Formation penetrating tool

a technology of penetrating tools and drilling holes, applied in the direction of fluid removal, drilling machines and methods, borehole/well accessories, etc., can solve the problem of radial fractures not being made, and achieve the effect of more control of the fracturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

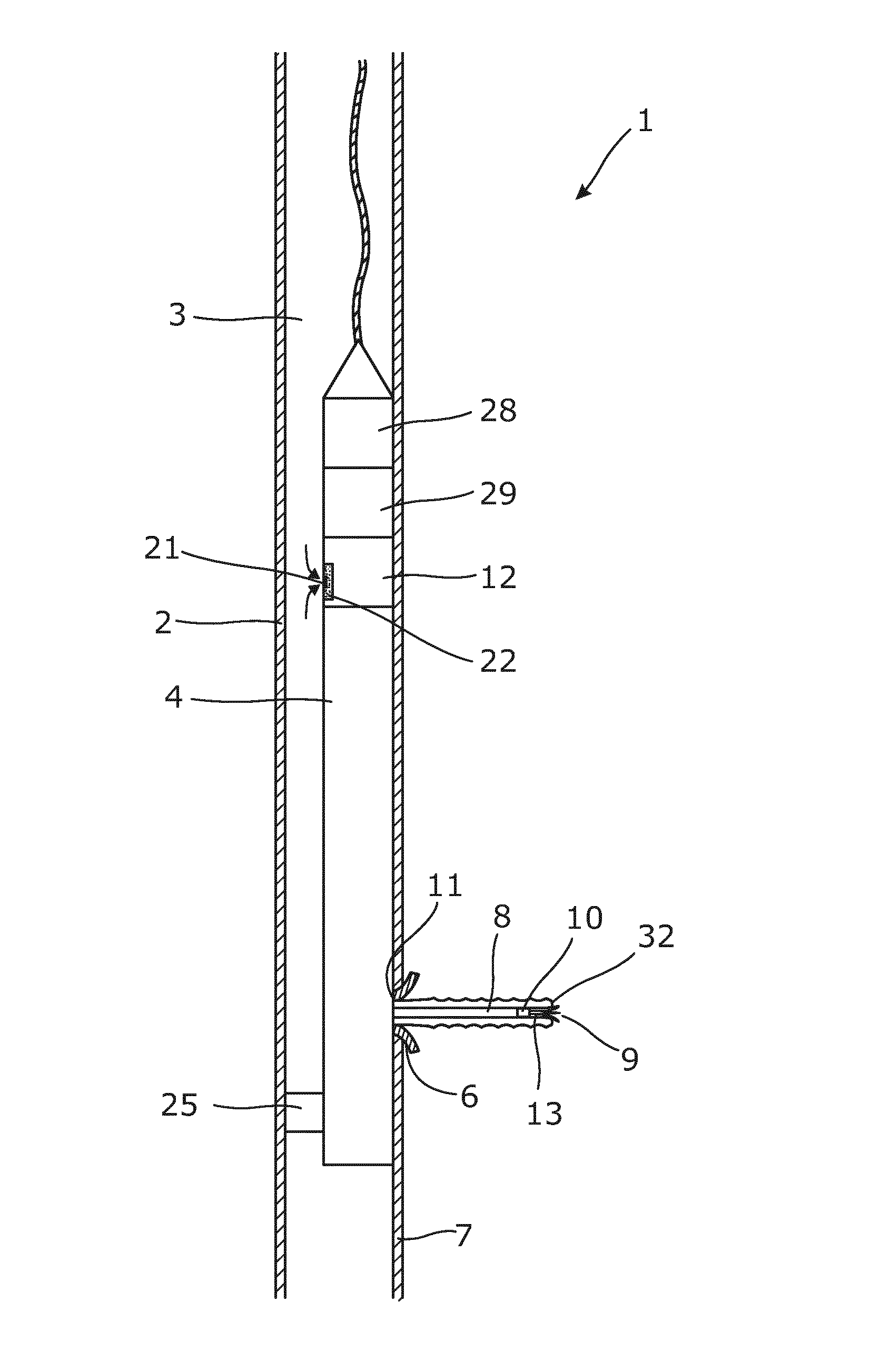

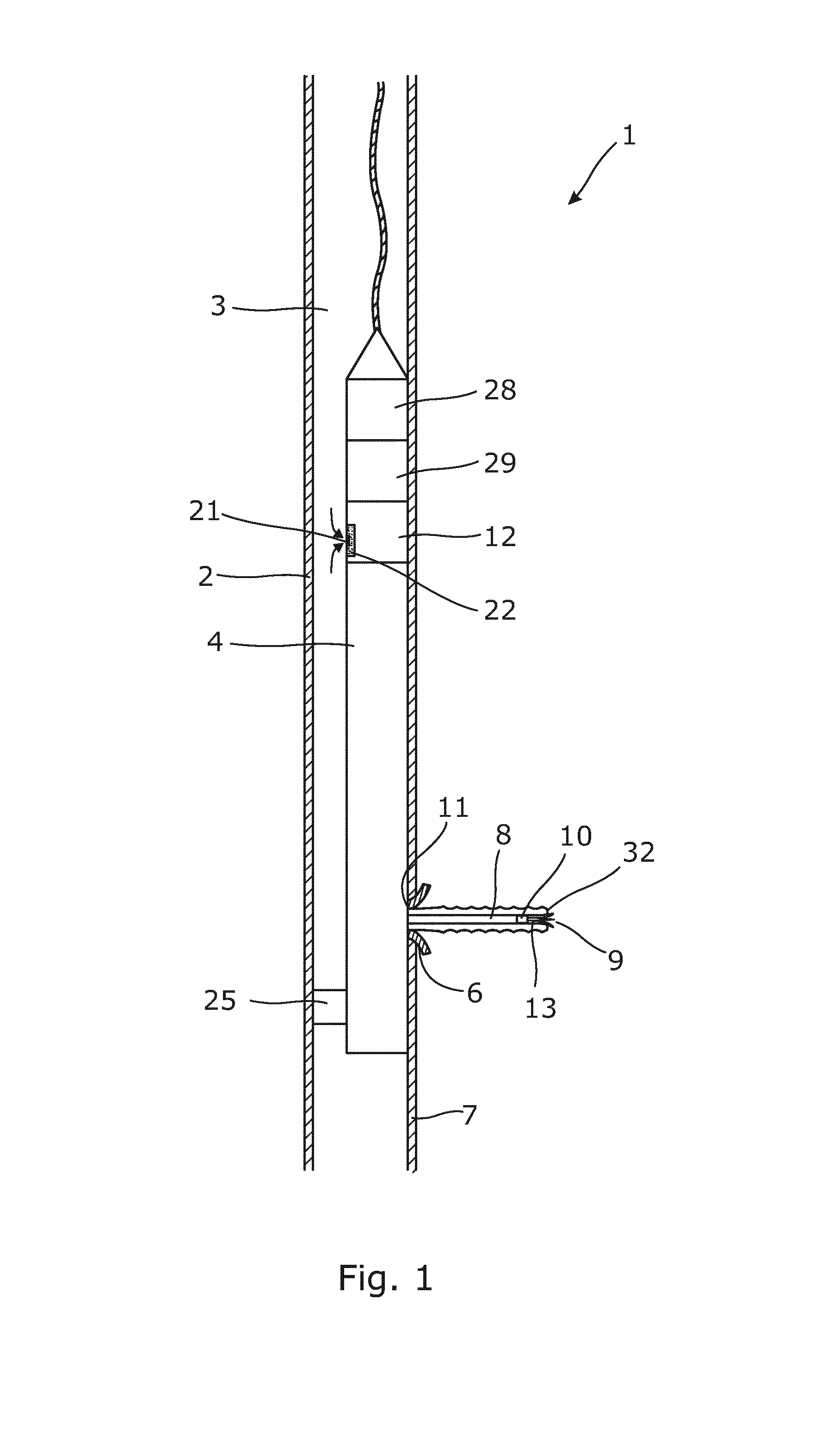

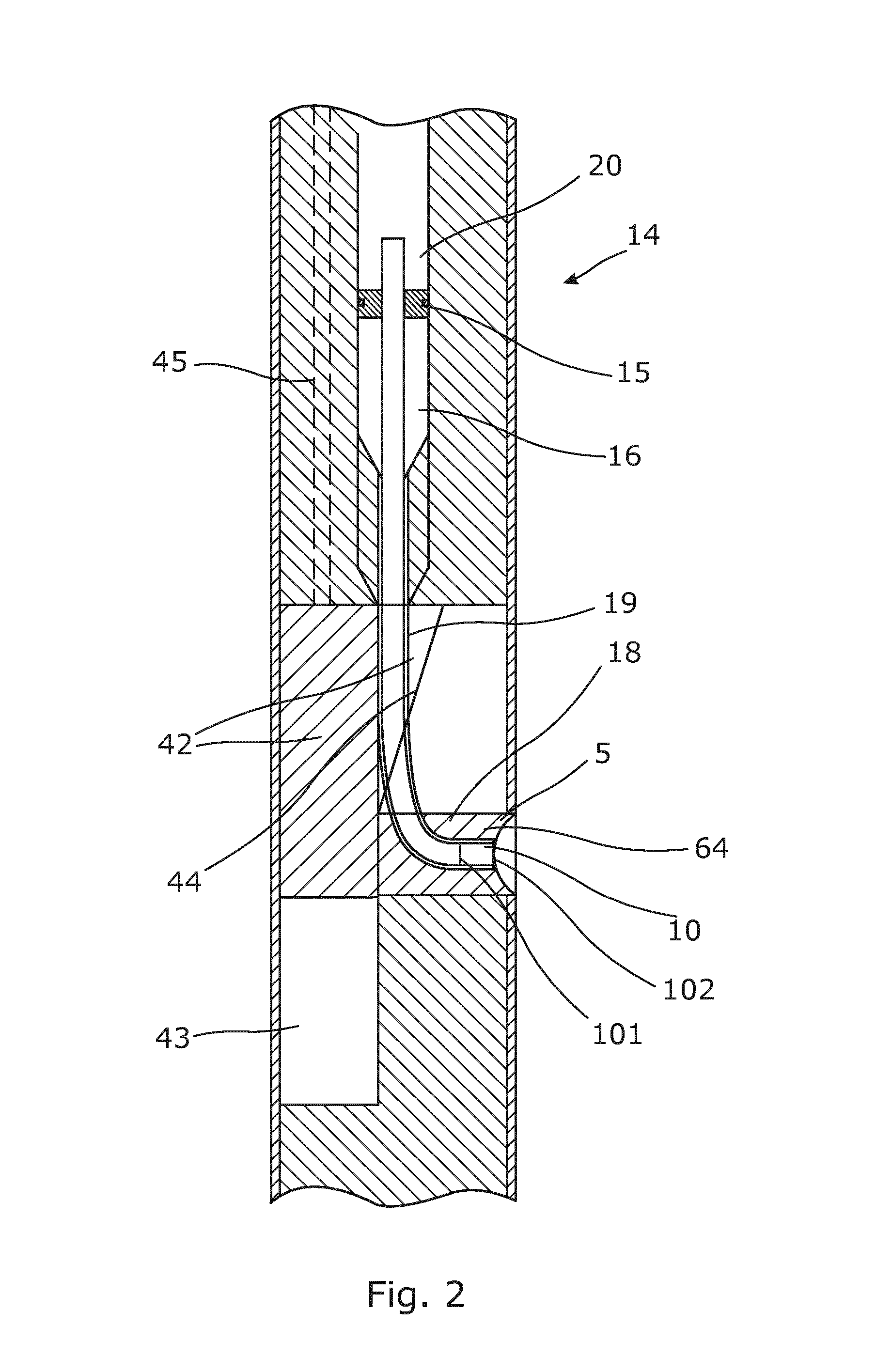

[0090]FIG. 1 shows a formation penetrating tool 1 submerged in a casing 2 in a well 3. In order to penetrate the formation, the tool 1 has a tool housing 4 in which a casing penetrating unit 5 adapted to provide a hole 6 in a wall 7 of the casing 2 is arranged. Subsequently, a nozzle 10 is arranged in an end of a supply hose 8, slidable within the tool housing 4. The supply hose 8 supplies a high pressurised fluid 9 to the nozzle 10 which is jetted as a jet stream out through the hole 6 in order to penetrate the formation, thereby providing a formation micro-bore substantially radially from the formation penetrating tool 1. The formation penetrating tool 1 comprises a pump 12 which is in fluid communication with the supply hose 8 for providing a jet 13 of fluid out of the nozzle 10 to penetrate the formation creating the micro-bore or formation bore 32. The formation penetrating tool 1 may penetrate the casing 2 by means of the high pressurised fluid jetted through the nozzle 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com