Fast replacement method and device for main material of power transmission line iron tower

A technology for a transmission line tower and a replacement method, which is applied in the field of transmission line towers, can solve the problems of many construction links, transmission line accidents, and large construction area, so as to ensure normal power consumption, reduce labor costs, and reduce construction area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

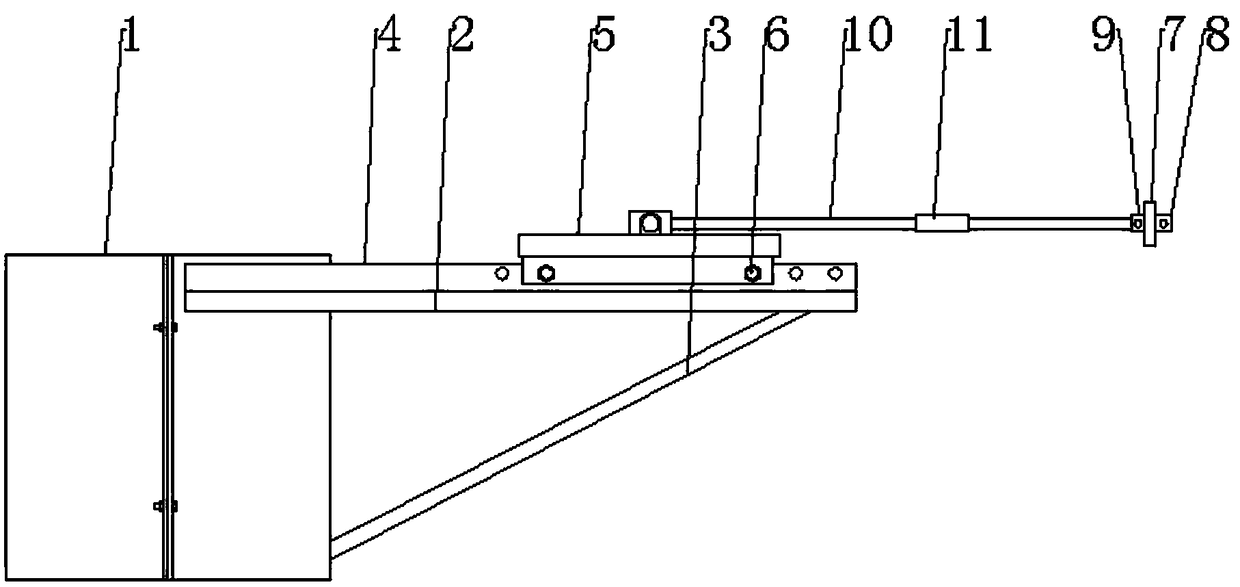

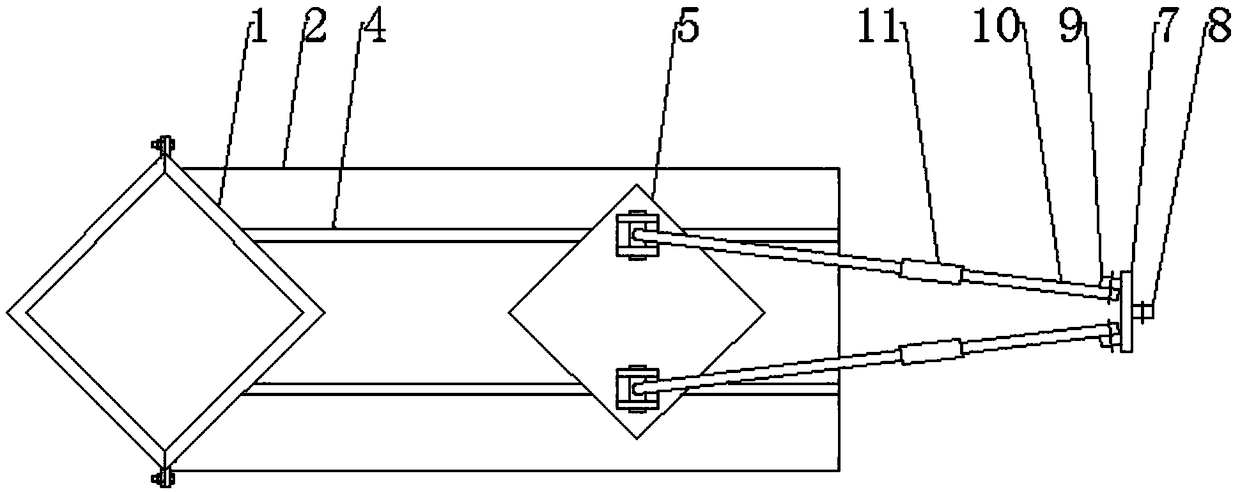

[0023] Such as figure 1 , figure 2 As shown, the quick replacement device for the main material of the transmission line iron tower includes a tower foot fixing seat, a connecting pendant, and a support rod connected between the tower foot fixing seat and the connecting pendant; The square fixed sleeve 1 composed of connected right-angle fixed sleeve splits, the horizontal support plate 2 fixed on the top of the right-angled fixed sleeve split, the bottom surface connected between the bottom surface of the horizontal support plate 2 and the right-angled fixed sleeve split bottom where it is located Oblique support 3, the guide rail 4 that is fixed on the top surface of the horizontal support plate 2, the slide plate 5 that slides with the guide rail 4, and the positioning bolt 6 that is connected between the guide rail 4 and the slide plate 5 are formed; 1. The first ear plate 8 that is located on one side of the connecting plate 7 and connected with the iron tower body of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com