Soft foundation treatment method capable of providing pre-pressing load by surcharge load in manner of inserting and piling water draining board to drain and capable of forming steel cylinder water-stop structure

A technology of soft foundation treatment and surcharge preloading, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of structural stability and construction difficulty, and achieve the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

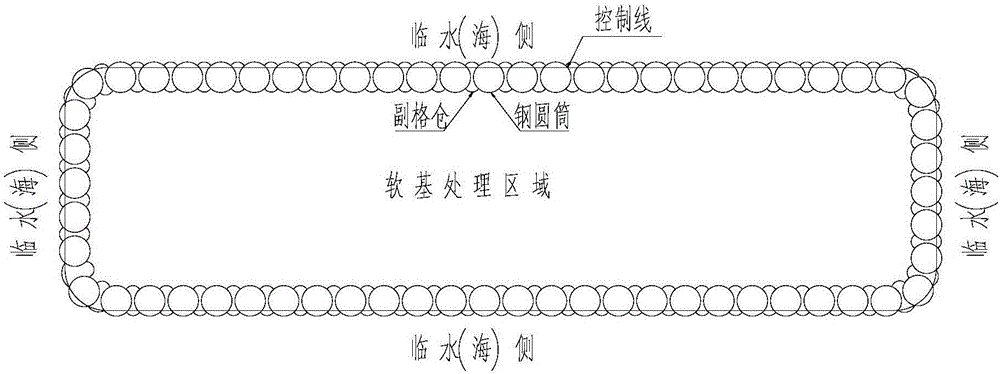

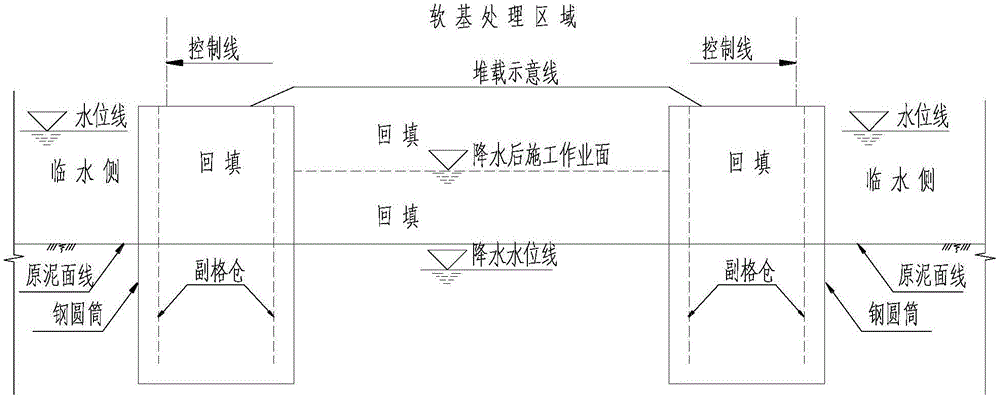

[0020] In this embodiment, the soft foundation treatment of an artificial island is taken as an example to describe in detail. The artificial island is in a harsh environment with deep soft soil foundation and deep water and large waves. The foundation treatment method enables the foundation treatment to obtain better results than conventional treatment schemes. refer to figure 1 with figure 2 , the basic processing steps are as follows:

[0021] 1) Use a large crane to vibrate the prefabricated steel cylinder to the impermeable layer, build a safe and reliable water-stop enclosure structure, and realize rapid water-stop for the entire island;

[0022] 2) Using the water-stop condition of the whole island, the island is backfilled to -5.0m, and the precipitation is to -6.0m; on the -5.0m construction platform, plastic drainage boards are inserted on land. The top elevation of the drainage board is -15.0m, and the bottom elevation is -15.0m. The maximum value is -40.0m, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com