Vertical shaft construction device and method

A construction device and shaft technology, which is applied in shaft equipment, earthwork drilling, shaft lining, etc., can solve the problem that the anti-heaving amount of the subway cannot meet the design requirements, and achieve the effect of strong structure and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

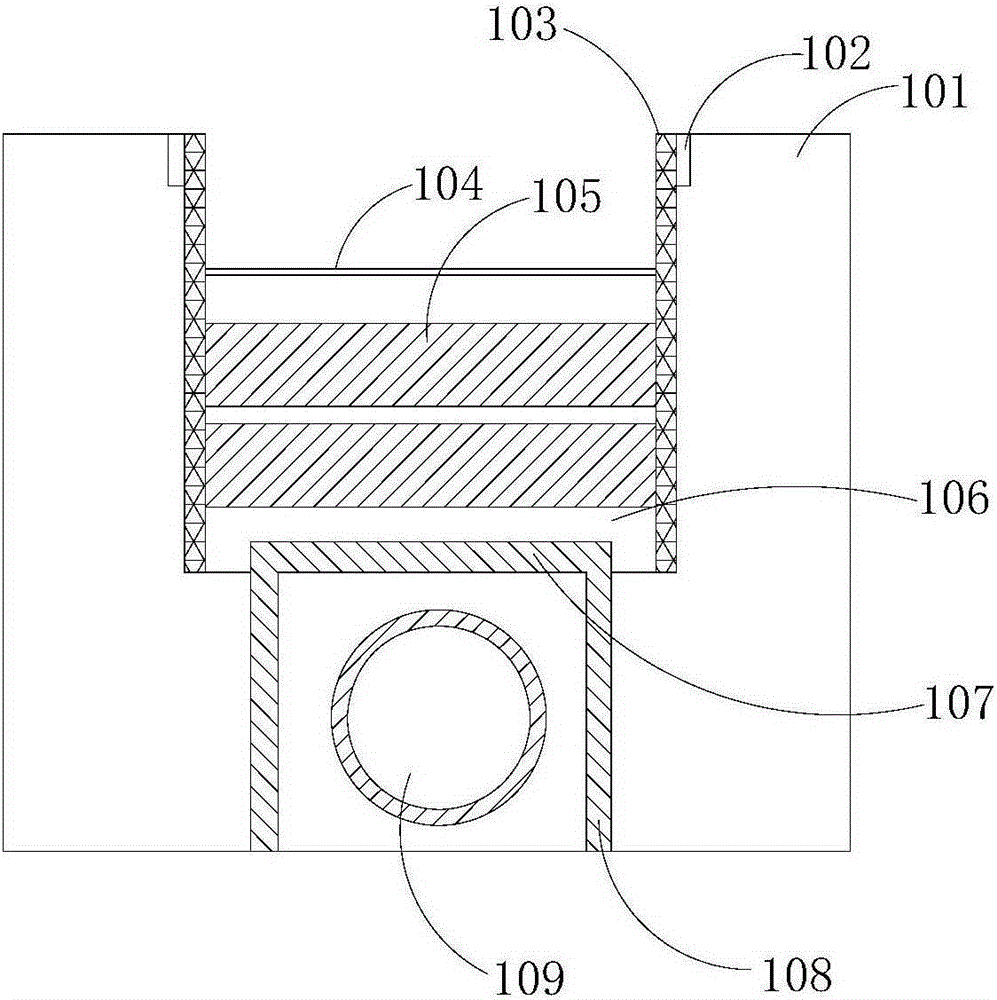

[0068] A shaft construction device, comprising a ring beam 102, a support 103, a support system and an anti-floating structure, the ring beam 102 is arranged in the soil 101 above the tunnel 109, the support 103 is a steel bar grid sprayed with concrete, and the support 103 is applied on the side wall of the shaft. The support system is a multi-layer structure, including a steel support structure 104 and a partition structure 105 arranged vertically. place. The height of the steel support structure 104 from the ground is 2.5m, and the middle partition structure 105 is fixedly connected in turn to form a middle partition wall, and the height of the top of the middle partition wall from the ground is 4.5m. The height between the bottom of the middle partition wall and the top of the anti-floating plate 107 is 1m. The support system is fixedly connected to the supports 103 on both sides of the shaft, and the anti-floating structure includes an anti-floating plate 107 and an anti...

Embodiment 2

[0070] A shaft construction device, comprising a ring beam 102, a support 103, a support system and an anti-floating structure, the ring beam 102 is arranged in the soil 101 above the tunnel 109, the support 103 is a steel bar grid sprayed with concrete, and the support 103 is applied on the side wall of the shaft. The support system is a multi-layer structure, including a steel support structure 104 and a partition structure 105 arranged vertically. place. The height of the steel support structure 104 from the ground is 3.5m, and the middle partition structure 105 is fixedly connected in turn to form a middle partition wall, and the height of the top of the middle partition wall from the ground is 5.5m. The height between the bottom of the middle partition wall and the top of the anti-floating plate 107 is 1.5m. The support system is fixedly connected to the supports 103 on both sides of the shaft, and the anti-floating structure includes an anti-floating plate 107 and an an...

Embodiment 3 1

[0071] Embodiment 3 A kind of shaft construction method, comprises the following steps:

[0072] a. Excavate and construct the ring beam 102 in the protection area above the tunnel, and then cure it to make the concrete strength reach 100%.

[0073] b. After the concrete to be poured meets the design strength, excavate from top to bottom in the ring beam 102 to protect the earth above the subway. The depth of each excavation is 0.5m. Support 103.

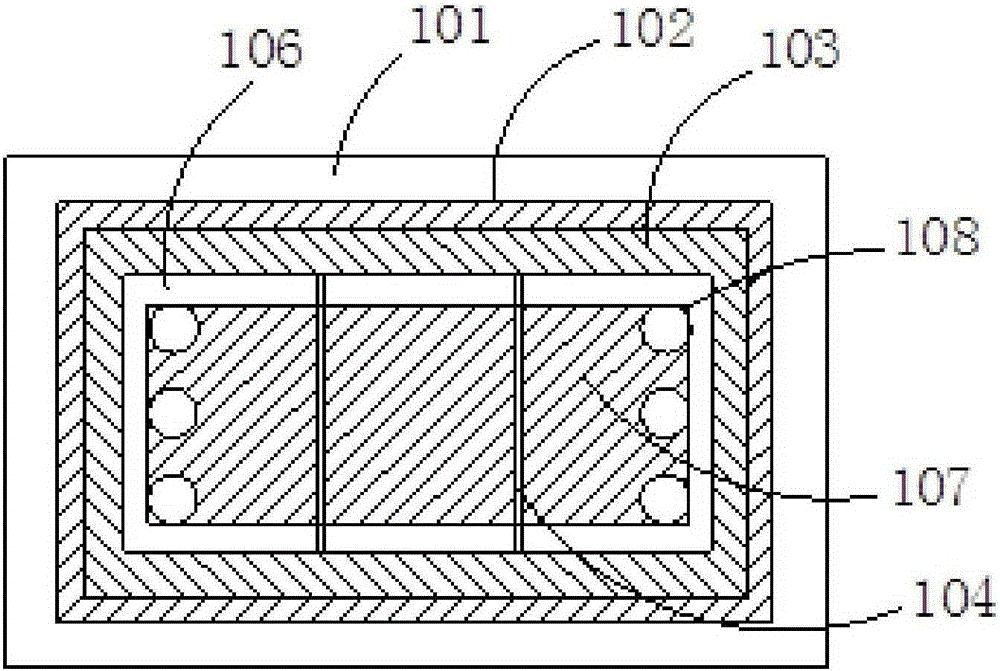

[0074] c. When the installation depth of the support reaches 3m, after setting two steel support structures 104 at the trisection point in the length direction of the shaft, repeat step b.

[0075] d. When the installation depth of the support reaches 5m, two intermediate partition structures 105 are arranged at the trisection point in the length direction of the shaft. The intermediate partition structures 105 are steel bar structures, including main reinforcement, and the main reinforcement is the intermediate partition structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com