Superconductivity electric-magnetic iron remover

An electromagnetic iron remover and superconducting technology, applied in the direction of superconducting magnets/coils, circuits, magnetic separation, etc., can solve the problems of high manufacturing cost, energy loss, and power consumption of less than 10KW, and achieve low safety hazards, light weight, and easy operation. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

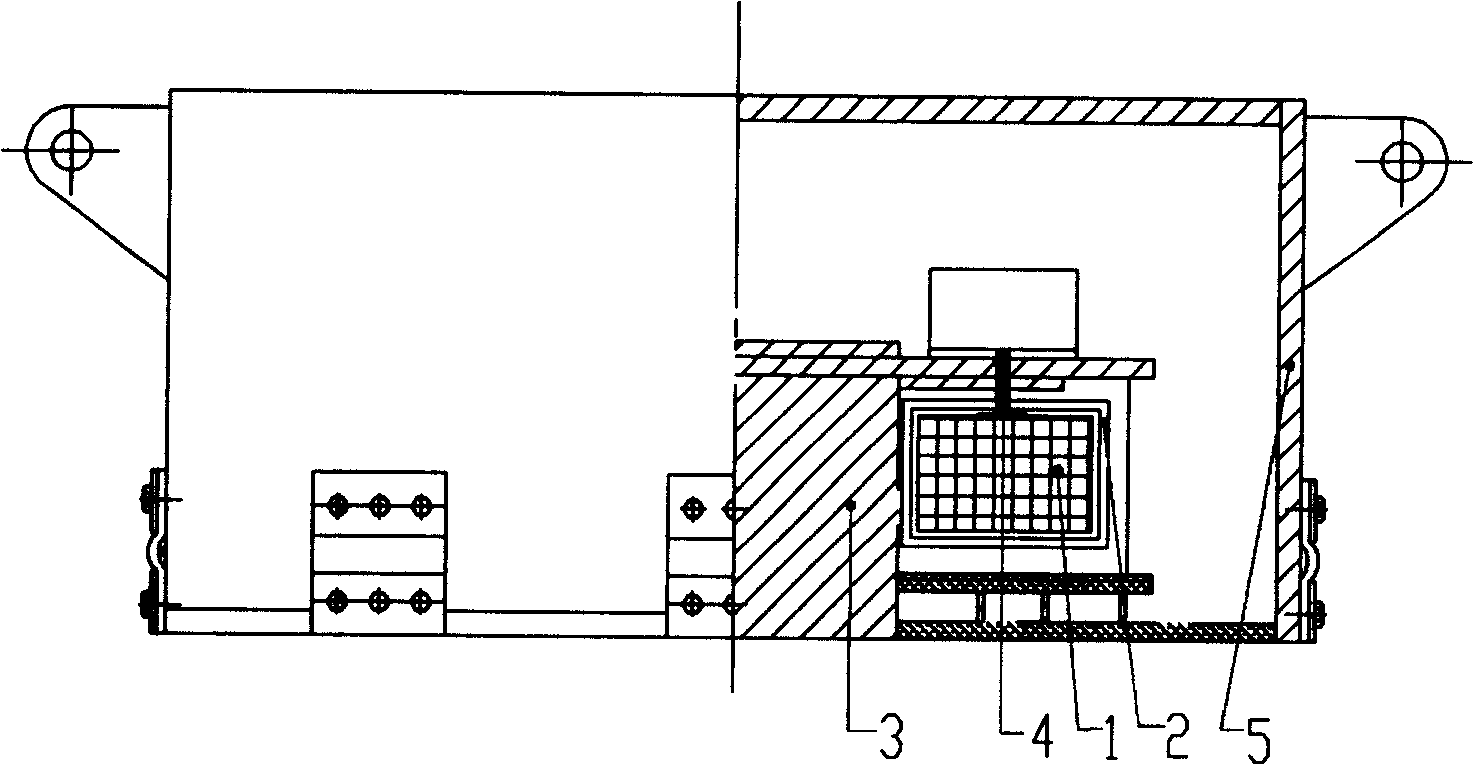

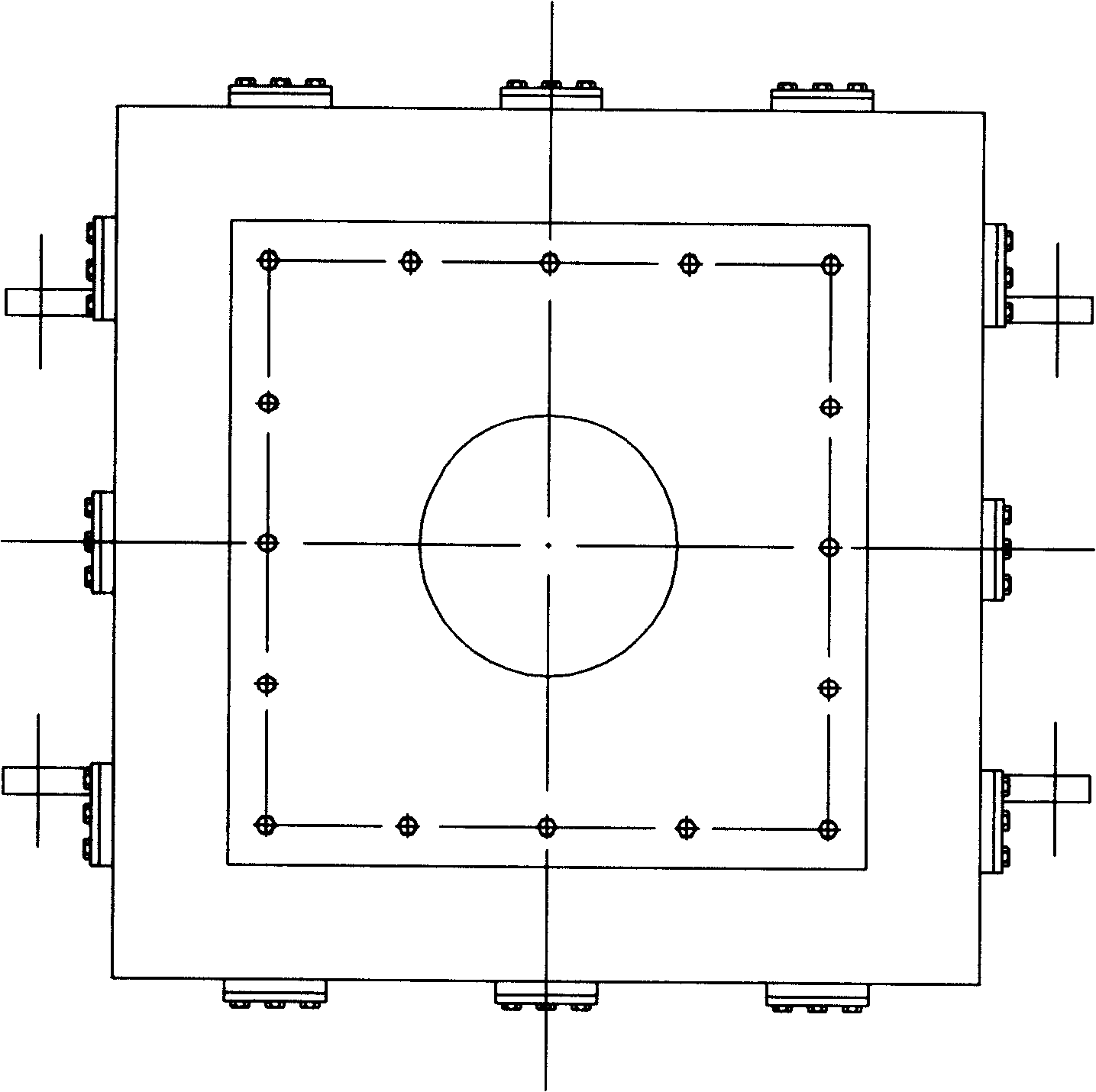

[0016] The superconducting electromagnetic iron remover is composed of two parts: the main machine of the iron remover and the special electric control cabinet for the superconducting iron remover. The magnet coil 1 of the present invention is made of superconducting materials such as NbTi, and the coil after winding is wrapped in the heat insulating layer 2, and the heat insulating layer adopts vacuum heat insulation, and the vacuum degree is 10 -7 Above Pa. The magnet coil wrapped with the heat insulating layer is fixed together with the iron core 3 of the iron remover, and the superconducting coil 1 , the heat insulating layer 2 , the iron core 3 and the refrigerator 4 are all fixed in the shell 5 of the iron remover. The refrigeration system uses a conventional G-M refrigerator, which directly acts on the coil through the cold head to prevent the superconducting coil from overheating and quenching due to internal heat generated due to mobile equipment and other reasons, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com