Semisolid centrifugal separating casting ball grinding process, process device and ball casting machine

A technology of centrifugal separation and casting grinding balls, which is applied in the direction of casting molding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of unsatisfactory short process process, lack of high-efficiency casting ball production equipment, and small production scale of casting grinding balls and other problems, to achieve the effect of cheap other equipment, green production of production cost and working capital, and high utilization rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

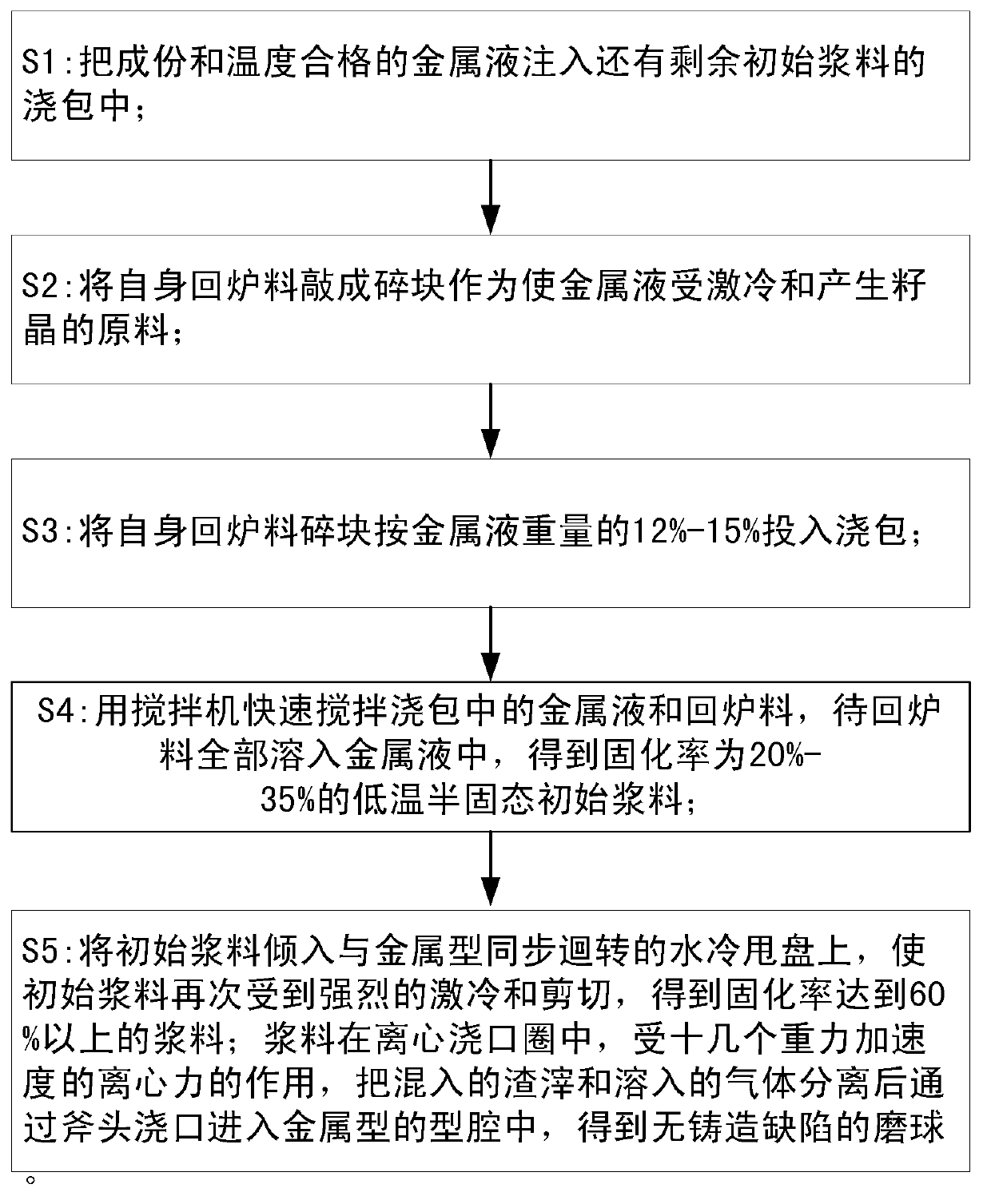

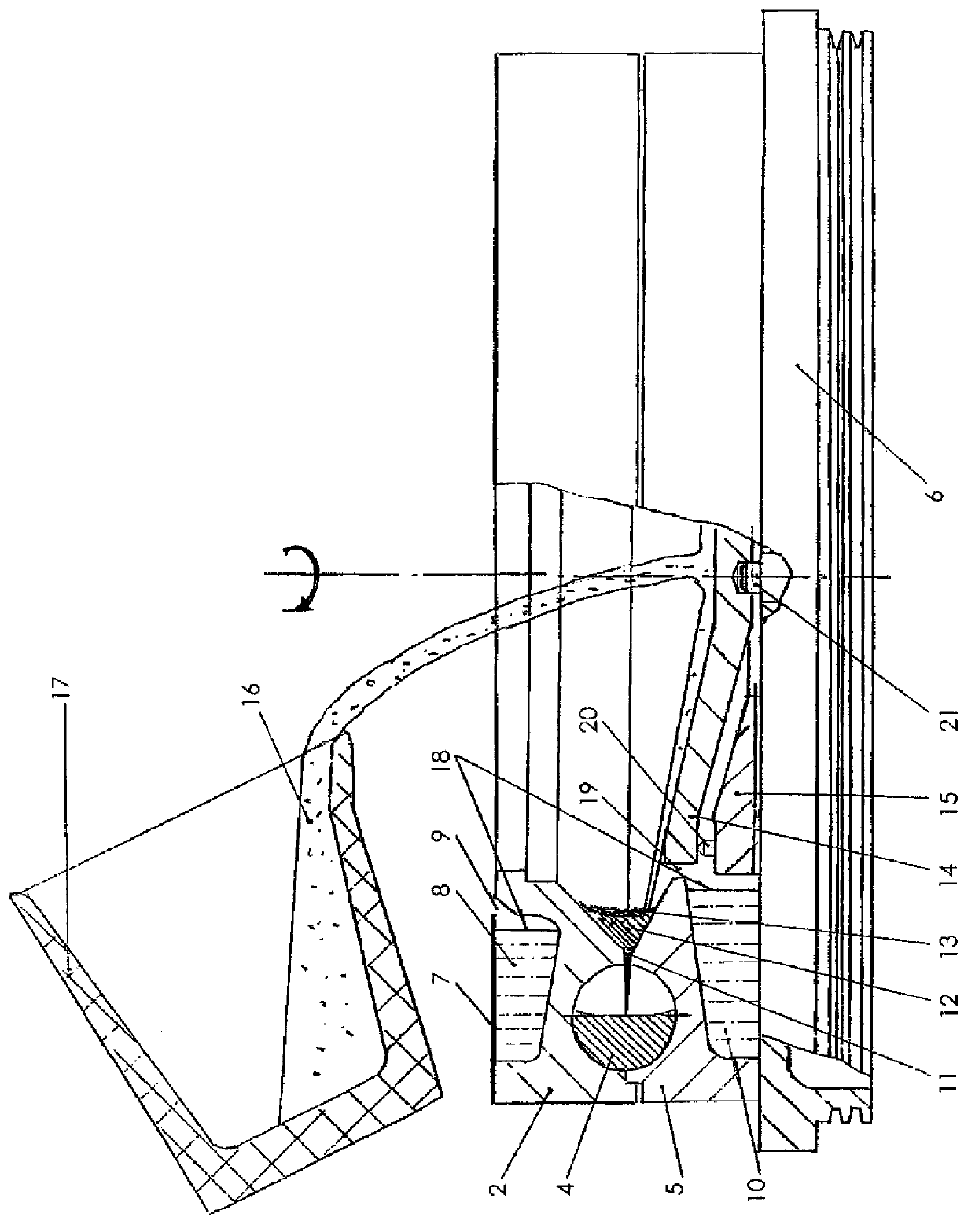

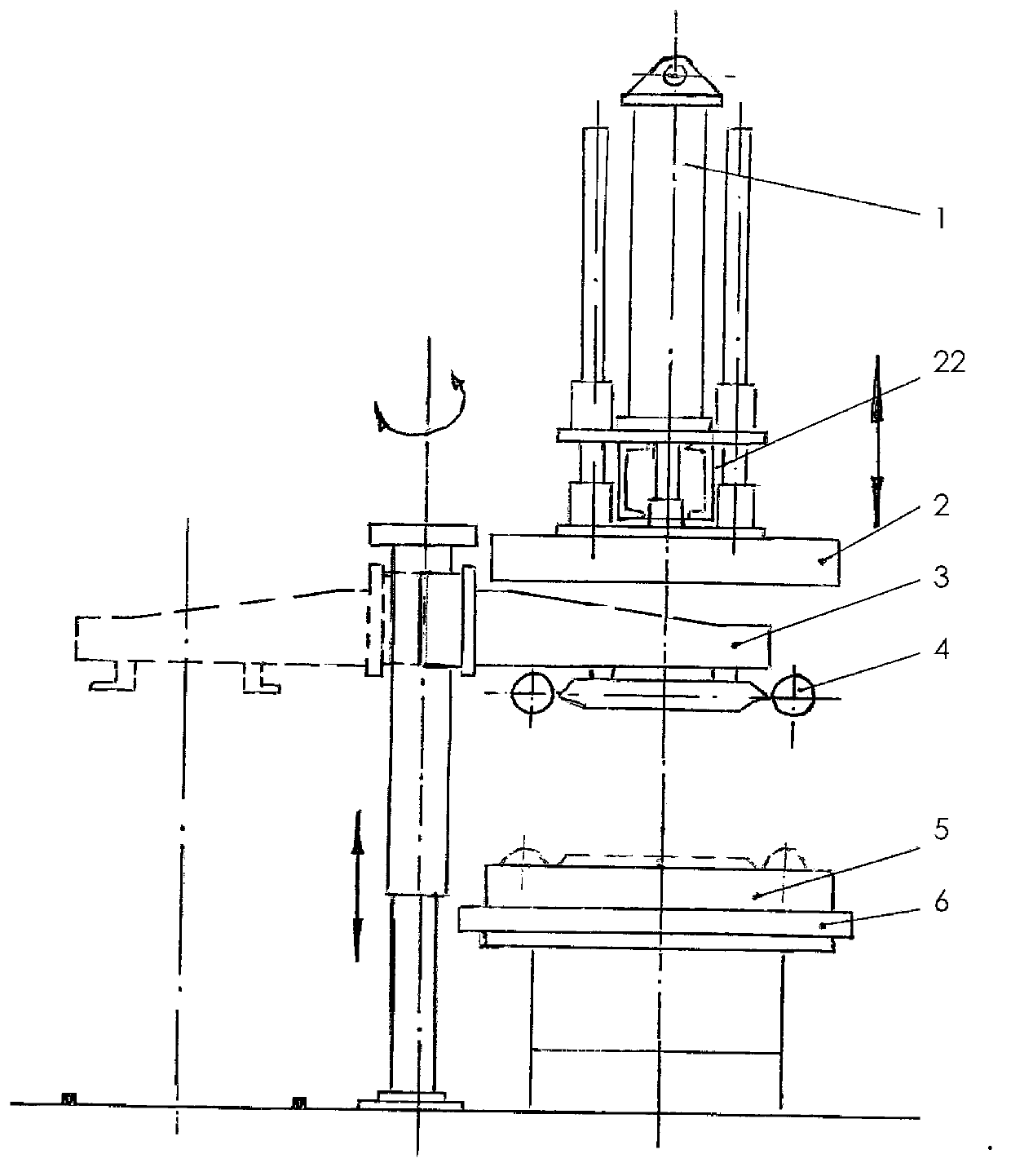

[0040] Such as figure 1It shows that the present invention is a semi-solid centrifugal separation casting grinding ball process. The process is to use the returned material itself as the raw material for the chilling of the preparation slurry and the generation of seed crystals, and put it into the ladle in a certain proportion, and after rapid stirring, it will be returned to the furnace. When all the charge is dissolved into the molten metal, it becomes a low-temperature semi-solid initial slurry with a high solidification rate and good fluidity. The initial slurry is injected into the water-cooled spinner that rotates synchronously with the metal mold, and is subjected to strong chilling and shearing again, and the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com