Vacuum dewatering process for deep foundation pit

A deep foundation pit and vacuum technology, applied in infrastructure engineering, construction, excavation, etc., can solve problems such as scattered drainage, inability to lower well pipes, and complicated installation of water and electricity pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: (choose a well pipe with a small diameter)

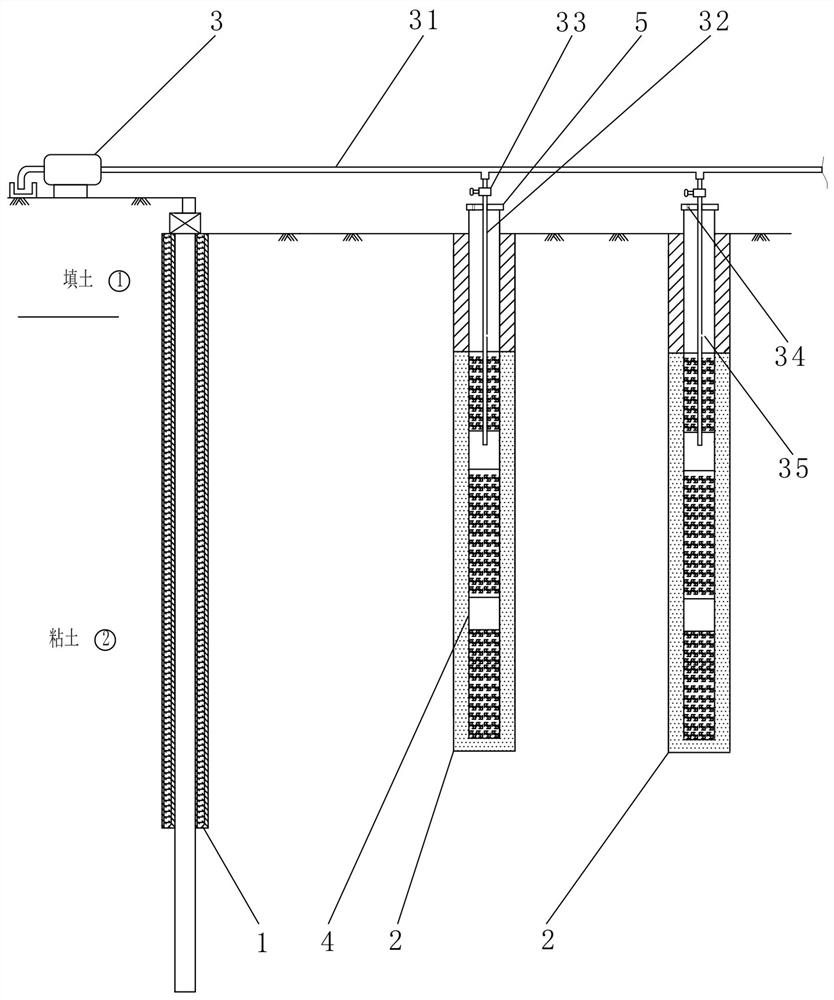

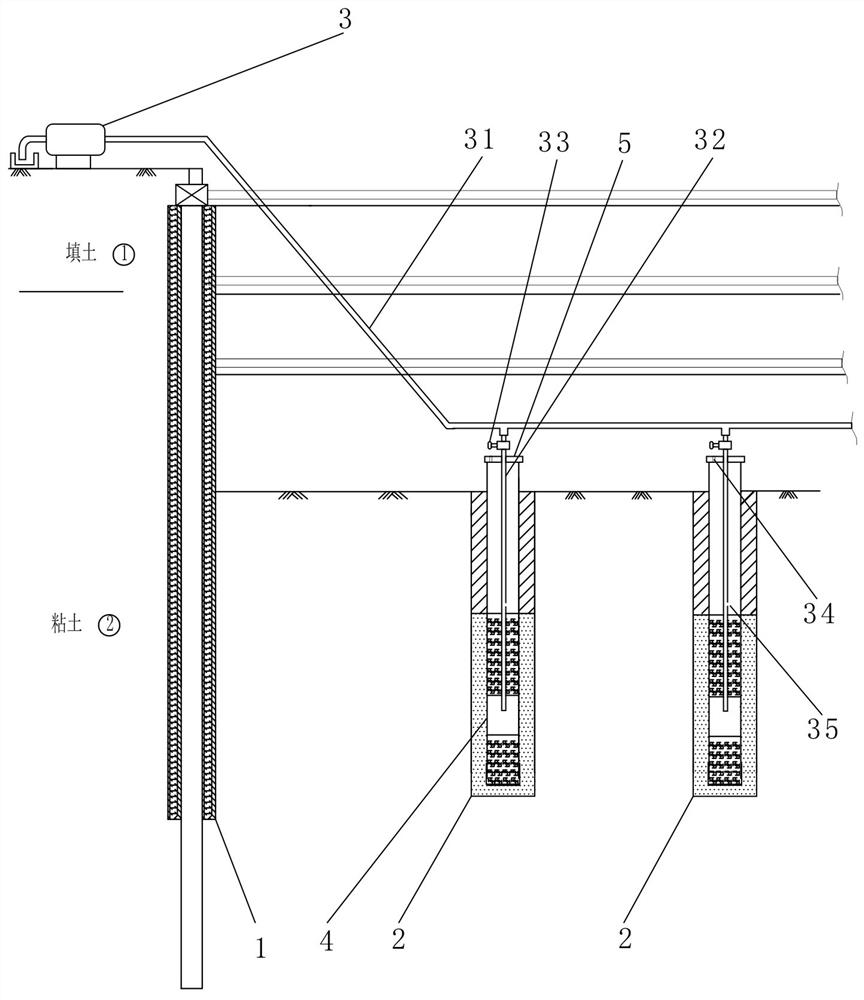

[0034] refer to figure 1 , figure 2 , the present invention comprises the following steps:

[0035] 1.1. Preparations before precipitation:

[0036] 1.1.1. Complete the enclosure 1 of the foundation pit, arrange the dewatering well point 2 in the foundation pit according to the design requirements, and arrange the vacuum pump station 3 around the foundation pit, and the vacuum pump station 3 is equipped with a jet vacuum pump;

[0037]1.1.2. To drill a dewatering well, drill a dewatering well at point 2 of each dewatering well in turn. The diameter of the dewatering well is 300 mm; the depth of the dewatering well is 5500 mm below the elevation of the large floor of the foundation pit;

[0038] 1.1.3. Fill the bottom of the dewatering well with a medium-coarse sand cushion with a thickness of 300mm;

[0039] 1.1.4. Lower the well pipe 4, insert the well pipe 4 in the dewatering well, the diameter of the well p...

Embodiment 2

[0054] Embodiment 2: (choose large-diameter well pipe)

[0055] refer to figure 1 , figure 2 , the present invention comprises the following steps:

[0056] 1.1. Preparations before precipitation:

[0057] 1.1.1. Complete the enclosure 1 of the foundation pit, arrange the dewatering well point 2 in the foundation pit according to the design requirements, and arrange the vacuum pump station 3 in or around the foundation pit, and the vacuum pump station 3 is equipped with a mechanical vacuum pump;

[0058] 1.1.2. To drill a dewatering well, drill a dewatering well at point 2 of each dewatering well in turn. The diameter of the dewatering well is 650mm; the depth of the dewatering well is 5000mm below the elevation of the large floor of the foundation pit;

[0059] 1.1.3. Fill the bottom of the dewatering well with a medium-coarse sand cushion with a thickness of 500mm;

[0060] 1.1.4. Lower the well pipe 4, insert the well pipe 4 in the dewatering well, the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com