Method for inserting RFID tags in corrugated cardboard

A cardboard and corrugated technology, which is applied in the field of embedding RFID tags in corrugated cardboard, can solve problems such as troublesome and error-prone, and achieve the effect of improving reliability and preventing miscutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

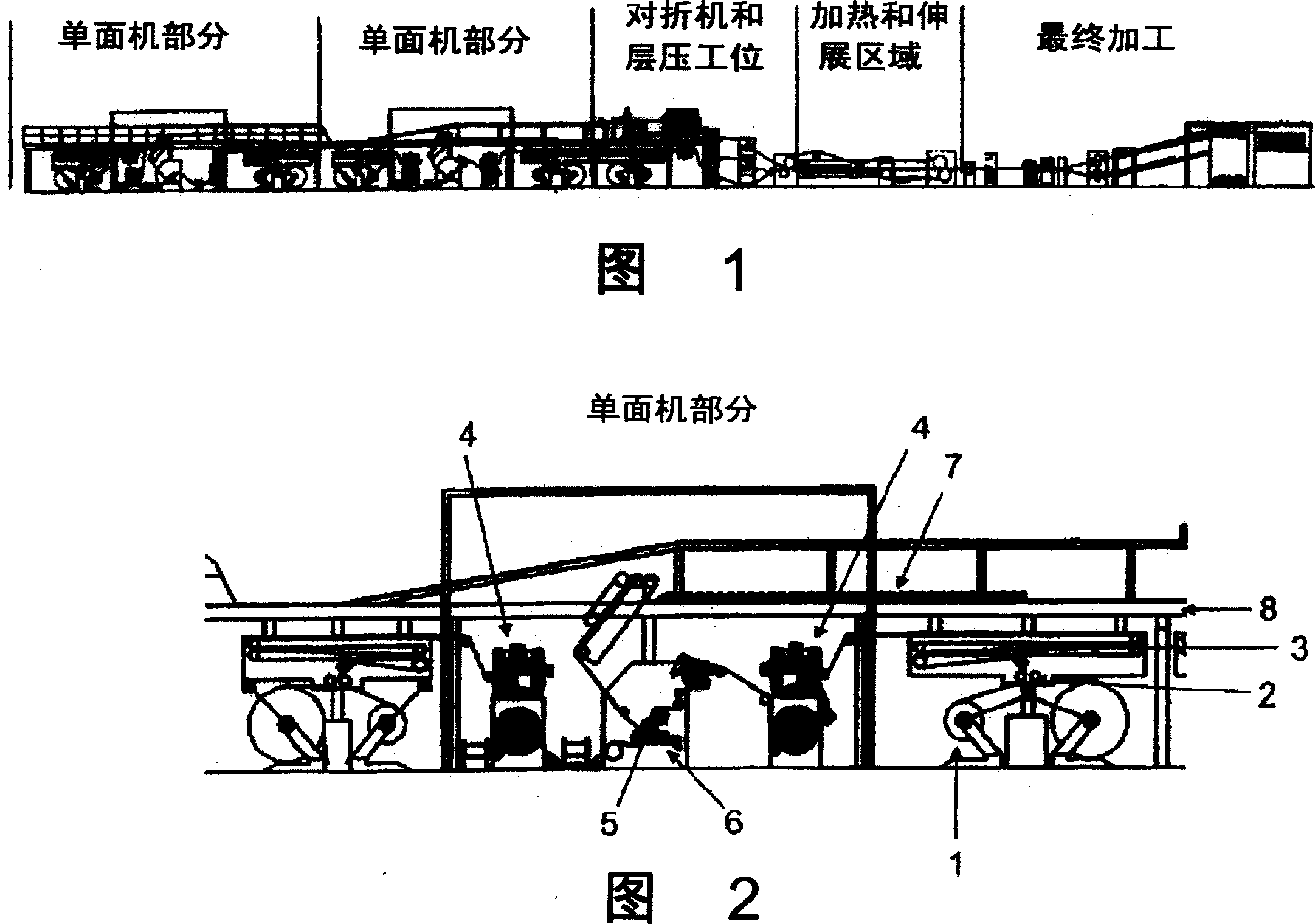

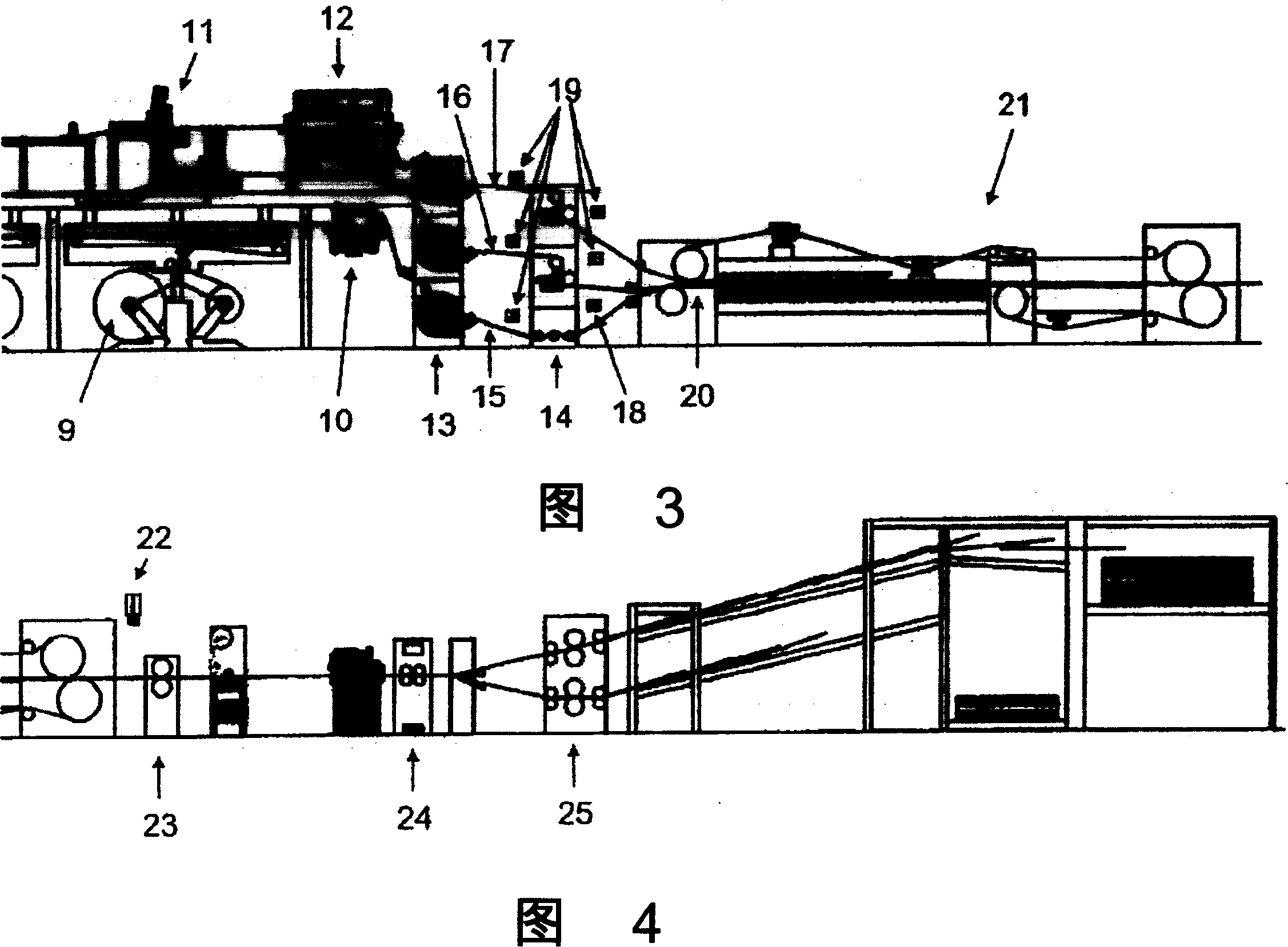

[0031] Fig. 2 is a schematic diagram of a single-sided machine part. A plant for the manufacture of corrugated cardboard may comprise one or more single facer sections of this type. They are identical in function and basic structure.

[0032] The feed of paper or paper pattern is arranged on the feed roller 1 . Feed rolls 1 are always arranged in pairs, material is unwound from one roll and the other roll is kept ready for replacement. When one roll runs out of material, a section is pulled out to the other roll at position 2 so that the feed of material is not interrupted. From there, the paper advances all the way into a first material box storehouse 3 . Here, the paper is stored to compensate for the lag in paper feed that occurs when a section is pulled out to a new roller. In order to adjust the storage volume in the magazine 3, the right and left deflection rollers in the magazine can be moved towards each other or away from each other.

[0033] From the first magaz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com