Method for reinforcing gravity type retaining wall

A retaining wall and gravity-type technology, applied to sheet pile walls, water conservancy projects, artificial islands, etc., can solve problems such as restricting the use of oblique anchor cables, reduce construction difficulty, improve overall stability, and enhance overall stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

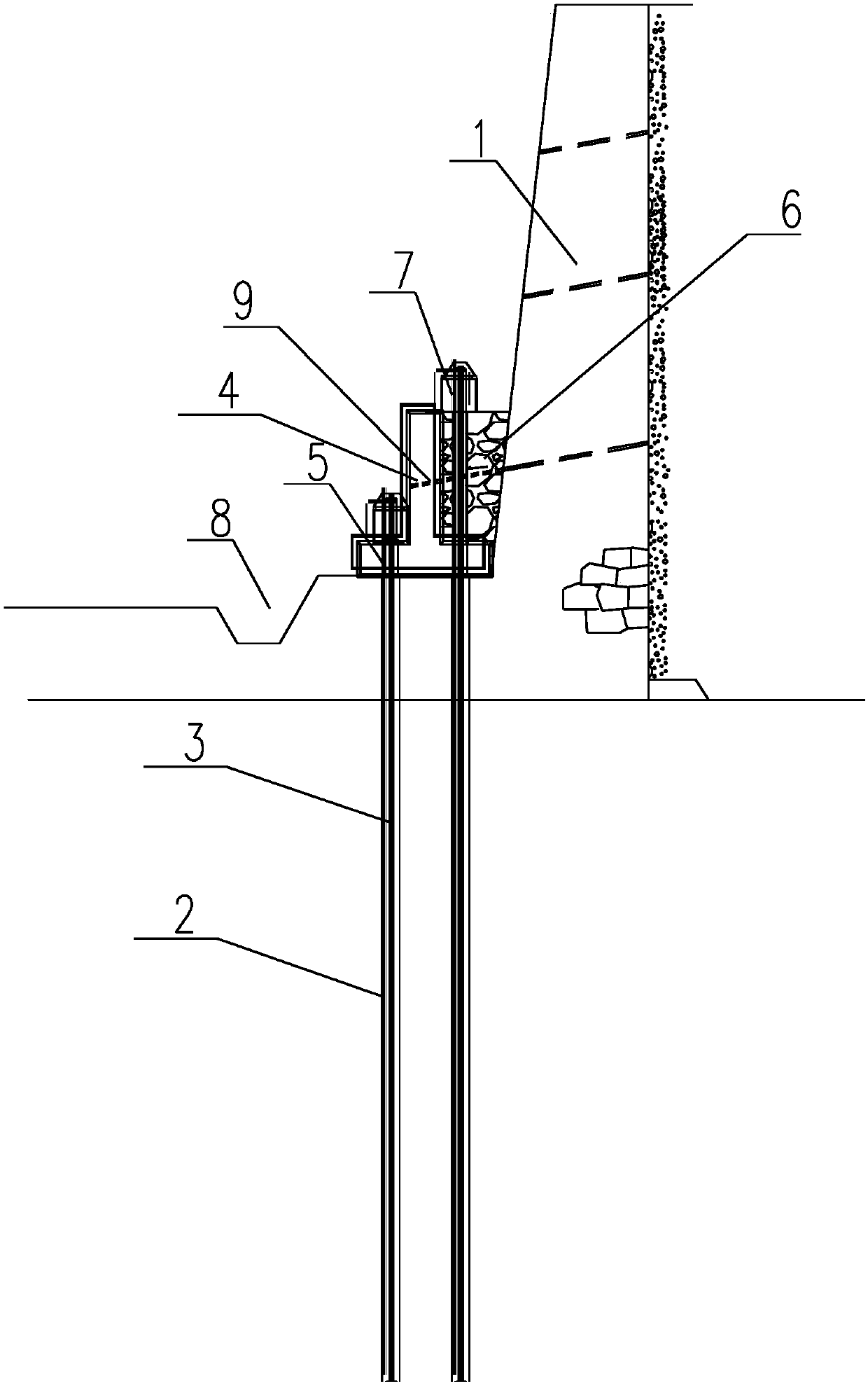

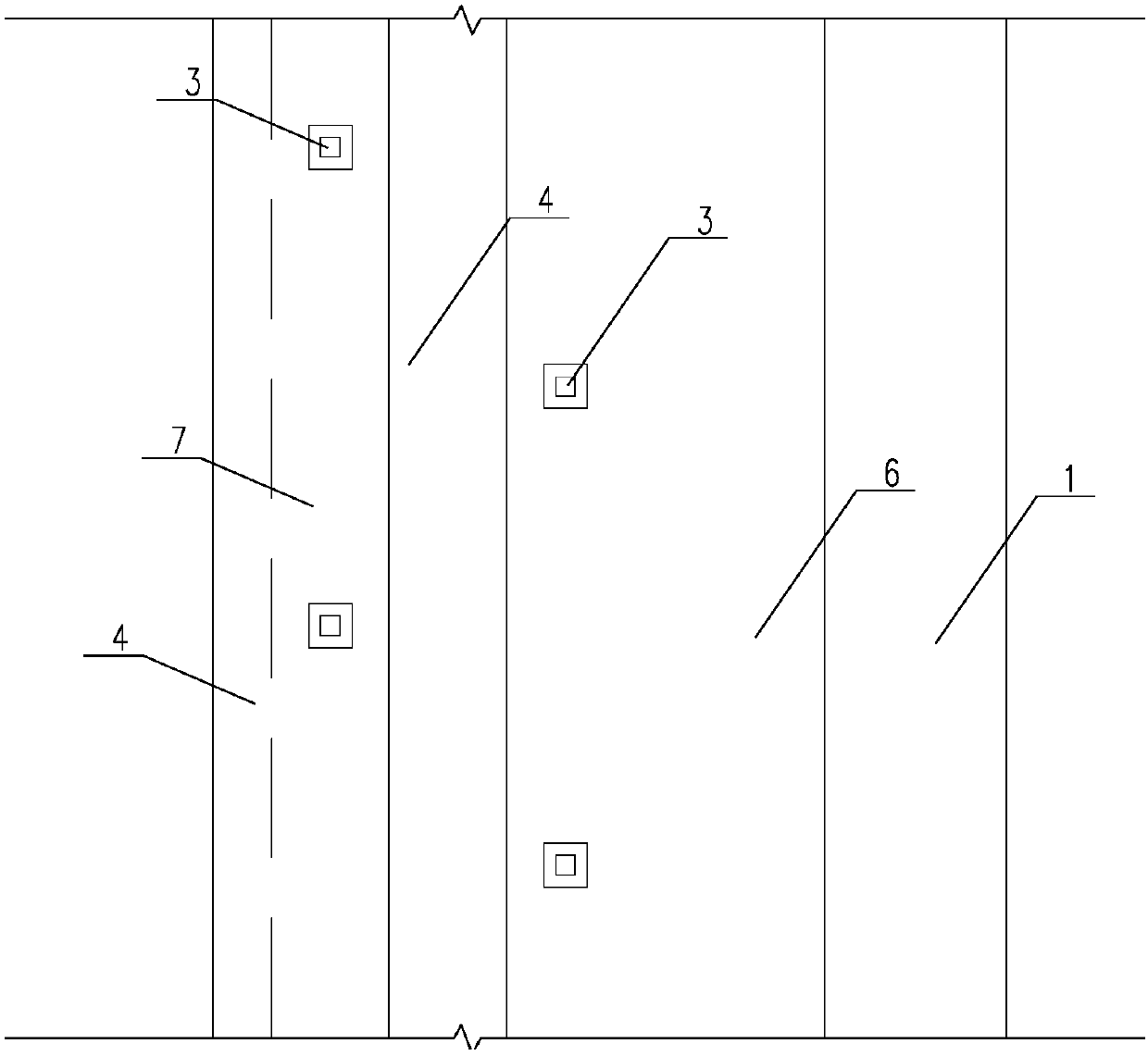

Embodiment 1

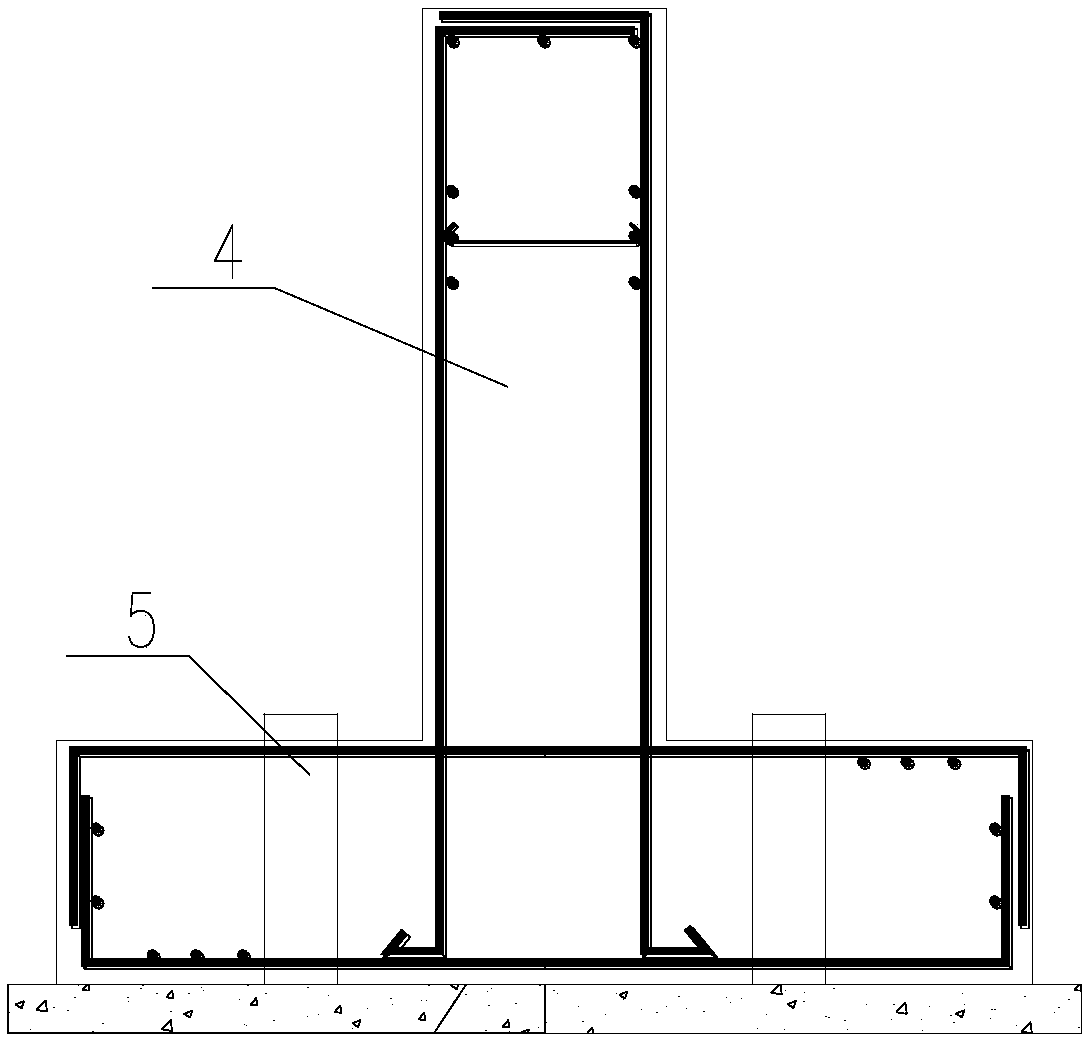

[0036] The original height of the gravity-type retaining wall in the family apartment area of a factory was 6.0m, and the height of the rear retaining wall increased to 9.0m with the increase of the fill behind the wall. After 2 to 3 years of operation, it was found that the back of the retaining wall appeared A large number of "bulging", cracks and other phenomena, the total length of the retaining wall with instability phenomenon is 50.0m. The preliminary reinforcement plan is to use lattice beams and columns + oblique prestressed anchor cables. However, since the red line of the retaining wall is located at the top of the retaining wall, local villagers do not allow this plan to be implemented. Later, vertical prestressed anchors are adopted. Cable + reinforced concrete cantilever retaining wall for reinforcement, so far, the operation is in good condition.

[0037] The cantilever retaining wall and the ground beams described in this embodiment are all made of reinforced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com