Three-level multi-spray-pipe central ejector

A multi-nozzle and ejector technology, used in jet pumps, machines/engines, non-displacement pumps, etc., can solve the problems of difficulty in complete mixing, large ejection airflow, and difficult processing, and shorten the length of the mixing chamber. , the effect of increasing the suction capacity and being easy to process and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

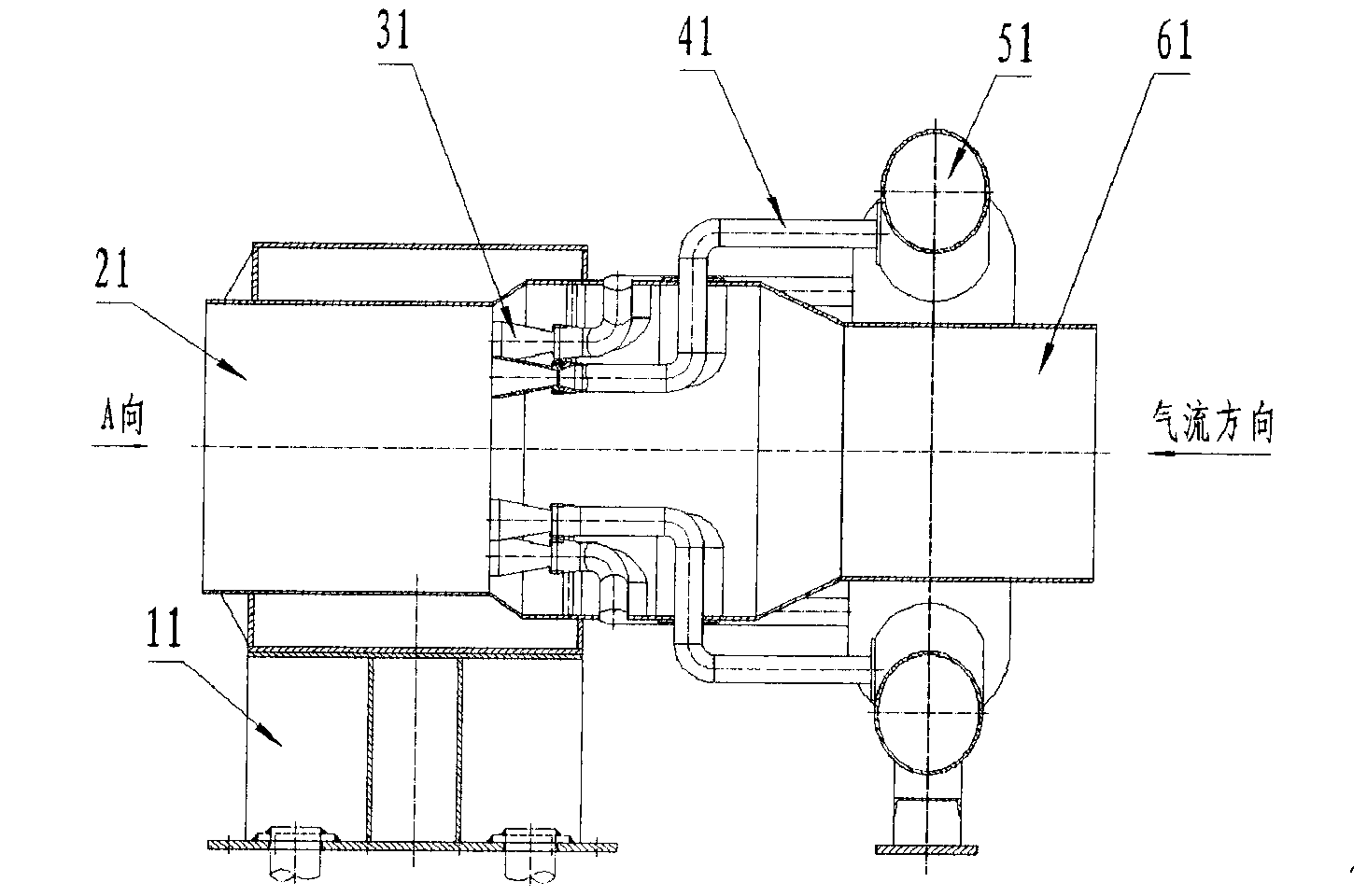

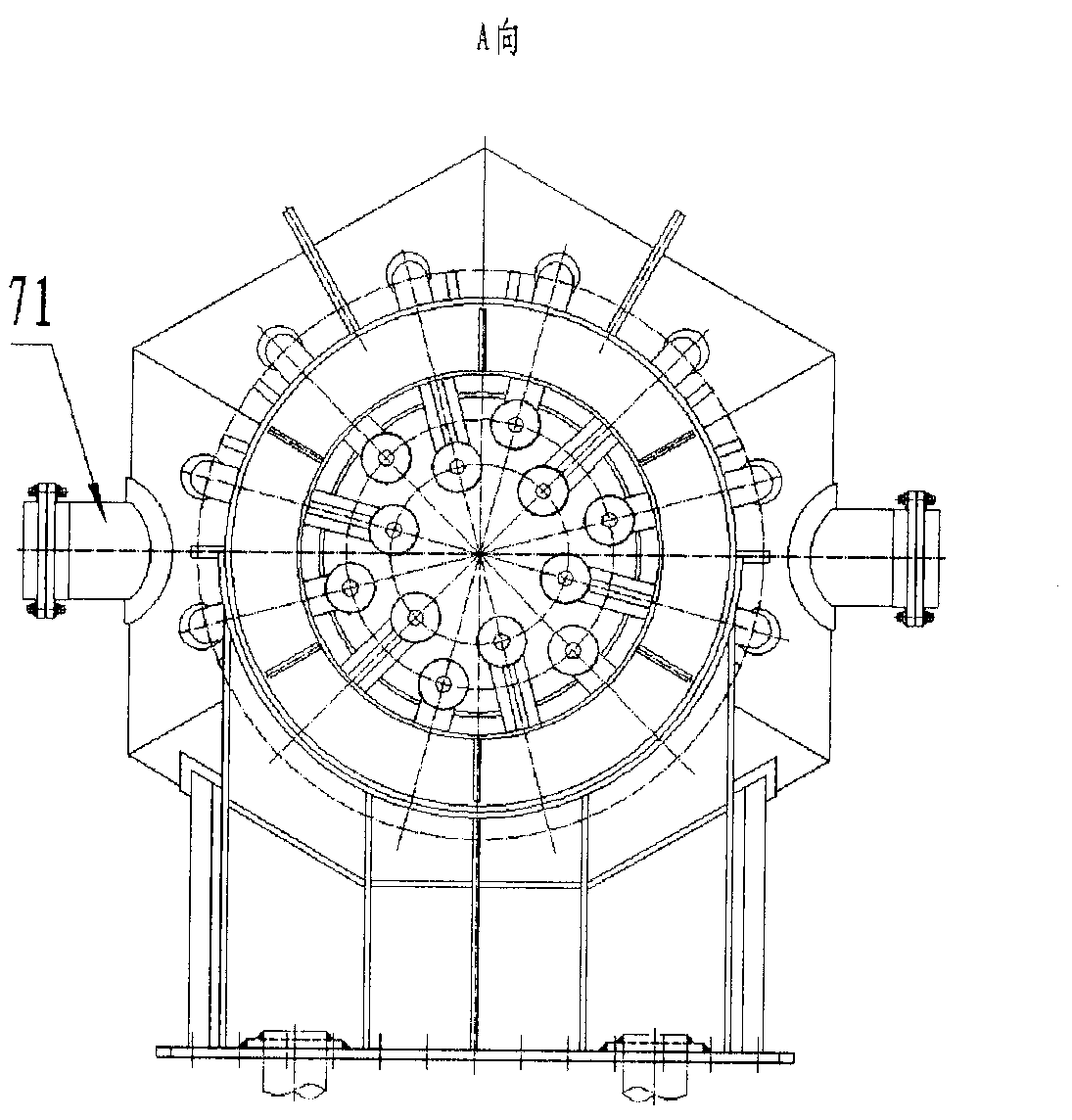

[0034] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] When multi-stage multi-nozzle central ejectors are connected in series, since the airflows of multi-nozzle central ejectors at all levels will affect each other, simply connecting multiple multi-nozzle central ejectors in series cannot improve the air flow rate. The pumping performance of the hole, and if the ejection parameters and structure do not match, the ejection performance will be degraded. The three-stage multi-nozzle central ejector of the present invention adopts the ejection parameters shown in Table 1 that match the structure, which greatly improves the suction performance of the wind tunnel.

[0036] Table 1

[0037]

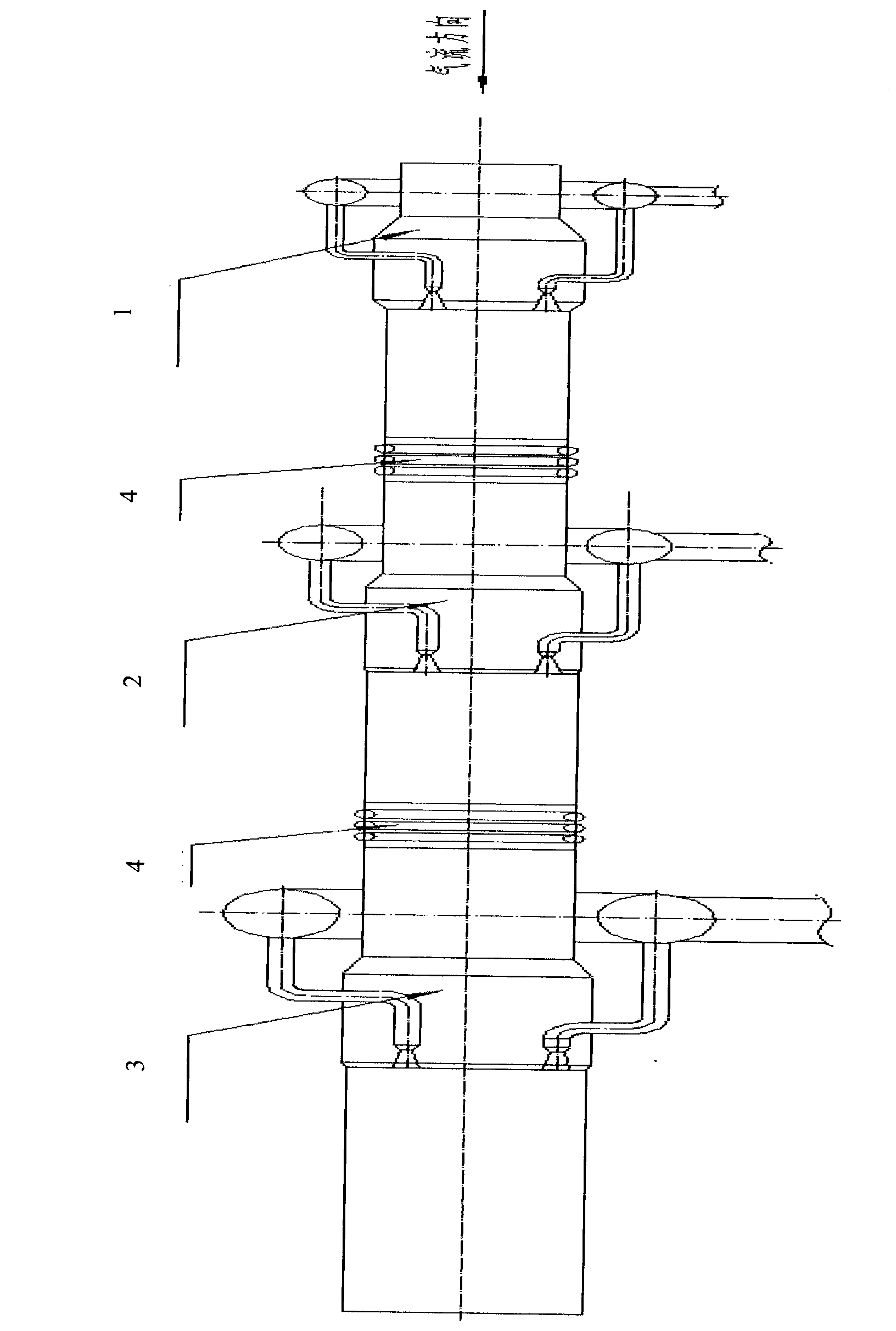

[0038] Such as figure 1 As shown, the three-stage multi-nozzle central ejector includes: a first-stage multi-nozzle central ejector 1 , a second-stage multi-nozzle central ejector 2 , and a third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com