Core-grouting reinforcing construction method for prestressed concrete pipe piles with post-grouting method

A technology of concrete pipe piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of insufficient length-to-diameter ratio construction control, poor pile working conditions, and insufficient bearing capacity of single piles, etc., to achieve compensation Pile body integrity and bearing capacity, quality control points are clear, and the effect of fewer operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, the present invention is further described:

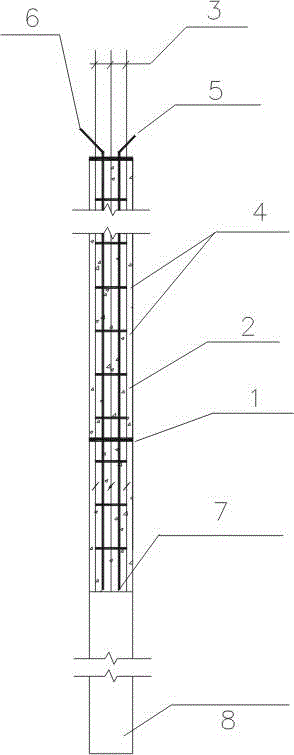

[0028] Such as figure 1 The post-grouting method for core reinforcement of prestressed concrete pipe piles is characterized in that it includes the following construction steps:

[0029] (1) Confirm the depth of the defect part 1 of the pile body of the prestressed concrete pipe pile 8 according to the results of the small strain test, or the depth of the core filling required to meet the requirements of the uplift bearing capacity of the single pile after design checking and calculation.

[0030] (2) Washing holes in the pile core cavity is an important construction process, and the pile core washing holes are cleaned with high-pressure water.

[0031] (3) When the inner cavity of the pile core is filled with sand and soil, use high-pressure water to clean the hole until the required cleaning depth is reached. Whether the inner cavity of the pile core is cleaned is based on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com