Aluminum alloy formwork special for fabricated concrete shearing wall structure

A technology of concrete shear wall and aluminum alloy formwork, which is applied in the fields of formwork/formwork/work frame, building structure, and on-site preparation of building components. To reduce the construction work area, standardize the construction process and speed up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

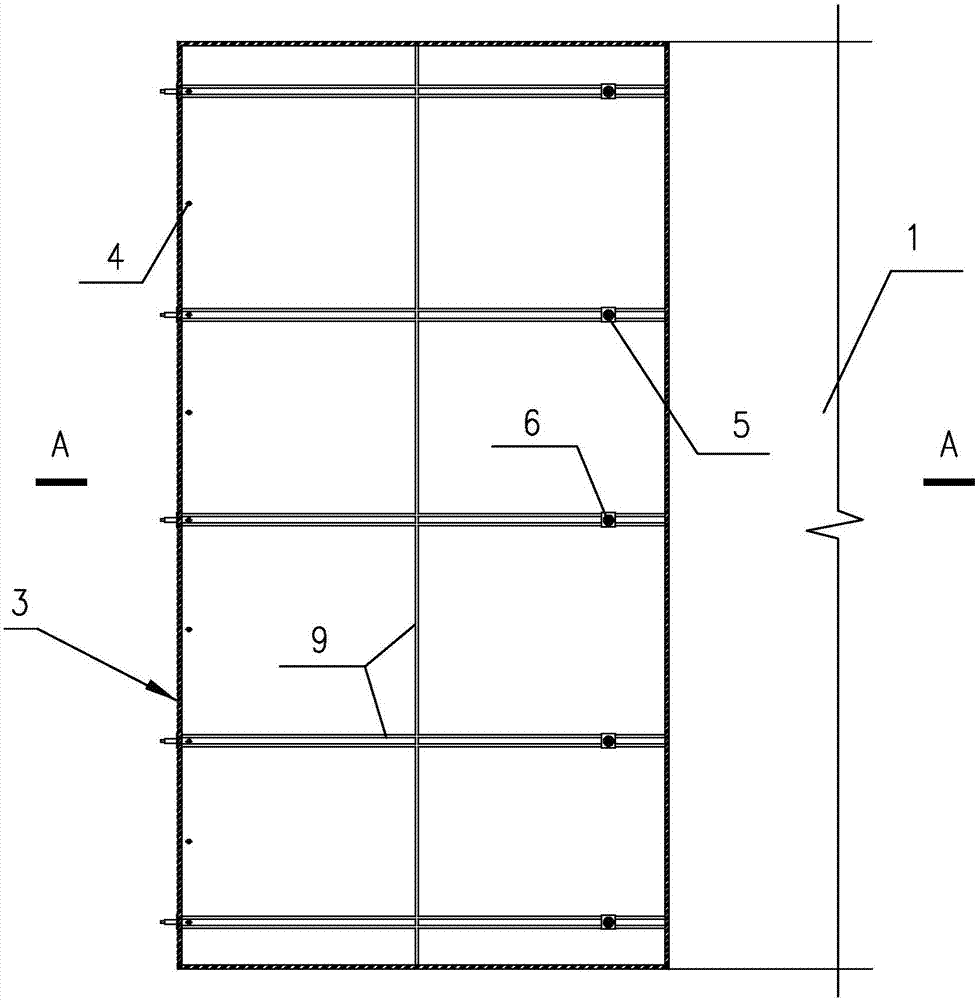

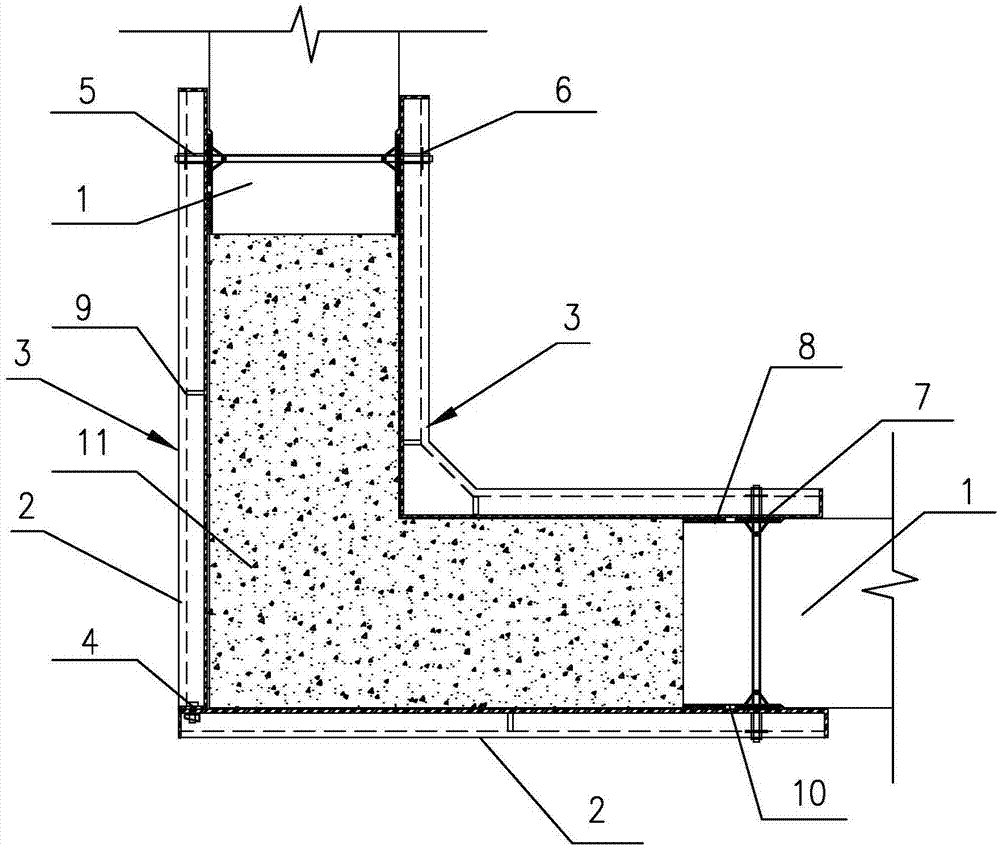

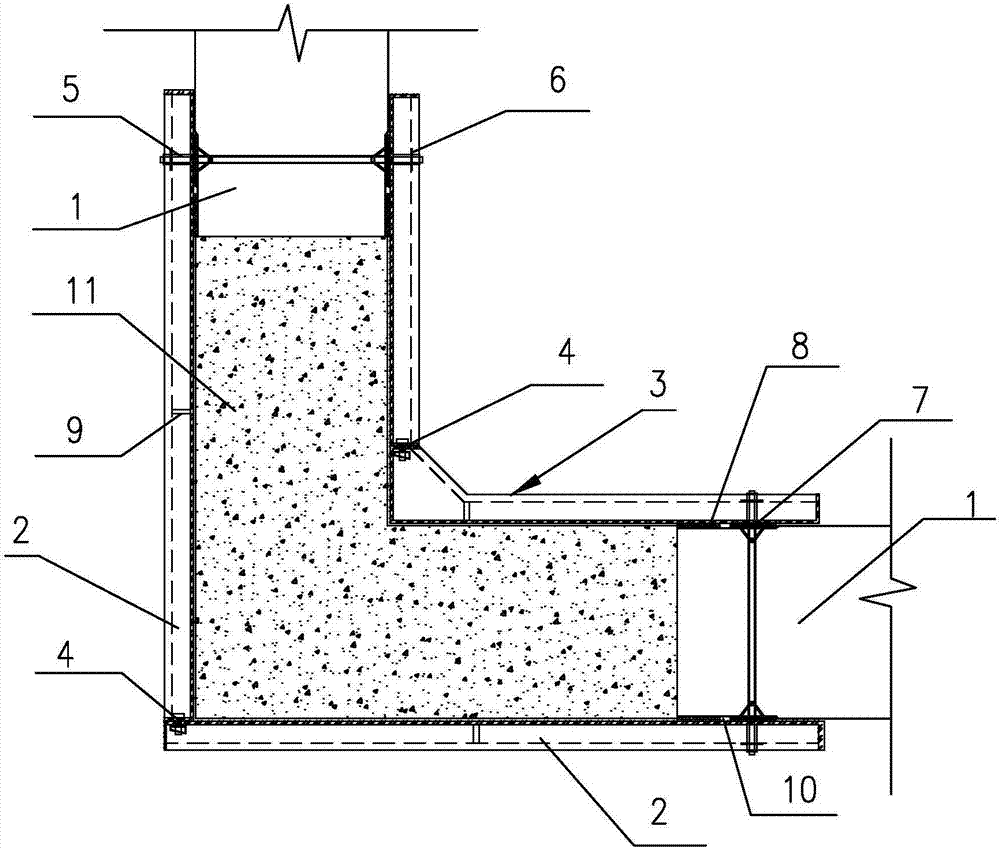

[0054] The present invention is a special aluminum alloy formwork for prefabricated concrete shear wall structure, which includes at least one vertical board. When there are more than two vertical boards, each vertical board is used to enclose the structural prefabricated component 1 to form a cast-in-place area so as to form concrete components, and the vertical plates are combined into open ends for fixing on structural prefabricated components, and each vertical plate is a complete plate body or spliced by multiple plate body units.

[0055] Such as Figure 1-9 As shown, this embodiment is applied to an aluminum alloy formwork in which the joints are located at the intersection of vertical and horizontal walls and the post-casting area is L-shaped (or T-shaped) when integral joints are used between adjacent prefabricated shear walls in the floor. . There are two vertical boards, the cross section of each vertical board is equilateral L-shaped, the vertical board located ...

Embodiment 2

[0063] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is applied to the vertical and horizontal prefabricated shear walls of the outer wall when integral joints are used, and the post-casting area is L-shaped, and the riser 3 It is one piece, and the cross section of the riser 3 is an equilateral L shape, which is located inside the cast-in-place area 11 and serves as the inner formwork of the cast-in-place area 11. The outside of the cast-in-place area 11 is provided with non-structural prefabricated components, and the non-structural prefabricated The component is specifically a prefabricated thermal insulation board 14 (or decoration hanging board), which is used as an external formwork for the cast-in-place area. Riser 3 can be divided into one-piece type, two-piece combined type and three-piece combined type, which is the same as that in Embodiment 1. The open-shaped end formed by the riser 3 and the prefabric...

Embodiment 3

[0066] Such as Figure 11 and 12 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is applied to the integral joint connection between adjacent prefabricated shear walls in the floor, the joint is located at the T-shaped junction of the vertical and horizontal walls and The cast-in-place area is a straight aluminum alloy formwork 3 . There are three vertical boards, and each vertical board is a complete board body. The cross-section of the two vertical boards is unequal L-shaped, and the long sides of the two vertical boards are opposite to form open ends for It is connected with the transverse wall in the structural prefabricated component, and the short sides of the two vertical plates are respectively opposite to another plate-shaped vertical plate to form an open end for connecting with the vertical wall in the structural prefabricated component 1 .

[0067] The installation process of this embodiment is: the aluminum formwork 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com