High-pier built-in stiff framework cross tie beam structure and construction method

A technology of rigid skeleton and transverse beam, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of high construction risk, large steel investment, long construction period, etc., and achieve low construction risk, small construction work area, The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the embodiment of the present invention, the construction technical requirements such as concrete pouring and construction, steel cage binding, welding, embedded parts setting, hoisting, etc. will not be described in detail, and the embodiment of the present invention will be emphasized. The present invention will be further described below in conjunction with the accompanying drawings and examples. Detailed description, the description is not limited to the following examples.

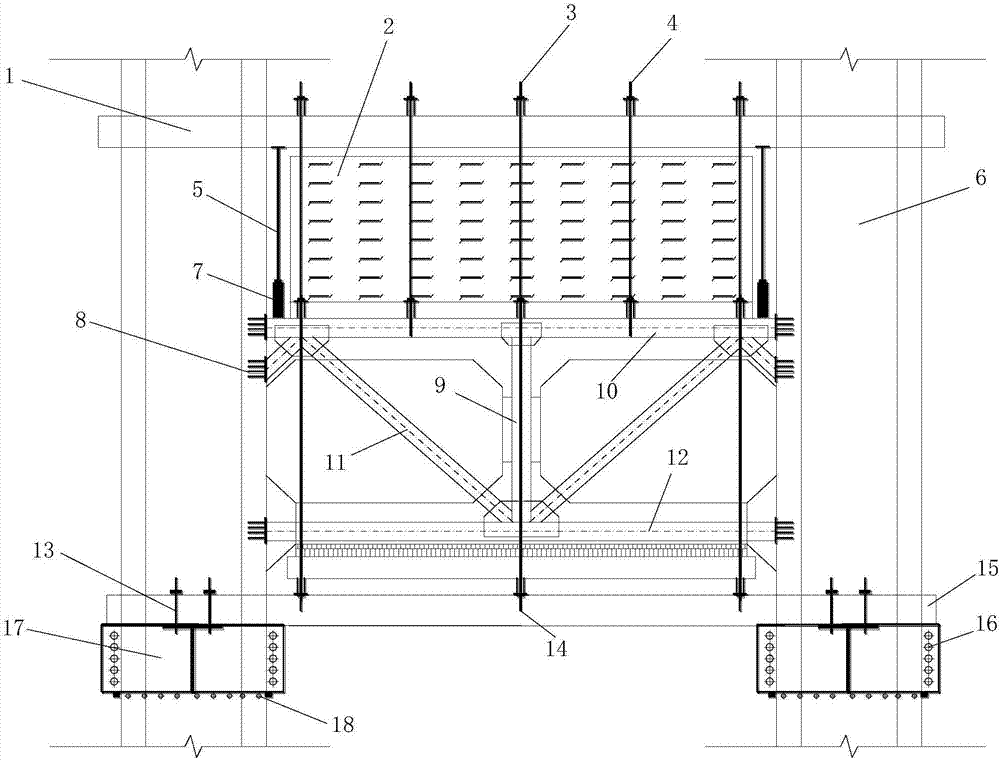

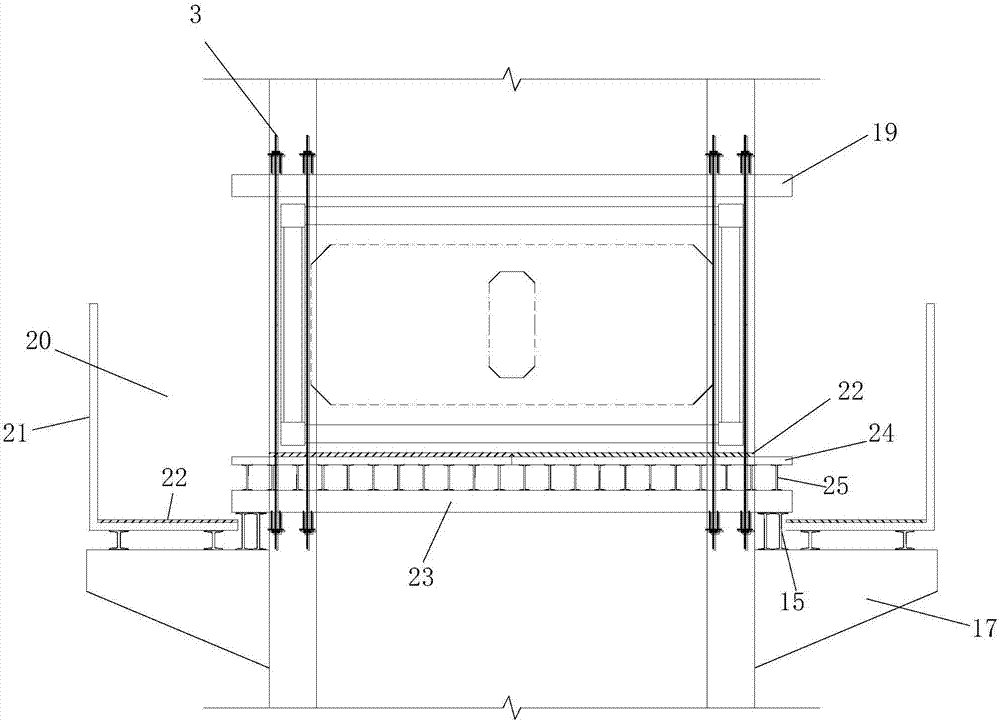

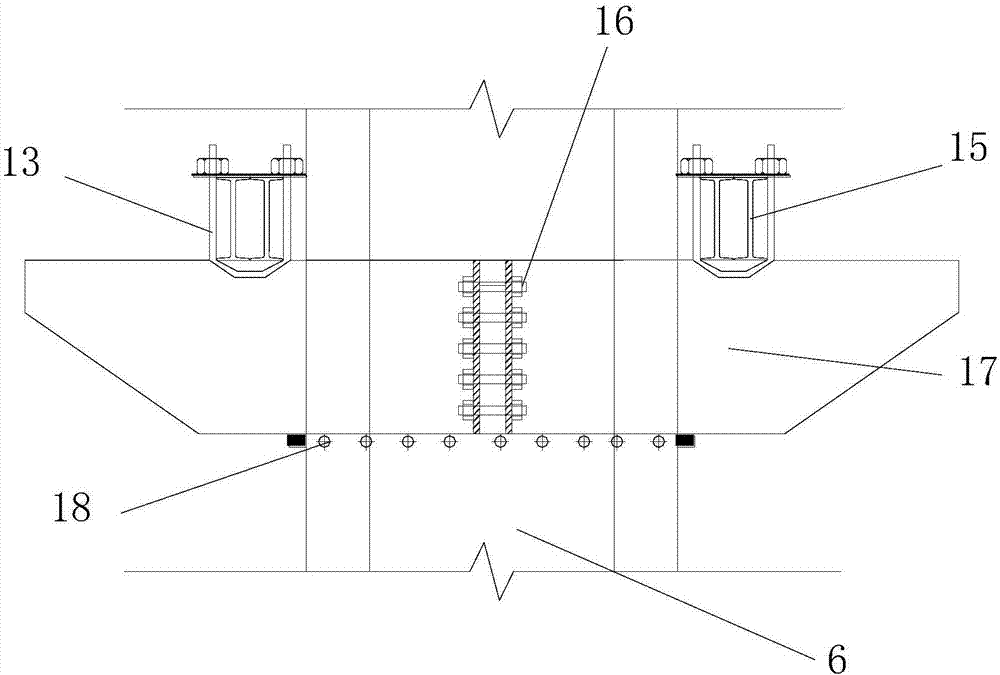

[0041] figure 1 It is the cross beam diagram of the built-in rigid frame of the high pier of the present invention, figure 2 It is the cross-sectional view of the transverse tie beam with built-in rigid frame of the high pier, image 3 It is a large sample of a hooped corbel, Figure 4 is a schematic diagram of water preloading, refer to Figure 1 ~ Figure 3 The shown high pier built-in rigid skeleton transverse beam structure mainly consists of 1. through-shaped steel beam, 2. embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com