Construction method for reinforcing T-beam through partially-bonded prestressed FRP

A technology of bonding prestressing and construction methods, applied in the field of bridges and construction, can solve the problems of large temperature influence, secondary damage of beam and rib, peeling brittle damage, etc., to improve shear resistance, improve bending resistance, avoid The effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A construction method for strengthening T-beams by using partially bonded prestressed FRP, comprising the following steps:

[0034] 1) Preparation of prestressed FRP sheets: use special equipment, that is, self-anchored prestressed tensioning machines for FRP quantitative control, to prepare prestressed FRP sheets;

[0035] 2) Paste the prestressed FRP sheet on the pre-reinforced T-beam: paste the pre-stressed FRP sheet prepared in step 1) on the matching position on the bottom surface of the pre-reinforced T-beam with epoxy glue;

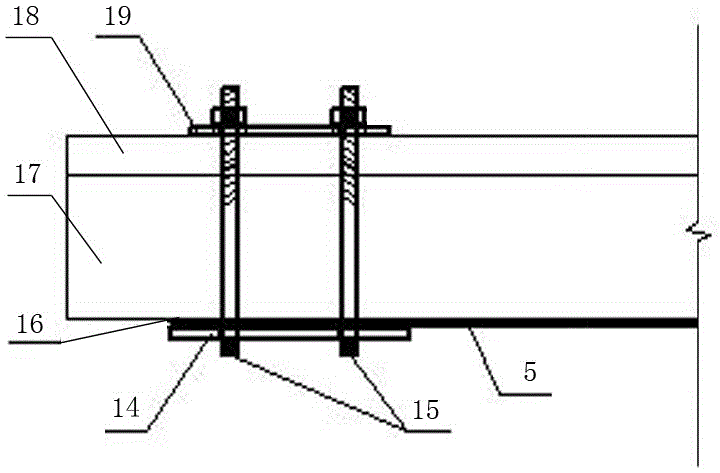

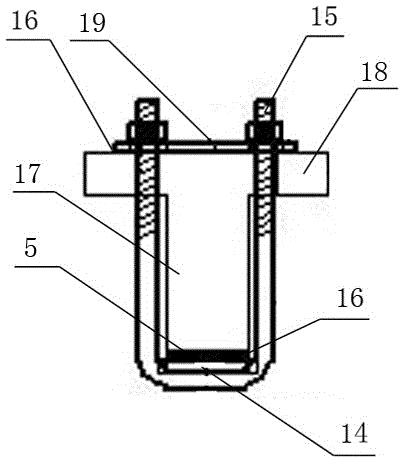

[0036] 3) Anchoring of prestressed FRP sheets: Use anchoring devices to anchor the prestressed FRP sheets at least at both ends and mid-span of the T-beam;

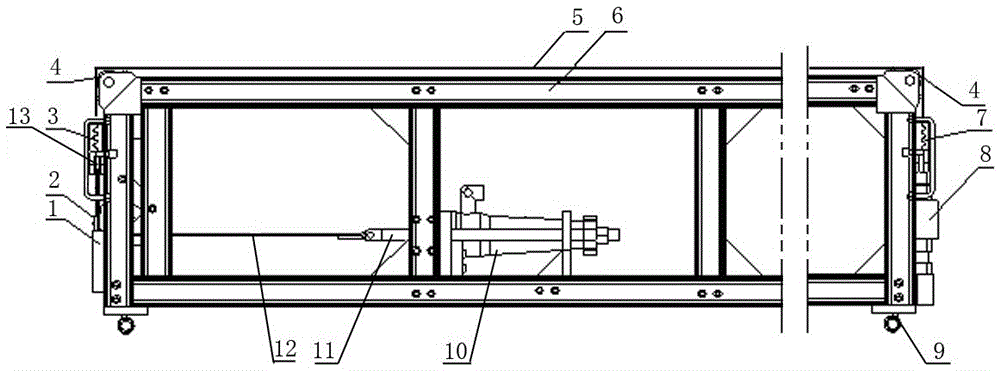

[0037]The self-anchored prestressed tensioning machine for FRP quantitative control includes a frame 6, a jack 10, a corrugated plate fixture, a displacement meter 1 and a dynamometer 8, and the jack 10 is horizontally arranged at the bottom of the frame 6 for adaptation In terms of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com