Hot press for bamboo floor

A technology of hot press and bamboo floor, applied in the direction of veneer press, plywood press, wood processing equipment, etc., can solve the problems of main pressure relief, labor-intensive, troublesome, etc., to improve production efficiency and uniform strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

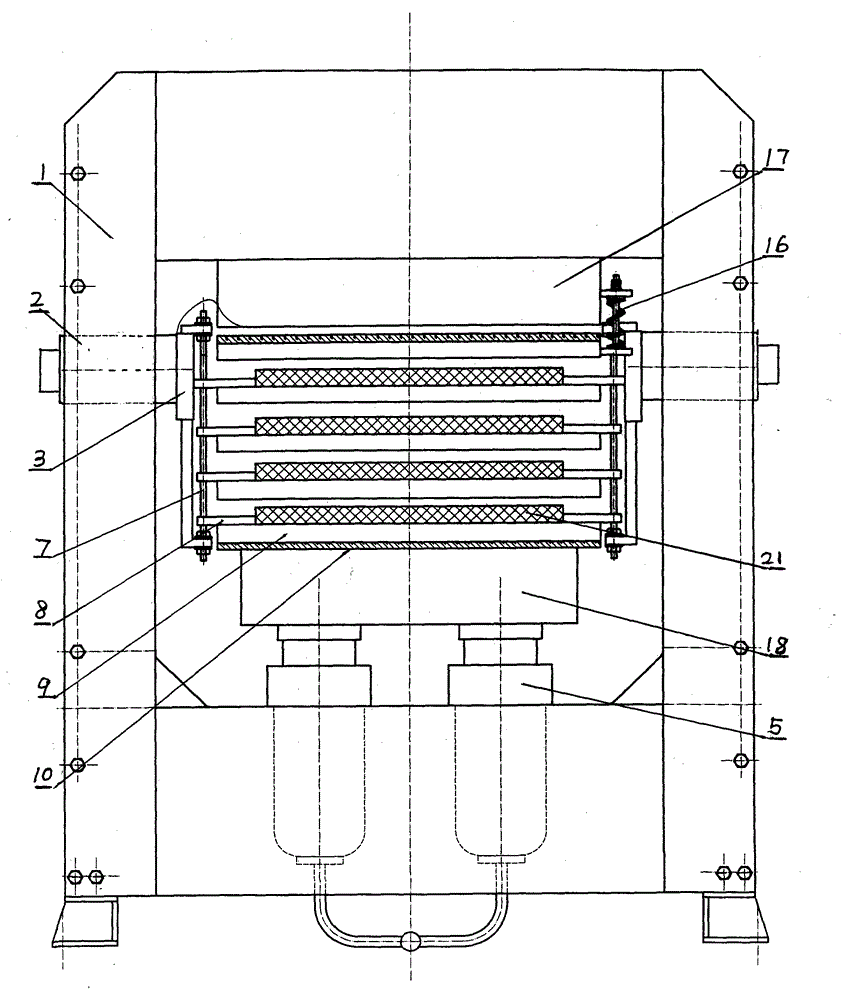

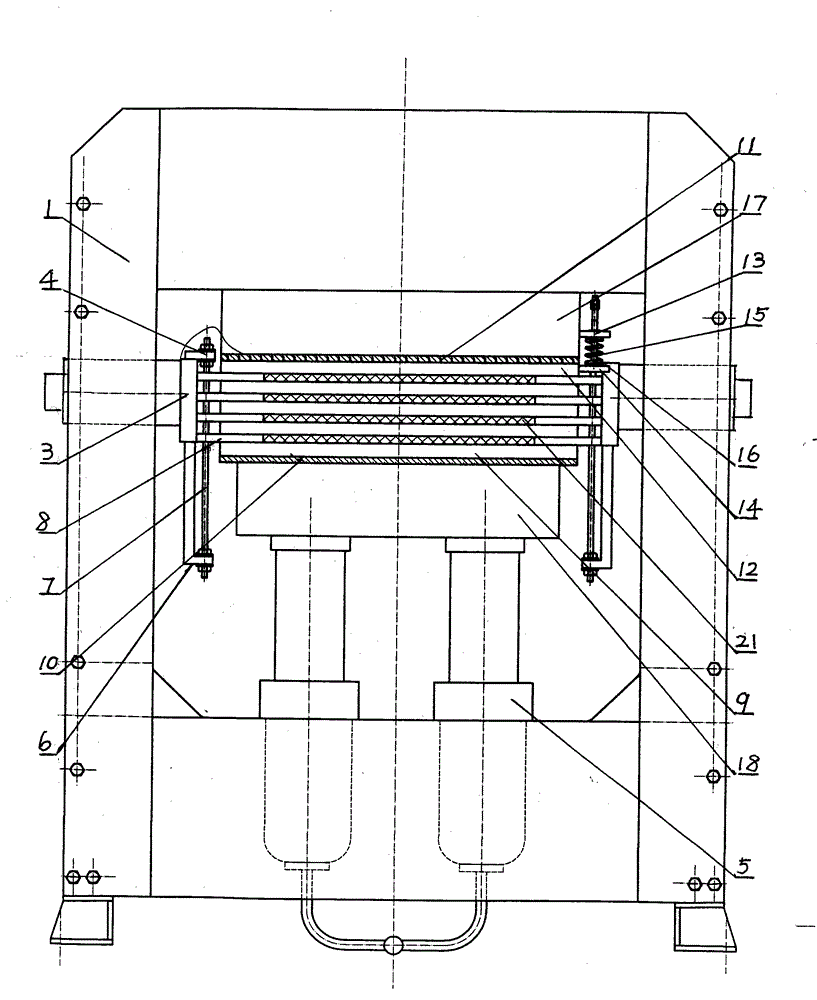

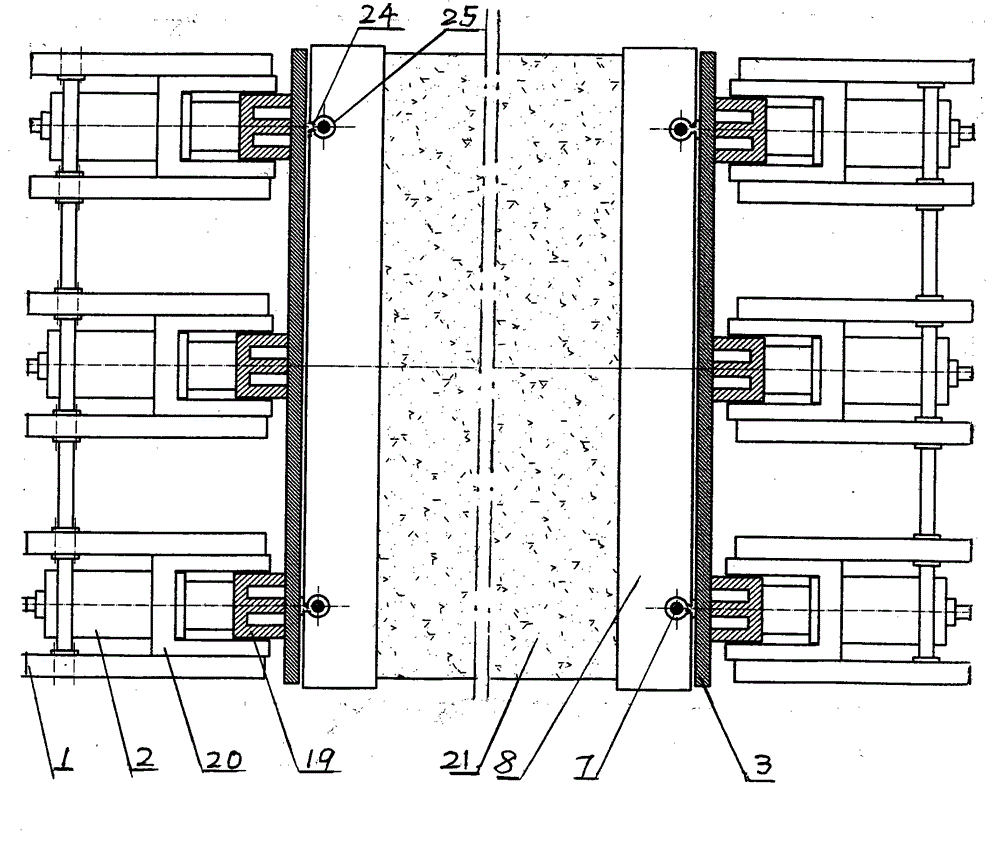

[0022] The first specific implementation mode, as attached figure 1 And attached figure 2 shown. Including frame 1, main oil cylinder 5, lower beam 18, upper beam 17, lower insulation board 10, upper insulation board 11, multi-layer hot pressing plate in between, side cylinder 2 on both sides of the frame, front push plate 3 of side cylinder , guide rod 7, multi-layer side pressure plate 8, hydraulic system and electric control system worn on the guide rod. The multilayer heat press board includes a top layer heat press board 12, a bottom layer heat press board 9 and a middle multilayer heat press board. In the prior art, the top layer of hot pressing plate 12 includes its upper heat insulating board 11 and the upper beam 17 is fixed, and the present invention changes it to be movable, and the top layer of hot pressing plate 12 includes its upper heat insulating board 11 and upper beam 17 Compression springs 16 are arranged between them, and the specific setting measures o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com