High temperature oxidation resistant environment-friendly coating with lubricating and heat conducting functions

An anti-oxidation, high-temperature technology, applied in coatings, epoxy resin coatings, etc., to achieve excellent corrosion resistance, high-temperature precision forming, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

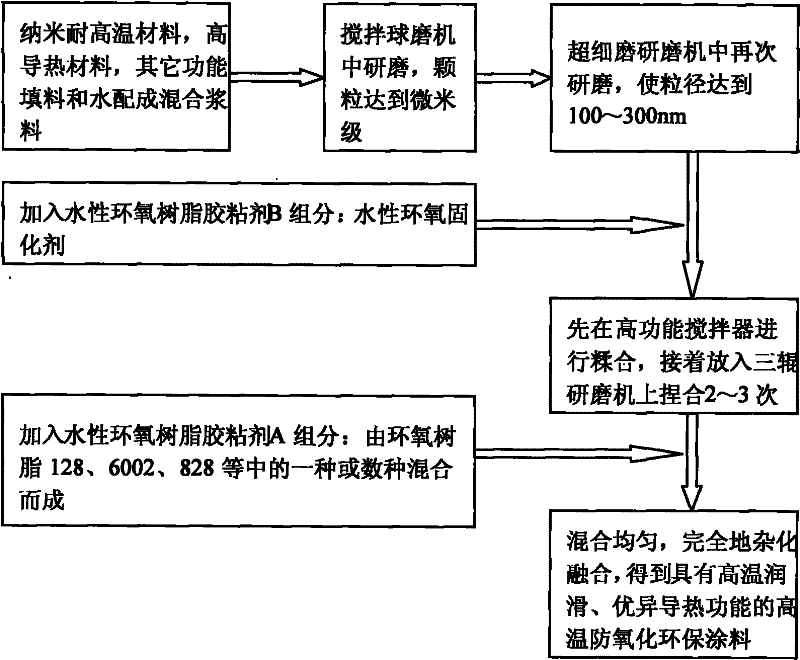

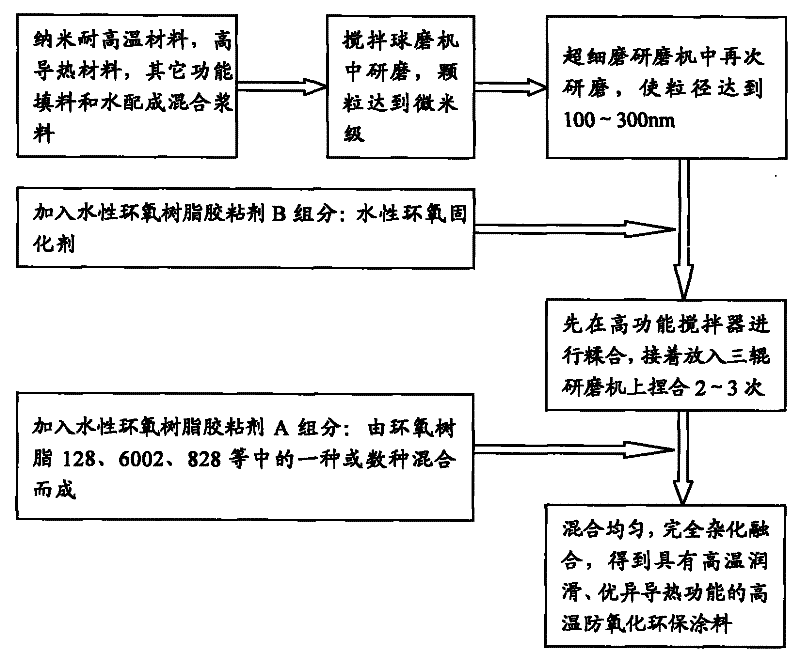

Method used

Image

Examples

Embodiment 1

[0036] (1) Prepare water-based epoxy resin adhesive:

[0037] Waterborne epoxy resin adhesive is composed of epoxy resin A and epoxy curing agent B:

[0038] i.A component is made by mixing epoxy resin 128 and 6002 in a ratio of 1:1;

[0039] ii. Component B is a water-based epoxy curing agent prepared by chain-extending polyethylene polyamine through flexible chain segments. The specific process is as follows:

[0040]Add 50 ml of propylene glycol methyl ether, 0.3 mol of diethylenetriamine, and 0.15 mol of polyethylene glycol diglycidyl ether in sequence into a four-necked flask ventilated with nitrogen. Among them, polyethylene glycol diglycidyl ether is added dropwise at a rate of 1 ml / min. After 10 minutes of dropping, the nitrogen flow is stopped and the temperature is kept for 2 hours. After the heat preservation is completed, a mixture of 0.15 mol epoxy resin 618 and 30 ml propylene glycol methyl ether is added dropwise at a rate of 1 ml / min and kept warm for 3 hours...

Embodiment 2

[0046] (1) Preparation of water-based epoxy resin adhesive.

[0047] (2) Micronano treatment of the coating material: first, the nano colloidal silicon dioxide solution: 20g; the mixture of titanium dioxide, boron trioxide and chromium trioxide 8g; aluminum powder: 10g; carbon black: 5 grams; Paraffin wax: 2g; white corundum powder: 2g; water: 30g to make a mixed slurry, and then put the slurry into a stirring ball mill to grind for 1-2 hours, and then put it into an ultrafine grinding machine for grinding.

[0048] (3) Mix and stir the micro-nano particle slurry prepared in (2) and the water-based epoxy resin adhesive 30g prepared in (1) evenly. The specific operation is: first mix the nano-particle slurry and the water-based epoxy resin adhesive Group B Put it into a high-function mixer for kneading, then put it into a three-roll mill and knead it for 2 to 3 times, and then fully stir and mix with A component. So far, the preparation of the high-temperature anti-oxidation e...

Embodiment 3

[0051] (1) Preparation of water-based epoxy resin adhesive.

[0052] (2) Micro-nano treatment of coating materials: first, nano-colloidal silicon dioxide solution: 15g; mixture of titanium dioxide, boron trioxide, and zinc oxide 5g; magnesium powder: 10g; graphite: 6g; paraffin: 4g Brown corundum powder: 2g; water: 35g to make a mixed slurry, then put the slurry into a stirring ball mill for 1-2 hours, and then put it into an ultra-fine grinding machine for grinding.

[0053] (3) Mix and stir the micro-nano particle slurry prepared in (2) and the water-based epoxy resin adhesive 35g prepared in (1) evenly. The specific operation is: first mix the nano-particle slurry and the water-based epoxy resin adhesive Group B Put it into a high-function mixer for kneading, then put it into a three-roll mill and knead it for 2 to 3 times, and then fully stir and mix with A component. So far, the preparation of a high-temperature anti-oxidation environmental protection coating with high-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com