Construction method for controlling two-dimension jacking of large-scale case

A construction method and box technology, applied in the field of large-scale box two-dimensional jacking control construction, can solve the problems of large impact on the surrounding environment of the construction area occupied by the construction, increased difficulty and cost of construction, and large demolition workload, etc., to achieve The effect of reducing the amount of demolition works, ensuring normal operation, and occupying a small construction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

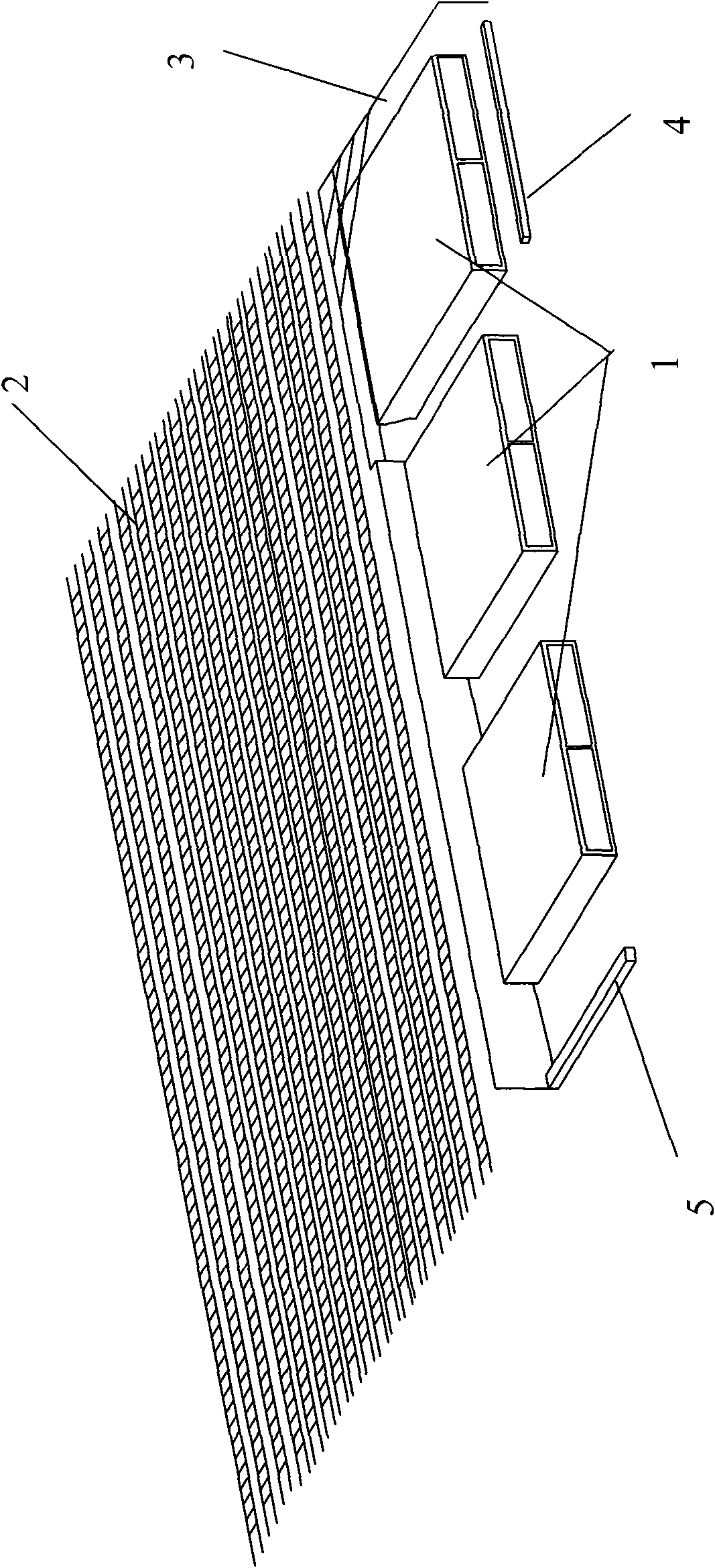

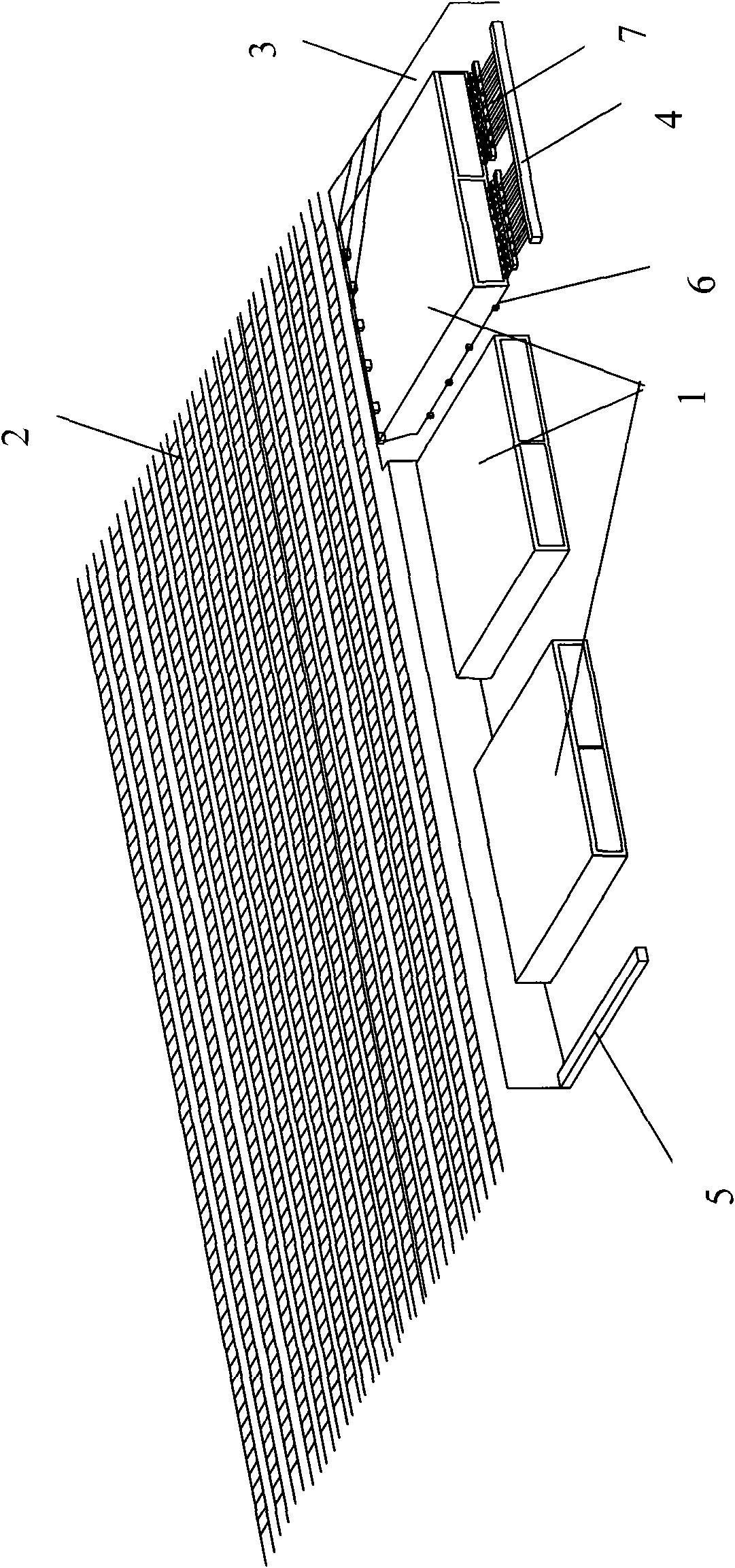

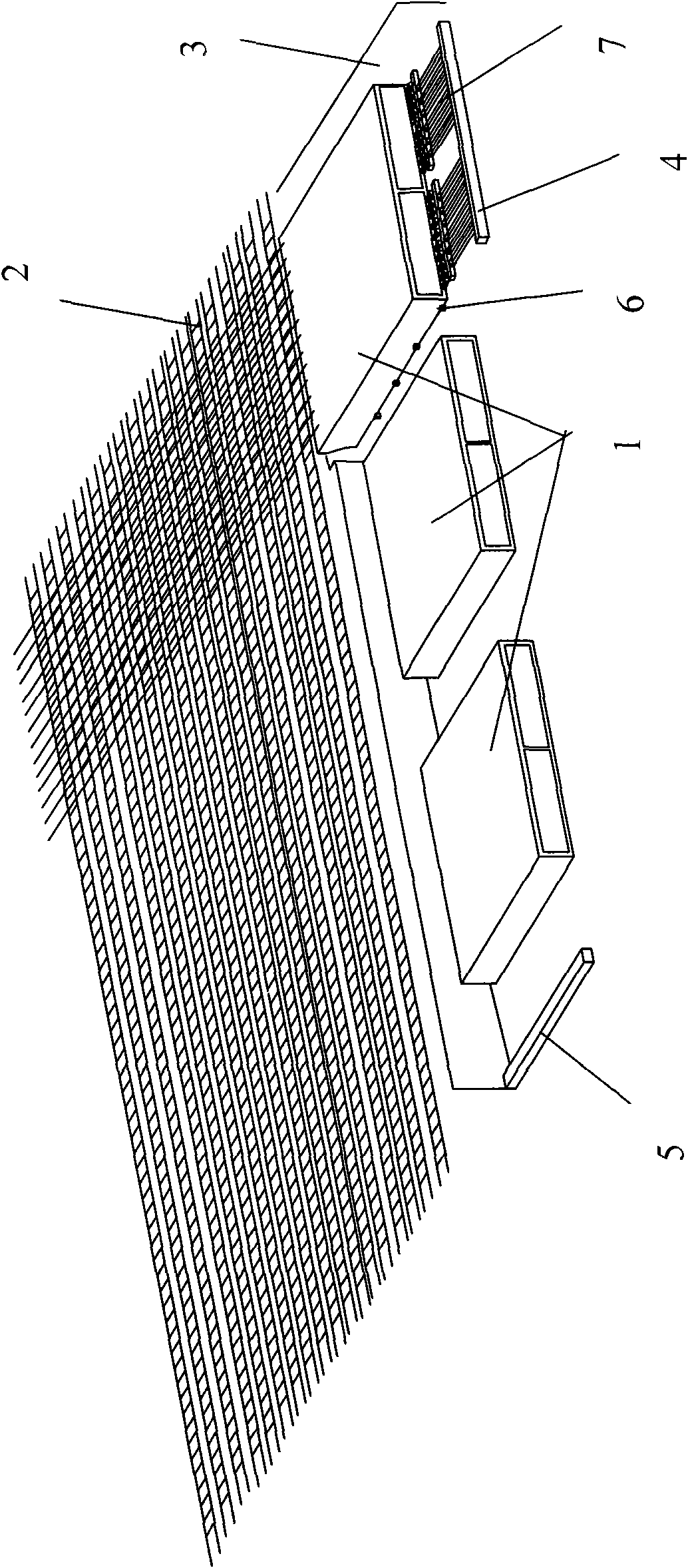

[0030] The two-dimensional jacking control construction method for a large box body provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] Such as Figure 1-Figure 10 As shown, the two-dimensional jacking control construction method for large boxes provided by this implementation includes the following steps in order:

[0032] 1) Determine the number of sections of the large box body 1 according to the overall length and weight of the frame bridge, and prefabricate the required number of large box bodies 1;

[0033] 2) Carry out grouting construction under the railway 2 where the frame bridge needs to be laid, the grouting depth is 1-3.5 meters below the line 2 to 5-8 meters below the bottom plate of the large box 1, and the grouting width is both sides of the large box 1 8-15 meters outside to reinforce the soft soil foundation in the area;

[0034] 3) On the side of the railway 2 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com