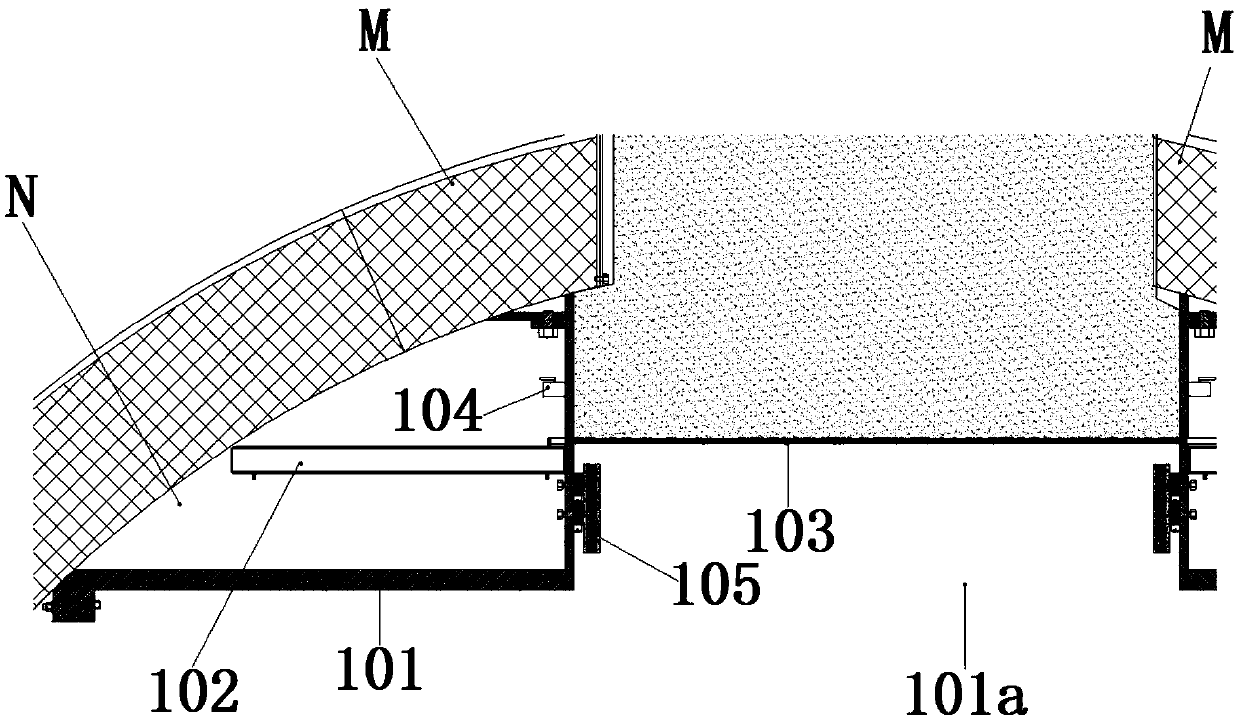

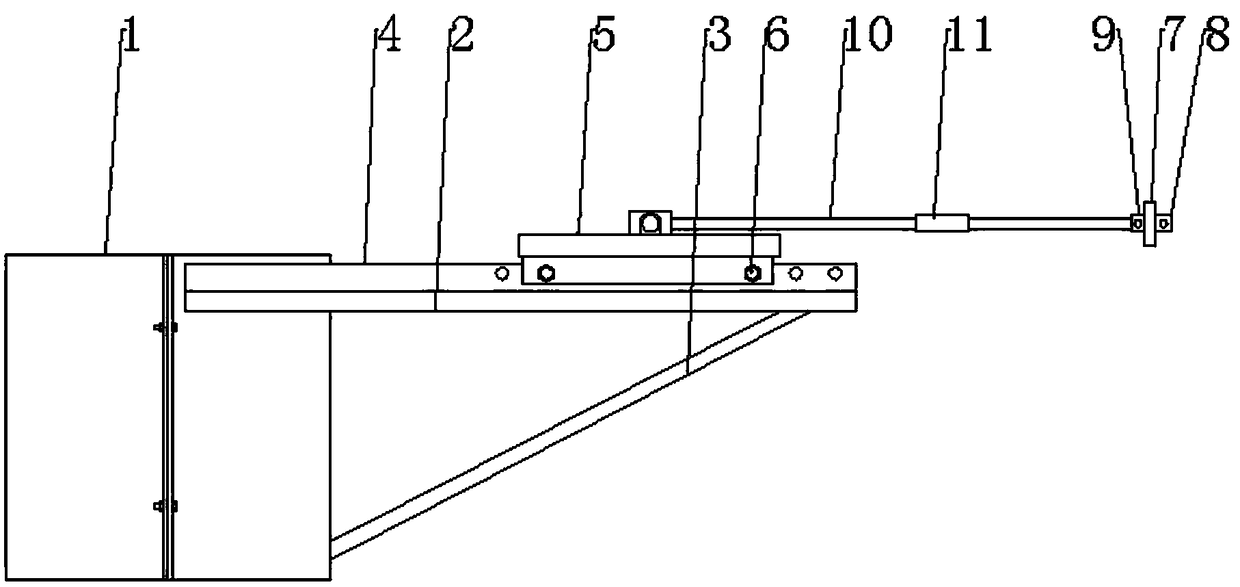

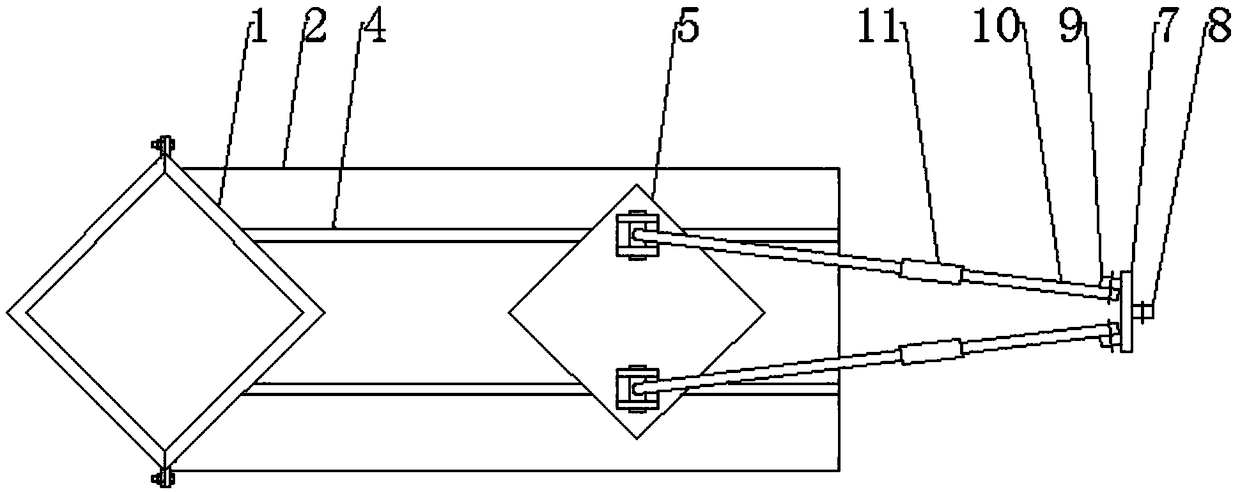

Construction method of quick replacement of suspension rods of mid-through and through arch bridges

ActiveCN109162209AQuick clearLittle impact on trafficBridge erection/assemblyBridge strengtheningEngineeringArch bridge

The invention discloses a quick replacement construction method of a halfway through arch bridge and a lower through arch bridge suspender, which comprises the following steps of: 1, installing an operation platform to prepare for measuring and monitoring; 2, installing a temporary pocket suspension system; 3, tensiong the temporary pocket suspension system to cut off the old boom; 4, removing that old boom; 5, installing and tensioning that new boom to realize the replacement of the boom; 6, removing the temporary hoisting system and adjust the cable force of the new boom. The construction method can achieve the purpose of quickly replacing the old boom under the condition of less investment of temporary boom, operators and machinery, especially in the early replacement construction of mid-through and through arch bridge boom which is suitable for anchoring the boom on the arch rib or cross beam, and the construction method is more efficient.

Owner:GUANGDONG HELI CIVIL ENG CO LTD

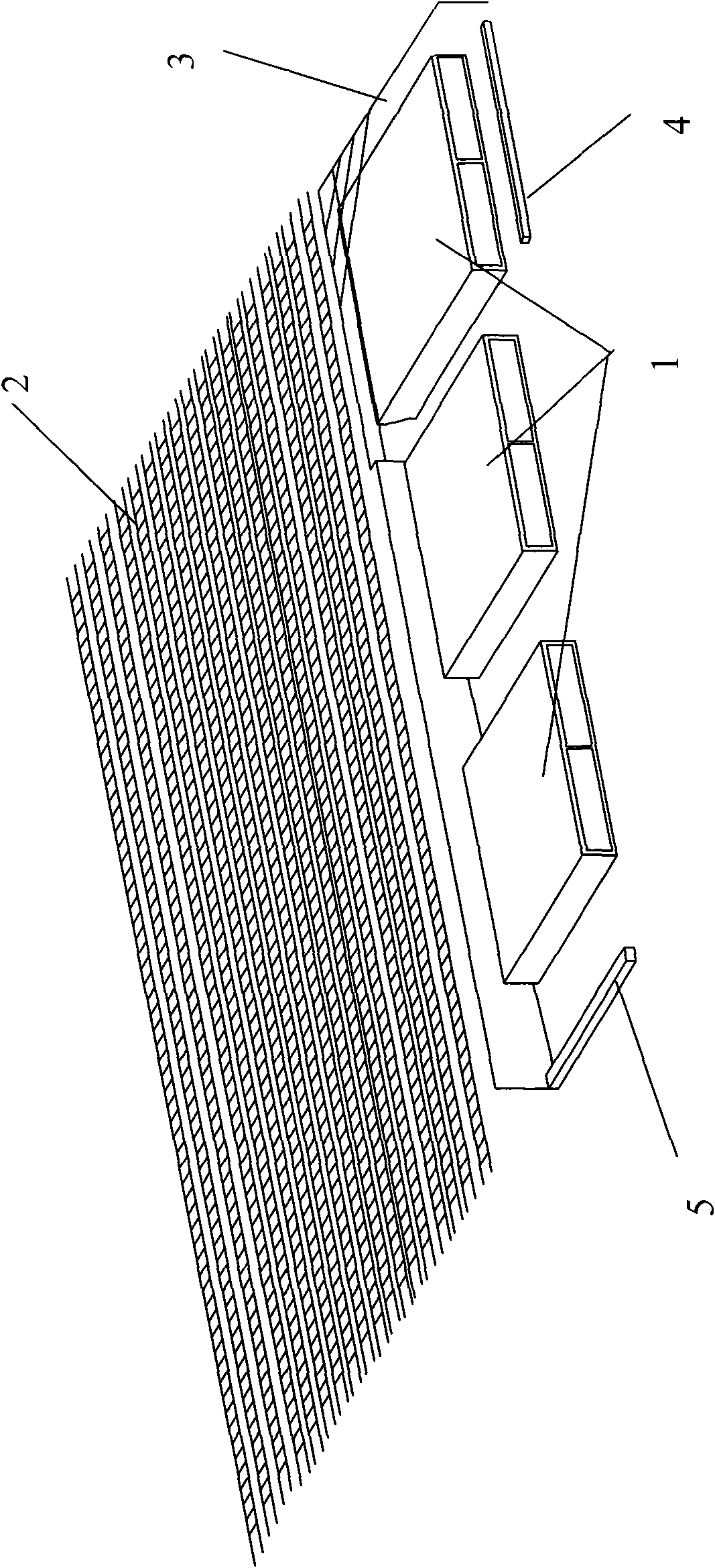

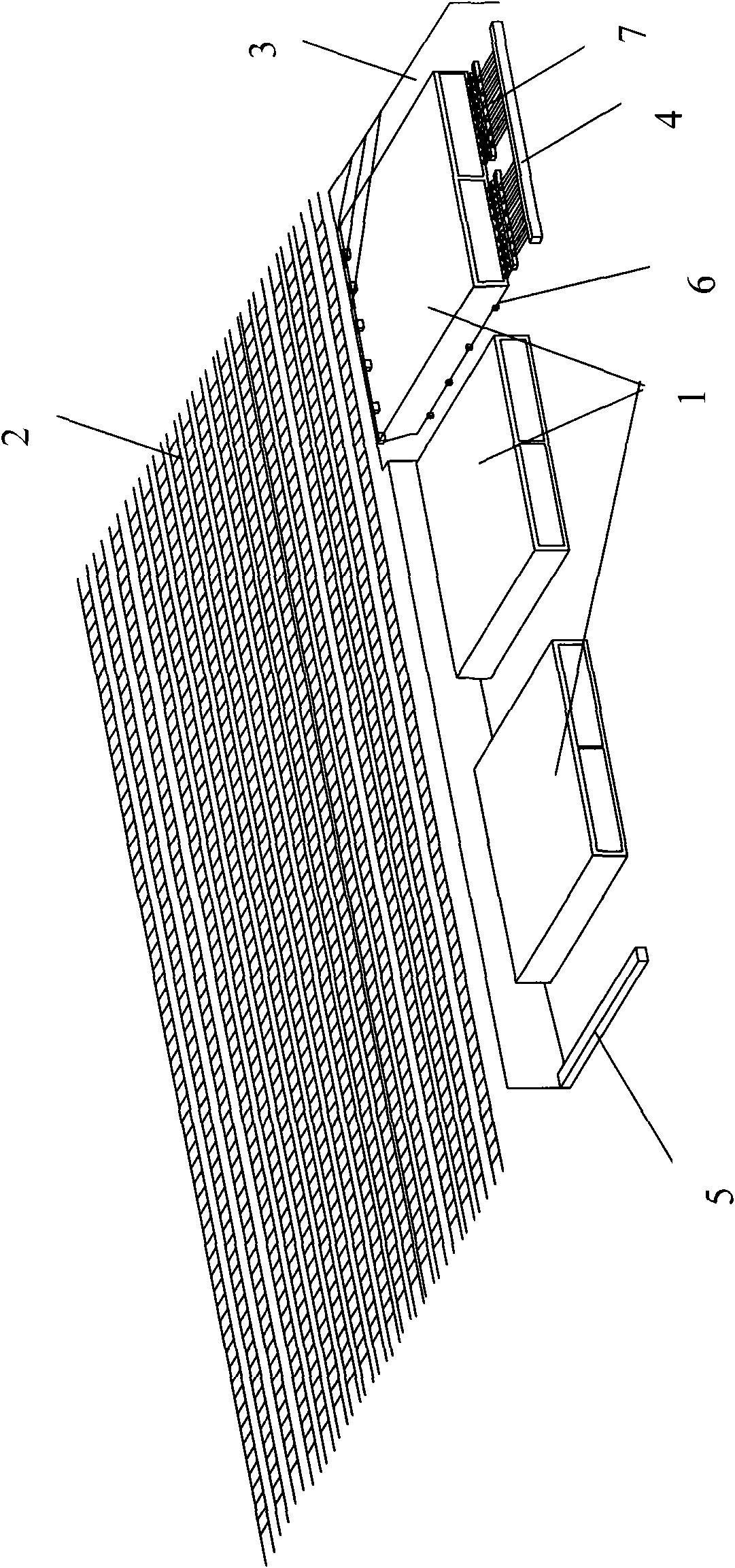

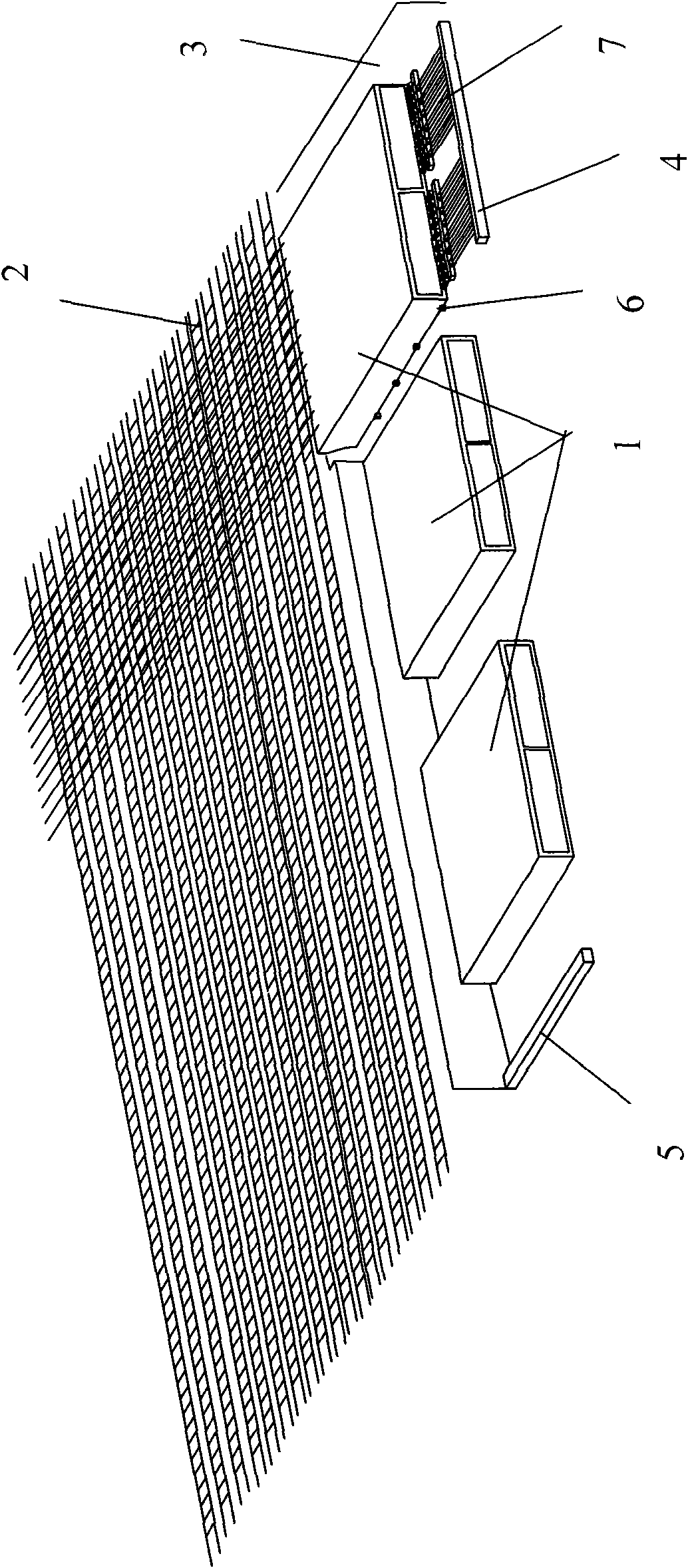

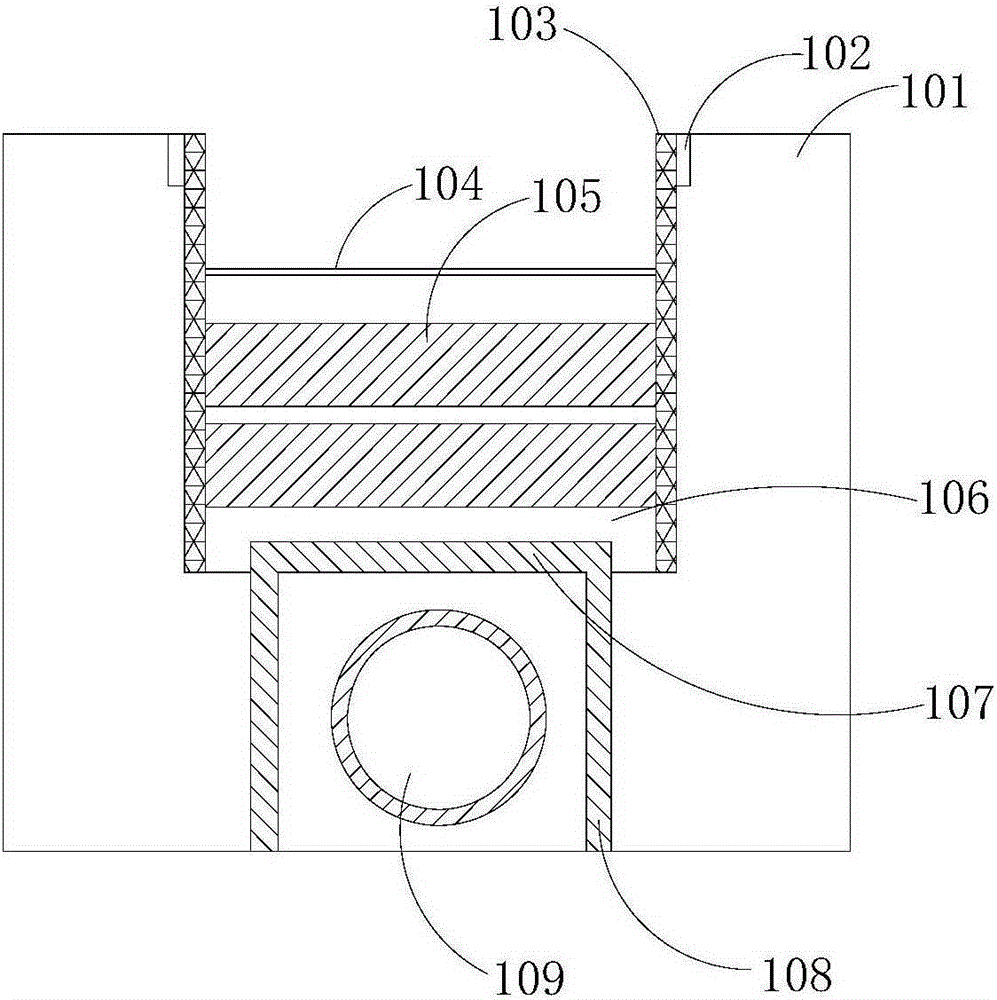

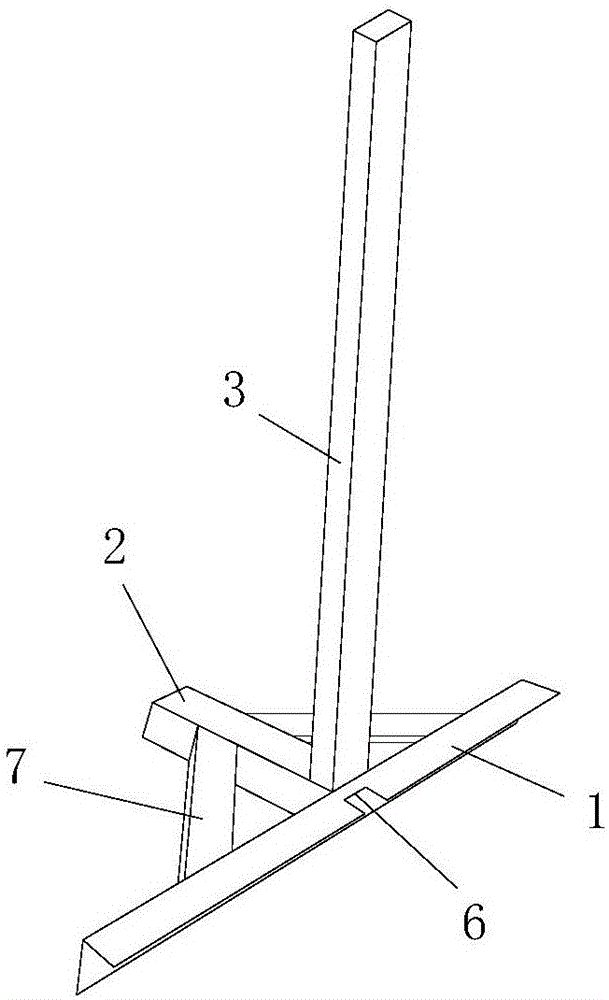

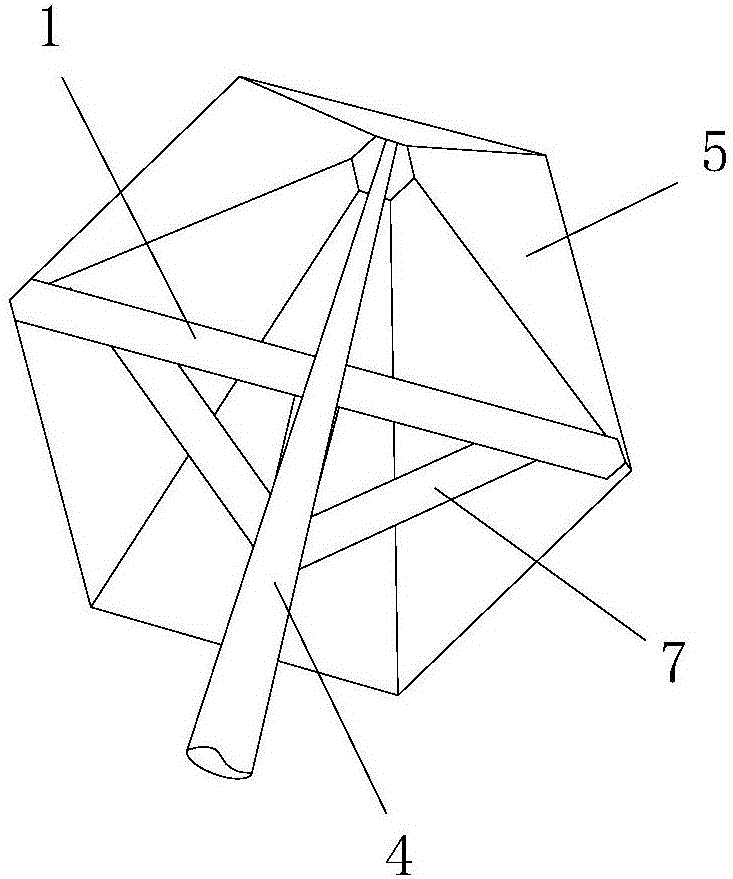

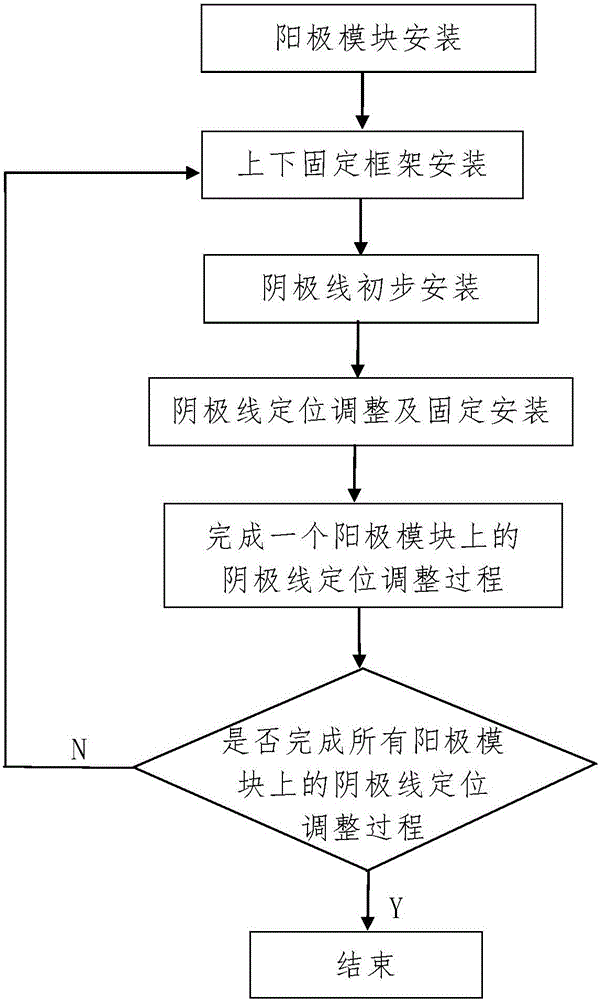

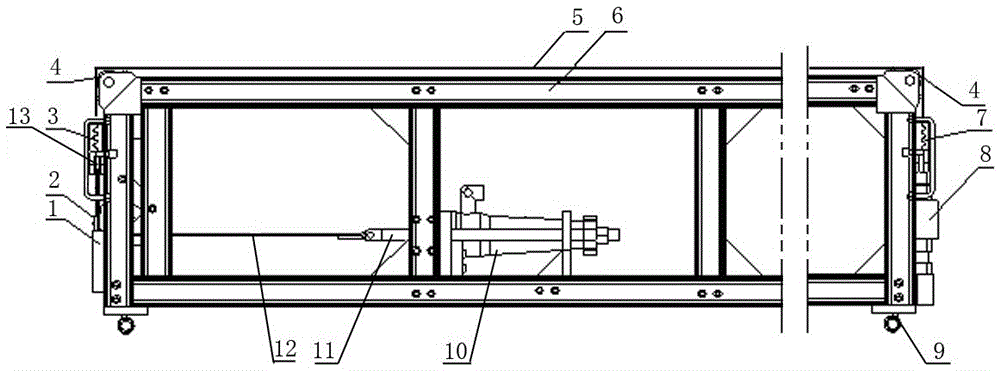

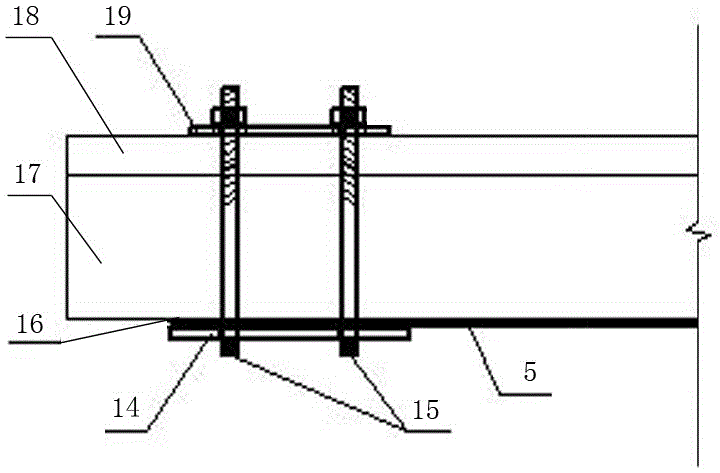

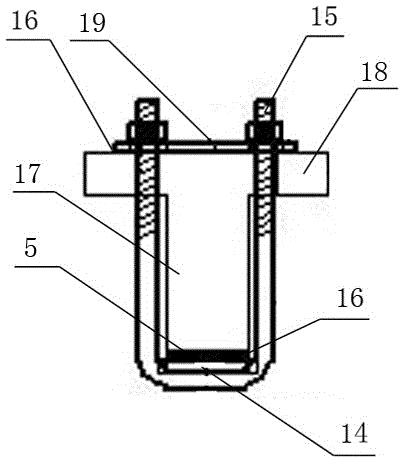

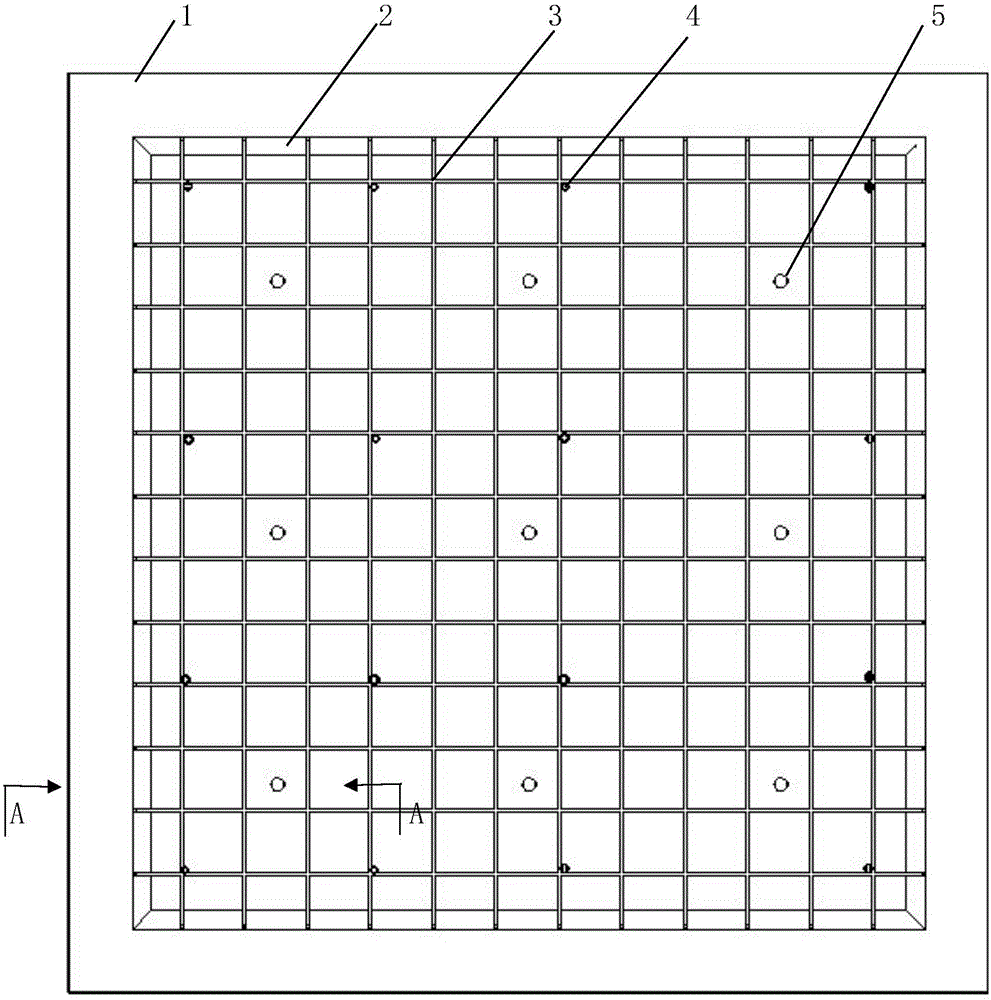

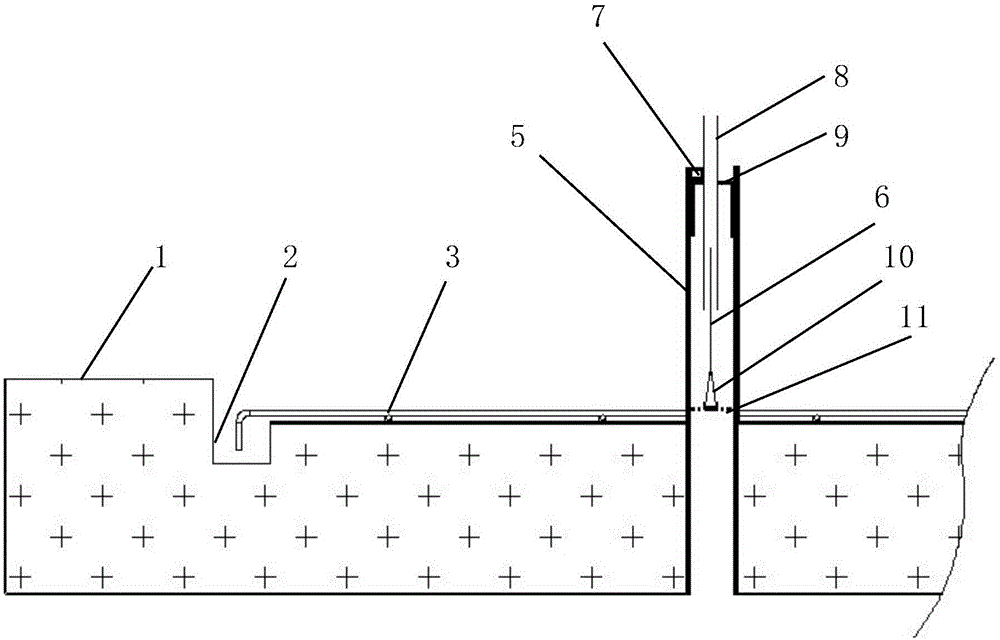

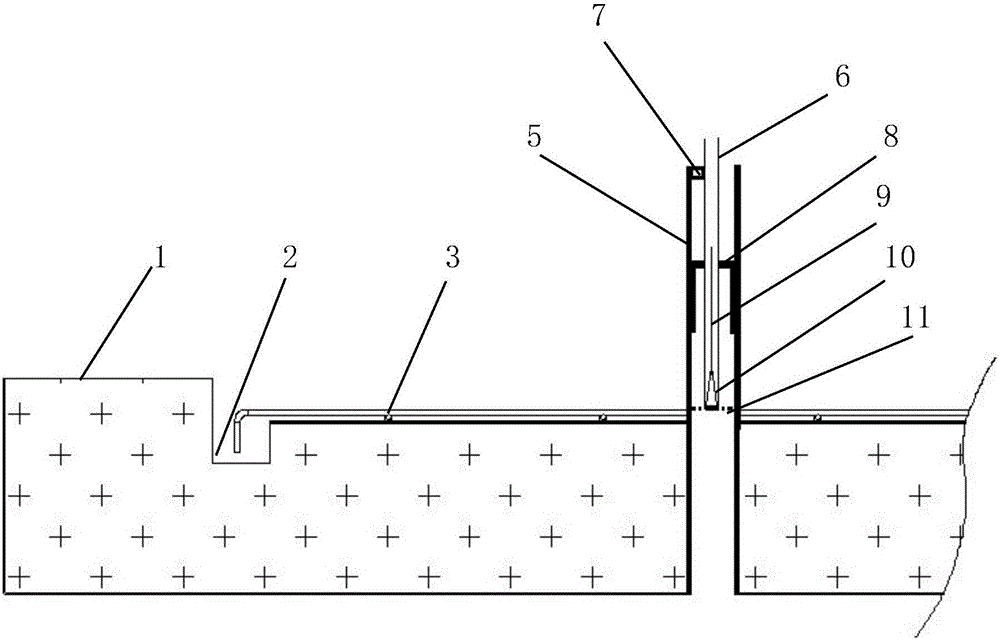

Cathode line positioning die and cathode lien positioning and adjustment construction method

ActiveCN106238212ASimple structureEasy to processElectrostatic separation detailsArchitectural engineeringAnode

The invention discloses a cathode line positioning die and a cathode lien positioning and adjustment construction method. The positioning die comprises a rear measuring rod, a front measuring rod arranged on the front side of the middle of the rear measuring rod and a vertical rod fixed behind the rear portion of the front measuring rod, wherein the front measuring rod and the vertical rod are located in front of the rear measuring rod, the rear measuring rod, the front measuring rod and the vertical rod are straight rods, the rear measuring rod and the front measuring rod are arranged in a perpendicular mode, the rear measuring rod and the front measuring rod form a horizontal positioning rack, and a clamping groove for positioning an adjusted cathode line is formed in the rear side of the middle of the rear measuring rod. The constriction method comprises the steps that 1, anode module installation is performed; 2, cathode line installation construction is performed: when the cathode line is installed on any group of anode modules, the process is that 201, upper and lower fixing frames are installed; 202, preliminary cathode line installation is performed; 203, cathode line positioning, adjustment and fixing installation are performed. The cathode line positioning die is reasonable in design, simple and convenient to use and operate, good in using effect and capable of simply, conveniently and rapidly perform accurate cathode line positioning and ensuring cathode line installing precision.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

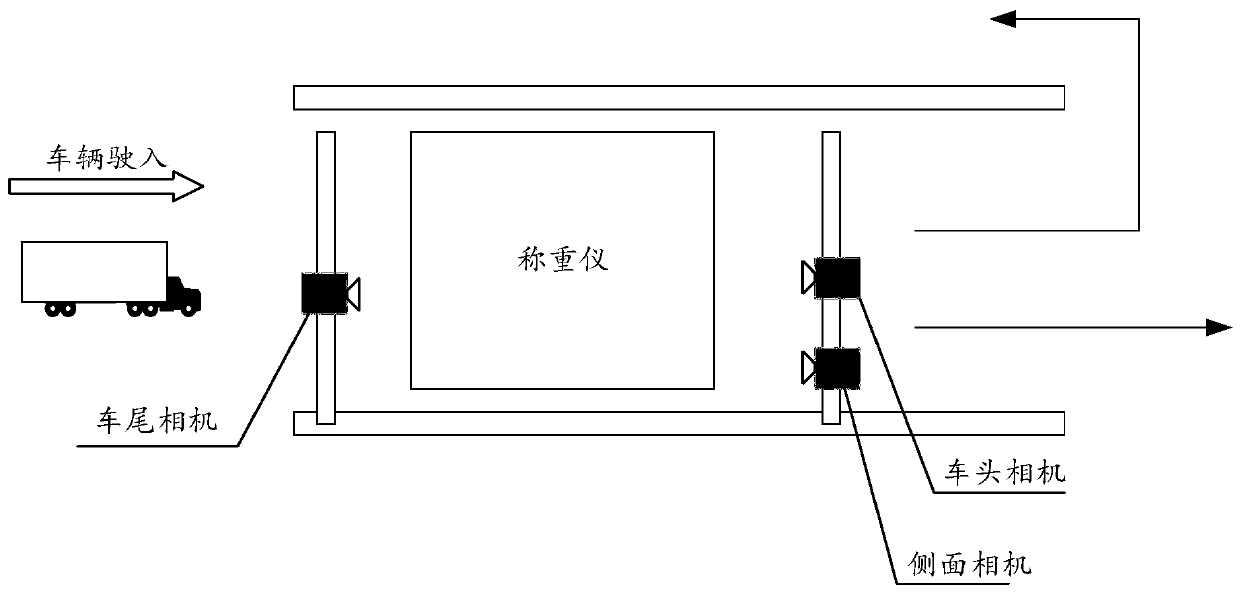

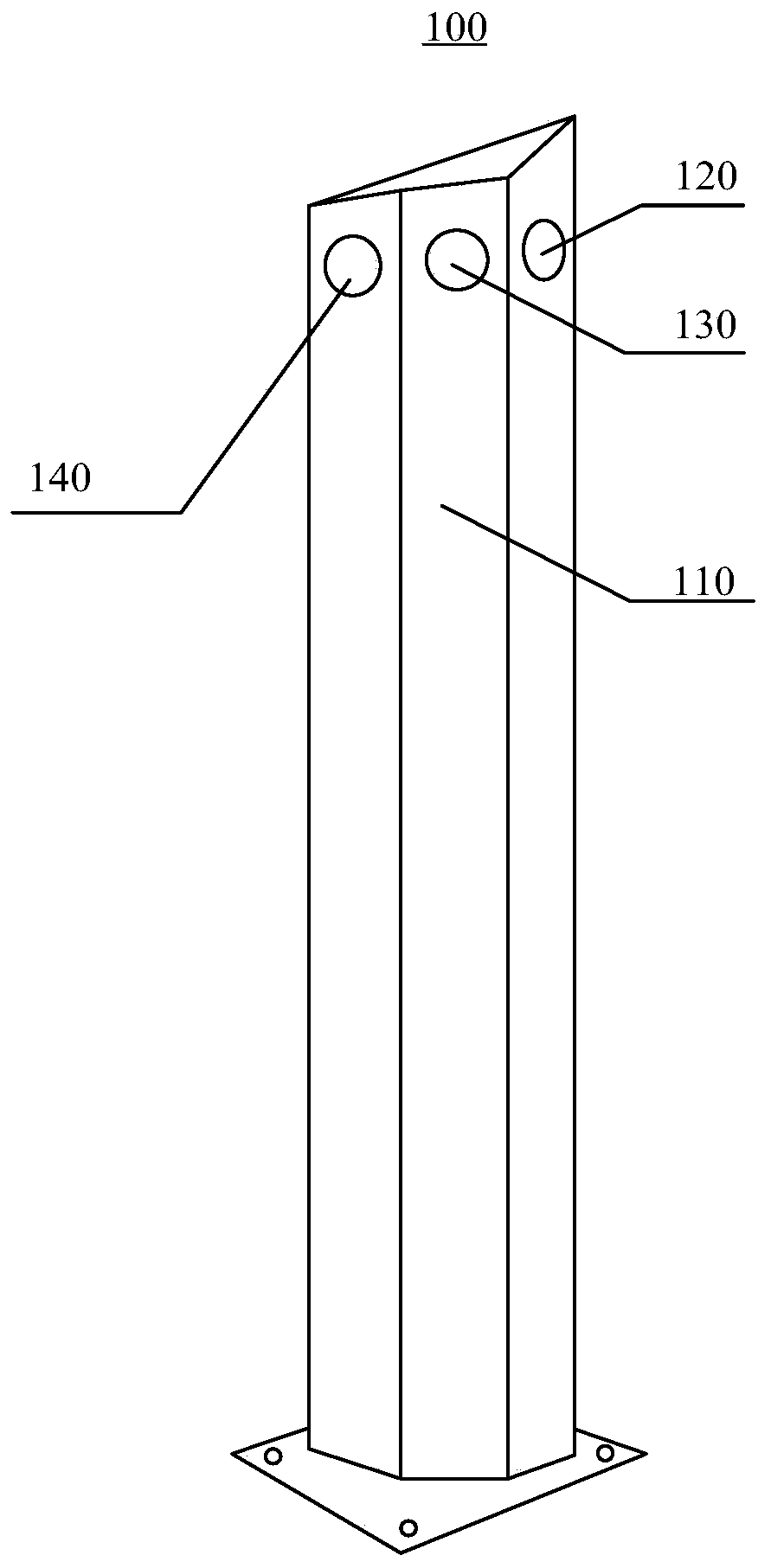

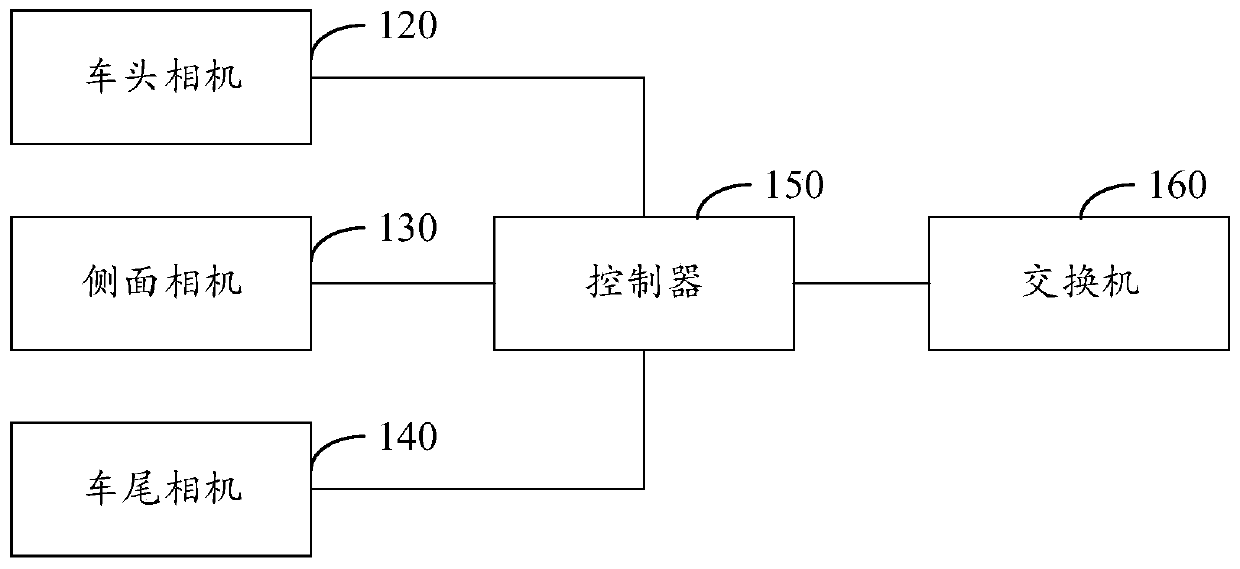

Over-limit information acquisition method, device and system and over-limit detection equipment

PendingCN111192462ASolve the problem that the profile photo of the vehicle cannot be fully capturedSmall construction areaRoad vehicles traffic controlComputer graphics (images)Engineering

The invention provides an over-limit information acquisition method, device and system and over-limit detection equipment, and relates to the technical field of road vehicle detection. According to the over-limit information acquisition method provided by the embodiment of the invention, the problem that identification results cannot be associated when a plurality of independent cameras respectively identify the characteristics of the vehicle head, the vehicle tail and the vehicle body in the prior art can be solved. The shooting view angles of three cameras arranged on the over-limit detection equipment are overlapped, and the vehicle in a video stream is accurately tracked and distinguished, so that the identification results of the three cameras can be accurately associated to the samevehicle to form correct and complete vehicle data, and chaos of retained evidences cannot be caused.

Owner:辽宁艾特斯智能交通技术有限公司

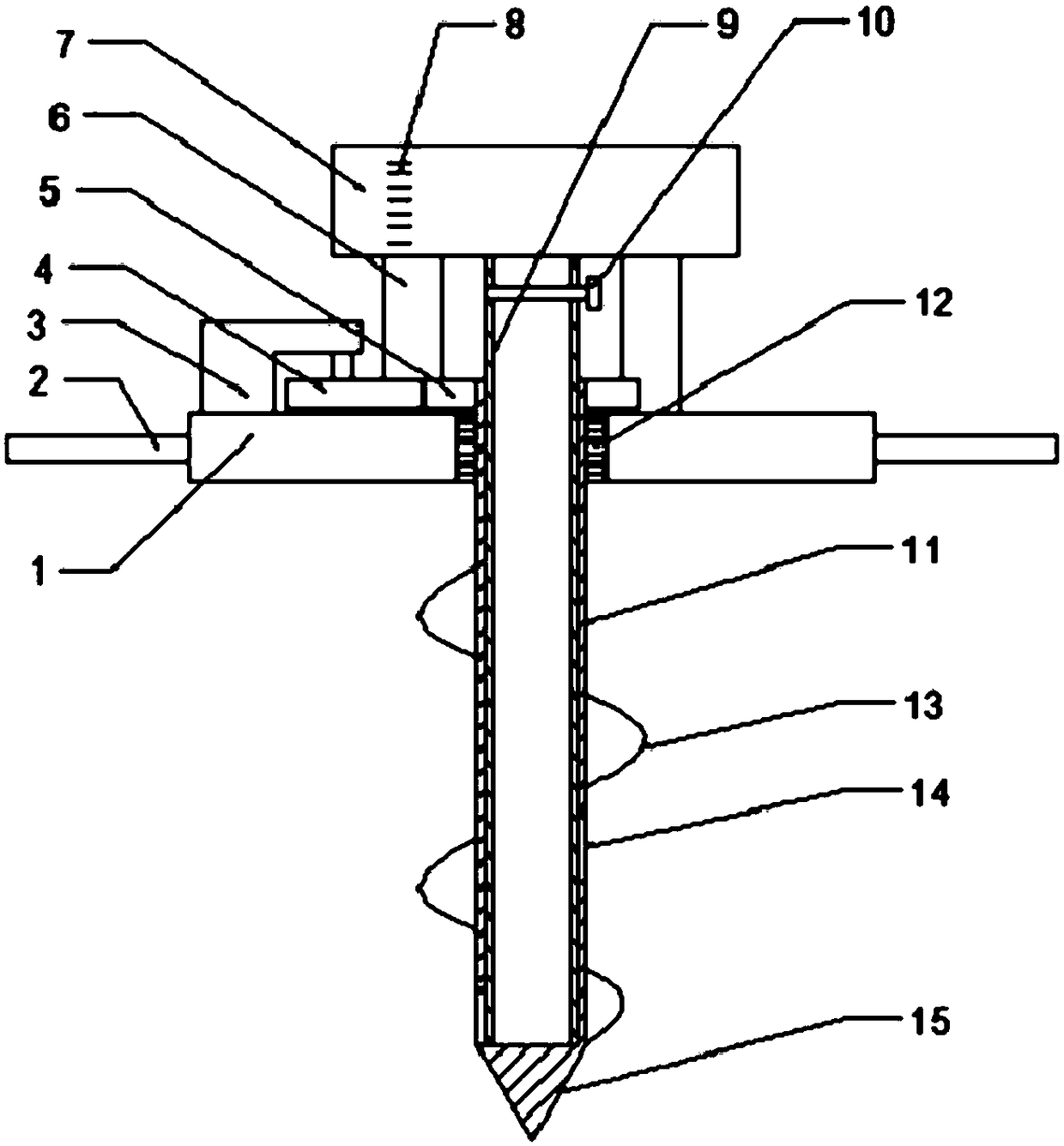

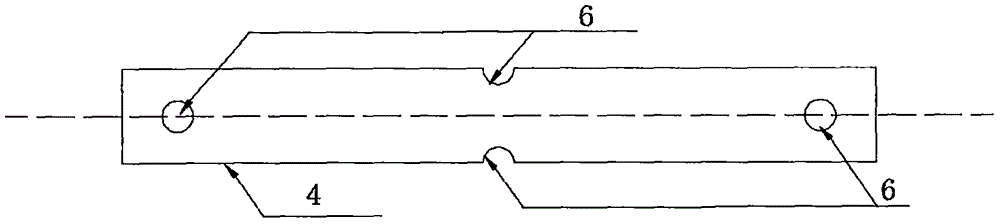

Fertilizer applying device for green crisp plums

InactiveCN108575198AAvoid Tilt JitterDrilling works smoothlyPlantingDirect liquid fertiliser deliverySpiral bladeEngineering

The invention discloses a fertilizer applying device for green crisp plums. The fertilizer applying device comprises a supporting plate, hand shanks are both arranged at the two sides of the supporting plate, a rolling bearing penetrates through the supporting plate, a motor is further arranged on the supporting plate, a motor is connected with a small gear, and the small gear is meshed with a biggear; a hollow rotary shaft is connected to the inside of the rolling bearing, the upper end of the hollow rotary shaft is connected to the inside of a center hole of the big gear, and a leaking holeis formed in the side wall of the hollow rotary shaft; a drilling head is connected to the bottom of the hollow rotary shaft, a spiral blade is arranged on the hollow rotary shaft, and the lower endof the spiral blade is located at the junction of the drilling head and hollow rotary shaft; a flow guiding pipe is arranged inside the hollow rotary shaft, the outer wall of the flow guising pipe closely fits the inner wall of the hollow rotary shaft, and a material box is arranged on the upper end of the flow guiding pipe; a through hole is formed in the bottom of the material box and is communicated with the flow guiding pipe, a control valve is arranged on the flow guiding pipe, the control valve is located between the material box and the big gear, and an air cylinder used for controllinglifting and lowering of the material box is arranged on the supporting plate. When the fertilizer applying device is adopted to apply fertilizer to the green crisp plums, damage to green crisp plum roots can be effectively reduced.

Owner:绥阳县瓦房水榭农旅发展有限公司

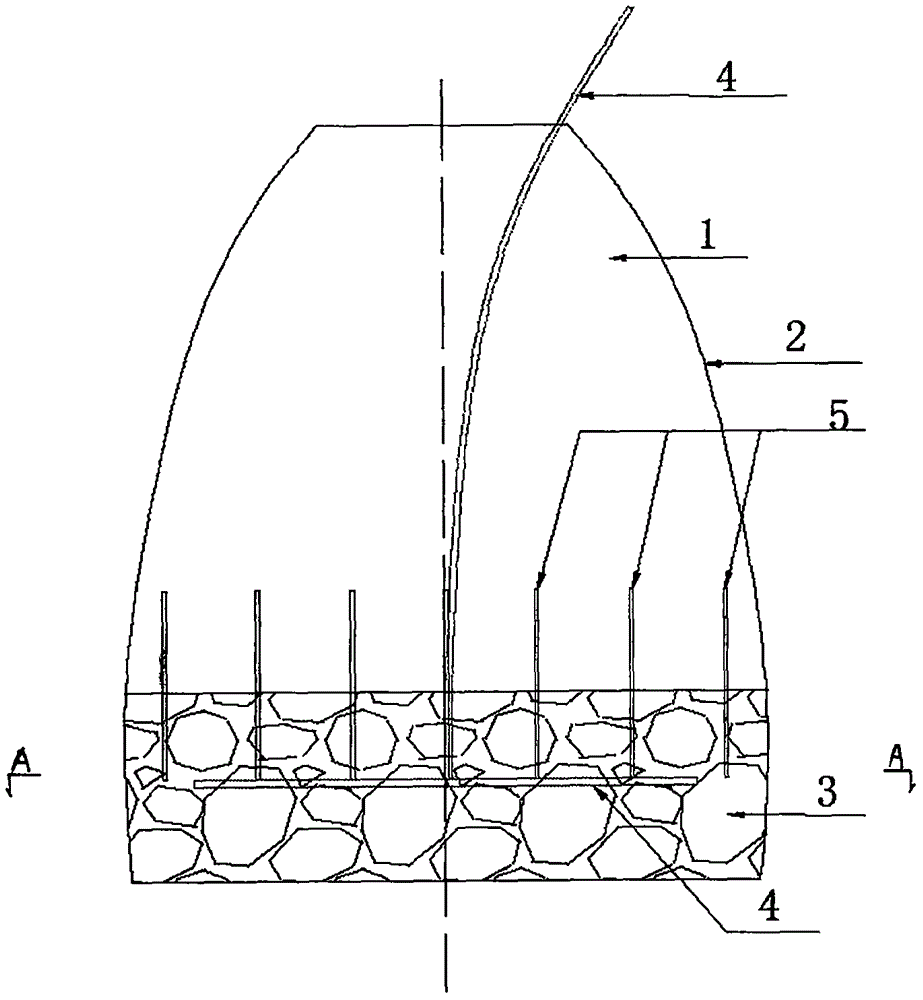

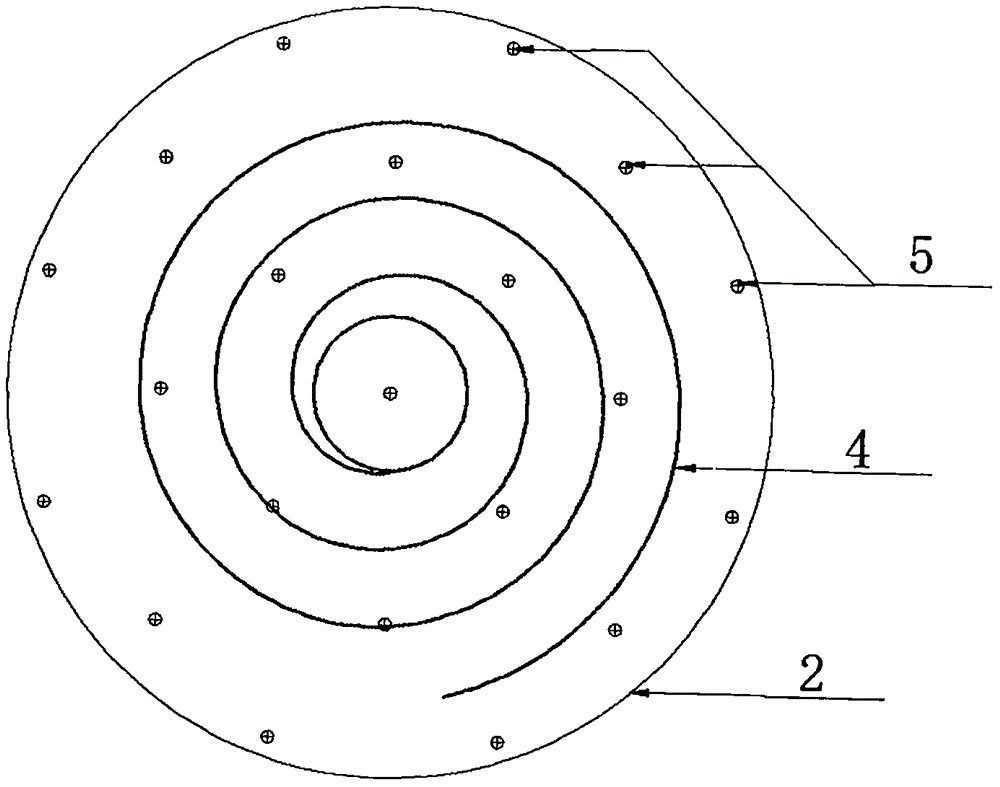

Irregular shallow karst cavity ribbing and grouting filling structure and construction method

The invention belongs to an irregular shallow karst cavity ribbing and grouting filling structure and a construction method. The structure is characterized in that a moundy earth rockfill mixed padding bottom layer with the middle higher than the periphery is arranged at the bottom of a karst cave, a plurality of layers of slip casting pipes which are distributed in a spiral line manner and spaced by a certain height are arranged in a plurality of layers of earth rockfill mixed padding, and the earth rockfill mixed padding between the corresponding slip casting pipes is filled with vertical reinforcement distributed in a quincunx shape at intervals and injected slurry. The method includes the steps of manufacturing of the slip casting pipes, filling of all layers of earth rockfill mixed padding, paving of all layers of slip casting soft pipes and driving of the vertical reinforcement and injecting of slurry into all layers of earth rockfill mixed padding. According to the structure and the method, shortcomings in an existing irregular shallow karst cavity ribbing and grouting filling structure and an existing construction method are overcome, the backfilling strength standard can be achieved, and the structure and the method have the beneficial effects of being simple in structure, low in construction cost, good in construction quality, high in speed, easy to construct, wide in applicability and good in energy-saving and environment-friendly effect, and saving time and labor.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

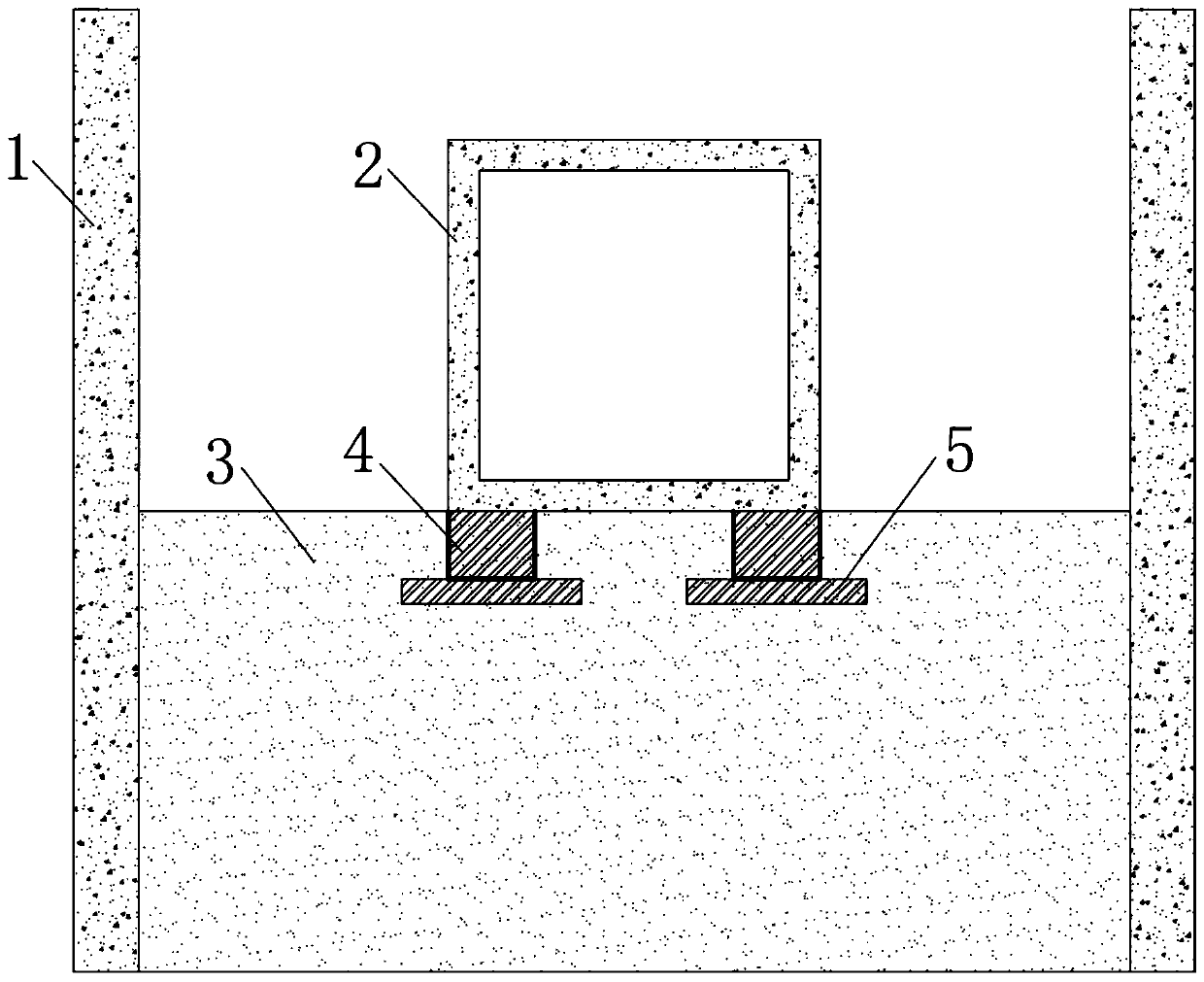

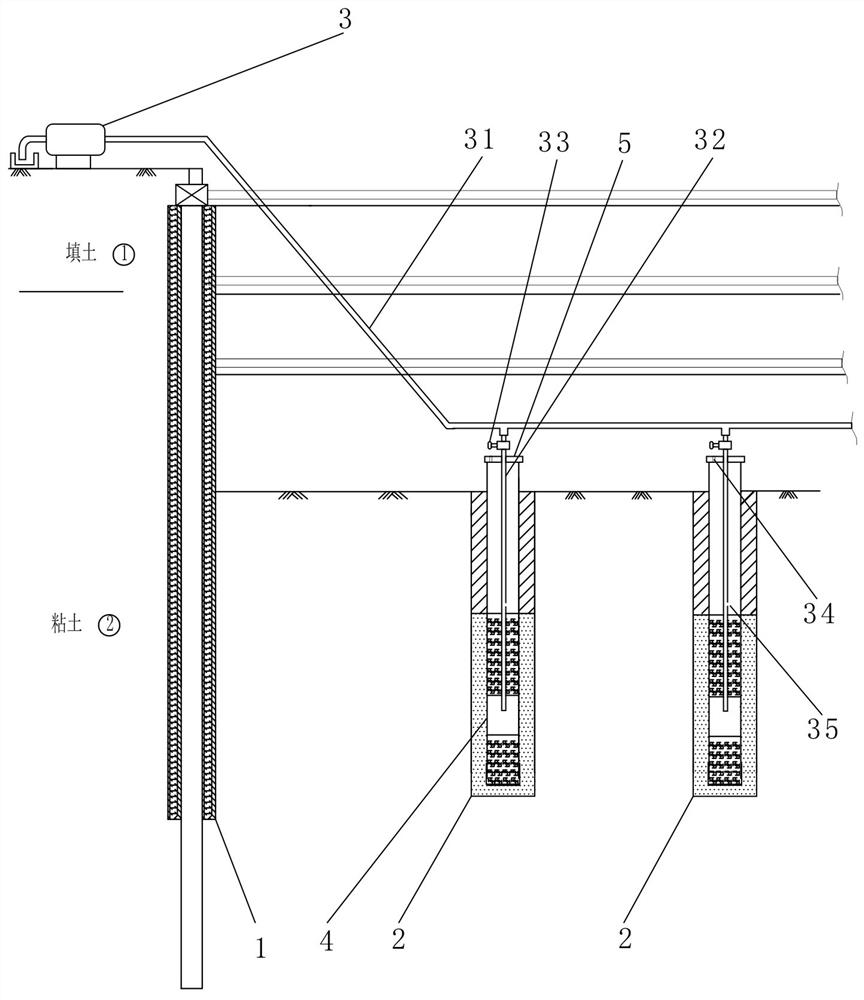

Existing pipe gallery underground space and supporting structure thereof and construction method of supporting structure

PendingCN110777850ASmall construction areaReduce construction areaArtificial islandsProtective foundationArchitectural engineeringPipe

The invention provides an existing pipe gallery underground space and a supporting structure thereof and a construction method of the supporting structure. The method comprises the steps that soil around a pipe gallery is pre-reinforced, and supporting walls are arranged along the two sides of the pipe gallery; soil is excavated to the bottom level position of the pipe gallery, soil is drawn out below the pipe gallery in the length direction of the pipe gallery, so that multiple dispersed containing spaces are formed below the pipe gallery, and first support structures are arranged in the containing spaces; soil is excavated to the position below the pipe gallery, the first support structures are dismounted in sequence, meanwhile, plate-shaped second support structures are paved below thepipe gallery to replace the first support structures, and the second support structures are jointed to form a support plate to abut against the position below the pipe gallery; the underground space is excavated, and support piles are arranged according to the positions of structure piles in the design drawing of the newly-added underground space; and a bottom plate is poured at the bottom of theunderground space, and the bottom plate, the support piles and the supporting walls are connected into a whole. A construction foundation of a reverse building method is provided for excavation of theunderground space, and on the premise of guaranteeing that the existing pipe gallery is not influenced, the underground space is built.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

Vacuum dewatering process for deep foundation pit

ActiveCN113279421AImprove suction effectSolve the problem that precipitation is difficult to drainExcavationsPumping vacuumVacuum pump

The invention discloses a vacuum dewatering process for a deep foundation pit. The vacuum dewatering process comprises preparation work before dewatering, dewatering well equipment and mounting procedures and dewatering and foundation pit excavation. The vacuum dewatering process is suitable for foundation pit dewatering of various soil layers such as floury soil, clay, muddy clay and silt, the whole deep foundation pit dewatering process including vacuumizing, water pumping and outward water drainage in a well pipe can be completed through a jet vacuum pump or a mechanical vacuum pump, a vacuum main water pipe and a vacuum water pumping pipe, the vacuum degree is controlled to be about -0.06 Mpa, and the effective depth of water pumping can be larger than 10 meters. A traditional mode that a submersible pump, a pipeline and auxiliary facilities are arranged in a dewatering well is thoroughly changed, full-automatic vacuum deep well dewatering is achieved through the vacuum pump, and the purposes of shortening the dewatering period, improving the dewatering quality, saving the dewatering cost and improving the overall environment of a construction site are achieved.

Owner:上海兴怡基础工程有限公司

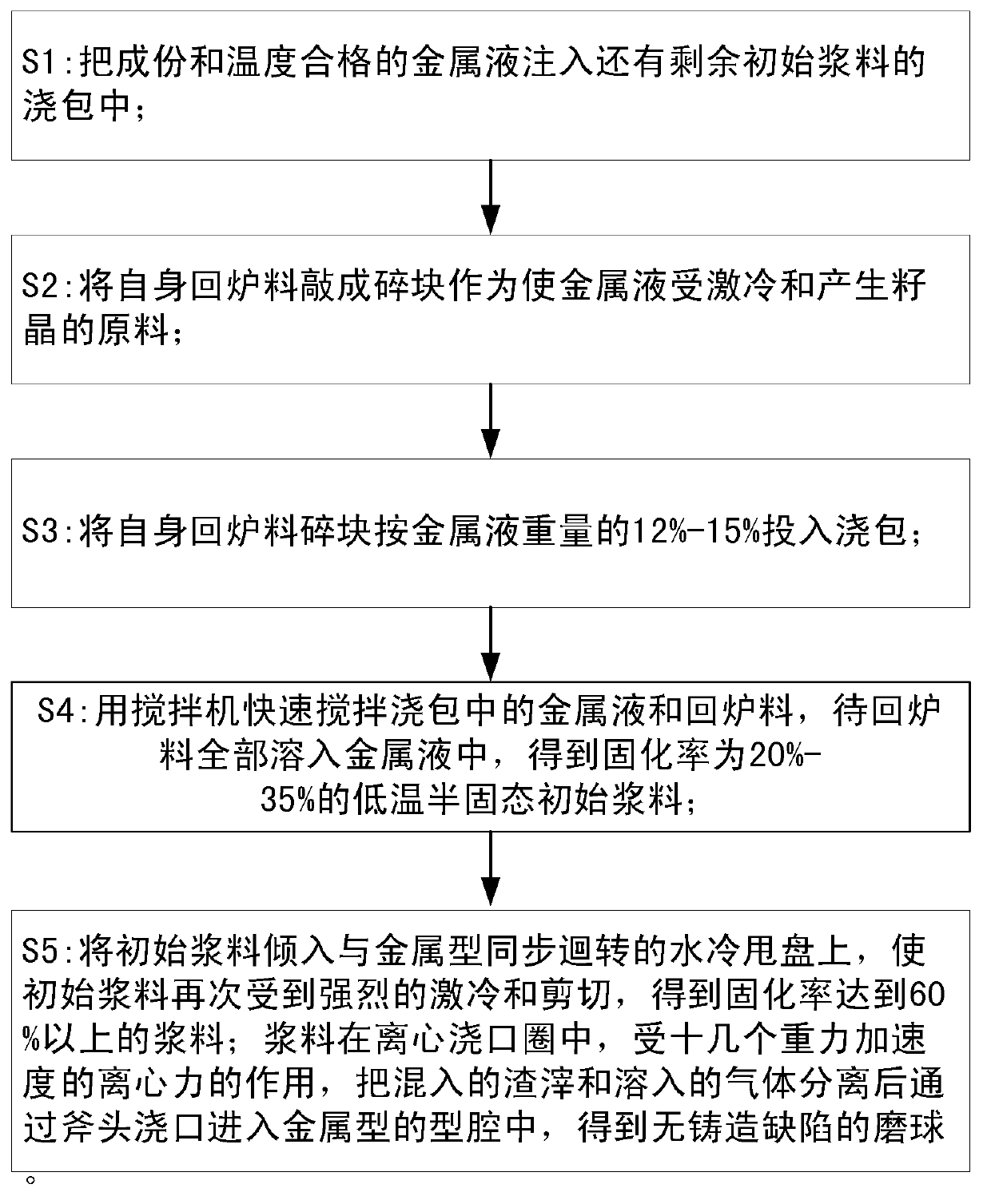

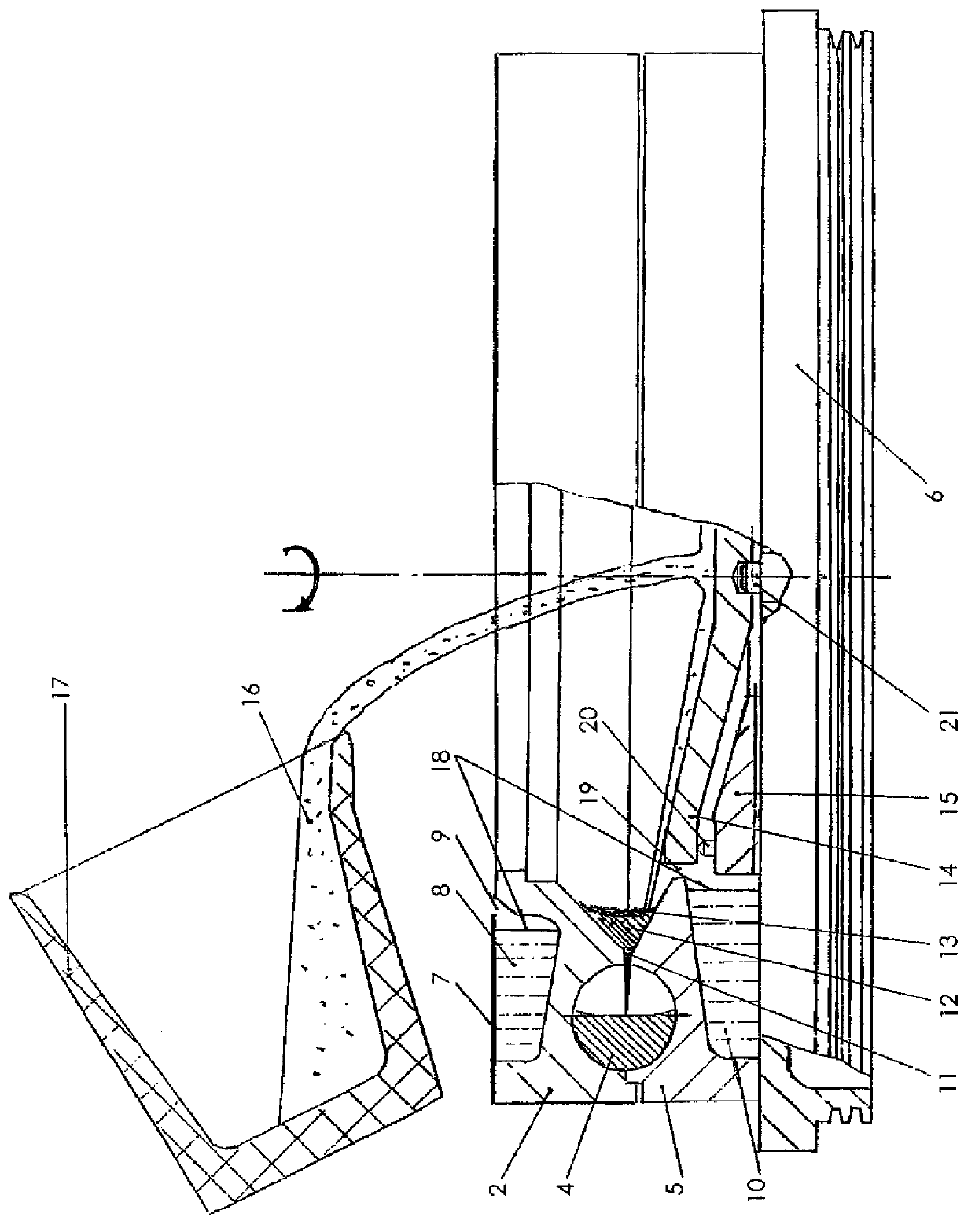

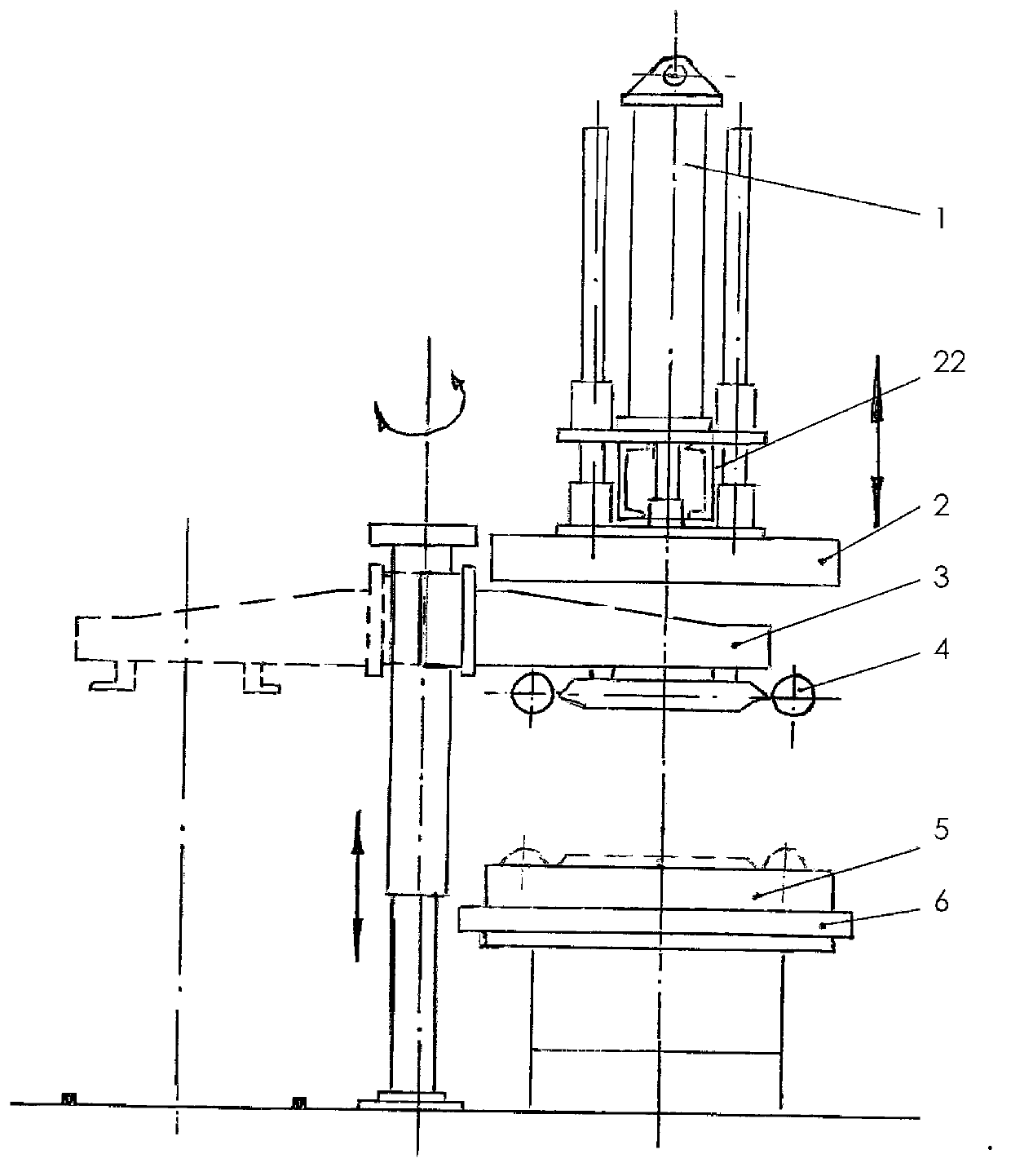

Semisolid centrifugal separating casting ball grinding process, process device and ball casting machine

InactiveCN103128248AObvious advantage of energy savingGreen productionFoundry mouldsFoundry coresProduction lineSemi solid

The invention discloses a semisolid centrifugal separating casting ball grinding process, a process device and a ball casting machine. Returns serve as raw materials, and a metal liquid is processed into metal semisolid slurry conforming to requirements in a casting ladle and the ball casting machine, so that high-quality ball grinding can be achieved; and the metal liquid is subjected to evaporative cooling, so that the semisolid centrifugal separating casting ball grinding process can be actually applied in industrial production, however, if a short-flow process is to be adopted, a production line is required to be formed by a plurality of ball casting machines in a group casting mode, and the yield of the production line can be improved exponentially.

Owner:武达兼

High-pier built-in stiff framework cross tie beam structure and construction method

ActiveCN107401113ASimple construction processEasy to operateBridge structural detailsBridge materialsCorbelBolt connection

The invention relates to a high-pier built-in stiff framework cross tie beam structure which comprises a hoop-type corbel bracket. Each hoop is composed of two semi-circular-arc-shaped steel plates, and adopted high-strength bolts are connected with pier columns. An operating platform is formed by assembling, machining and hoisting thick steel plates and profile steel on the ground and connecting the materials with the hoop-type corbel bracket by using high-strength bolts. Penetration-type steel beams are made of profile steel or steel rods, the height and width of penetrating I-steel and the thickness of flange web plates are determined according to self weight, people load and the like, and the penetrating I-steel is manufactured according to design values when being prefabricated. A formwork system consists of a bottom formwork, distributing beams, bearing beams, shoulder pole beams and the like, wherein the parts are connected by adopting bolts. The built-in stiff framework is of a truss structure, is formed by welding channel steel and I-steel and is structurally divided into upper chord rods, diagonal bracings, vertical rods and lower chord rods. The high-pier built-in stiff framework cross tie beam structure has the advantages that a built-in stiff framework construction operation face is small and is relatively closed, no crossed operation exists, and the construction risk is low.

Owner:ANHUI ROAD & BRIDGE GRP

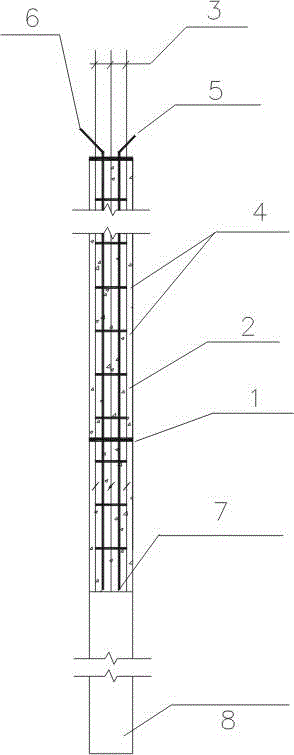

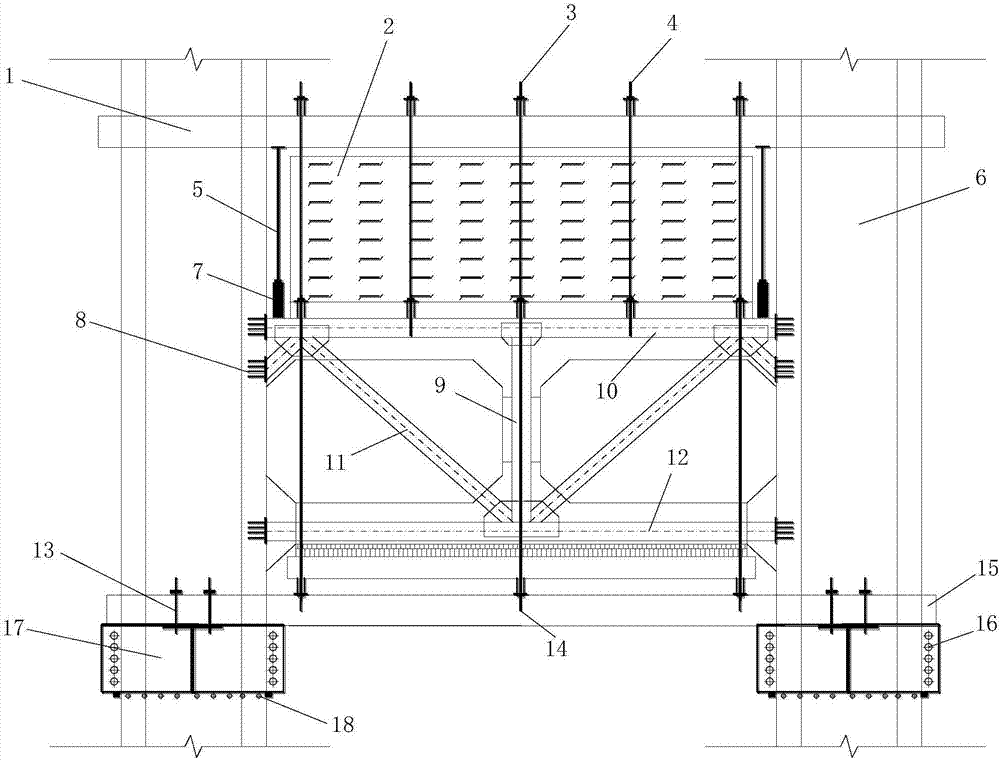

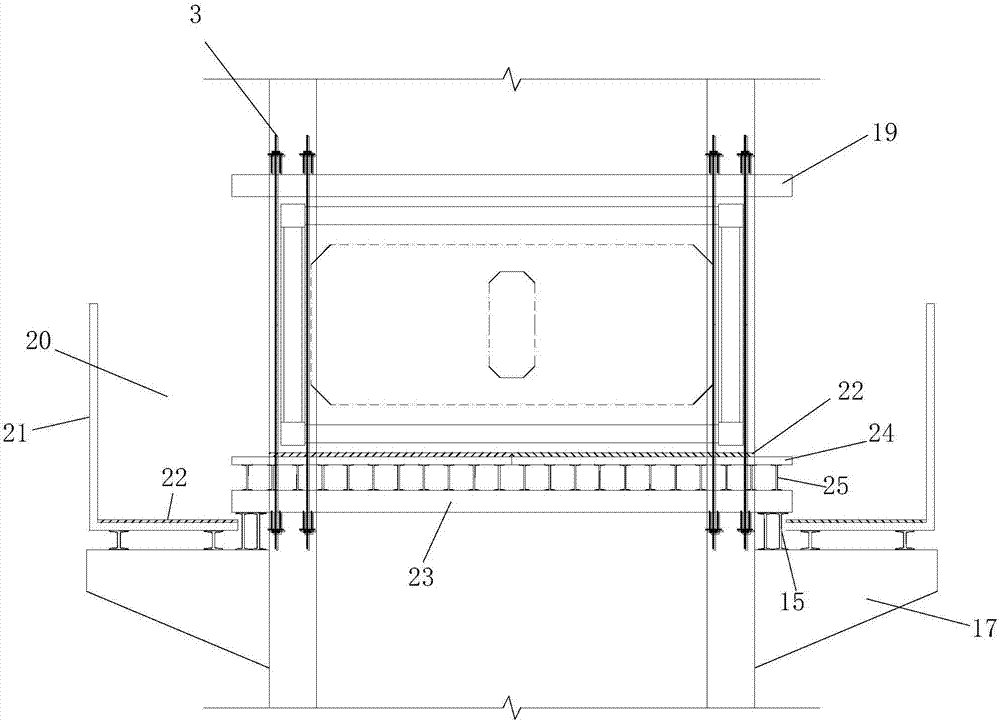

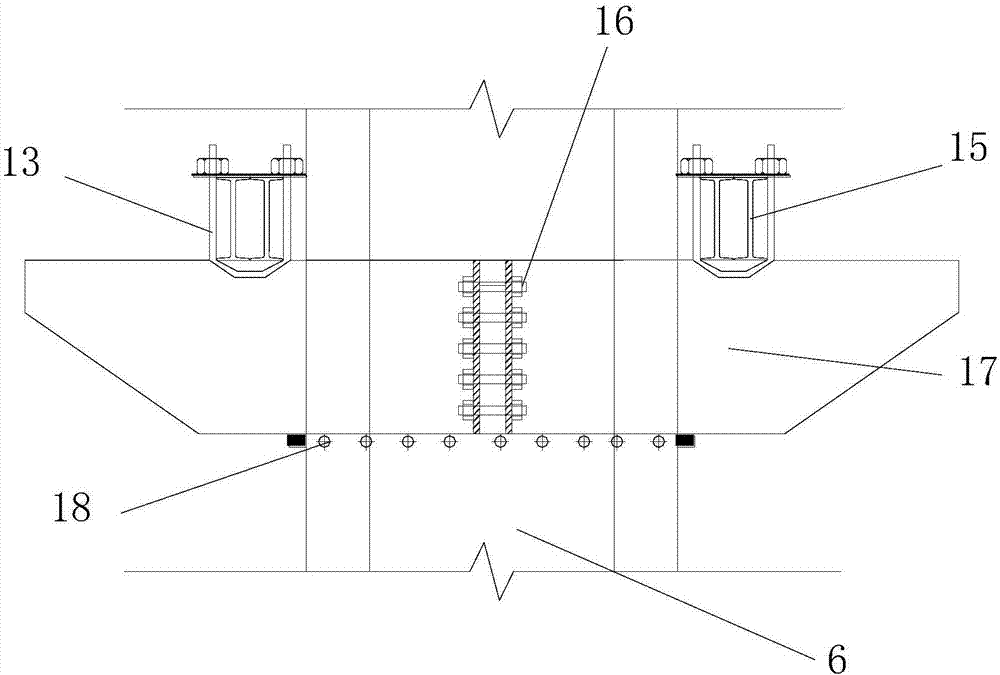

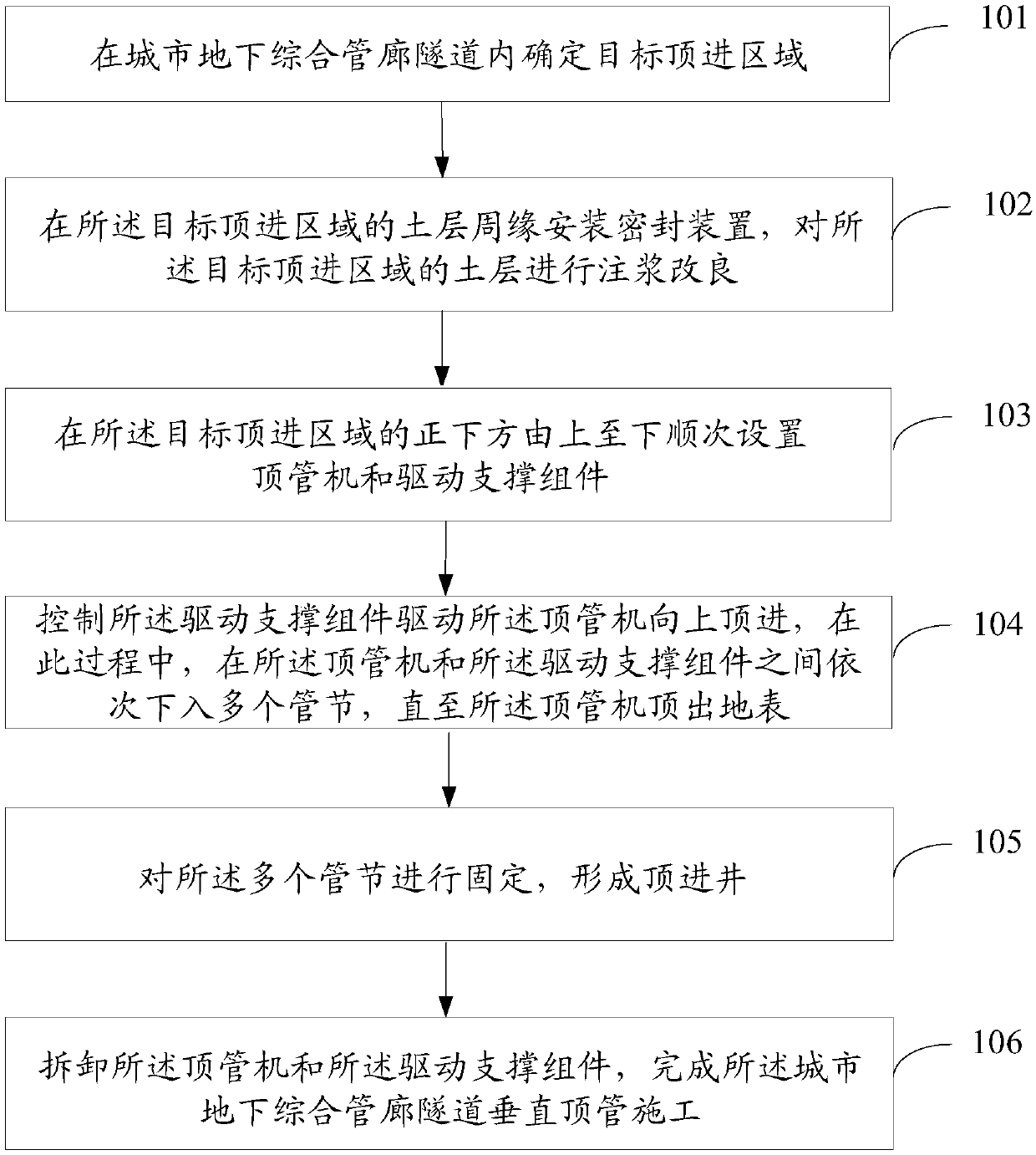

Construction method of vertical pipe jacking of urban underground comprehensive pipe gallery tunnel

ActiveCN110388215AImprove construction efficiencySmall construction areaTunnelsTunnel constructionSoil horizon

The invention discloses a construction method of the vertical pipe jacking of an urban underground comprehensive pipe gallery tunnel, and belongs to the technical field of pipe gallery tunnel construction. The method comprises the steps of determining a target jacking area in the urban underground comprehensive pipe gallery tunnel; installing a sealing device around a soil layer of the target jacking area, and improving the grouting of the soil layer of the target jacking area; arranging a pipe jacking machine and a driving support assembly in sequence from top to bottom just below the targetjacking area; controlling the driving support assembly to drive the pipe jacking machine to jack upwards, and arranging a plurality of pipe joints in sequence between the pipe jacking machine and thedriving support assembly in the process until the pipe jacking machine is ejected out of the ground; fixing the plurality of pipe joints so as to form a jacking well; and removing the pipe jacking machine and the driving support assembly so as to complete the construction of the vertical pipe jacking of the urban underground comprehensive pipe gallery tunnel. According to the method, by constructing the underground vertical pipe jacking, the construction efficiency is improved, the construction area is reduced, and potential safety hazards of collapse and the like are avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

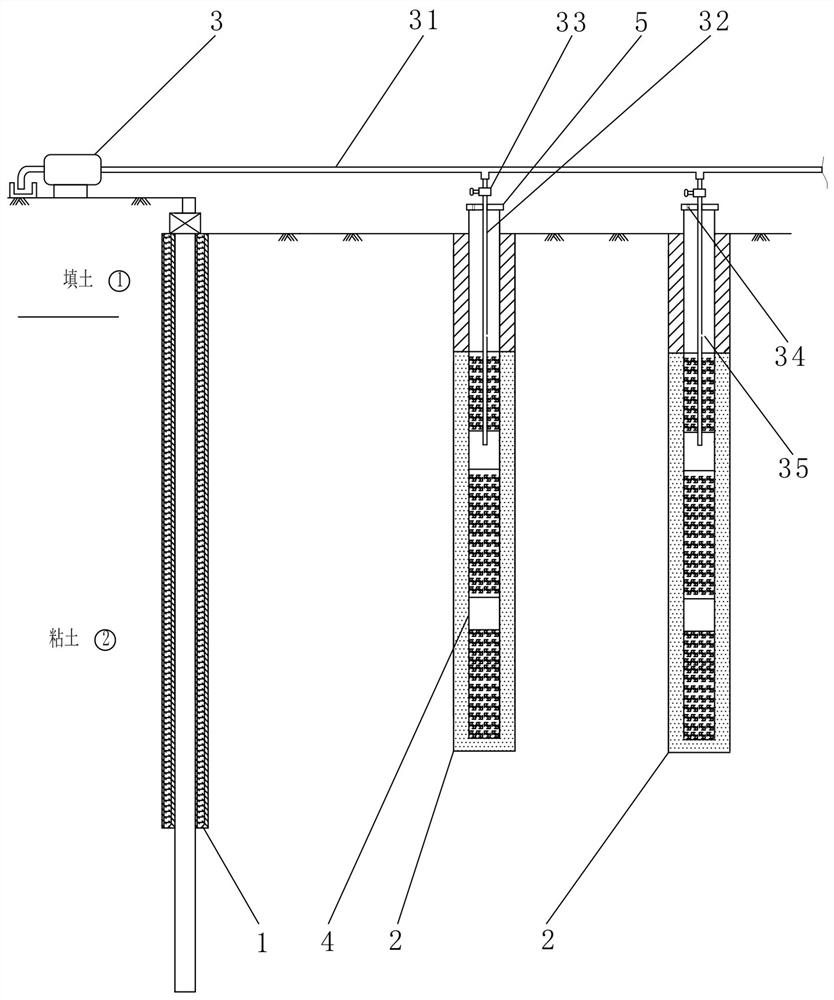

Rapid construction method of pipe jacking working well in upper soft and lower hard stratum

The invention discloses a quick construction method of a pipe jacking working well in an upper soft and lower hard stratum. A site is smoothed, staking out in survey is carried out, the position of apile hole is positioned; a rotary drilling machine is used for drilling in an upper soil layer, every time a certain distance is drilled, a drill head of the rotary drilling machine exits out of the pile hole, and a pile casing is put into the pile hole; the method is repeated until drilling is carried out into a lower base rock layer, and all the pile casings are anchored in the upper soil layer;the rotary drilling machine is continuously used for drilling in the lower base rock layer until drilling is carried out to a specified elevation; transverse excavation is carried out in the hole wall at the bottom of the pile hole to form a pipe jacking operation space, wherein the pipe jacking operation space is provided with an opening into which the pipe jacking to be constructed can enter; ajacking device is installed in the pipe jacking operation space; and at the bottom of the pile hole and at the position of the pipe jacking construction, the lower base rock layer is excavated transversely, and jacking construction is carried out on the pipe jacking through the jacking device. The quick construction method reduces the construction workload, reduces the construction difficulty, shortens the construction period and reduces the impact on the environment.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Foundation construction method of high-voltage tower

InactiveCN108343082ASmall construction areaReduce dosageFoundation engineeringTransmission lineEngineering

The invention provides a foundation construction method of a high-voltage tower and relates to the field of transmission line tower foundation construction. The foundation of the high-voltage tower adopts a rectangular iron tower foundation, and the foundation type adopts a foundation bolt foundation type. Foundation pit excavation mainly comprises the following steps that a rectangular foundationis divided into pits, and the positions of the four foundation pits are determined according to the divided pits; sample holes are dug according to the excavation sizes of the foundation pits; the sizes are measured again after the sample holes are excavated, and excavation continues after the design requirement are met; the sizes of the pit walls are controlled in the excavation process of the foundation pits, and the pit walls are guaranteed to be vertical; base plates are built; stand columns are built on the base plates; foundation bolts of thet rectangular foundation are aligned; the sizes of all parts are checked; and self-compacting concrete is adopted in the concrete pouring process. According to the foundation construction method, the self-compacting concrete is adopted, the mutual relation between the characteristics of the self-compacting concrete can be balanced, the compactness is improved, cracks can be effectively prevented from being generated, the structure durabilityis improved, and damage to soil caused by repeated construction is avoided.

Owner:国网山东省电力公司泗水县供电公司 +2

Fast replacement method and device for main material of power transmission line iron tower

PendingCN108843117AReduce work intensitySmall construction areaBuilding repairsTowersElectricityPower transmission

The invention relates to a fast replacement method and device for a main material of a power transmission line iron tower. The method specifically includes the following steps of connecting a cable between a tower body of the power transmission line iron tower on the side opposite to the main material to be replaced and the ground; mounting a tower foot fixing base on a tower foot foundation wherean originally damaged main material segment of the power transmission line iron tower is located; mounting a connector on the side where the originally damaged main material segment of the power transmission line iron tower is located; connecting a support rod adjustable in length between the outer side of the tower foot fixing base and the connector, and adjusting the length of the support rod so that the support rod is firmly supported between the tower foot fixing base and the connector; removing and replacing the damaged main material of the power transmission line iron tower with a new main material; removing a tower foot fixing plate, the connector and the support rod; removing the cable connected between the tower body of the power transmission line iron tower and the ground. According to the method and device, the work intensity can be reduced, the construction area is decreased, the labor cost is reduced, there is no need to cut off power, and the normal use of electricity byenterprises and residents is ensured.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Method for reinforcing gravity type retaining wall

ActiveCN107604939AEnhanced overall stabilityImprove stabilityArtificial islandsUnderwater structuresLarge applicationsPre stressing

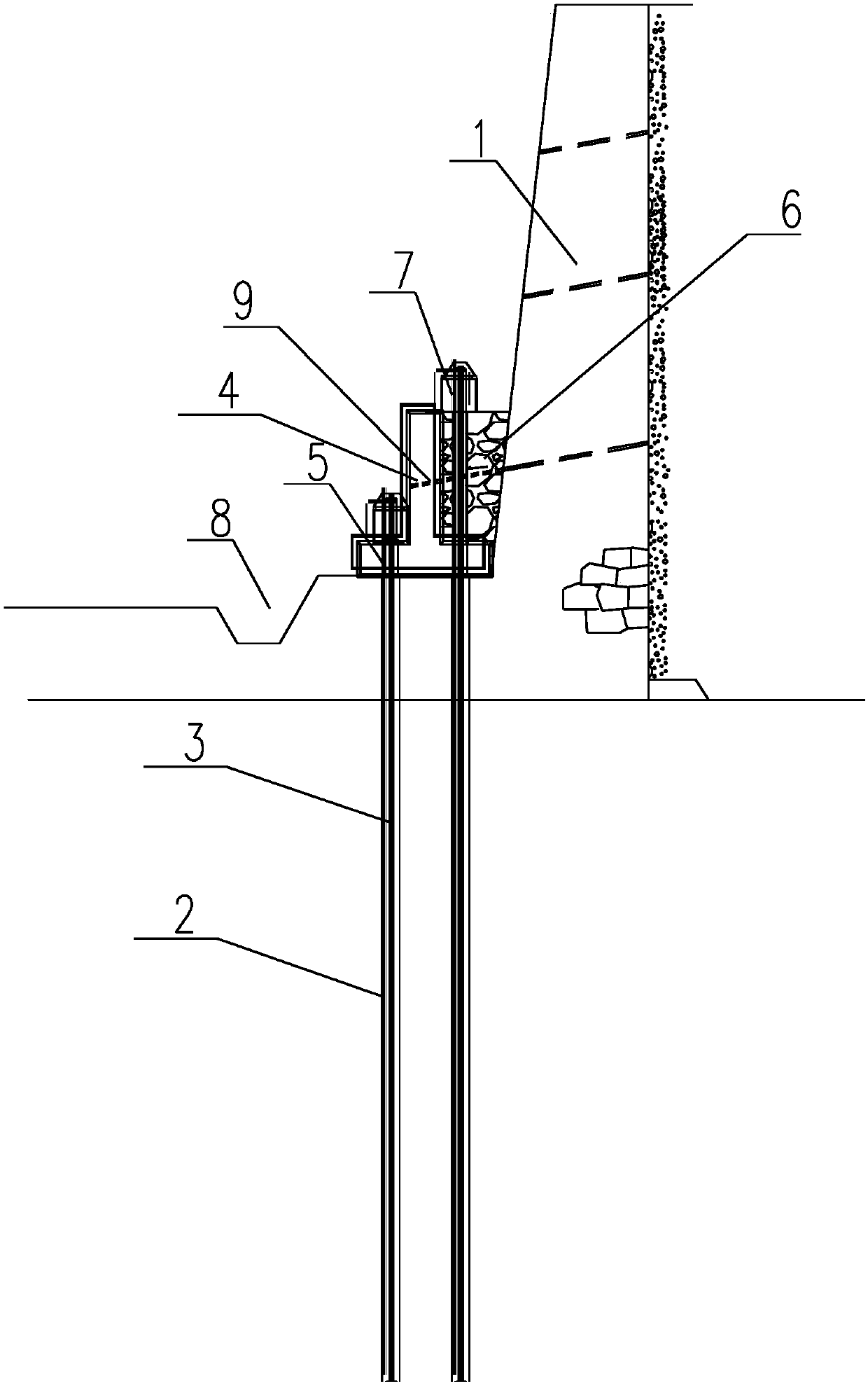

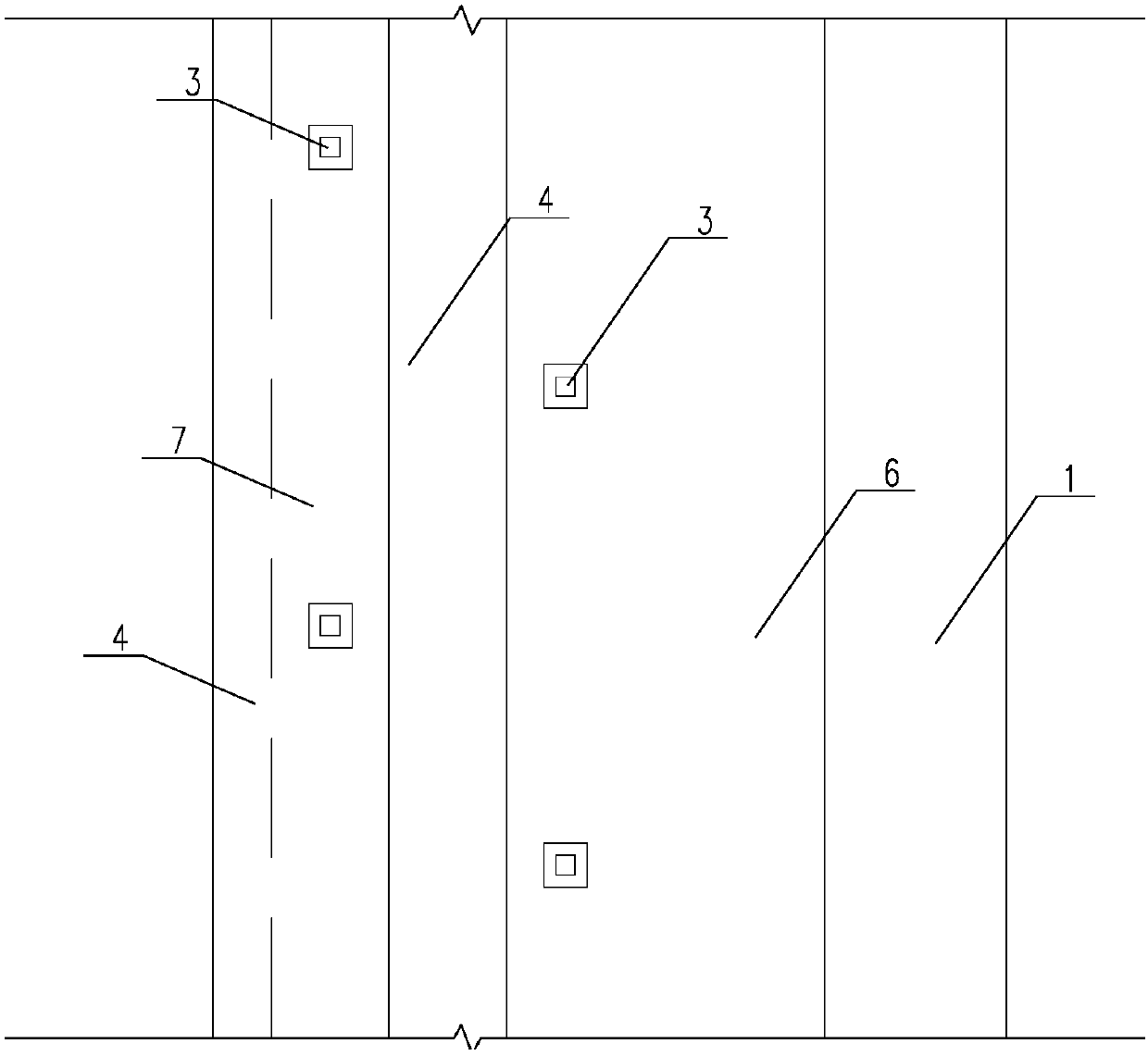

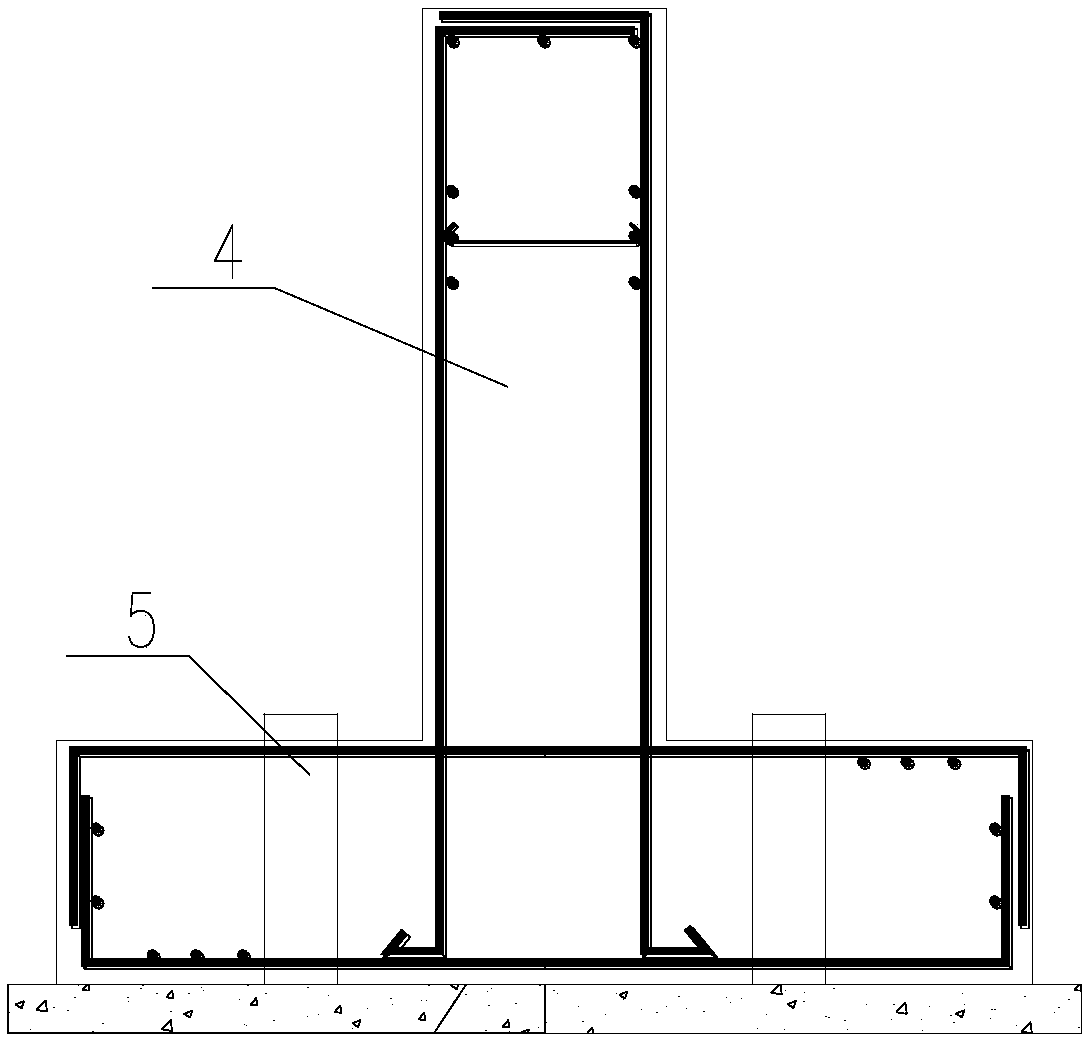

The invention provides a method for reinforcing a gravity type retaining wall. A cantilever type retaining wall (4) is additionally arranged nearby the wall foot of the gravity type retaining wall (1), a vertical pre-stressed anchor cable (3) is additionally arranged at the bottom of the cantilever type retaining wall (4), the position between the gravity type retaining wall and the cantilever type retaining wall is filled with rubble concrete (6), and therefore the overall stability of a side slope and the retaining walls can be improved through a three-pronged mode. According to the method for reinforcing the gravity type retaining wall, the deformation resistant capability is strong, the construction working face is small, the mode that hole drilling is conducted firstly, and then the cantilever type retaining wall (4) is constructed is adopted, hole drilling on the cantilever type retaining wall (4) can be avoided, and the construction difficulty is reduced; and the construction period is short, the construction cost is low, and large application value and social benefits are achieved.

Owner:同纳检测认证集团有限公司

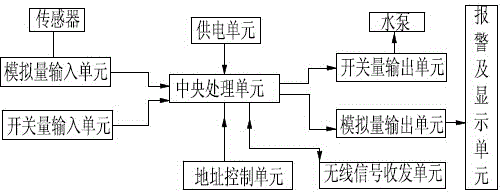

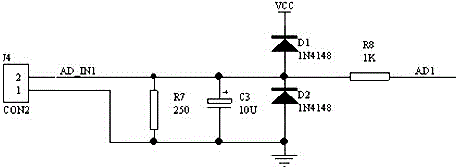

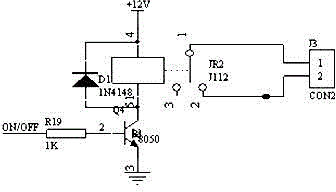

Water level monitoring device and monitoring system for transformer substation

The invention discloses a water level monitoring device and monitoring system for a transformer substation and relates to the technical field of water level monitoring devices. The water level monitoring device comprises an analog quantity input unit, a switch quantity output unit, a central processing unit, a power supply unit, a switch quantity input unit, an address control unit, a wireless signal receiving-emitting unit and an analog quantity output unit. The monitoring device is not only capable of monitoring the water level information in real time to control the running of a water pump but also capable of monitoring the current and voltage of the running water pump in real time to timely discover the abnormal work of the water pump, and the water level monitoring device is featured with safe and reliable use.

Owner:STATE GRID CORP OF CHINA +2

Construction method for reinforcing T-beam through partially-bonded prestressed FRP

InactiveCN105804425AAvoid secondary damageAccurately control the valueBuilding repairsBridge erection/assemblySocial benefitsEpoxy

The invention discloses a construction method for reinforcing a T-beam through partially-bonded prestressed FRP. The method includes the following steps that (1) prestressed FRP sheets are prepared through special equipment, namely the prestressed FRP sheets are prepared through an FRP quantitative-control self-anchored type prestress tensioning machine; (2) the prestressed FRP sheets are bonded to the T-beam to be reinforced, specifically, the prestressed FRP sheets prepared in the step (1) are bonded to matched positions of the bottom face of the T-beam to be reinforced through epoxy resin glue; and (3) the prestressed FRP sheets are anchored at least at the two ends and the midspan portion of the T-beam correspondingly through an anchoring device. According to the construction method, due to adoption of the specialized tools, the construction method has the characteristics that the construction method is simple, the construction speed is high and universality is high; the characteristic that multiple procedures can be conducted in parallel is achieved, and the T-beam reinforcing construction period can be shortened to the maximum extent; meanwhile, the wet-method construction range is small, the construction program is simplified, and high economic and social benefits are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

Wind power plant low voltage ride through control method

ActiveCN103248054AHigh control precisionDoes not affect reliabilityPower network operation systems integrationAc network voltage adjustmentPeaking power plantPower grid

The invention discloses a wind power plant low voltage ride through control method, and particularly relates to a control method of a system and a device having a wind power plant low voltage ride through function. A basic principle of the wind power plant low voltage ride through control method is as follows: a three-phase current and voltage of an end, which accesses to a grid, of the wind power plant are measured, and equivalent impedance of the grid is calculated, so that a modularization impedance array which can be adjusted quickly is constructed; and the impedance array is connected with a high-speed circuit breaker in parallel and then is in series connection between a wind power plant converging wire and a boosting transformer incoming circuit breaker, judgment of generation of low voltage is completed within 2-4 milliseconds, the time point of a voltage sine wave zero crossing point is calculated, the high-speed circuit breaker completes a disconnection motion at the zero crossing point, the time of the low voltage judgment and the circuit breaker motion is not more than 12 milliseconds, access in series with a impedance array with the equivalent impedance of the grid is realized, and wire concentration voltage of the wind power plant is maintained to be unchanged.

Owner:北京光耀电力科技股份有限公司

Construction method of stilling pool base slab reinforcing structure

InactiveCN106638506AReduce lossesSimple structureBarrages/weirsSewerage structuresWater resourcesHydraulic engineering

Owner:SUZHOU HUICHENG ZHIZAO IND DESIGN

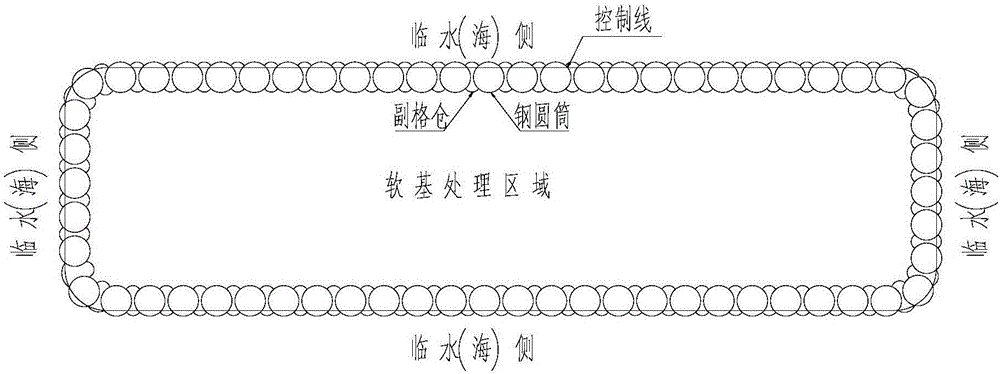

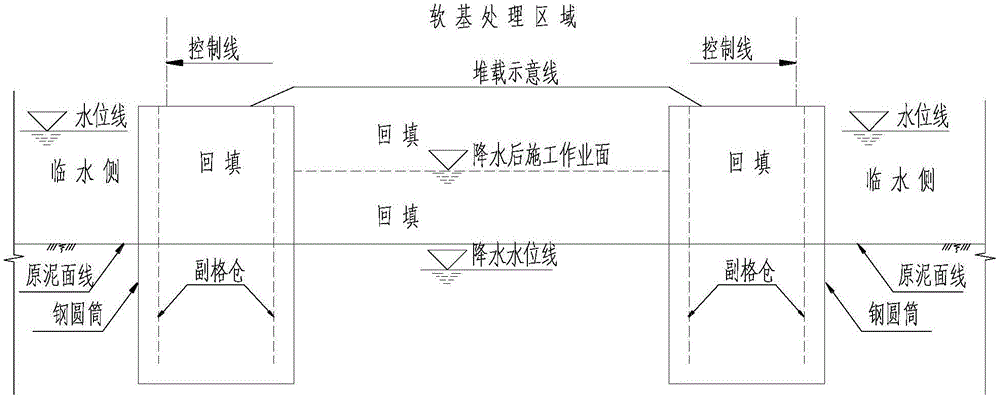

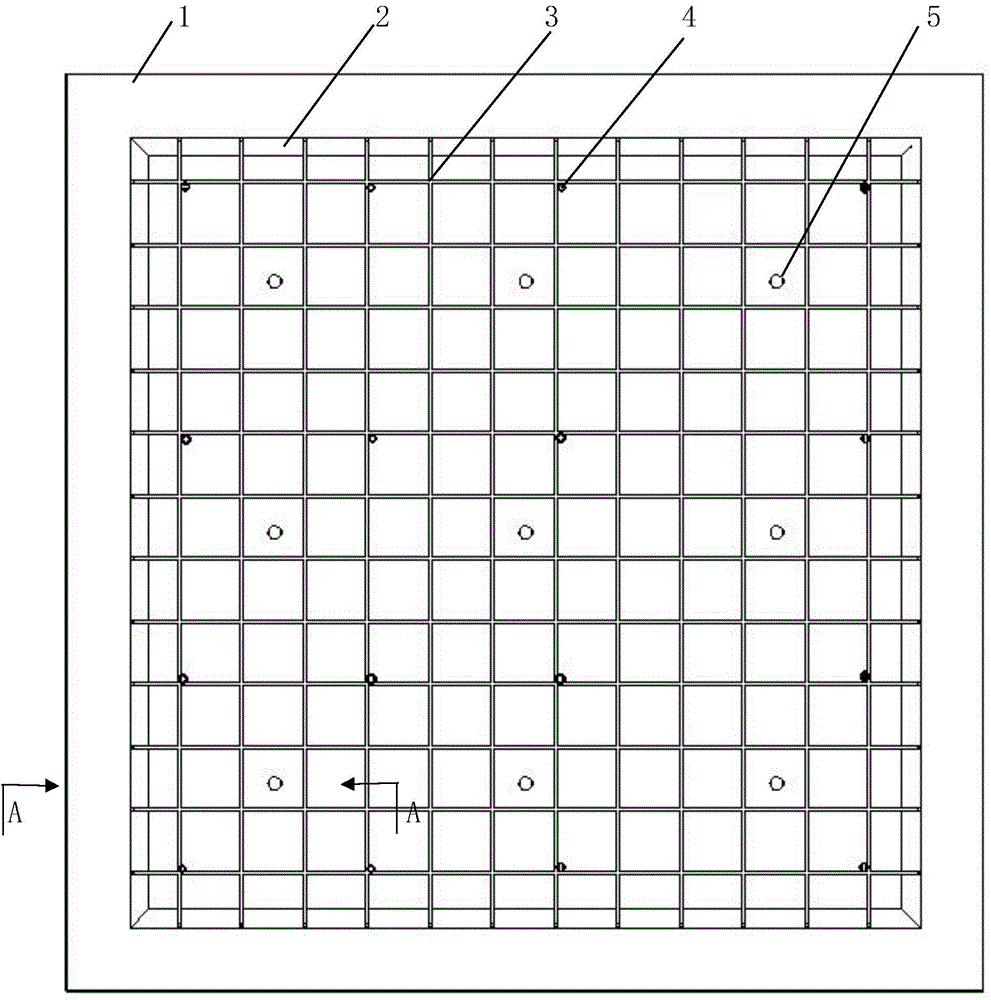

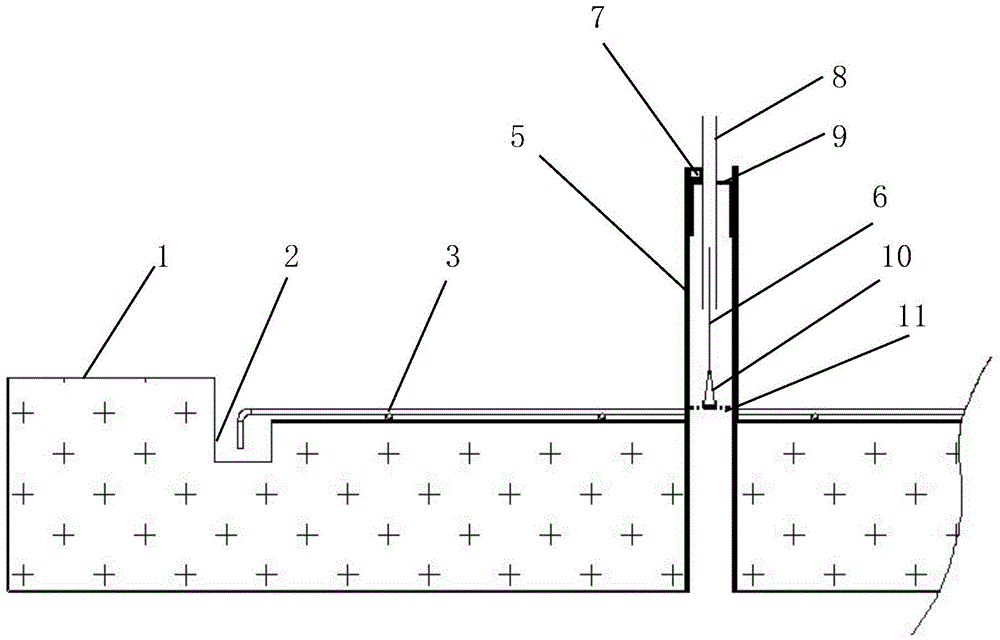

Soft foundation treatment method capable of providing pre-pressing load by surcharge load in manner of inserting and piling water draining board to drain and capable of forming steel cylinder water-stop structure

InactiveCN106284291AGood for meeting stability requirementsMeet stability requirementsSoil preservationProcess regionWater level

The invention discloses a soft foundation treatment method capable of providing pre-pressing load by surcharge load in a manner of inserting and piling a water draining board to drain and capable of forming a steel cylinder water-stop structure. The soft foundation treatment method comprises the following steps of: sinking as steel cylinder and an assistant bin; backfilling the steel cylinder and the assistant bin with sand; closing a soft foundation treatment area, connecting the steel cylinder to the assistant bin to carry out water stop treatment; backfilling the closed area until a construction operation surface, and draining water to a position below the backfilled surface, inserting and piling the plastic water draining board on land; backfilling to pre-pressing height and regulating water-draining water level; carrying out full-load pre-pressing; and unloading after processing requirements are met. The soft foundation treatment method disclosed by the invention can quickly provide a water stop environment to an area which needs soft foundation treatment, and can artificially reduce the construction operation surface, so that the difficulty of inserting and piling the plastic water draining board is reduced, and stability requirements of the structure are favorably met by regulating the water draining water level; and backfilling and heap-loading can be continuously carried out and water draining is combined, so that an overload ratio of providing pre-pressing load is 1.5-3.0; and moreover, stability requirements of the structure are favorably met by water draining, so that the soft foundation treatment method is obviously superior to a conventional foundation treatment mode.

Owner:CCCC FHDI ENG

Stilling pool bottom plate reinforcing composition and construction method thereof

InactiveCN104947636AReduce the impactReduce lossesBarrages/weirsSewerage structuresWater storageWater resources

The application relates to a stilling pool maintenance method in a water conservancy project, and specially relates to a stilling pool bottom plate reinforcing composition and a construction method thereof; the method comprises the following steps: scabbling in a construction field or on a primary bottom plate; arranging a drain system; setting a reinforcement mat; pouring concrete; maintaining. The stilling pool bottom plate reinforcing composition and construction method can reinforce and maintain the stilling pool bottom plate, saves cost and construction time, and an upstream water storage needs not to be emptied, thus reducing water resource loss.

Owner:王海雷

Underwater concrete bearing platform building method

ActiveCN103993612AFast constructionSmall construction areaFoundation engineeringSteel tubeEngineering

The invention belongs to the field of buildings, and particularly relates to an underwater concrete bearing platform building method. The method comprises the steps that the bearing platform base block pouring process is carried out on the ground, a steel pipe is used underwater for pumping water and pouring concrete to build a pile foundation, then bearing platform base blocks are placed underwater to be matched with the pile foundation, and bearing platform pouring is carried out in a cofferdam formed by square pipes and the bearing platform base blocks. According to the underwater concrete bearing platform building method, construction is fast, the bearing platform base blocks and steel reinforcement cages above the bearing platform base blocks can be manufactured on the ground, and meanwhile, the pile foundation is built at the same time, so that time and labor are saved, the construction area is small, the water pumping quantity is small, construction efficiency is improved, and the construction period is shortened.

Owner:湖北宏联众装配集成房屋有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com