Alloy plate electromagnetic punching and flanging forming method and device

An alloy plate and punching technology, which is applied in the field of electromagnetic punching and flanging forming of alloy plates and devices, can solve the problems of reducing forming efficiency, increasing manufacturing cost, difficult positioning, etc., so as to improve forming limit, improve production efficiency, and overcome positioning effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

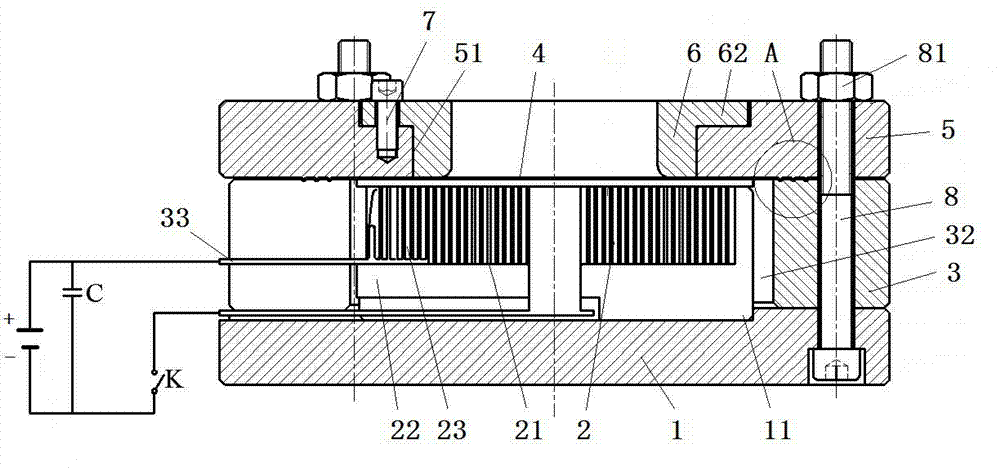

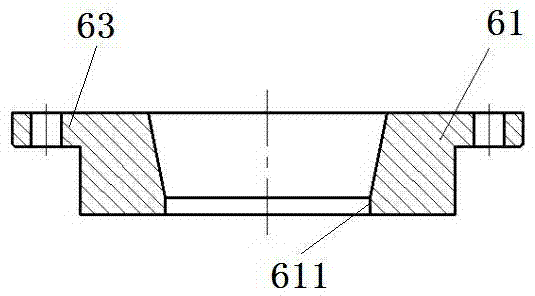

[0031] like Figure 1~7 As shown, in the present invention, an alloy plate electromagnetic punching flanging forming method comprises the following steps:

[0032] (1) Install flat-plate helical coil group 2: First, a flat-plate helical coil group 2 for providing electromagnetic repulsion is fixedly installed in the positioning groove 11 of the base 1, and the positive and negative poles of the flat-plate helical coil group 2 are passed through the capacitor group C is connected in series with the discharge control switch K, the capacitor group C is connected in parallel with the power supply, and a lower mold 3 is provided outside the flat spiral coil group 2;

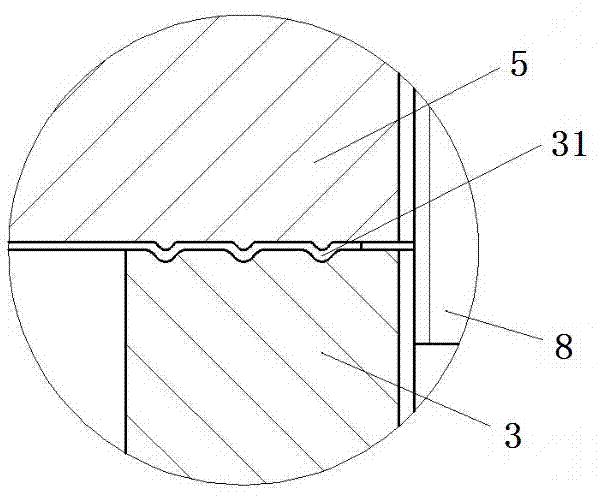

[0033] (2) Install the blank 4: then place the blank 4 at the predetermined position on the annular lower mold 3, the selected blank 4 is preferably an aluminum alloy sheet, then place the upper mold 5, and use the stretching provided on the upper end surface of the lower mold 3 The rib 31 clamps and positions the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com