Irregular shallow karst cavity ribbing and grouting filling structure and construction method

A construction method and irregular technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problem that the corner pores of irregular karst caves cannot be fully filled, the concrete structure is harmful to the environment, and it is difficult to meet the strength standard of landfill, etc. problems, to achieve the effect of wide applicability, avoid high cost, and no safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

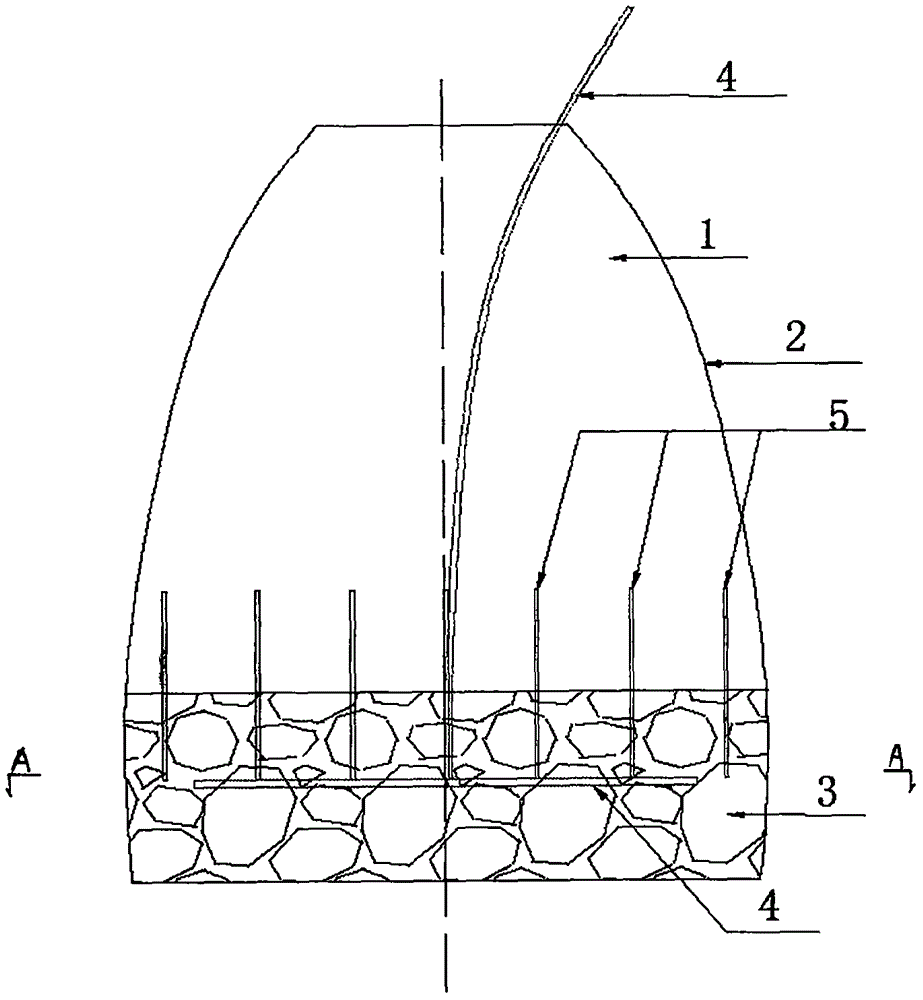

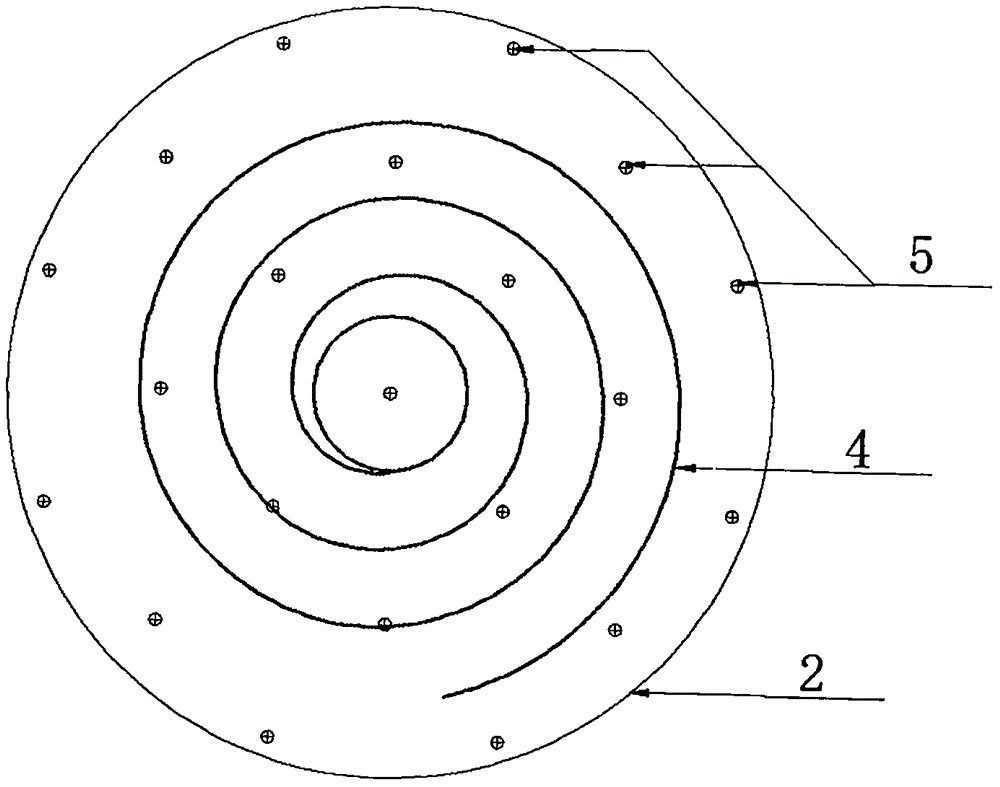

[0036] Embodiment 1: as Figure 1 to Figure 10 As shown, an irregular shallow cave reinforced grouting filling structure, including soil-rock mixed filler 3. The bottom 7 of the karst cave has a mound-like soil-rock mixed filler bottom layer 8 in the middle that is higher than the periphery. A number of layers of grouting pipes arranged at interval heights and arranged in a helical line are arranged in several layers of earth-rock mixed filler, and vertical steel bars and injected grout are arranged in each layer of earth-rock mixed filler in a plum blossom-shaped distribution at intervals; :

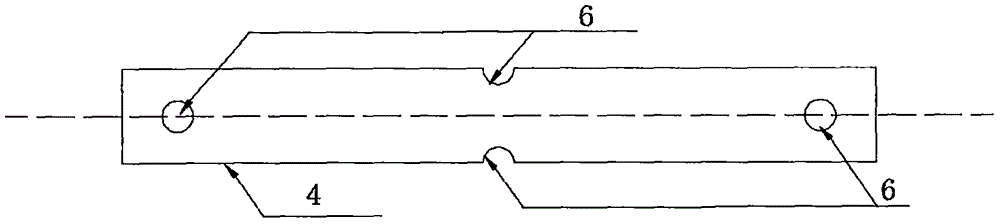

[0037] The grouting pipe 4 is used for grouting from the top of the cave 1 into the soil-rock mixed filler. The grouting pipe is a composite pipe with a diameter of 28-35mm, and the composite pipe is a high-strength composite material hose, which should ensure compression resistance. Two centrally symmetrical grouting holes are arranged on the composite pipe every 0.4-0.6m. The diame...

Embodiment 2

[0049] Example 2: The irregular shallow buried cave is located 2m below the ground level, the diameter of the bottom of the cave is 10m, the diameter of the top is 4m, and the height of the cave is 10m. The landfill structure of earth-rock mixture (tube name: filler layer) has 4 layers in total, and the filler is earth-rock mixture obtained locally. The average thickness of each filler layer is 3m, and each layer is buried in its upper and lower parts, both of which are 1.5m in length, with grouting pipes arranged in the middle. The outer ring of each layer of grouting pipe is 1m away from the cave wall, and spirally surrounds the cave wall to the center of each layer at a parallel interval of 1m. One end is closed and the other end is open, and the open grouting end is led out to the surface to facilitate grouting. Each layer of vertical reinforcement is 3m long and 10mm in diameter, arranged in a plum blossom shape around the center of the packing layer, and embedded in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com