Patents

Literature

77results about How to "Avoid miscutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing transmission microscope samples on basis of non-precision positioning

InactiveCN108037146ARapid positioningAvoid miscuttingMaterial analysis by transmitting radiationFailure analysisSemiconductor technology

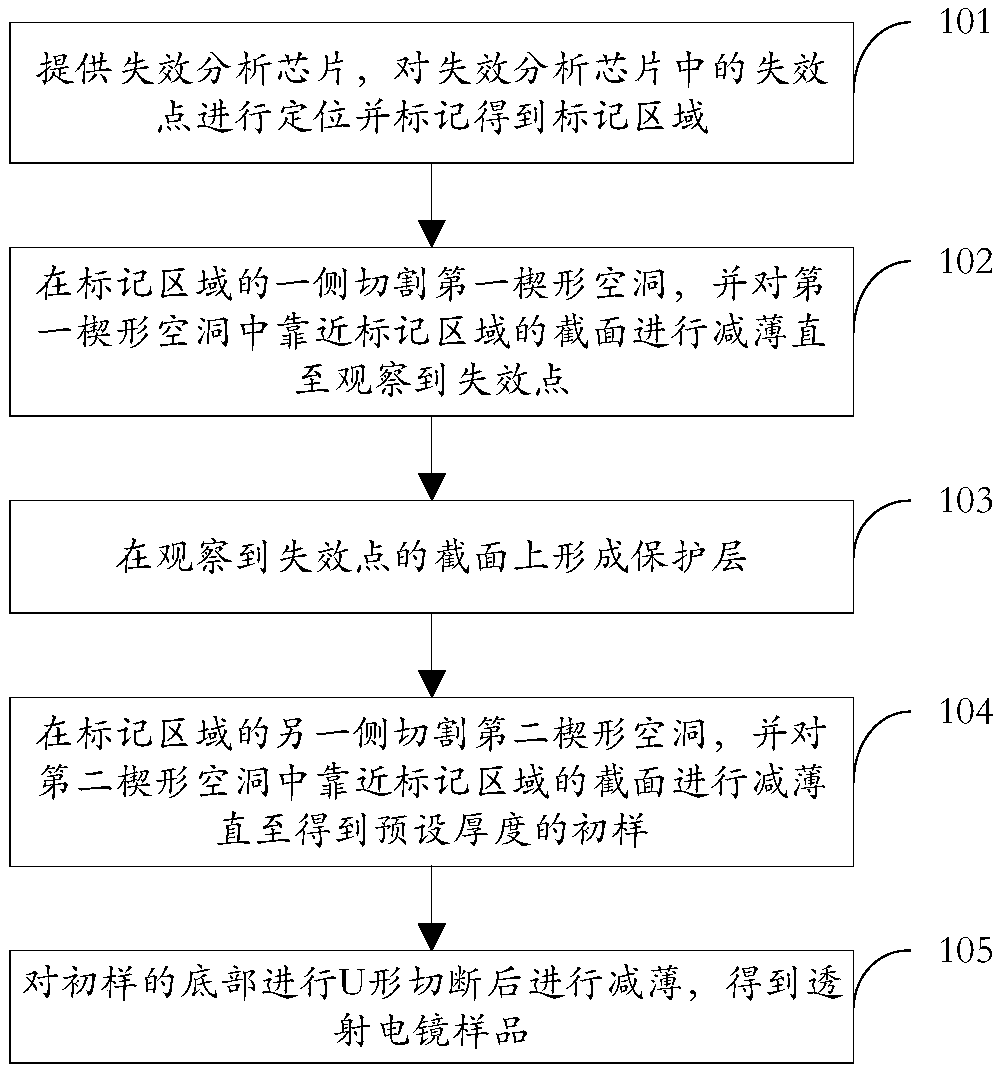

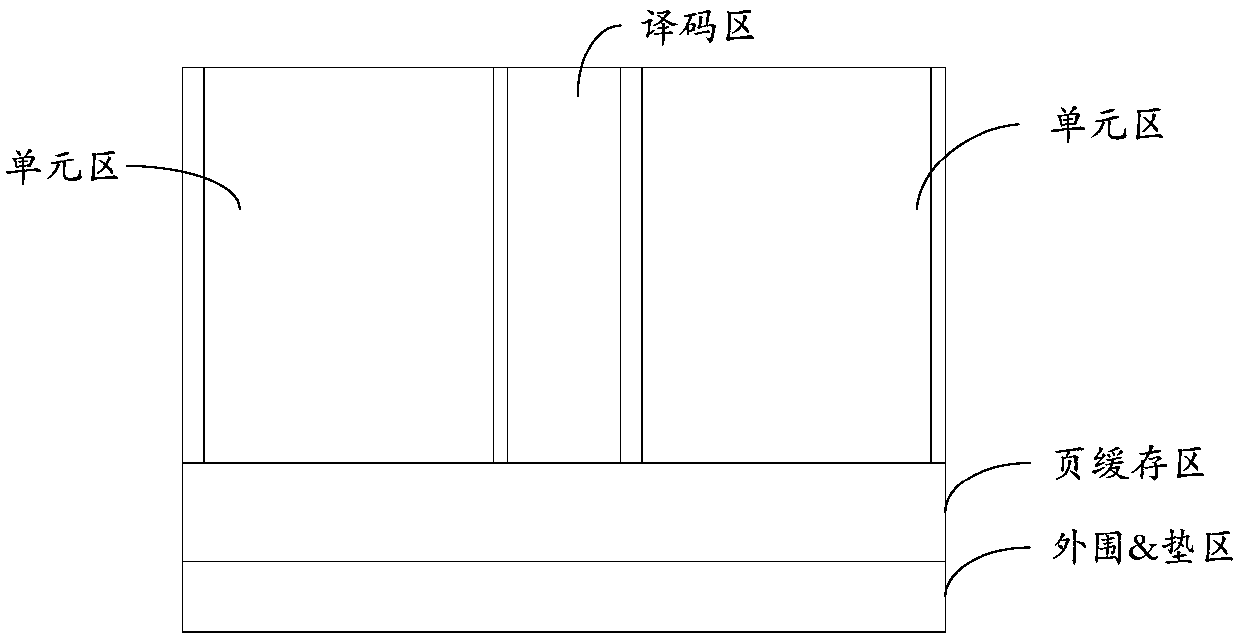

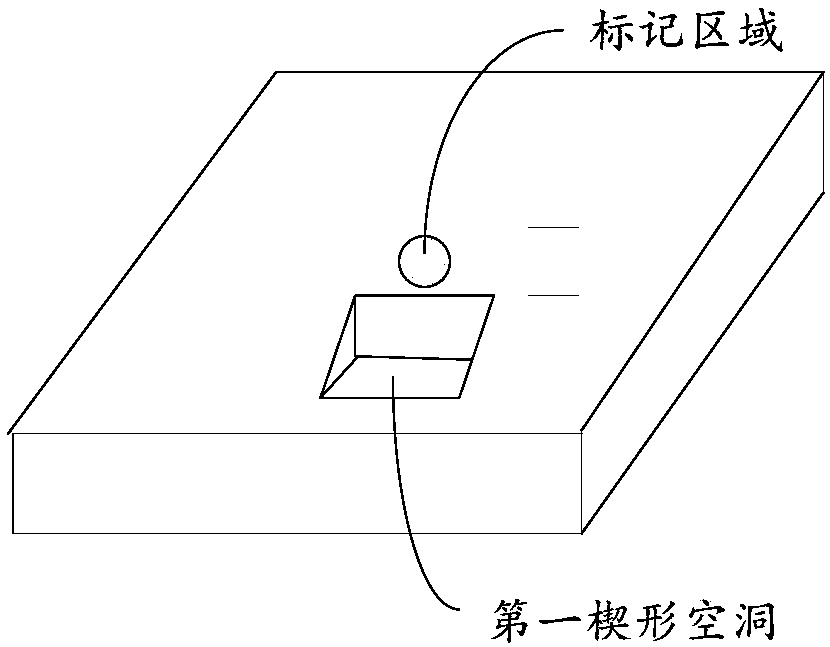

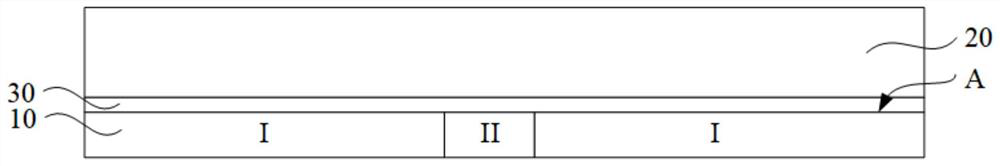

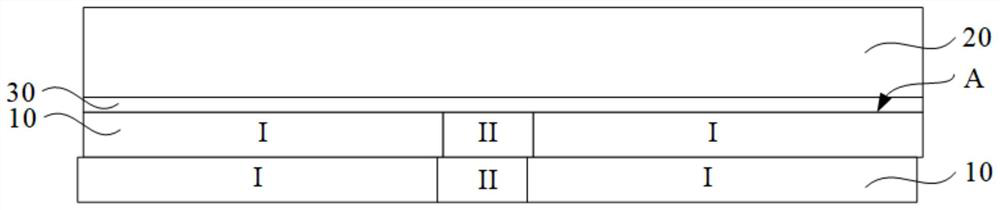

The invention discloses a method for preparing transmission microscope samples on the basis of non-precision positioning, and belongs to the technical field of semiconductors. The method includes providing failure analysis chips and positioning and labeling failure points in the failure analysis chips to obtain labeled zones; cutting a side of each labeled zone to form first wedge-shaped cavitiesand thinning the sections, which are close to the labeled zones, of the first wedge-shaped cavities until the failure points can be observed; forming protective layers on the sections where the failure points are observed; cutting the other side of each labeled zone to form second wedge-shaped cavities and thinning the sections, which are close to the labeled zones, of the second wedge-shaped cavities until primary samples with preset thicknesses are obtained; carrying out U-shaped cutting-off on the bottoms of the primary samples and then thinning the primary samples to obtain the transmission microscope samples. The method has the advantages that the failure points can be effectively prevented from being cut by mistake, each cut surface with the corresponding failure points can be prevented from being damaged or stained by splashing in follow-up processes, accordingly, the sample preparation success rate can be increased, and observation results can be improved.

Owner:YANGTZE MEMORY TECH CO LTD

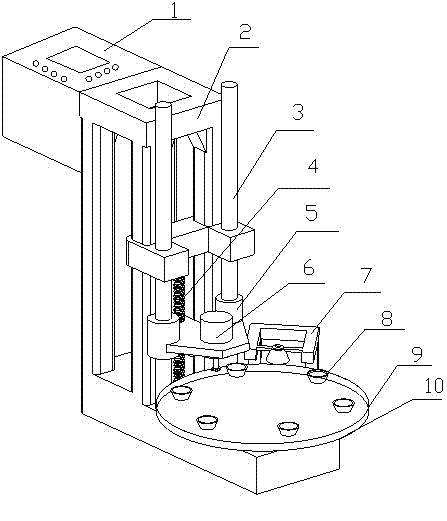

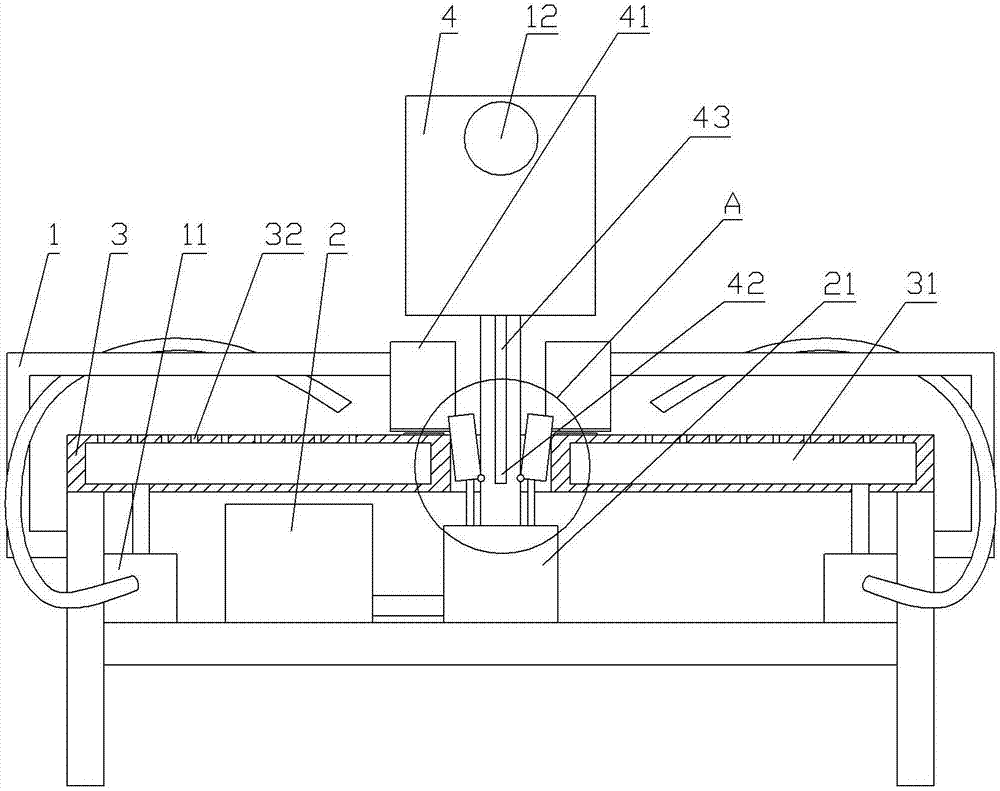

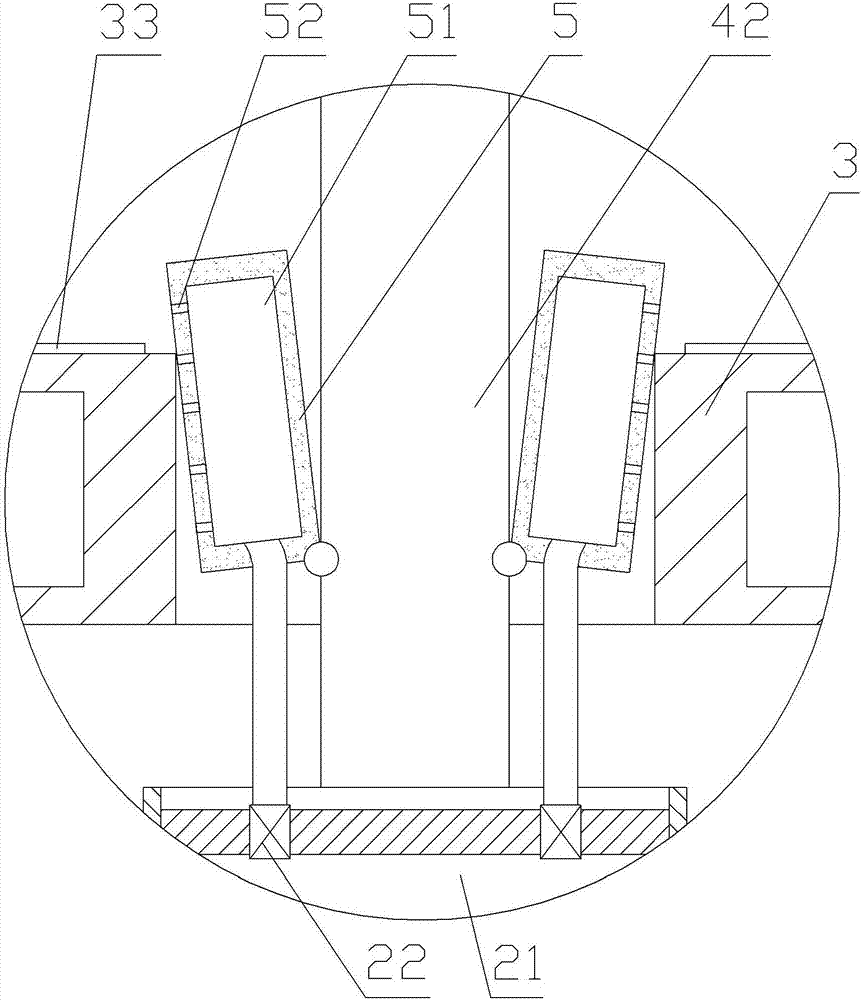

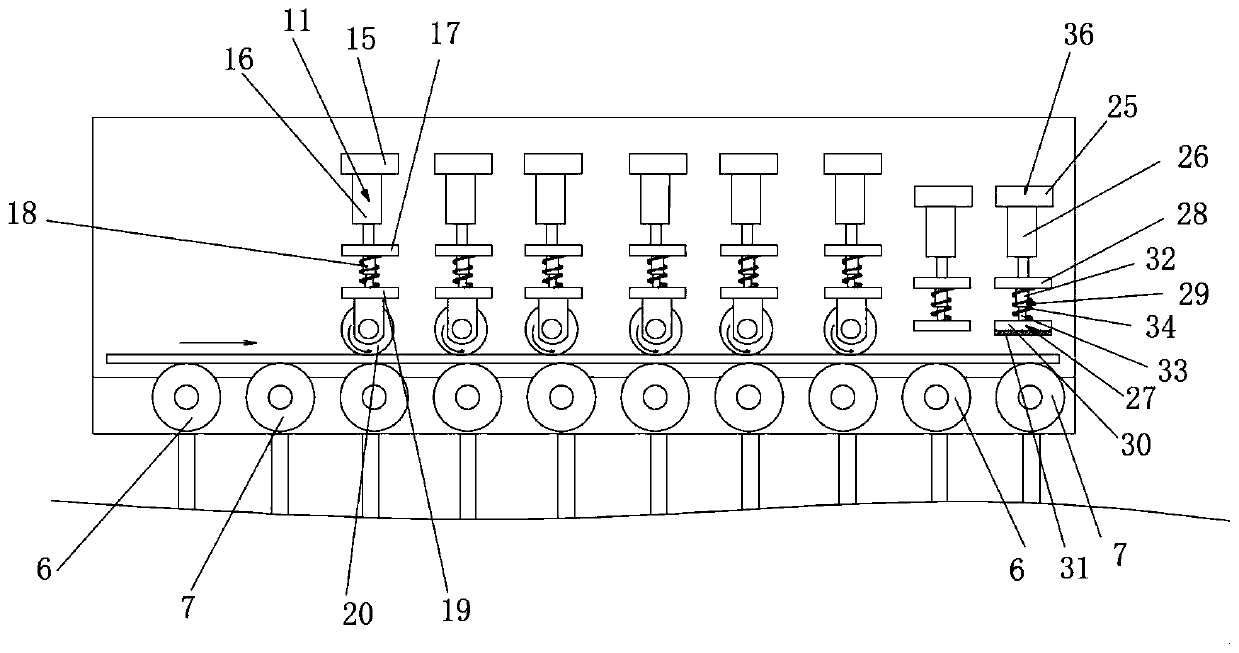

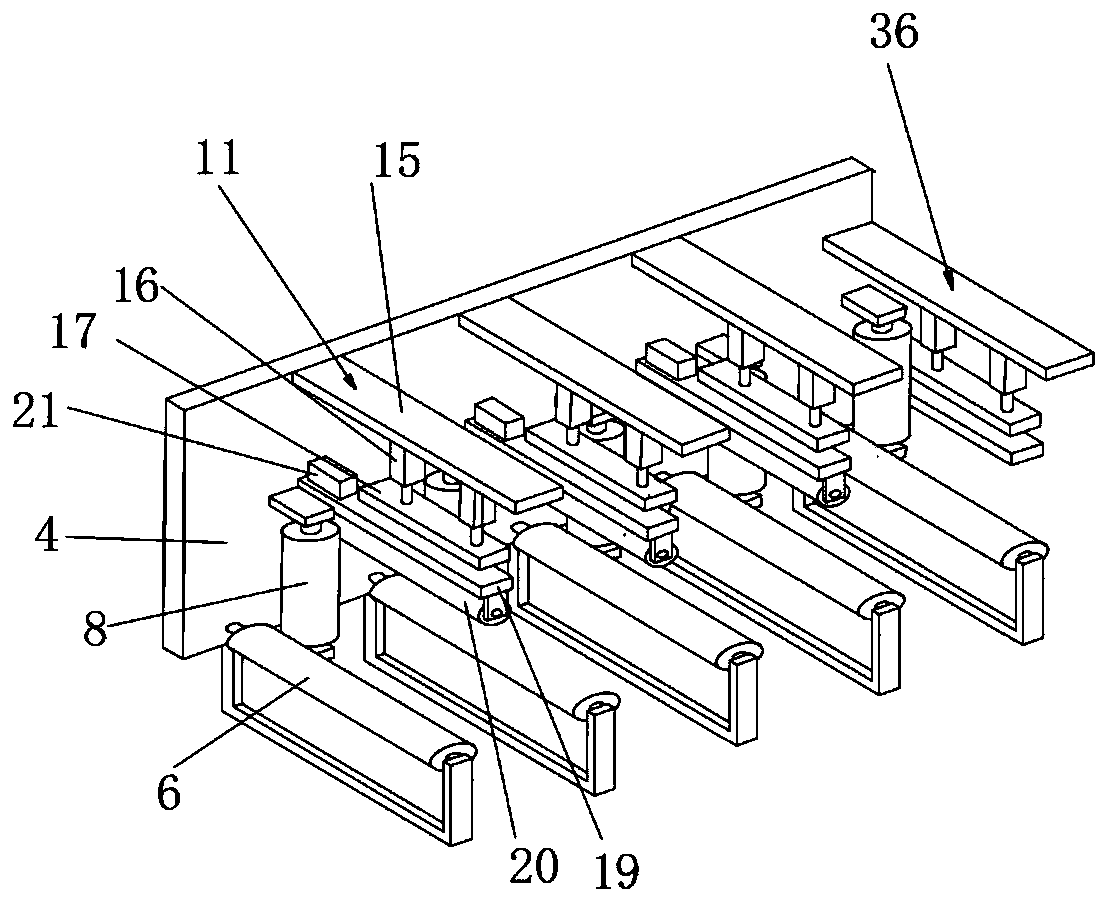

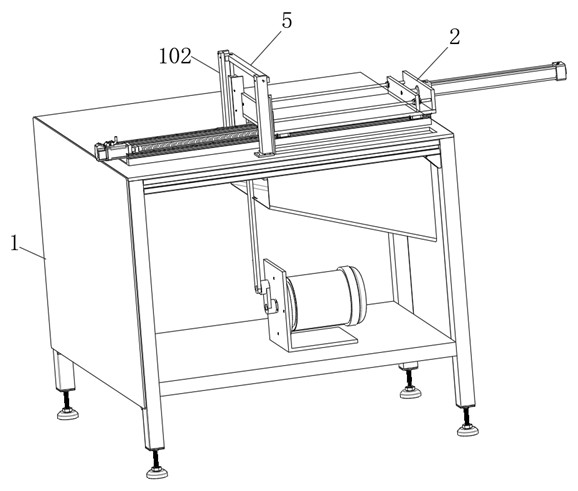

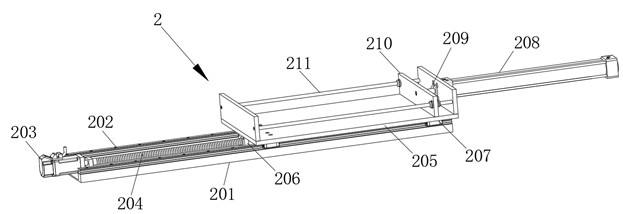

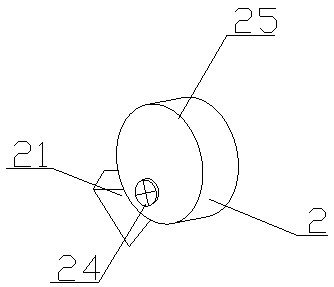

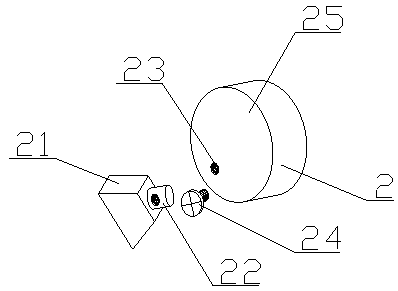

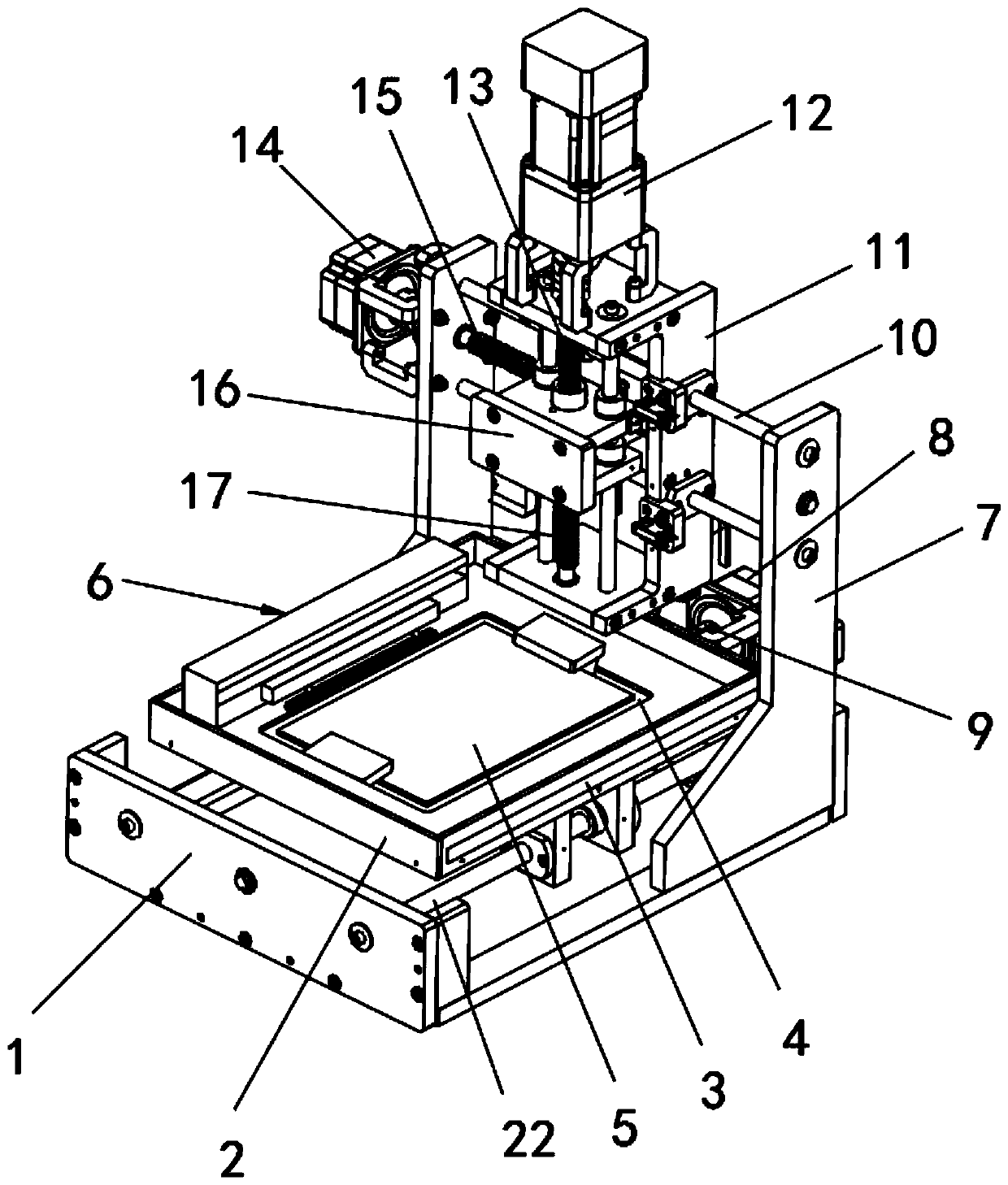

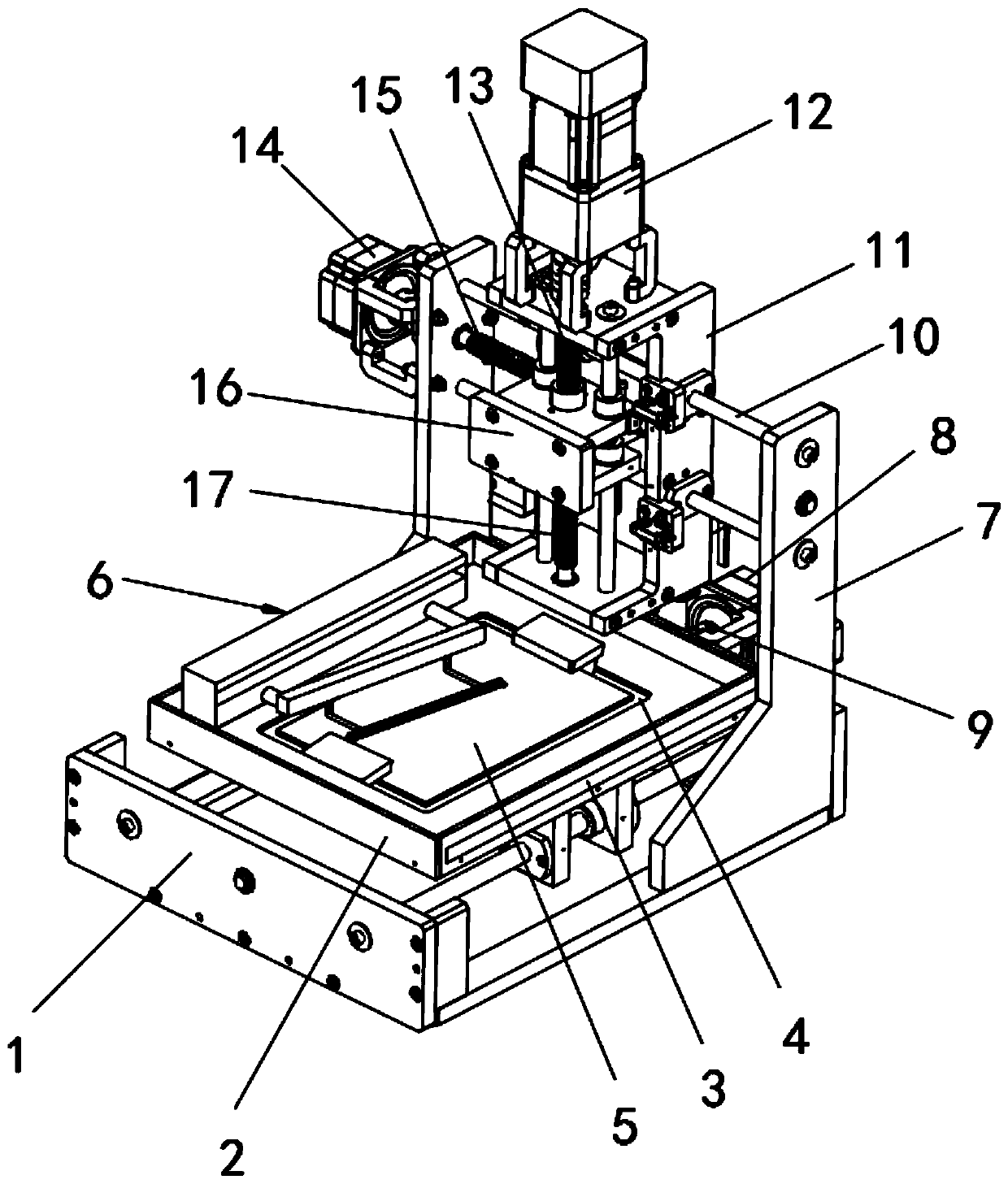

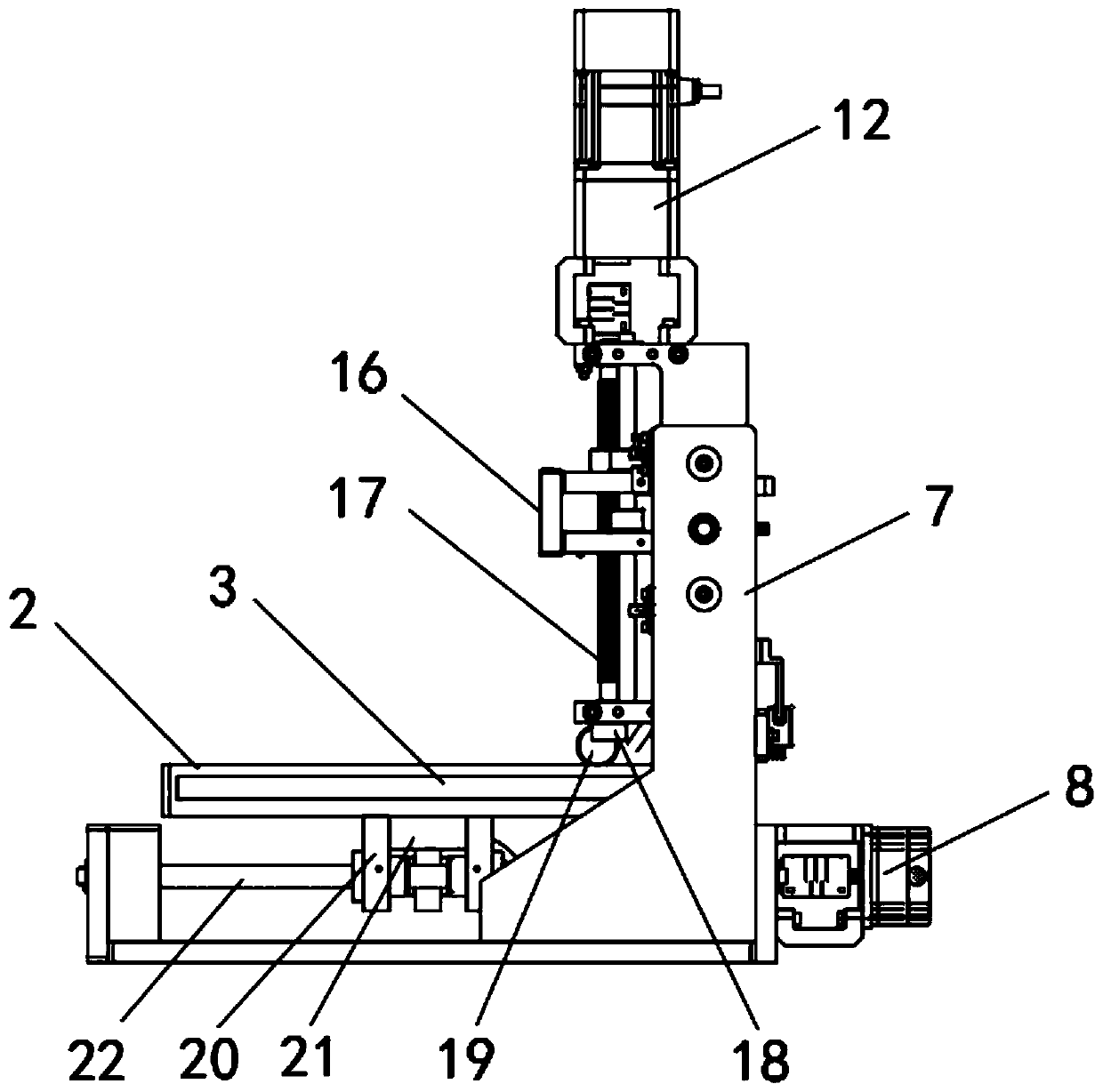

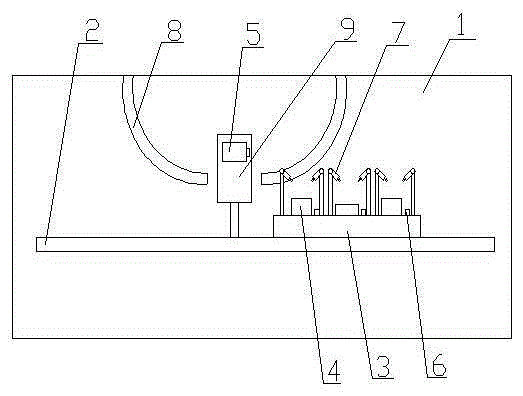

Automatic garlic root cutting machine based on image processing technique

InactiveCN103027368AAchieve consistencyAchieve precisionFood treatmentHuman interactionAutomatic control

The invention relates to an automatic garlic root cutting machine based on an image processing technique. The automatic garlic root cutting machine comprises a base, a machine frame, a control box I, a material conveying mechanism, a cutting mechanism and an image collecting mechanism, wherein the control box I, the material conveying mechanism and the cutting mechanism are arranged on the machine frame, the control box is respectively connected with the material conveying mechanism and the cutting mechanism, the material conveying mechanism comprises a driving motor I and a material disc, the driving motor I and the material disc are fixedly arranged on the base, the cutting structure comprises a driving motor II, slide rails, a ball screw and a cutting knife, the cutting knife is arranged on the cutting seat, the cutting seat is also provided with a cutting motor and a site detection device, the cutting seat is fixedly connected with the ball screw, the cutting knife is slidingly connected with the slide rails, the image collecting mechanism is connected with the control box, the image collecting mechanism comprises a bracket and a lens, the lens is arranged on the bracket, and the lens is arranged directly above the circle of material cups. The automatic garlic root cutting machine has the advantages that the garlic root cutting quality is improved, and the loss is reduced; and the functions of real-time communication, human-human interaction and multiple protections are realized, and the automatic control of the garlic root cutting is realized.

Owner:QINGDAO AGRI UNIV

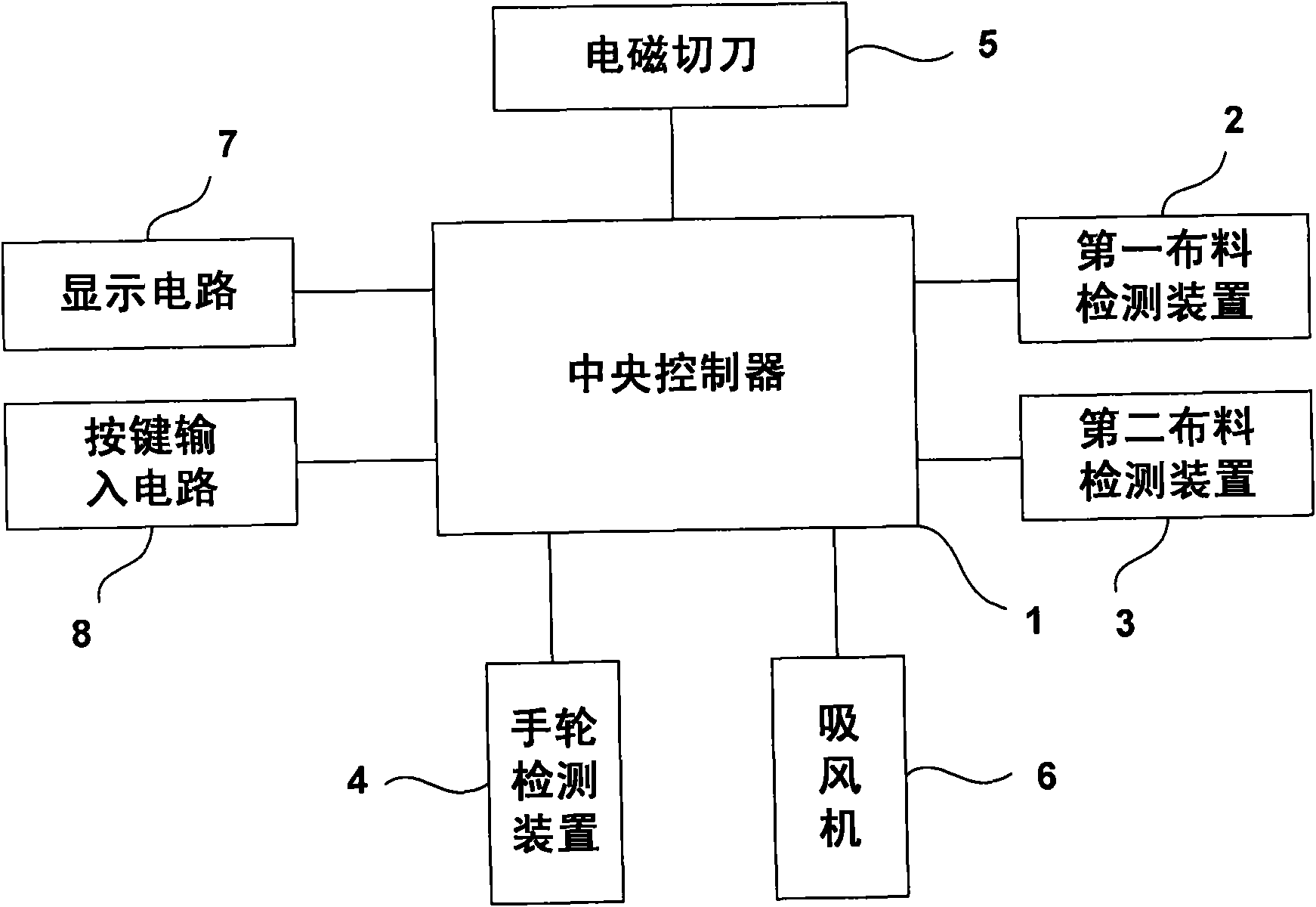

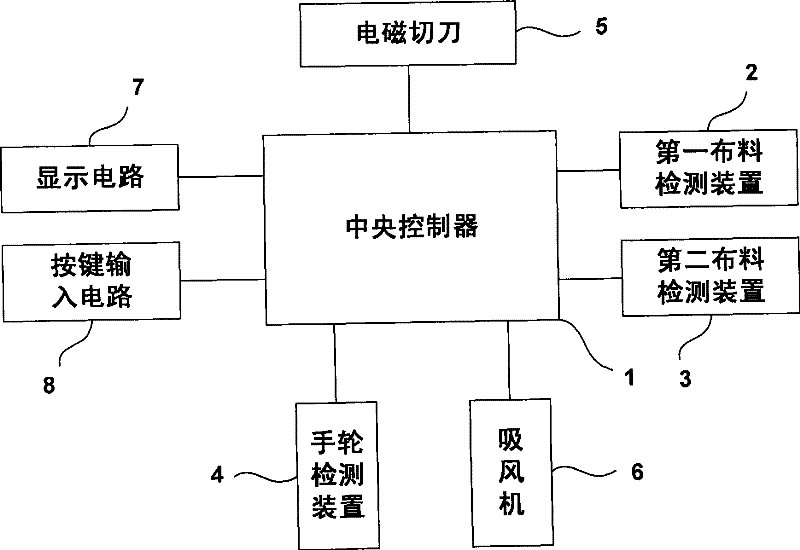

Automatic tangent apparatus of overedger

InactiveCN101676468AIncrease profitReduce labor intensityNeedle severing devicesKey pressingElectricity

The invention discloses an automatic tangent apparatus of an overedger, which comprises a centre controller, a first cloth detection apparatus, a handwheel detection device, an electromagnetic cuttingknife, a suction fan, a display circuit and a button input circuit. The centre controller electrically connects with the first cloth detection apparatus, the handwheel detection device, the electromagnetic cutting knife, the display circuit and the button input circuit respectively; wherein, the first cloth detection apparatus is arranged on a feeding cloth side of a feeding cloth table of the overedger, the handwheel detection apparatus is used for detecting a turning circle number of the handwheel of the overedger. A cutting-line work can be automatically completed by the apparatus provided by the invention, which can reduce labor intensity of operators, simultaneously, a cutting-line length can be controlled accurately which can increase utilization ratio of the line, thereby, increase production efficiency greatly.

Owner:SHANGHAI AKITA ELECTRICAL TECH

Cloth cutting device

ActiveCN108004758AReduce wasteAvoid constant proliferationTextile selvedgesSevering textilesHydraulic cylinderPulp and paper industry

The invention relates to the field of textile and particularly discloses a cloth cutting device. The cloth cutting device comprises a frame, a hydraulic cylinder, a cutter, a worktable and a glue applying mechanism, wherein the frame is fixedly provided with a guide bar and a spring; the piston rod of the hydraulic cylinder is fixedly provided with a sliding bar; the cutter is fixed onto the sliding bar; the worktable is provided with a sliding groove; a rotating block is hinged to the sliding bar, and the hinge point of the rotating block and the sliding bar is arranged at the bottom of the rotating block; the hydraulic cylinder is provided with an L-shaped separating blade; the glue applying mechanism comprises a glue storage tank and an air cylinder, the glue storage tank is provided with a glue inlet, the air cylinder is provided with a glue inlet check valve, and the glue storage tank is communicated with the glue inlet check valve; the piston of the air cylinder is fixedly provided with a glue outlet check valve, the inside of the air cylinder is provided with a pressure spring, the inside of the rotating block is provided with a cavity, and the side wall of the cavity is provided with a through hole. The cloth cutting device can avoid yarn slippage after cloth is cut.

Owner:NINGBO WENZE TEXTILE CO LTD

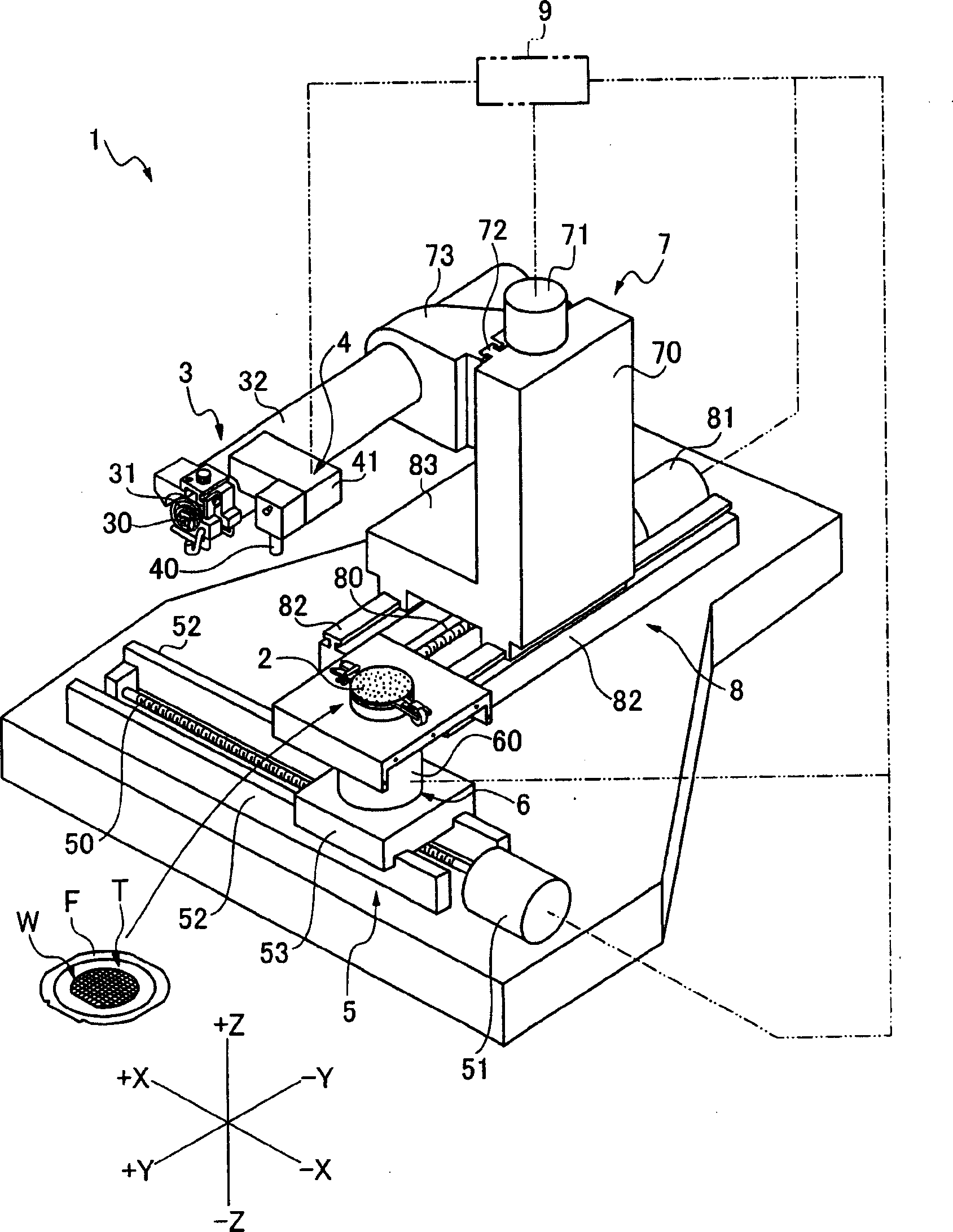

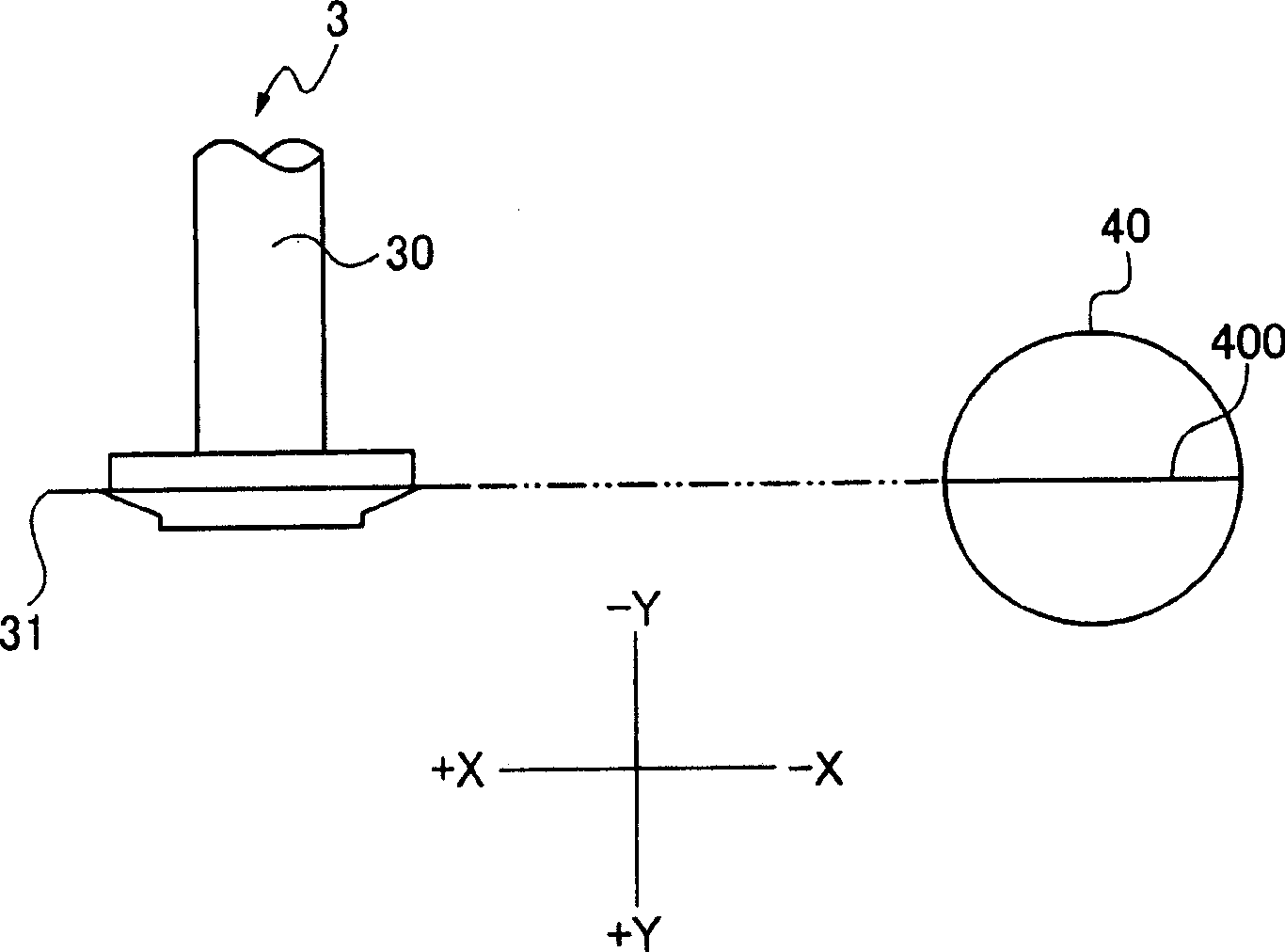

Method for detecting position displacement of cutting blades

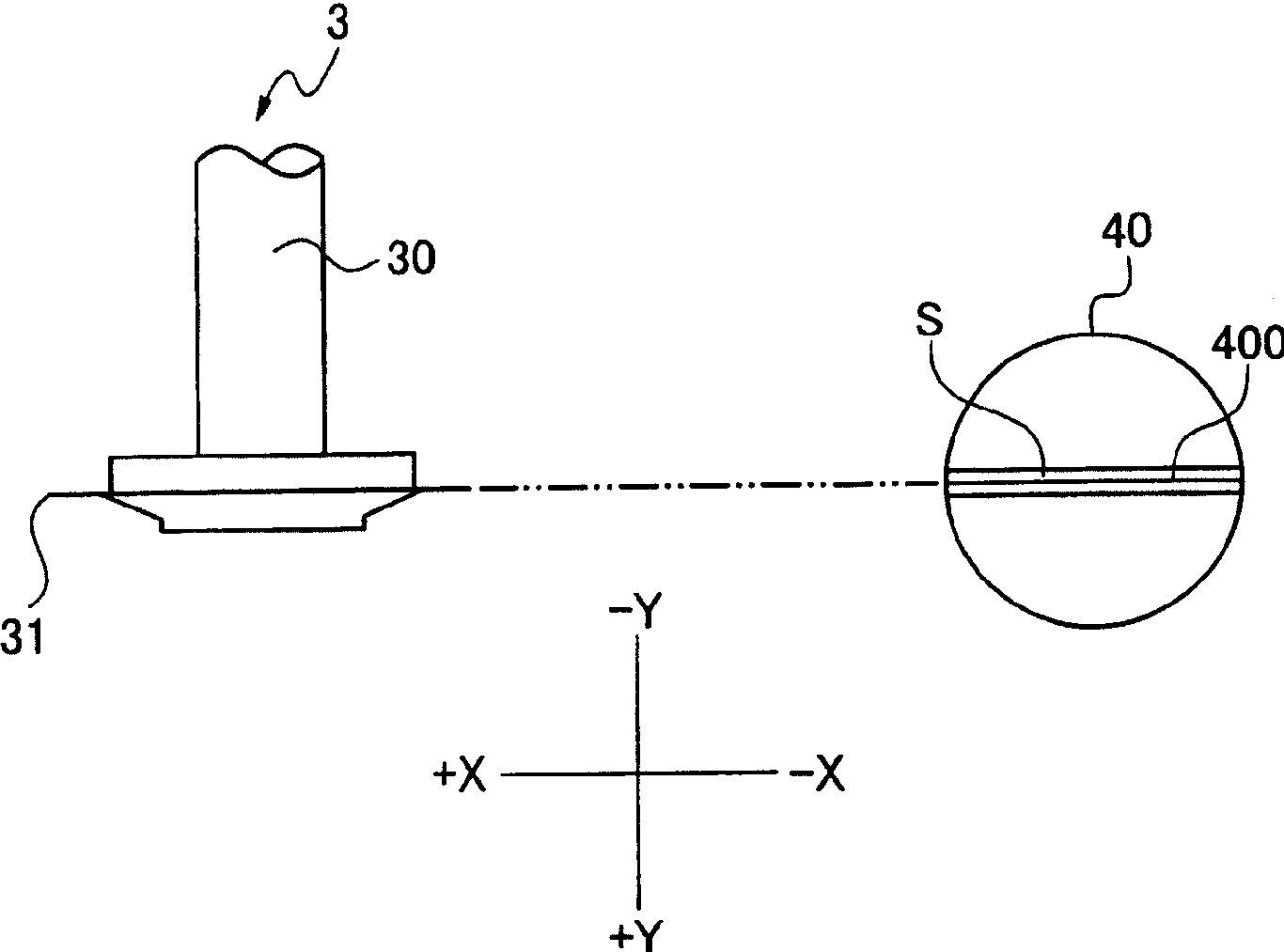

ActiveCN1691302APosition offsets are correctly detectedAvoid miscuttingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The objective is to exactly cut a desired position by exactly detecting the misregistration of a cutting blade in a cutting apparatus so as to prevent erroneous cutting. On the premise that a base line 400 and the cutting blade coincide with each other, an area to be cut and the base line 400 are made to coincide with each other. In a state that the base line 400 is made to coincide with the area to be cut, an objective area is cut. While index-feeding a cutting means by each space of the objective area, a plurality of the objective areas are cut. In addition to the cutting of a sheet-like matter, a cut flaw 100 is formed by making the cutting blade cut in a sheet-like matter absence area T1 to detect the positional displacement of the cut flaw 100 and the base line 400 by detecting the flaw 100 by an alignment means.

Owner:DISCO CORP

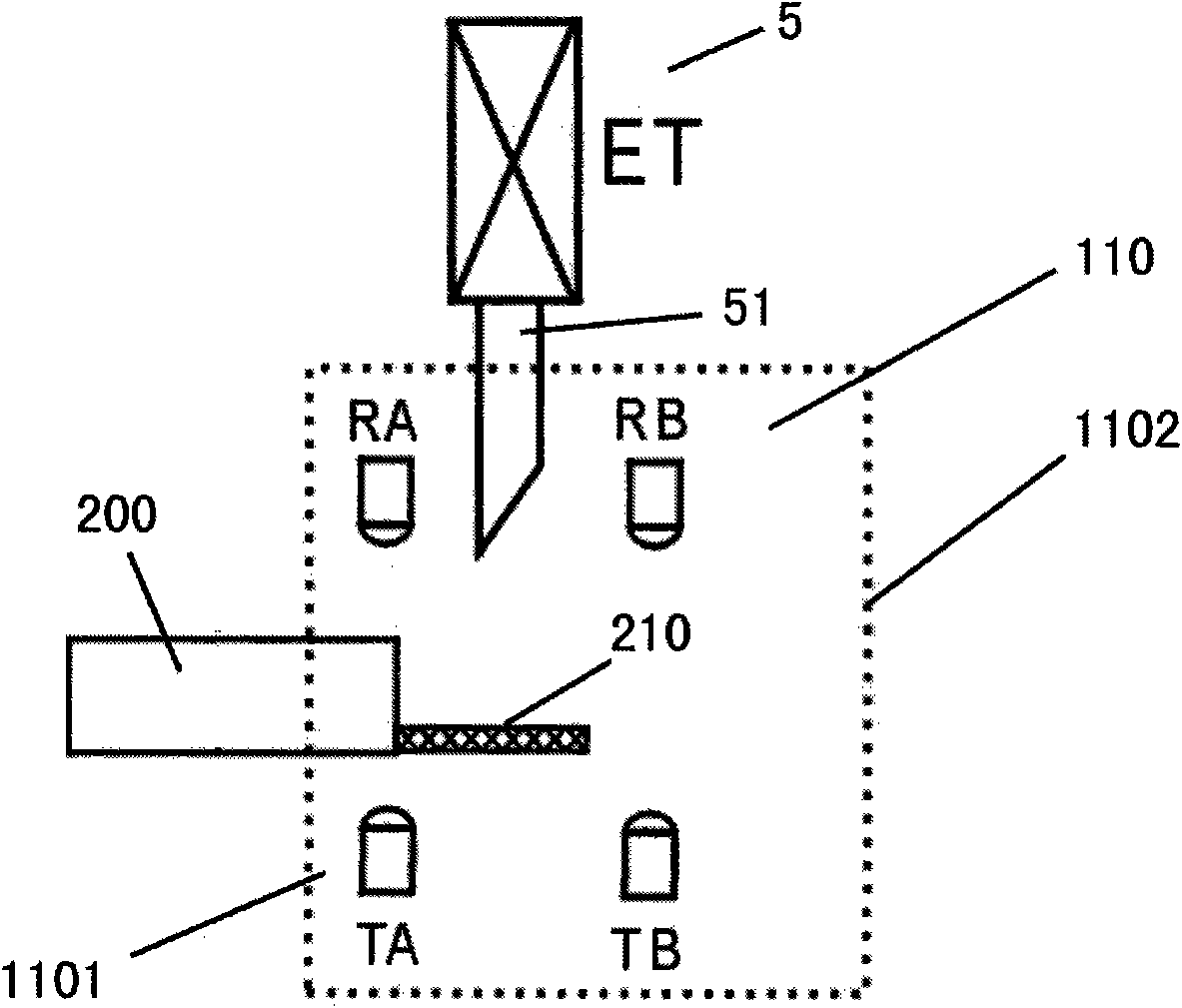

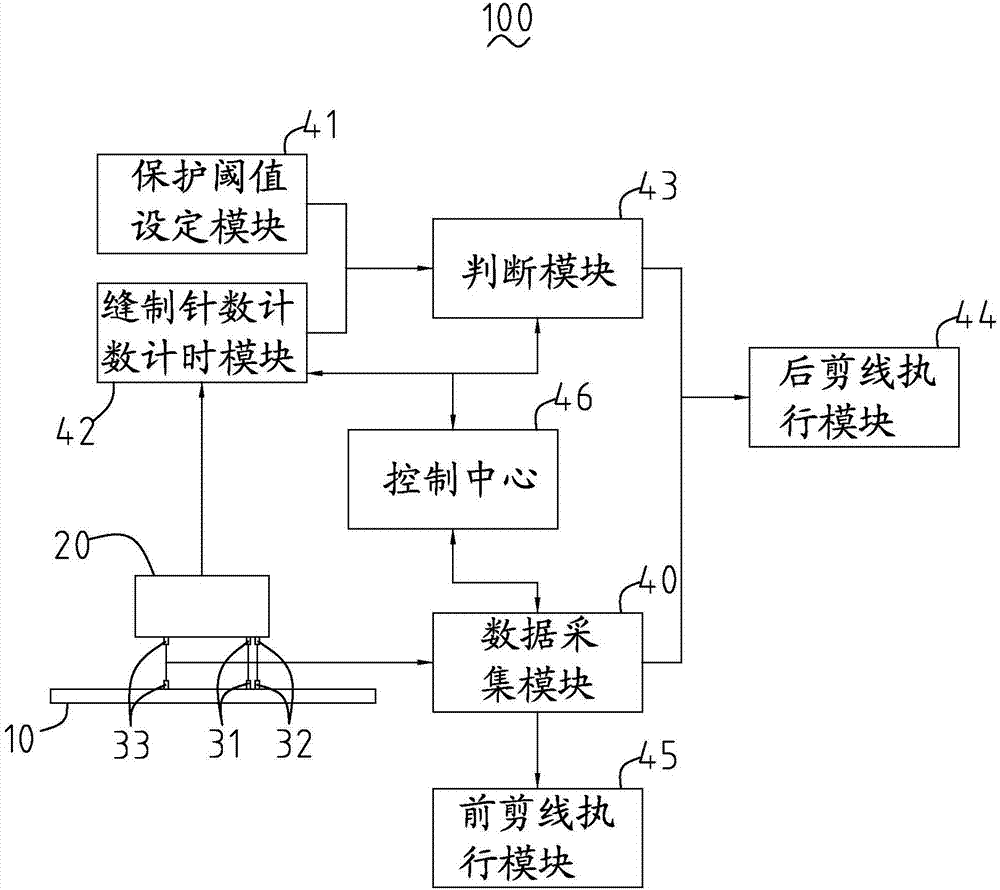

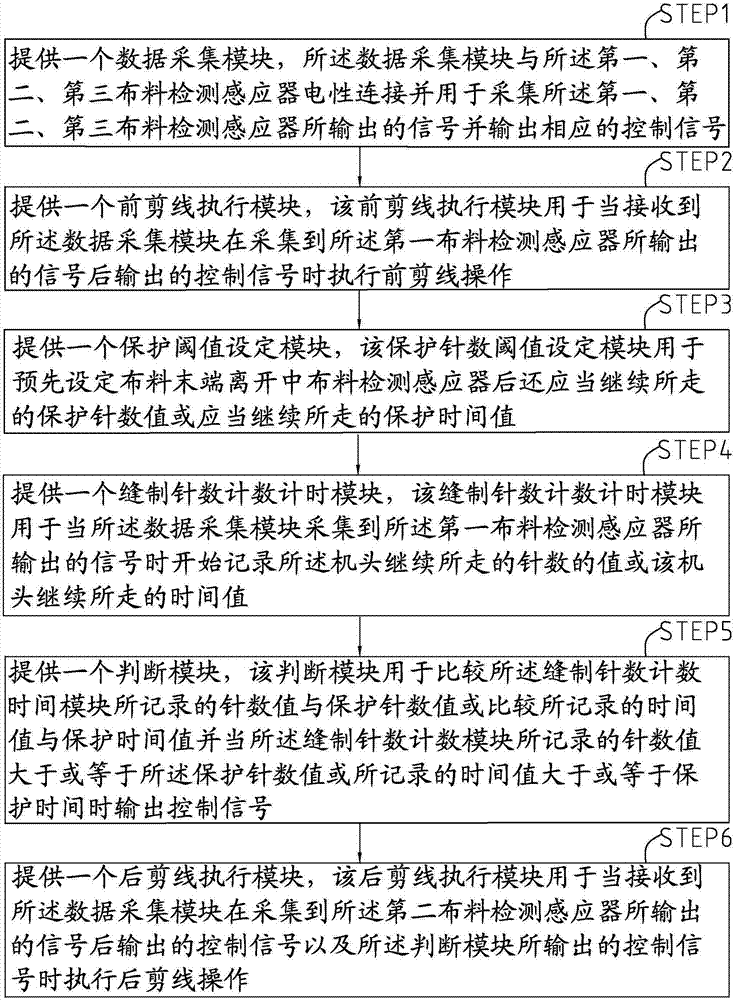

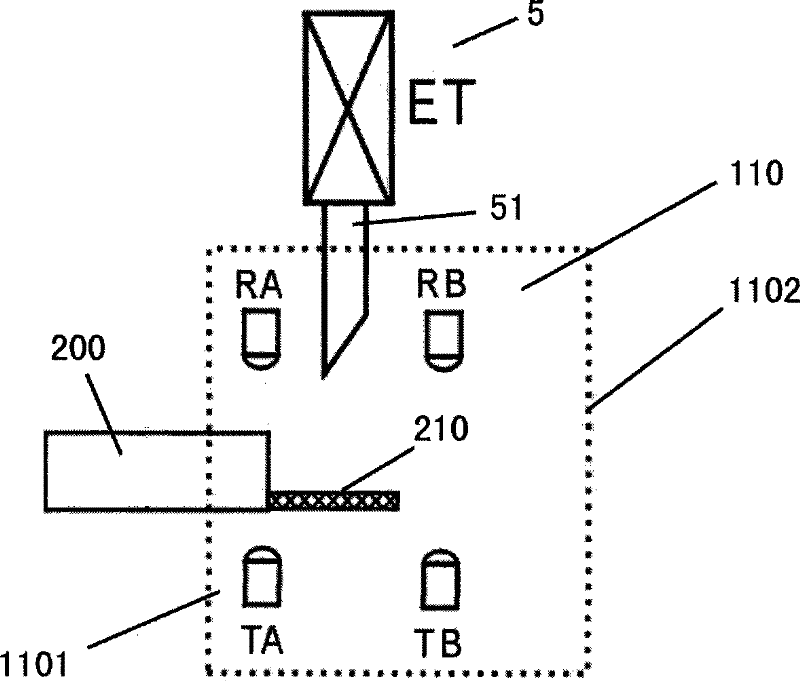

Anti-cloth-cutting device used for sewing machine and control method of anti-cloth-cutting device

The invention provides an anti-cloth-cutting device used for a sewing machine and a control method of the anti-cloth-cutting device. The device includes a data acquisition module, a protection threshold setting module, a sewing needle counting and timekeeping module, a judging module and a post-trimming execution module, wherein the data acquisition module is electrically connected with a first cloth detection sensor and a second cloth detection sensor. The post-trimming execution module is used for executing post-trimming when the data acquisition module receives a control signal output after the second cloth detection sensor outputs a signal and a control signal output by the judging module. According to the device and the method, only when the control signal output after the second cloth detection sensor outputs the signal and the control signal output by the judging module are received by the data acquisition module, can the post-trimming execution module execute post-trimming so that it can be ensured that well-sewn cloth is avoided from being cut by mistakes and whether the cloth becomes warped or is folded does not need to be worried about.

Owner:JACK SEWING MASCH CO LTD

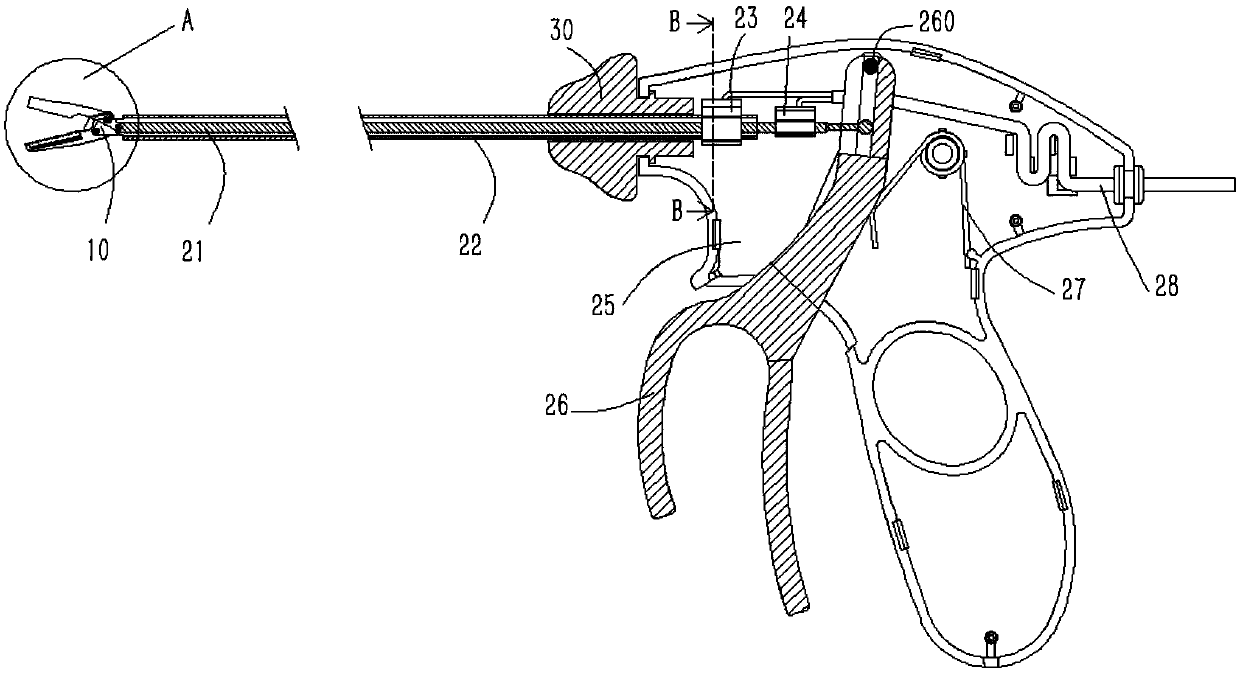

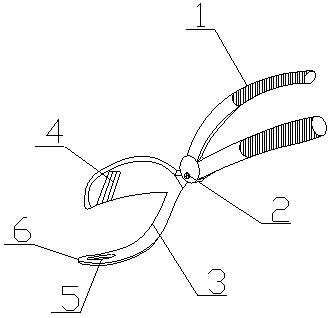

Bipolar coagulation electric knife

InactiveCN105496550AFunctionalSafe and reliable outputSurgical instruments for heatingTool bitRelative displacement

The invention provides a bipolar coagulation electric knife which comprises a tool bit assembly, a pull rod, an outer pipe and a handle assembly. The pull rod and the outer pipe are sleeved and isolated. The pull rod and the outer pipe are connected with a high frequency energy source through a twin-core conductor. The tool bit assembly comprises an acting pole tool bit, a loop pole tool bit, a loop pole tool bit insulating part and a middle insulating part arranged between the intersections of the acting pole tool bit and the loop pole tool bit. The handle assembly comprises a fixedly-arranged handle and a spanner capable of swinging relative to the handle. The loop pole tool bit insulating part is installed on the loop pole tool bit in the mode of being capable of insulating when the acting pole tool bit and the loop pole tool bit are closed. The loop pole tool bit and the outer pipe are connected, the acting pole tool bit is connected to the spanner through the pull rod, relative displacement is generated between the pull rod and the outer pipe through swinging of the spanner, and therefore the acting pole tool bit and the loop pole tool bit can be opened or closed. According to the bipolar coagulation electric knife, electrocoagulation and electric cutting instruments do not need to be replaced frequently, and the operation time is saved.

Owner:SCANMED CHINA

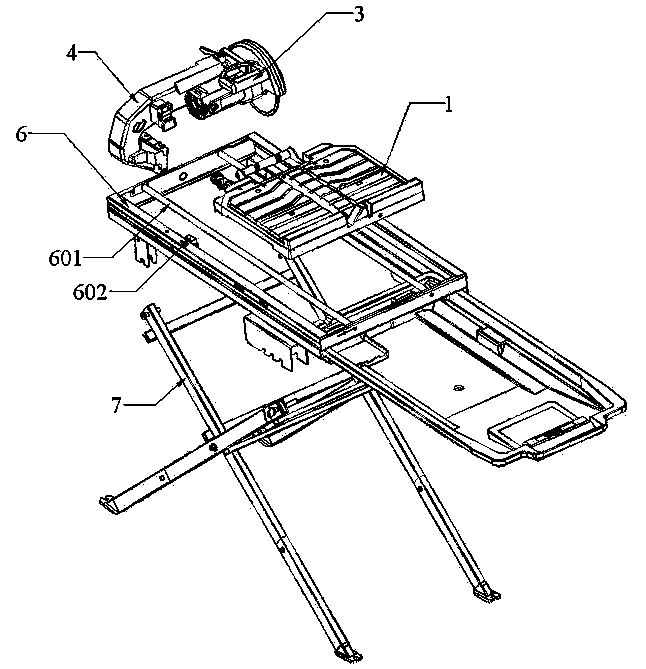

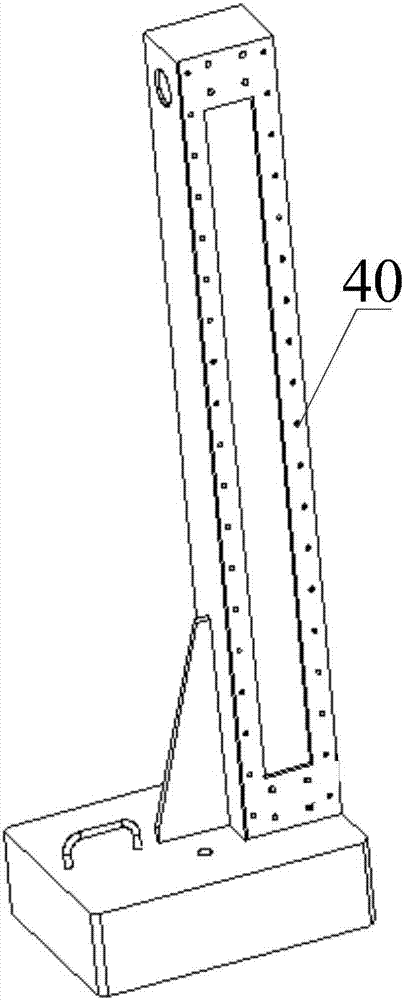

Table-type cutting machine and cutting work table thereof

ActiveCN104210034AAvoid miscuttingEffectively fixedMetal sawing devicesWorking accessoriesMechanical engineeringWorkbench

A cutting worktable includes a worktable body have a distal side located away from a cutting tool and a proximal side located adjacent to the cutting tool. The cutting worktable further includes a support frame assembly disposed at the proximal side of the worktable body and used to lift an object to be cut so that the object to be cut is placed on a top surface of the worktable body in an inclined posture. The support frame assembly includes a support roller for contacting the object to be cut and the worktable body is provided with a limiting structure for abutting against the object to be cut and limiting its position. The object to be cut can thus be inclined via the support frame assembly and fixed by the limiting structure. The limiting structure can be in the form of a plurality of placement grooves to achieve placement of the object to be cut at different angles relative to the cutting tool and worktable.

Owner:NANJING CHERVON IND

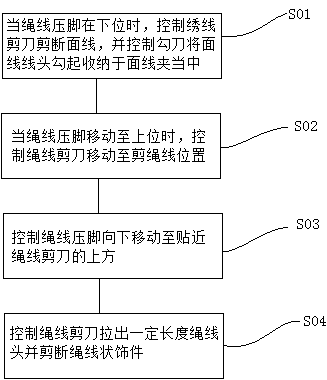

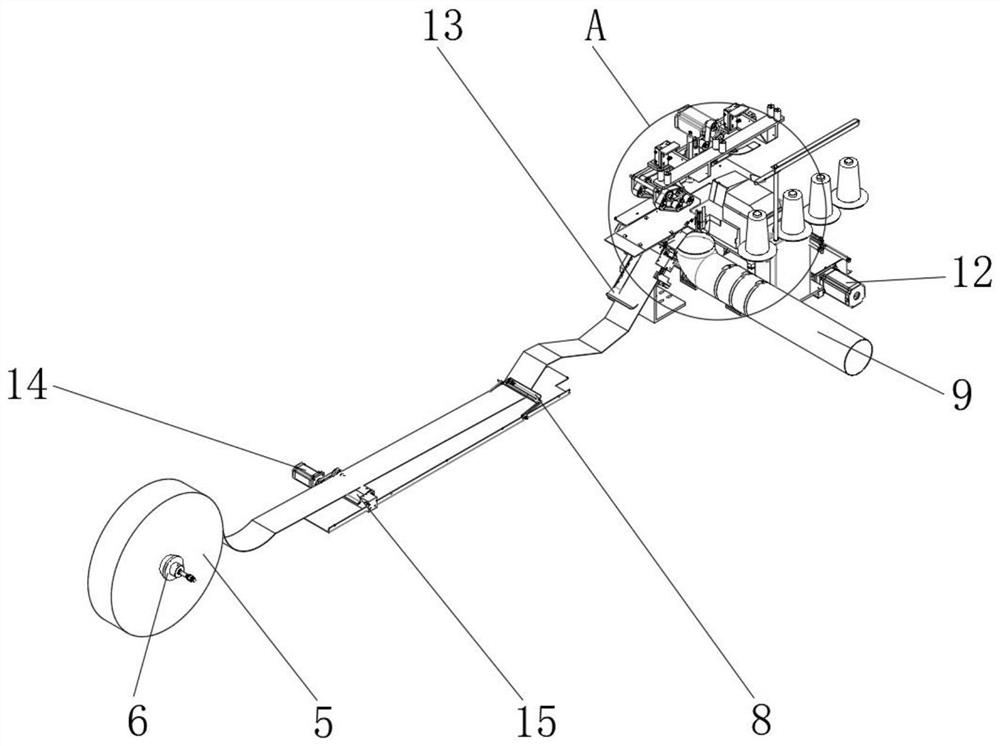

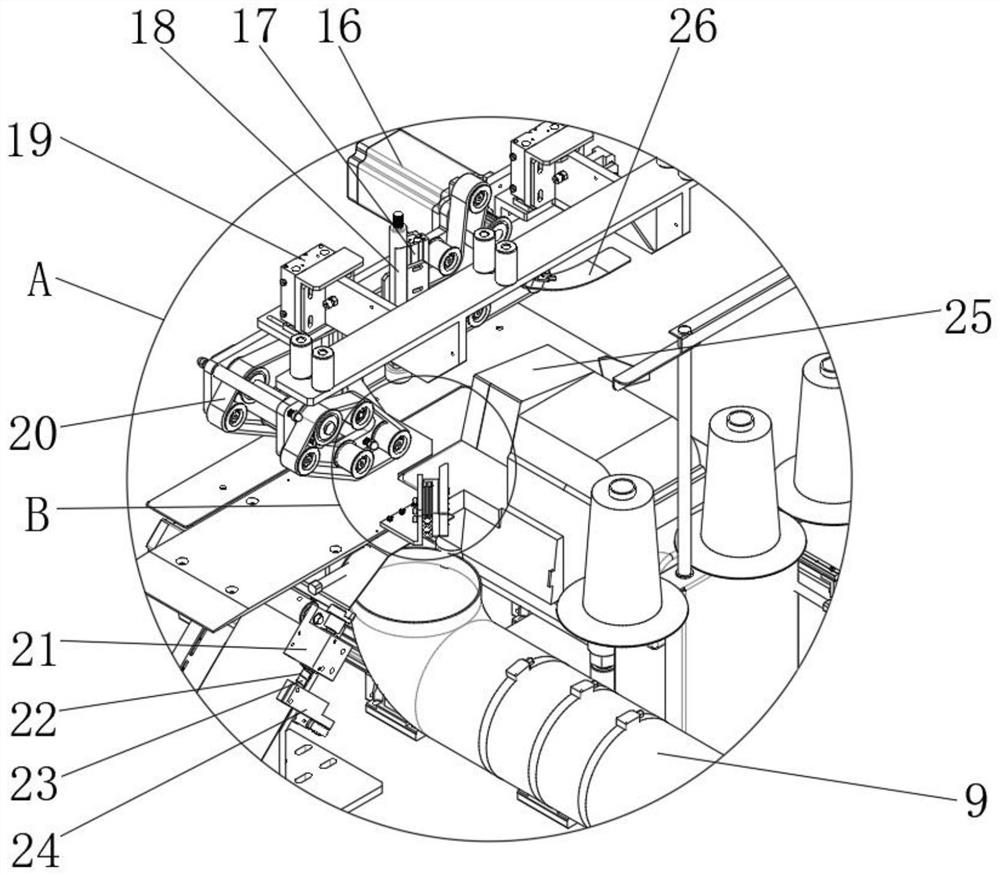

Thread trimming method and thread trimming control device of embroidery machine for sewing rope yarn-shaped ornaments

ActiveCN111206350AControl lengthThread trimming orderlyAutomatic machinesAuxillary devicesYarnStructural engineering

The invention relates to a thread trimming method and thread trimming control device of an embroidery machine for sewing rope yarn-shaped ornaments and belongs to the technical field of embroidery machines. The method comprises the following steps of step S01, when a rope yarn presser foot is at a lower position, embroidery thread scissors are controlled to cut off an upper thread, and a hooking cutter is controlled to hook up an upper thread end and store the upper thread end in an upper thread clip; step S02, when the rope yarn presser foot moves to an upper position, rope yarn scissors arecontrolled to move to a rope yarn trimming position; step S03, the rope yarn presser foot is controlled to move downwards to the upper part close to the rope yarn scissors; and step S04, the rope yarnscissors are controlled to pull out a rope yarn end with a certain length and cut off a rope yarn-shaped ornament. The thread trimming control device is realized by adopting the method. The thread trimming control device is capable of intelligently controlling thread trimming of embroidery threads and rope yarns, avoiding error trimming and simultaneously improving the thread trimming efficiencyand the quality of embroidery.

Owner:浙江镨美科智能刺绣设备有限公司

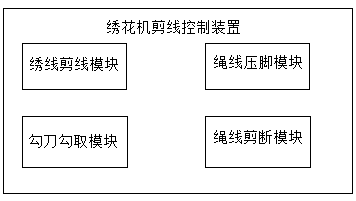

Rapid fixed-point method for metallic grounding fault of high-voltage cable joint

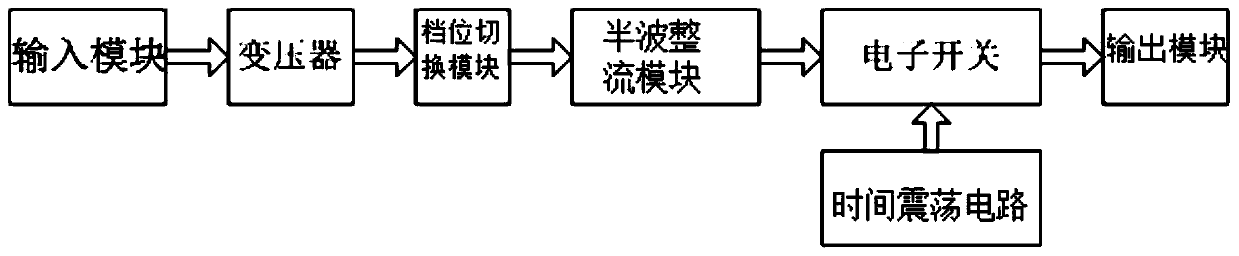

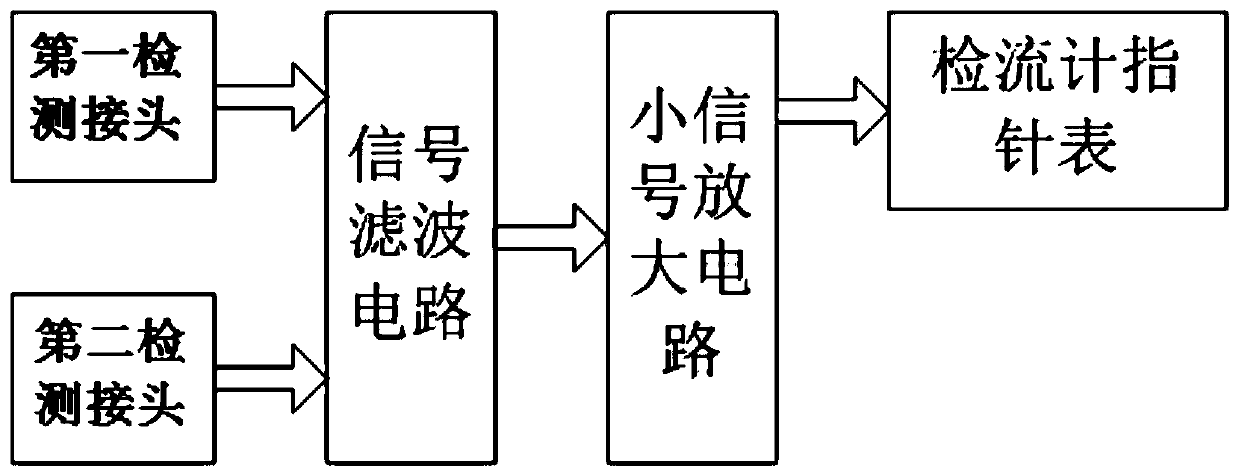

ActiveCN110346679AAvoid MiscuttingLess susceptible to interferenceFault location by conductor typesTransformerComputer module

The invention provides a rapid fixed-point method for a metallic grounding fault of a high-voltage cable joint. The method comprises the following steps: (1) inputting a step voltage signal source byan input module, a transformer, a gear switching module, a half-wave rectifying module, a time and driving circuit module and an output module; (2) performing step voltage signal detection by utilizing a step voltage indicator composed of a signal connecting module, a signal filtering circuit module, a signal amplifying circuit module and a galvanometer pointer table; and (3) determining a fault point. According to the method, the position of the fault point can be rapidly and accurately found in the metallic grounding cable fault of the joint, and the interference of external signals is not easily caused.

Owner:GUANGDONG POWER GRID CO LTD +1

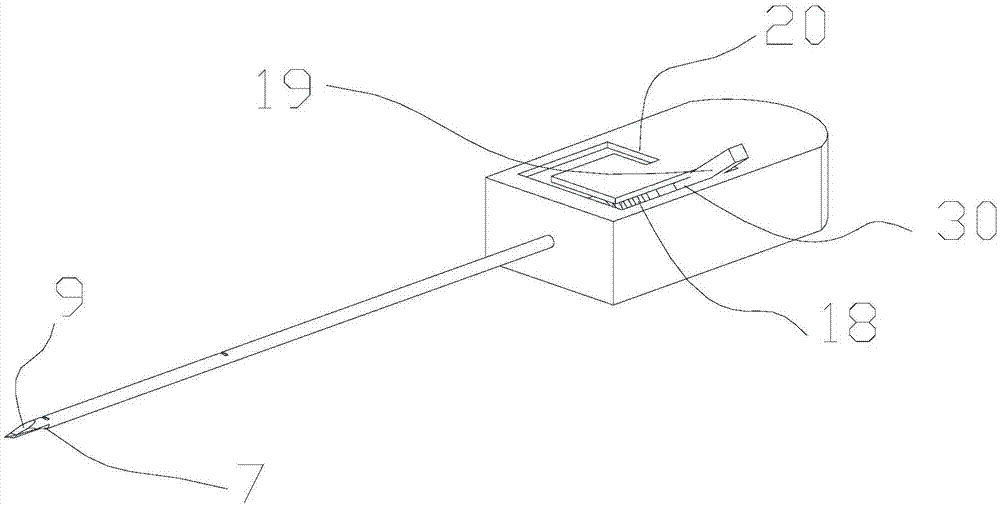

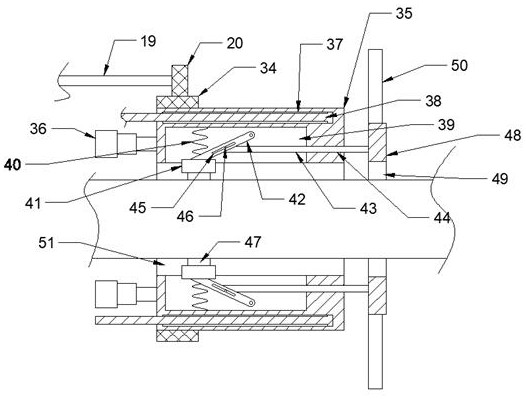

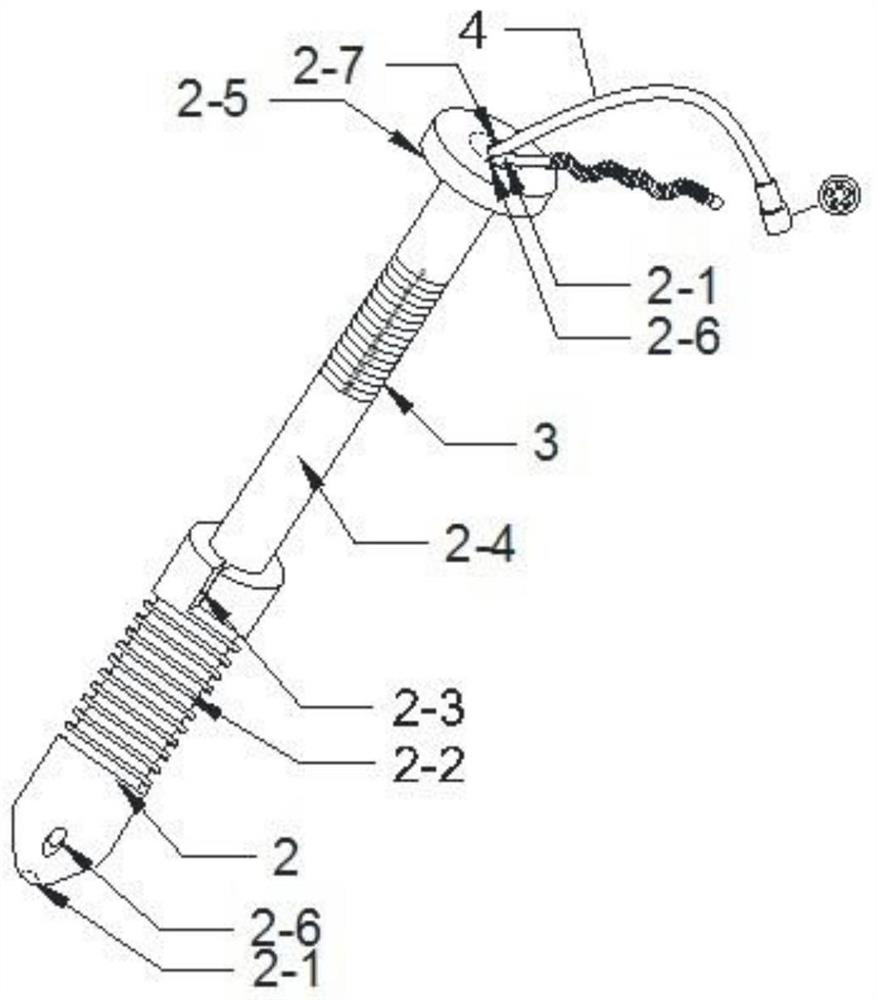

Needle knife

PendingCN106963454AImprove securityReduce the risk and complications of blindsight surgeryIncision instrumentsAcupunctureBiomedical engineeringNeedle knife

The invention discloses a needle knife. The needle knife comprises a needle handle and a first needle body. The needle handle is provided with a movable device; one end of the first needle body is fixed to the movable device, and the other end of the first needle body is provided with a needle edge or a dull edge; a second needle and the first needle are arrange side by side in the length direction; the second needle body is fixed to the movable device, and the other end of the second needle body is provided with a cutting sharp edge; the second needle body or the first needle body is driven by the movable device so that the second needle body and the first needle body can move relative to each other, and a first work station and a second work station are formed respectively; when the needle knife is located on the first work station, the needle edge or the dull edge goes beyond the cutting sharp edge so that the needle edge or the dull edge can work and the cutting sharp edge cannot work; when the needle knife is located on the second work station, the cutting sharp edge goes beyond the needle edge or the dull edge so that the cutting sharp edge can work and the needle edge or the dull edge cannot work. The combined needle knife can provide the function of free switching between the dull edge and the cutting sharp edge, and all parts of the needle knife are allowed to move in a retractable mode so as to provide quick selective operation of sharp, dull and special functions of the needle knife for a doctor.

Owner:刘旭 +1

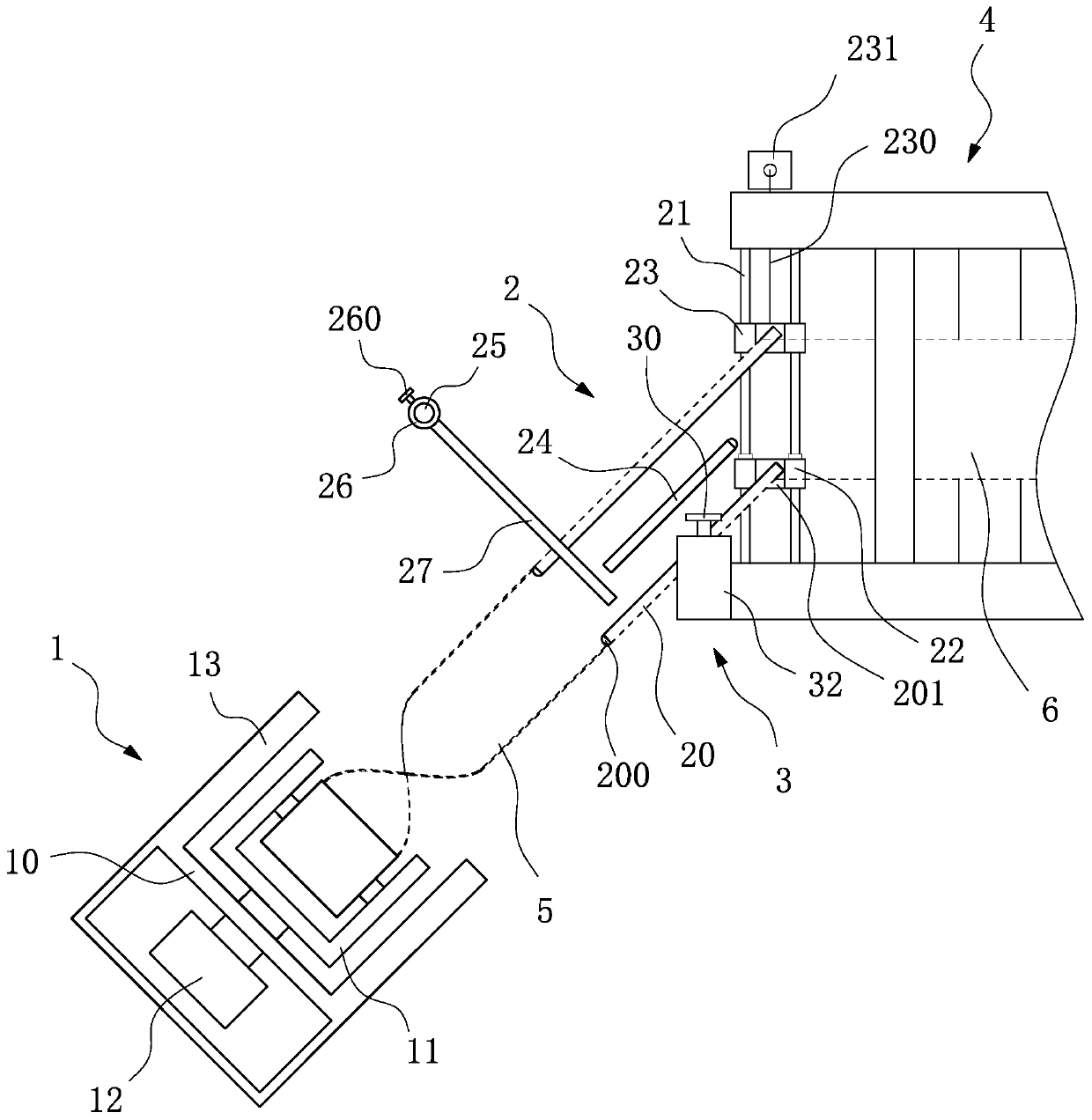

Plate positioning device for laser cutting

ActiveCN111331267APrecise positioningAccurate feeding positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The invention discloses a plate positioning device for laser cutting. The plate positioning device comprises a base frame in butt joint with a laser cutting device, wherein a plate centering positioning frame is arranged on the base frame and comprises a first moving frame and a second moving frame which are oppositely arranged; a plurality of first rotating rollers are arranged on the first moving frame; a plurality of second rotating rollers which are as high as the first rotating rollers are arranged on the second moving frame; inserting gaps are formed between the adjacent first rotating rollers and between the adjacent second rotating rollers correspondingly; the first rotating rollers and the second rotating rollers are arranged in a staggered mode and form a conveying roller way; and plate positioning conveying mechanisms are arranged on the first moving frame and the second moving frame correspondingly. According to the plate positioning device, plates are centered, positionedand conveyed, the to-be-cut plates are fed into the laser cutting device at a fixed placement position, thus precise positioning feeding of the laser cutting device is achieved, and the cutting efficiency and the cutting progress are effectively improved.

Owner:GUANGDONG SAMPU GARAGE CO LTD +1

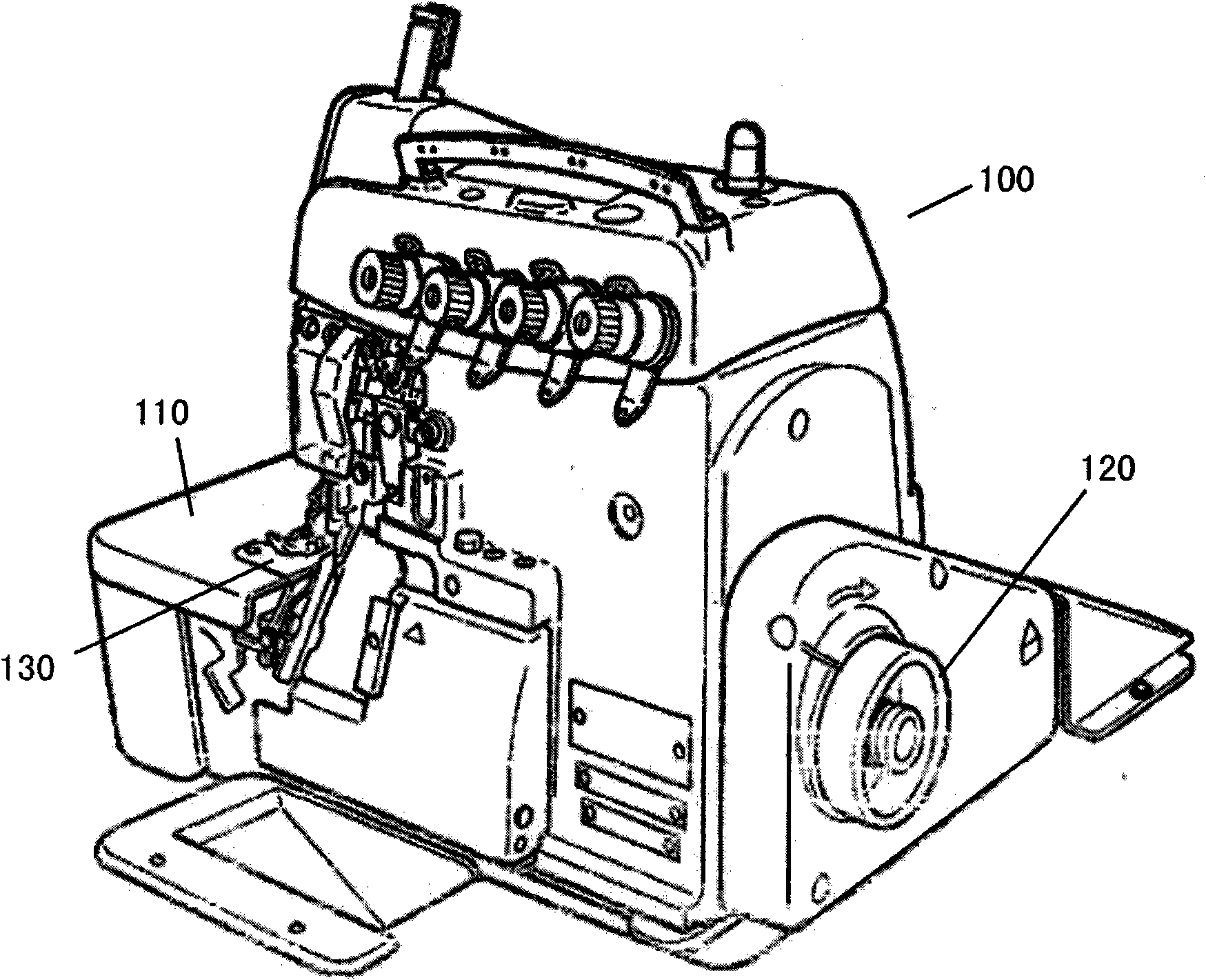

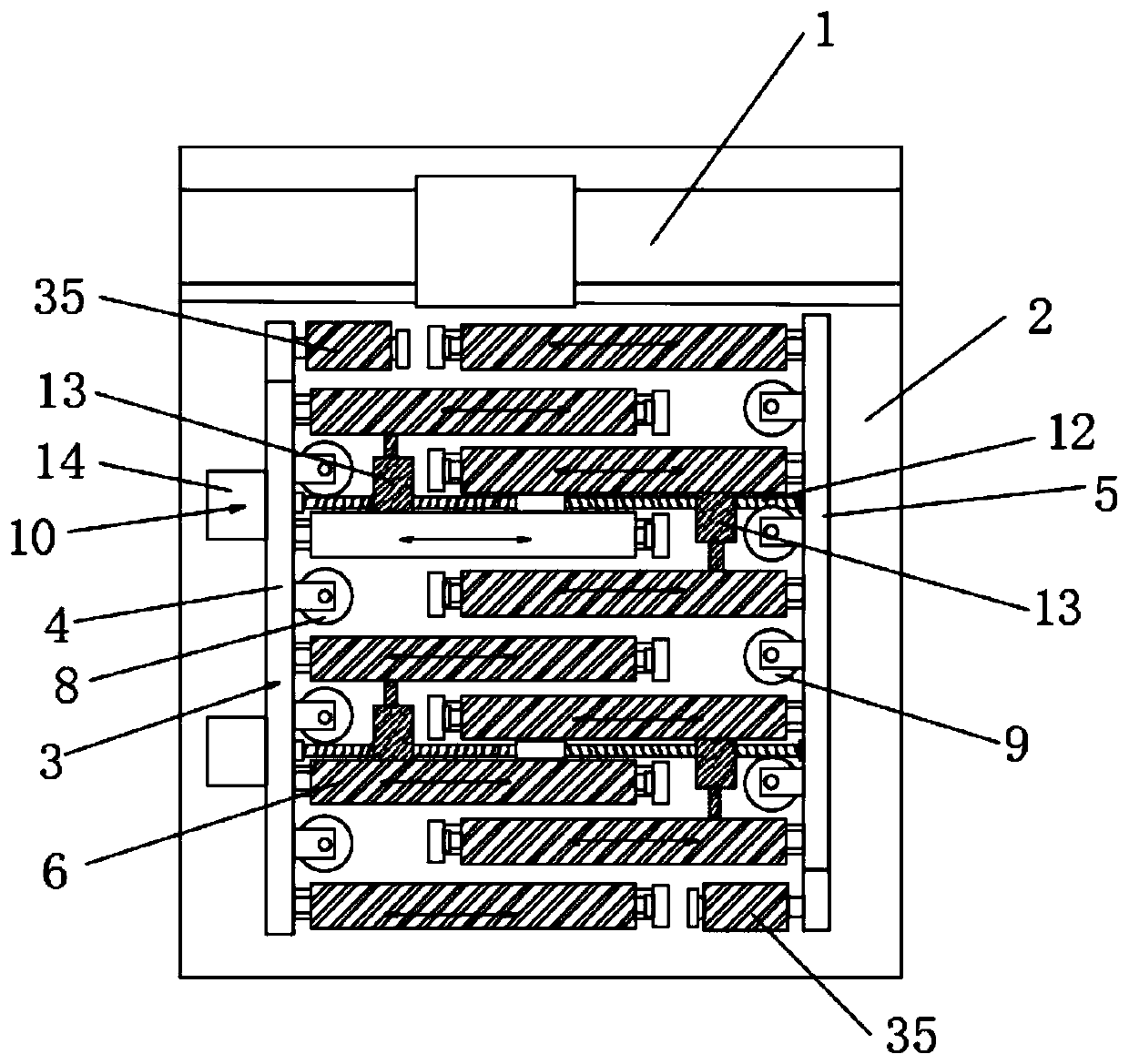

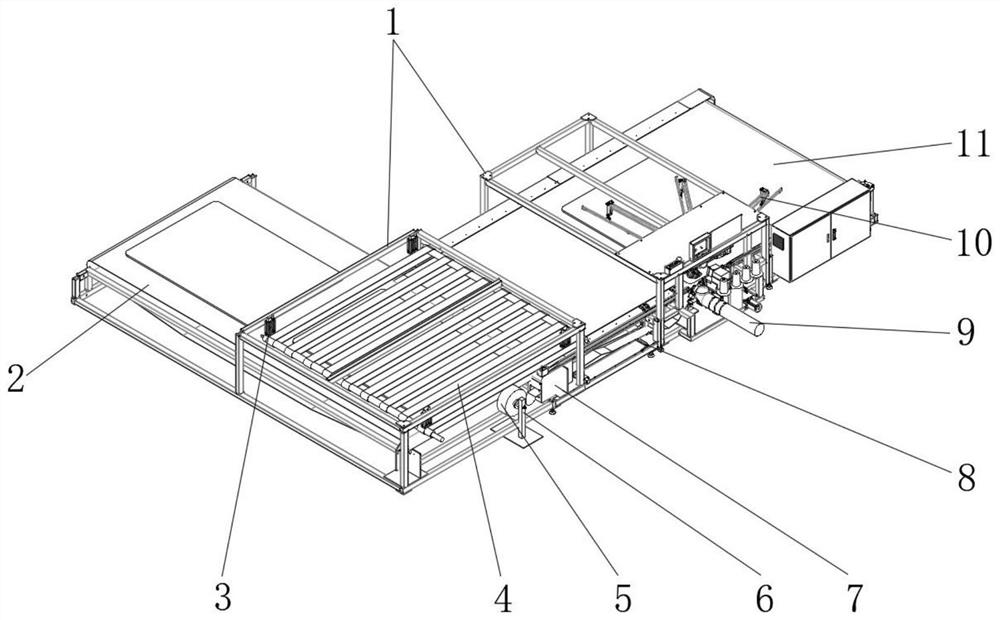

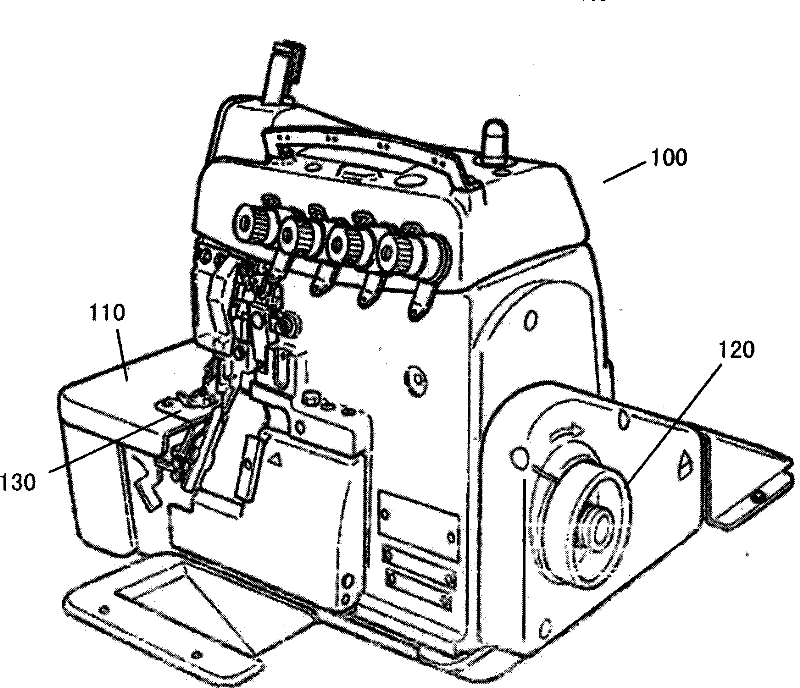

Mattress surrounding edge overlock sewing machine

PendingCN112301560AQuality improvementAvoid miscuttingWorkpiece carriersWork-feeding meansElectric machineryMachining

The invention discloses a mattress surrounding edge overlock sewing machine, and relates to the technical field of mattress production and processing. Round corners are more tightly surrounded under the condition of guaranteeing product quality. The machine specifically comprises a main body frame, a feeding conveying belt, a machining conveying belt, a lining belt conveying mechanism, an edge surrounding mechanism, a cutting mechanism and a mistake-cutting preventing mechanism, wherein the machining conveying belt is arranged on inner walls on two sides of the main body frame, the feeding conveying belt is arranged on inner walls on the other two sides of the main body frame, the lining belt conveying mechanism comprises a lining belt mounting frame used for mounting a surrounding edge lining belt, a lining belt conveying motor, a lining belt conveying wheel and an adjustable feeding set, the lining belt conveying mechanism is arranged below one side of the machining conveying belt, and the surrounding edge lining belt is wound on the outer wall of the lining belt mounting frame. Through arrangement of a guide plate and a guide seam, the quality of surrounding edge overlock at theround corners of a mattress can be improved; and meanwhile through arrangement of a protection air cylinder and a protection head, the mattress can be protected when the surrounding edge lining beltis cut by the cutting mechanism, and mistaken cutting is prevented.

Owner:苏州匠博智能科技有限公司

Edge cutting equipment for processing soft package foil of battery

ActiveCN114700993AEasy to useFast processingCell component detailsMetal working apparatusElectric machineryEngineering

The invention relates to the technical field of battery soft wrapping foil processing, in particular to edge cutting equipment for battery soft wrapping foil processing, and the edge cutting equipment comprises an operation table, a pushing assembly, a feeding assembly, an adjusting assembly, a cross rod and a fourth motor, according to the edge cutting equipment, feeding is conducted through the feeding assembly, and the edge cutting position of a soft wrapping foil battery is adjusted through the adjusting assembly; according to the edge cutting equipment, the pushing assembly is matched with the blade to conduct edge cutting machining on the soft wrapping foil battery, the edge-cut soft wrapping foil battery is taken down through the feeding assembly, the edge cutting equipment achieves the streamlined machining process of automatic feeding and discharging, edge cutting machining is conducted on the soft wrapping foil battery automatically, the machining speed is higher, and the machining efficiency is improved. According to the edge cutting equipment, the carrying, edge cutting, material taking and feeding operations are achieved on the soft-packed foil battery by moving the carrying plate left and right, the machining process exists in each movement of the soft-packed foil battery, a series of streamlined edge cutting machining is conducted on the soft-packed foil battery by moving the carrying plate left and right, and therefore the equipment is more compact in structure and smaller in size.

Owner:安徽力幕新材料科技有限公司

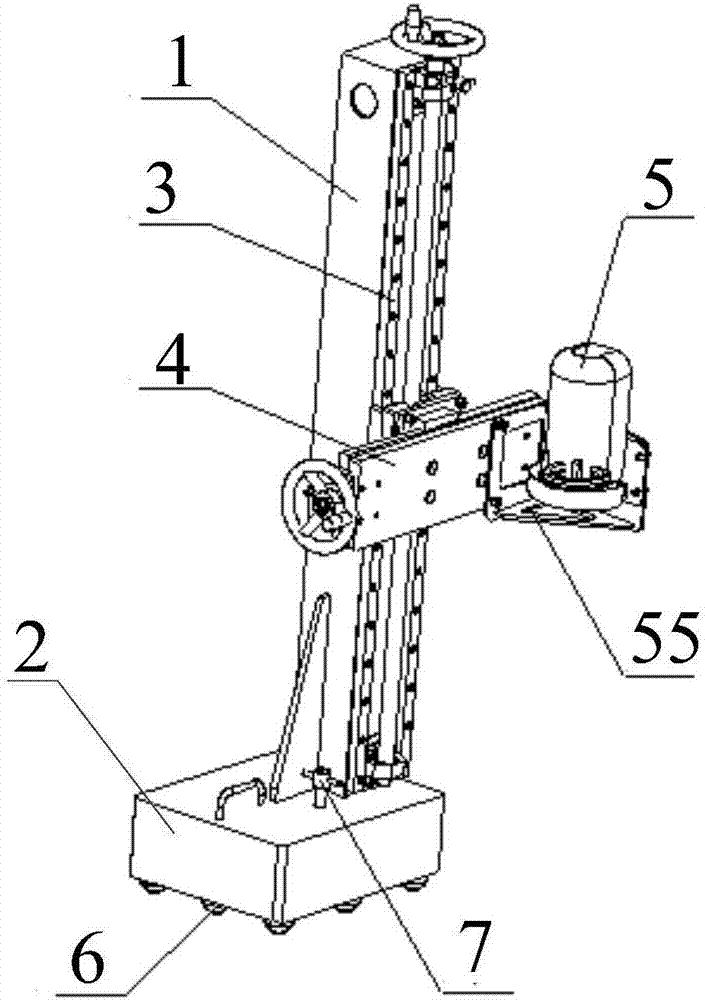

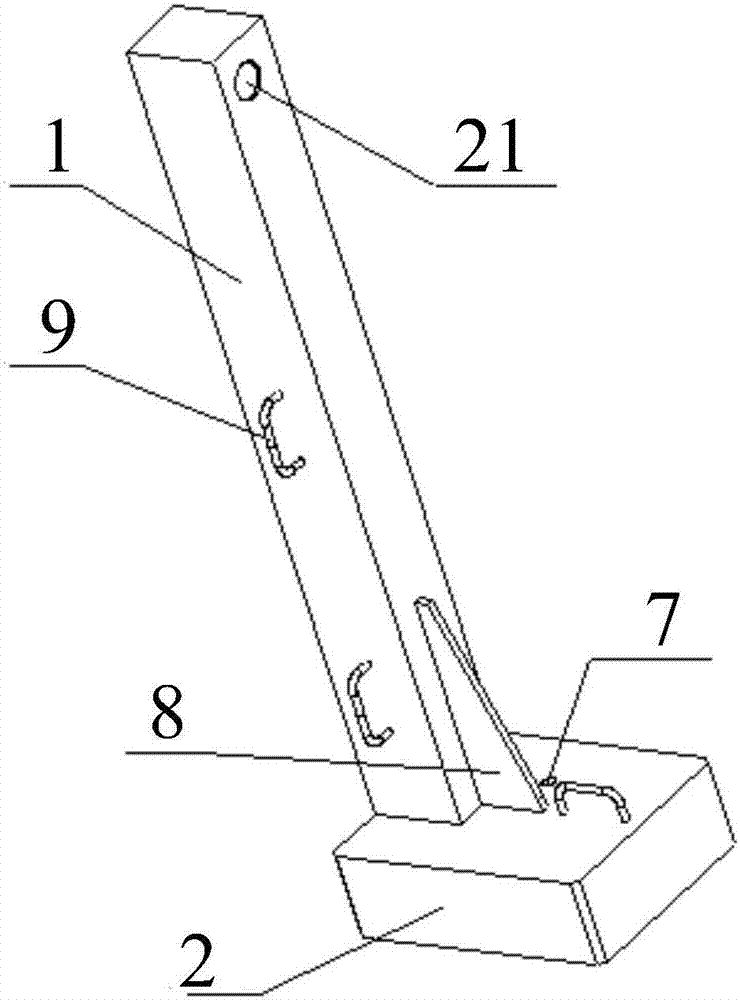

Cutting device

The invention provides a cutting device. According to the device, one end of a first supporting pillar is connected with one end of a base, and one side of the first supporting pillar is further provided with a perpendicular moving mechanism; the perpendicular moving mechanism is used for adjusting the position, in the vertical direction, of the cutting device; a horizontal moving mechanism is connected with the perpendicular moving mechanism through a driving plate; the horizontal moving mechanism is used for adjusting the position, in the horizontal direction, of the cutting device; the cutting device is connected with the horizontal moving mechanism through a second supporting pillar; a walking part is installed at the other end of the base; and thus, the position, in the vertical direction, of the cutting device can be adjusted according to the perpendicular moving mechanism, the position, in the horizontal direction, of the cutting device can be adjusted through the horizontal moving mechanism, the cutting device can accurately reach the cutting position, and the cutting precision is improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

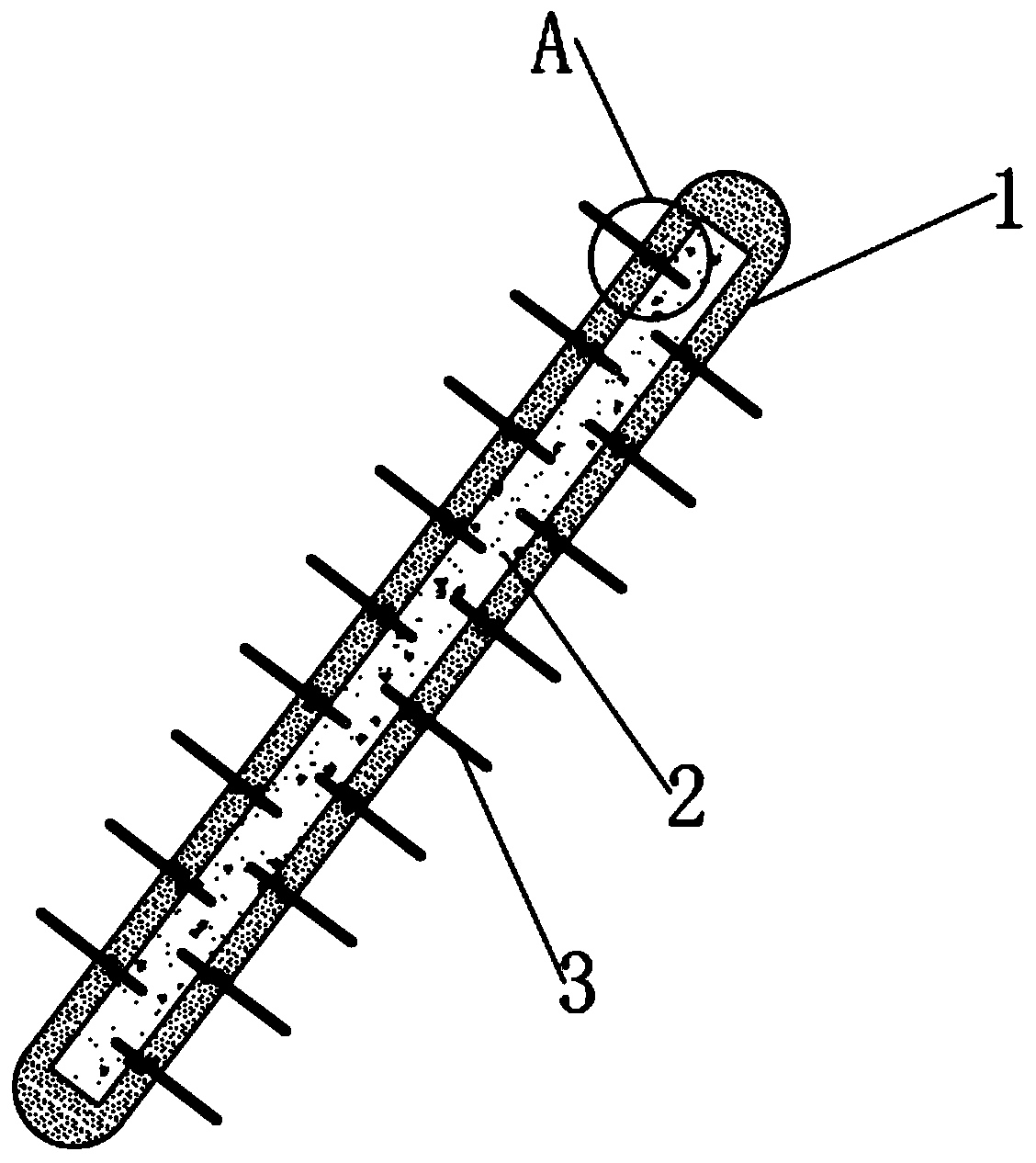

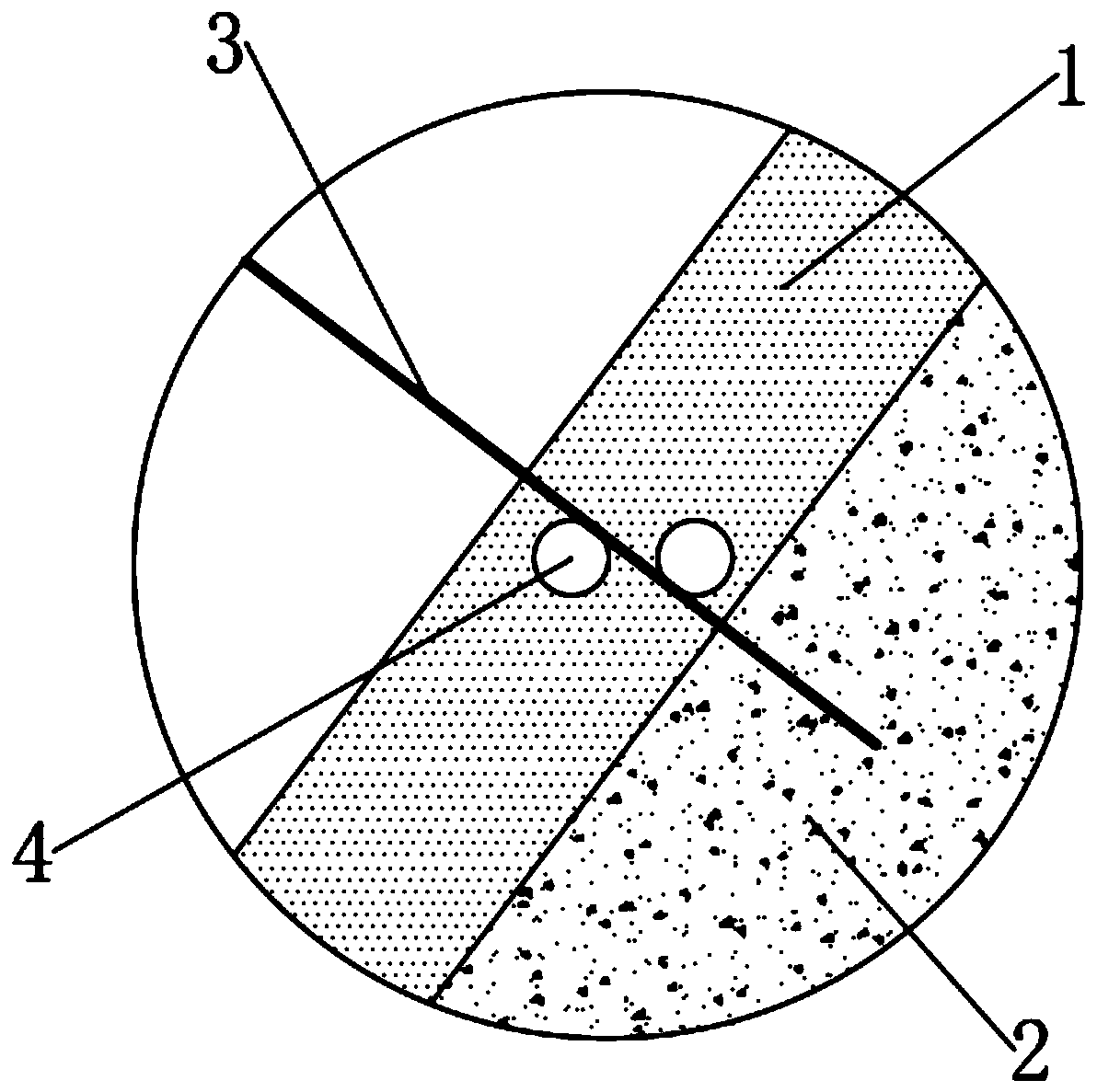

Scalp separating cutter

The invention discloses a scalp separating cutter which structurally comprises a handle, a connecting device, a cutter main body, a blade fixing pile, a cutter head clamping groove and a separating end. The connecting device is arranged between the cutter main body and the handle, a fixing piece is disassembled through a fixing hole, and then the fixing hole is separated from the connecting main body through an inner shaft rod, and then an inner shaft rod is separated in the connecting main body, so that the problem is solved that the space is occupied when the scalp separating cutter is placed after the scalp separating cutter is used. The back portion is of a handheld wood handle structure, so that comfort and stability during surgical cutting are improved, a blade is reversely fixed, scalp and subcutaneous tissues can be effectively separated when the scalp is cut in front of the scalp cutter, tissues such as the fascia, muscles, blood vessels, periosteum and the like are preventedfrom being cut by mistake, intraoperative bleeding is reduced, operation time is saved, and guarantee is provided for good prognosis of patients.

Owner:中国人民解放军联勤保障部队第九0四医院

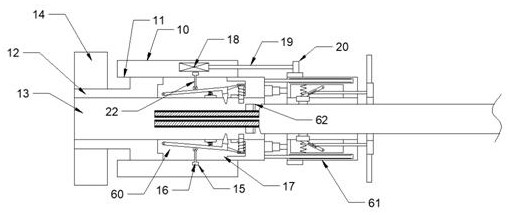

Equipment for quickly stripping optical fiber

InactiveCN112485862AHigh degree of automationImprove accuracyCoupling light guidesEngineeringMaterials science

The invention discloses equipment for quickly stripping an optical fiber. The equipment comprises an adjusting sleeve which is internally provided with a transmission hole which is through from left to right, the inner wall of the transmission hole is provided with a thread, the interior of the transmission hole is in threaded connection with an adjusting body, and the adjusting body is internallyprovided with a through groove which is through from left to right, and an adjusting handle is fixedly arranged on the left side of the adjusting body and located on the left side of the transmissionhole. By using the equipment, a sheath of the optical fiber is stripped according to the set depth, personnel participation is not needed in the working process, the automation degree is high, the device is provided with the shearing mechanism 62, and a shearing mechanism 62 can be used for shearing two optical fibers of the same optical fiber according to the requirement, the functions of distinguishing optical fibers of different colors and automatically cutting off unnecessary optical fibers are achieved, the shearing angle and position can be automatically judged, the shearing precision is improved, mistaken cutting off is avoided, the accuracy degree is high, and the efficiency is high.

Owner:福州妆缘红电子科技有限公司

Cutting equipment for foam sheet and working method of cutting equipment

The invention discloses cutting equipment for a foam sheet, and the equipment comprises a base, a movable seat, a cutter trend positioning mechanism, a support and a movable frame; two guide rails arearranged on the base, and a sliding plate is jointly connected between the two guide rails in a penetrating mode. The problem that the existing equipment still has certain defects during use can be solved: a large number of foam scraps are generated in the cutting process, and is not cleared timely, which affects the cutting efficiency, and is liable to cause the reduction of the cutting accuracy; the cutting direction of the existing cutting equipment is often adjusted by adjusting the direction of a slice in the cutting process, which enables the situation that cutting errors are caused byerrors due to the fact that the slice adjusting amplitude is too large to be extremely likely to happen; components for limiting the slice trend are lacked; meanwhile, in the oblique line or curve cutting process of existing equipment, direction and position adjustment needs to be continuously conducted on slices and foam sheets, which is very troublesome.

Owner:沃时派客(上海)包装科技有限公司

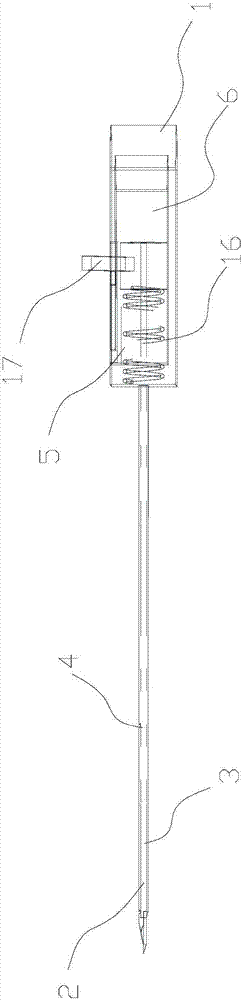

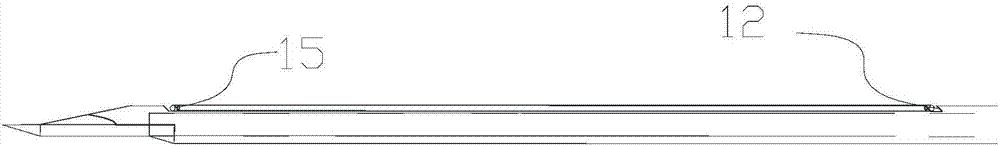

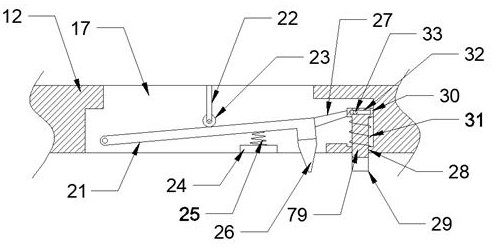

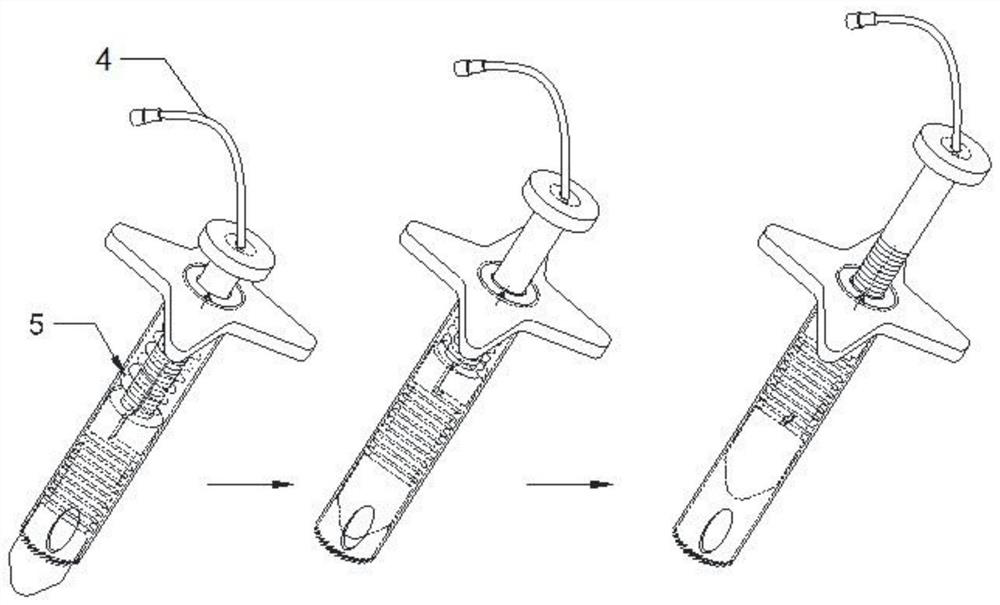

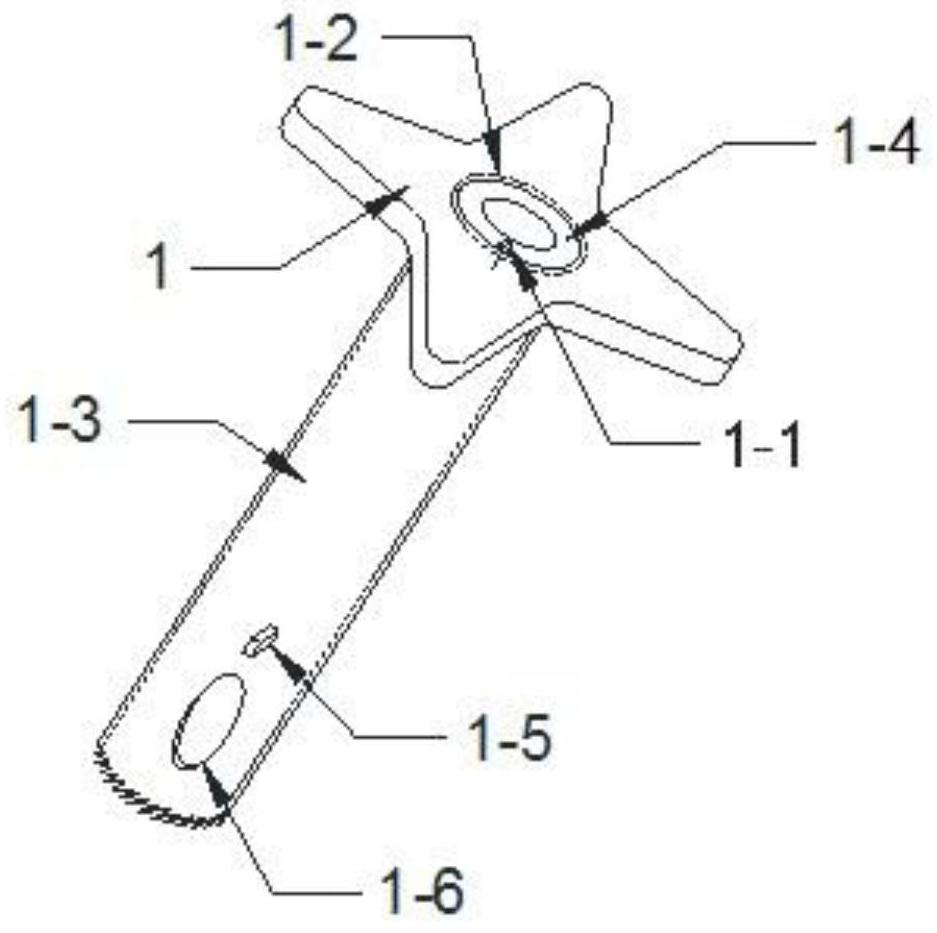

Multifunctional visible trepan for two-channel minimally invasive operation

PendingCN112754588APrevent trepanation from accidentally cutting nervesExpanded surgical field of viewDiagnosticsSurgical sawsSpinal operationPercutaneous

The invention discloses a multifunctional visible trepan for two-channel minimally invasive operation. The multifunctional visible trepan comprises a trepan body, a positioning device, a spring and an endoscope, wherein the trepan body is used in a percutaneous spinal operation; the positioning device is clamped in the trepan body and used for achieving a positioning effect; the spring is connected to the positioning device in a sleeving mode and located inside the trepan body; and the endoscope is located in the positioning device and used for enlarging the operation view field. The trepan can monitor the nerve position in real time and is prevented from cutting the nerve by mistake, when the trepan moves, the endoscope can follow up in time, the operation view field is enlarged, and tissue fluid at the affected part can be flushed and sucked in time.

Owner:青岛钰仁医疗科技有限公司

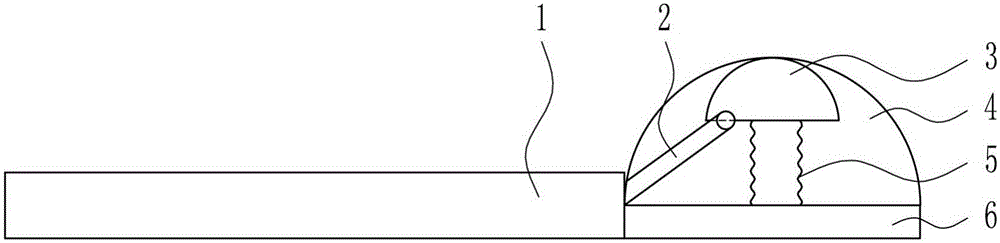

Cutting ruler for assisting tailoring

ActiveCN106197186APrecise croppingLength measurementMetal working apparatusRulers for direct readingEngineering

The invention relates to a cutting ruler, in particular to a cutting ruler for assisting tailoring and aims at achieving the technical effect of providing the cutting ruler for assisting tailoring with diversified assisting functions. The cutting ruler for assisting tailoring comprises a scale plate, a connecting rod, a pressing handle, an air bag, a first spring, a circular plate, a first outer scale, an inner scale, a sliding block, sliding rails, a blade and a movable plate; the circular plate is arranged on the right side of the scale plate, the air bag is arranged on the top of the circular plate, the first spring is arranged on the top of the circular plate, the pressing handle is arranged at the upper end of the first spring and located in the air bag, the connecting rod is connected to the left side of the bottom of the pressing handle in a hinged mode, the sliding rails are arranged on the front side and the rear side of the top of the scale plate respectively, and the sliding block is connected between the sliding rails. By the adoption of the first outer scale and a second outer scale, the length of the front side and the length of the rear side of cloth can be measured at the same time, size measuring time is saved, the scale plate does not need to be turned over, and the effort saving effect is achieved.

Owner:湖北鱼鹤制衣有限公司

Manufacturing method of semiconductor structure

ActiveCN111696968AAvoid miscuttingImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsEngineering

The embodiment of the invention relates to a manufacturing method for a semiconductor structure, and the method comprises the steps: forming a wafer stacking structure which comprises at least two wafers, wherein each wafer comprises a plurality of chips; performing a cutting step on the wafer stacking structure, and after the cutting step of the wafer stacking structure, enabling the plurality ofchips in the wafer stacking structure to be in an unseparated state; and carrying out the chip separation step, so that the chips in the wafer stacking structure are separated. According to the invention, the mistaken cutting of the chip in the wafer can be effectively avoided, and the performance of the semiconductor structure is improved.

Owner:CHANGXIN MEMORY TECH INC

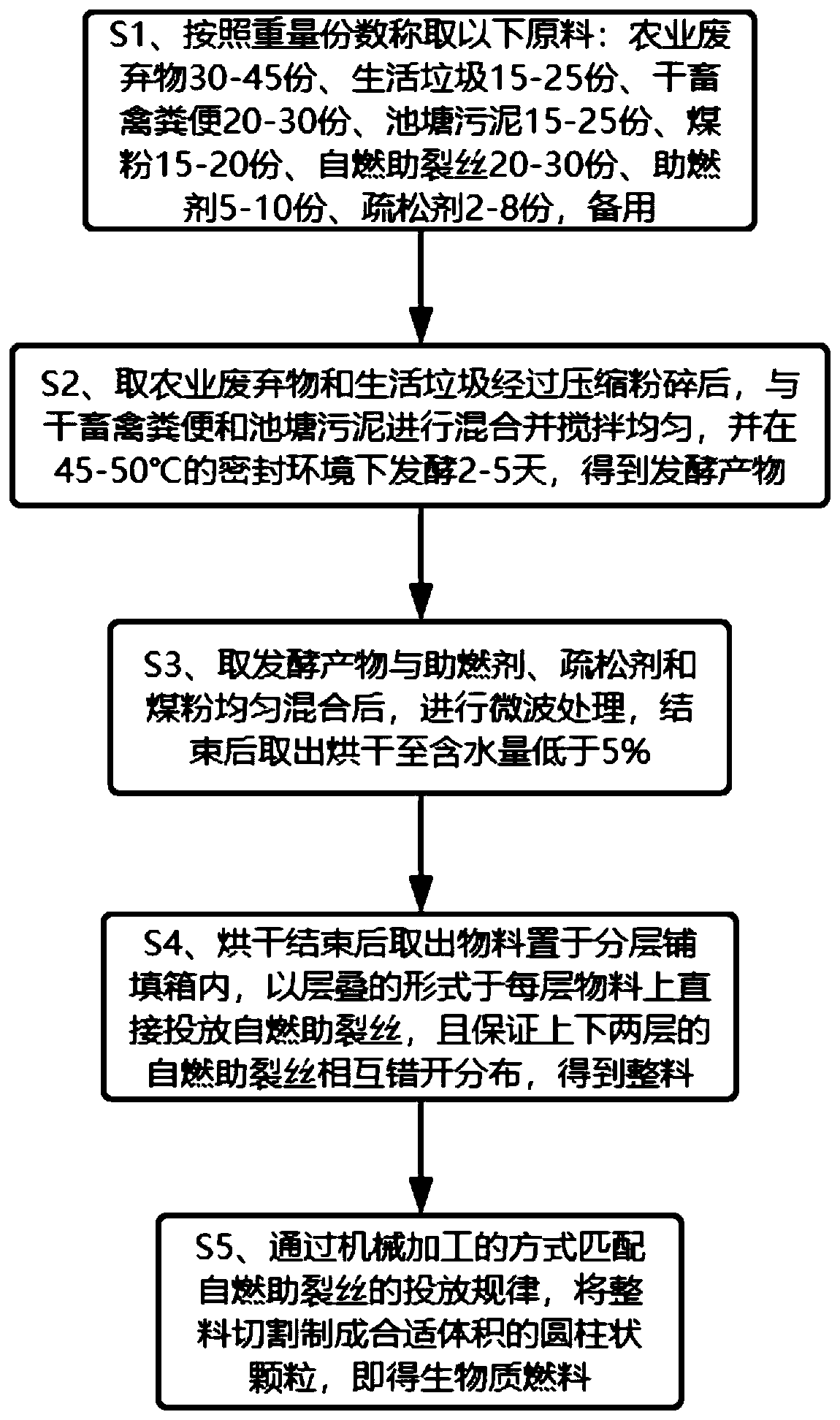

Preparation method of self-oxygen-supply type biomass fuel

ActiveCN111548837AIncrease profitImprove fuel efficiencyBiofuelsSolid fuelsSpontaneous combustionFuel efficiency

The invention discloses a preparation method of a self-oxygen-supply type biomass fuel, and belongs to the technical field of biomass fuels. Various materials with simple sources can be adopted; afterthe pretreatment, fermentation is carried out, a part of auxiliary agents is added, and microwave treatment is carried out; the raw materials are mixed and then powdered; a layered paving and fillingbox is used for paving and filling the raw materials layer by layer; spontaneous combustion cracking-assisting wires are innovatively introduced and put into each layer of raw materials; oxygen supply particles are wrapped by a flammable material; the oxygen supply particles are decomposed under the action of high temperature to release oxygen; the immediate combustion fuses inserted into the spontaneous combustion crack-assisting wires are immediately combusted to release a large amount of heat; the consumption and oxygen release of the spontaneous combustion crack-assisting wires are further promoted along with multiple tiny explosion impacts, finally expanded cracks are formed in the biomass fuel, the biomass fuel is forced to crack and crush, oxygen is directly provided from multiplepositions in the biomass fuel, oxygen needed by combustion of the biomass fuel is maintained, the combustion is more sufficient, and the fuel utilization rate and the fuel efficiency are greatly improved.

Owner:兴隆县一通新能源科技有限公司

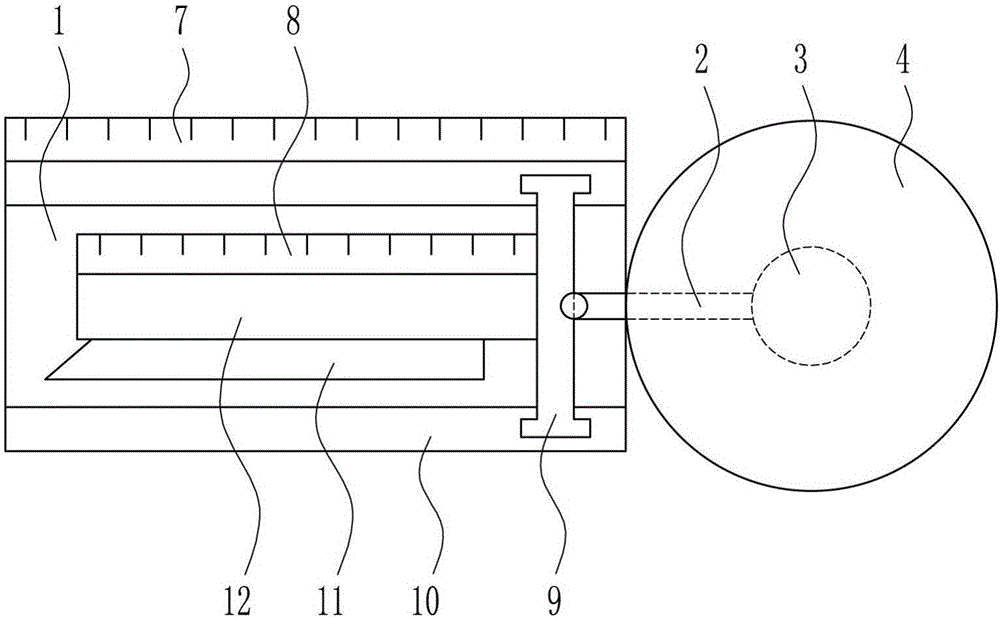

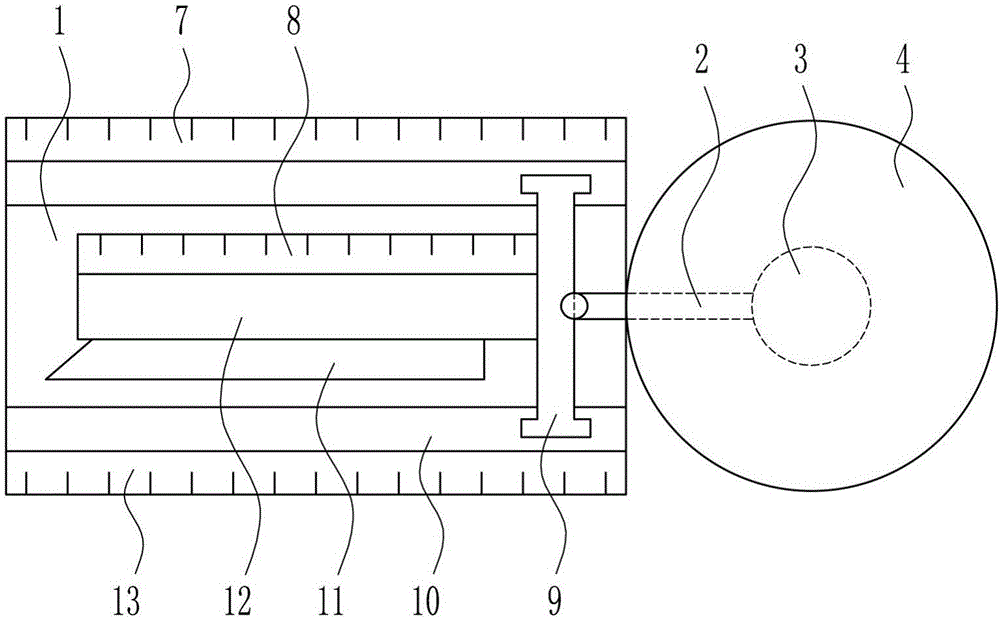

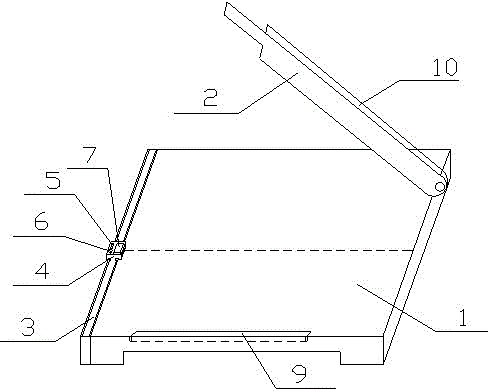

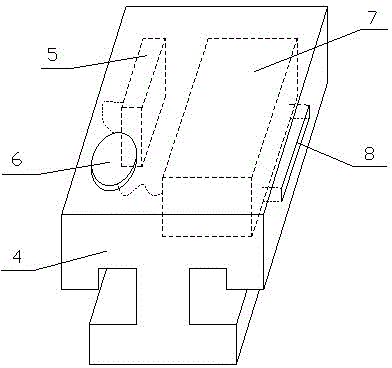

Paper cutting cutter

The invention discloses a paper cutting cutter, which comprises a base plate (1) and a cutter body (2) arranged on the base plate (1), wherein at least one slide rail (3) is fixedly arranged on the base plate (1), a slide block (4) provided with an open hole (8) is arranged in the slide rail (3) in a clamping way, an illuminating mechanism is arranged on the slide block (4), and comprises a battery (5), a switch (6) and a laser emitter (7) in sequential connection, an emitting opening of the laser emitter (7) is projected out of the open hole (8) and is pasted with the horizontal plane of the base plate (1), the switch (6) controls the laser emitter (7) for emitting laser, and laser emitted by the laser emitter (7) forms linear radioactive rays on the horizontal plane of the base plate (1). The paper cutting cutter has the advantages that the radioactive rays capable of being directly displayed on paper can be formed, the radioactive rays are provided for people to directly judge whether the paper is correctly placed or not, and the paper on a plane can be regulated in time, so the paper cutting cutter has an auxiliary promoting effect.

Owner:JIANGSU KANG BAISI MECHANICAL TECH

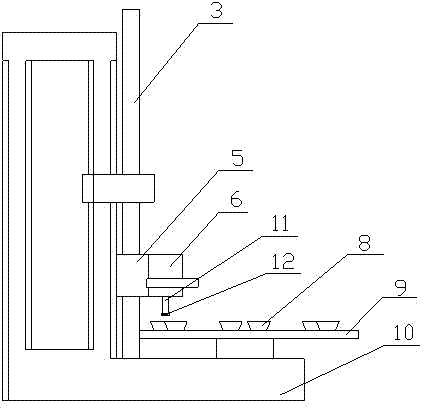

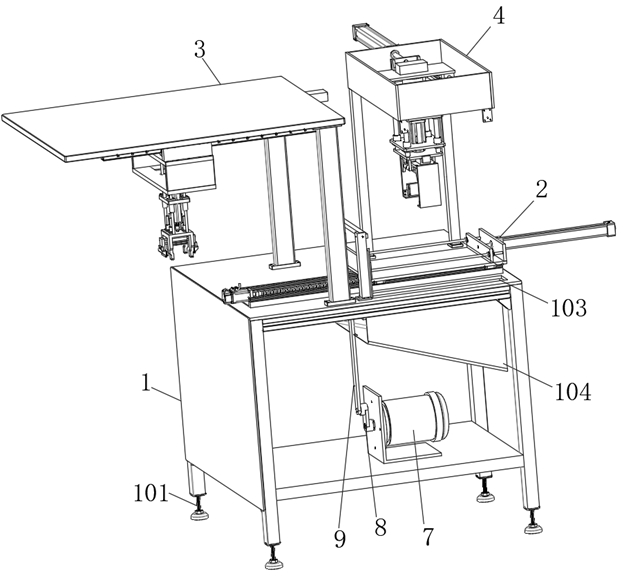

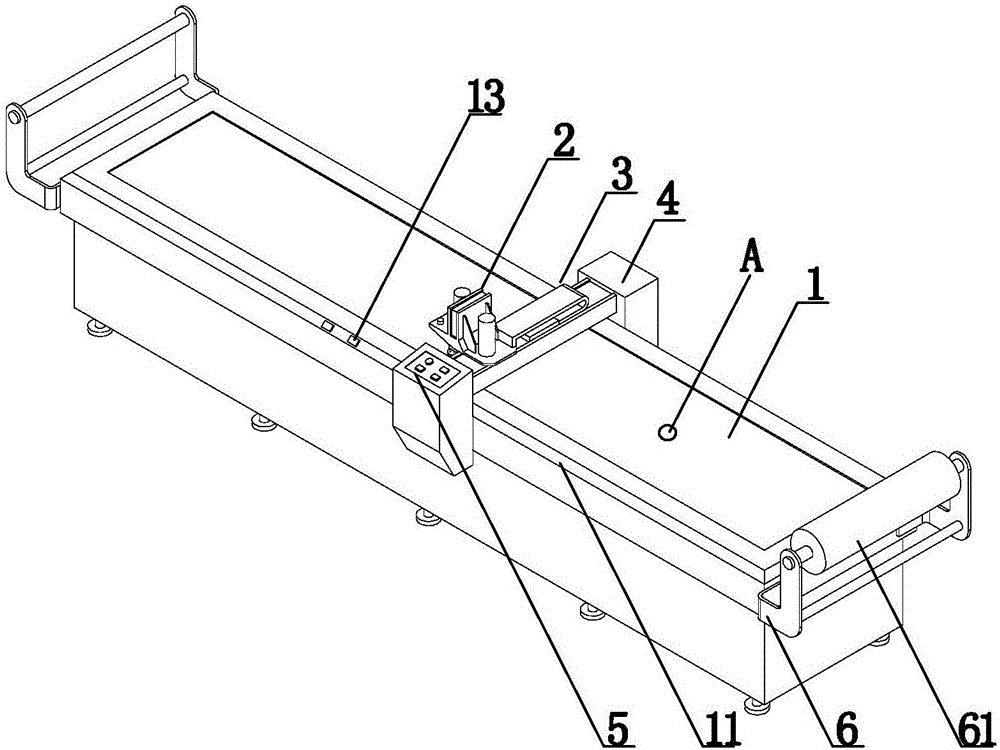

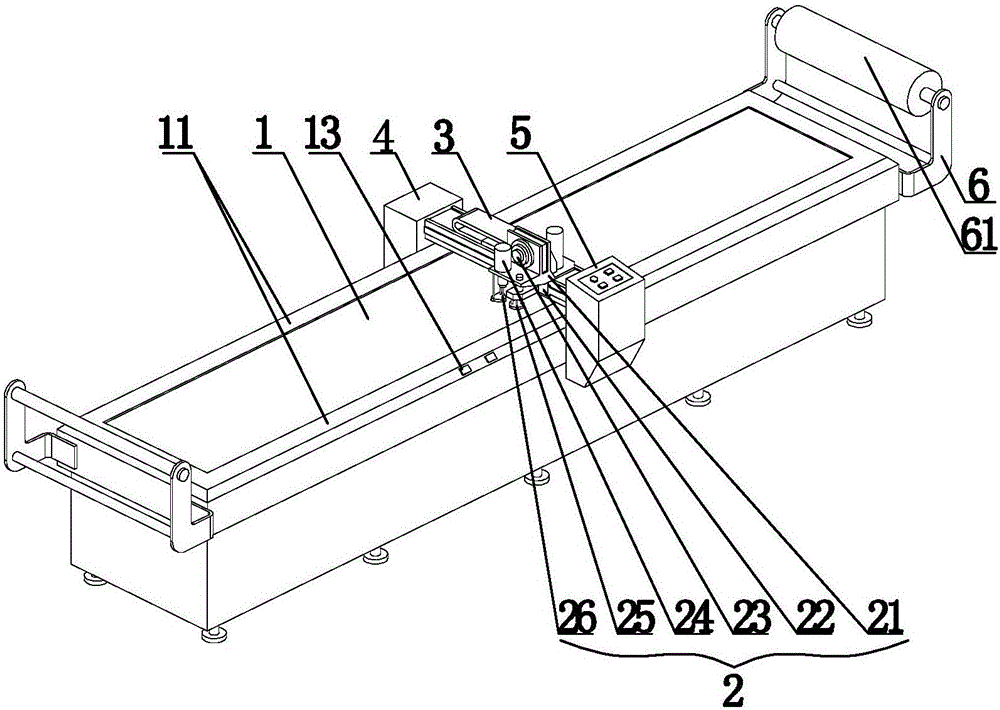

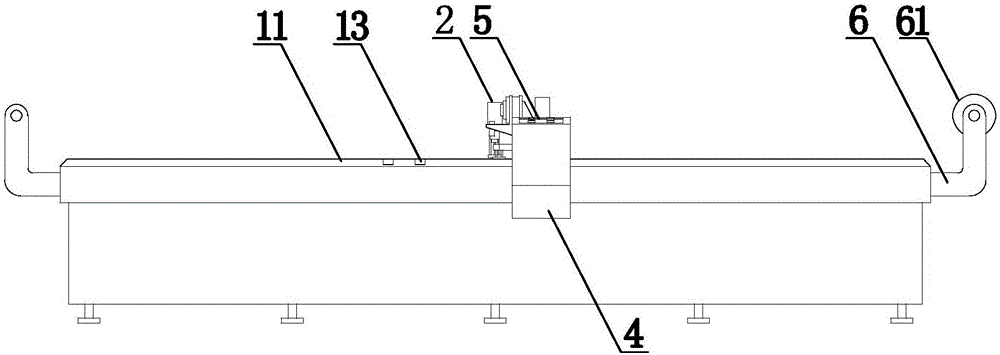

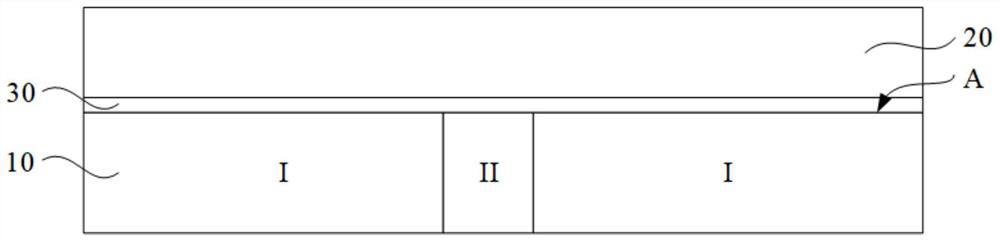

Automatic single piece cutting machine

ActiveCN106702712AAvoid miscuttingAvoid one-sided emphasisSevering textilesEngineeringMechanical engineering

The invention relates to an automatic single piece cutting machine, and belongs to the field of textile processing and forming technologies. The automatic single piece cutting machine comprises a worktable, a cutting head and a track. The track is erected on the worktable by a track frame, the track frame can move front and back along the worktable under the control of a controller, and the cutting head is connected with the track and can be driven by the track to move left and right; the cutting head can be repositioned jointly under the effect of the track frame and the track; the cutting head can be driven by driving sources to move up and down, and cloth pieces can be cut by the cutting head in up-down, left-right and front-back movement procedures. The automatic single piece cutting machine has the advantages that the automatic single piece cutting machine can be applied to processing western-style clothing and garments, the cloth pieces can be integrally cut and can be automatically clipped, and the like.

Owner:SHAOXING BOYA FASHION CO LTD

Semiconductor structure and forming method thereof

PendingCN111696969AAvoid damageImprove cutting accuracySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureWafer stacking

The embodiment of the invention relates to a semiconductor structure and a forming method thereof. The forming method comprises the following steps: providing a wafer stacking structure to be cut; performing first cutting processing on the wafer stacking structure, forming a first through hole in the cutting channel, and extending the first through hole to form a first extending pattern in the direction perpendicular to the first surface and the extending direction of the cutting channel; performing second cutting treatment on the cutting channel at the bottom of the first through hole, cutting the wafer stacking structure until the wafer stacking structure is cut through; forming a second through hole in the cutting channel through second cutting treatment; in the direction perpendicularto the first face and the extending direction of the cutting channel, enabling the second through hole to extend to form a second extending pattern, wherein the second extending pattern and the firstextending pattern have an overlapping part, and the width of the overlapping part is less than the width of the first through hole and the width of the second through hole. According to the invention,the cutting of the wafer stacking structure can be effectively realized, and mistaken cutting of the chip is avoided.

Owner:CHANGXIN MEMORY TECH INC

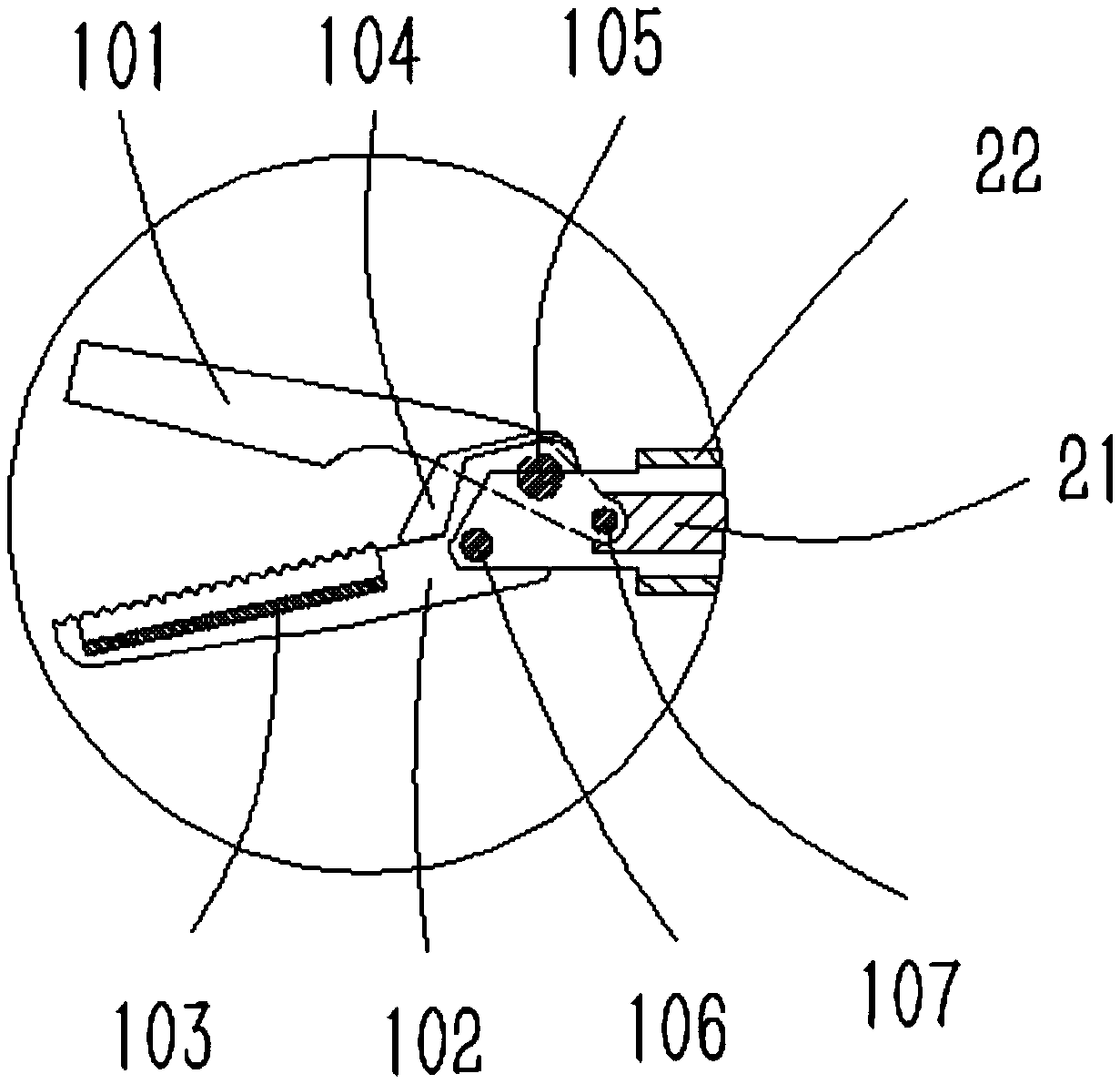

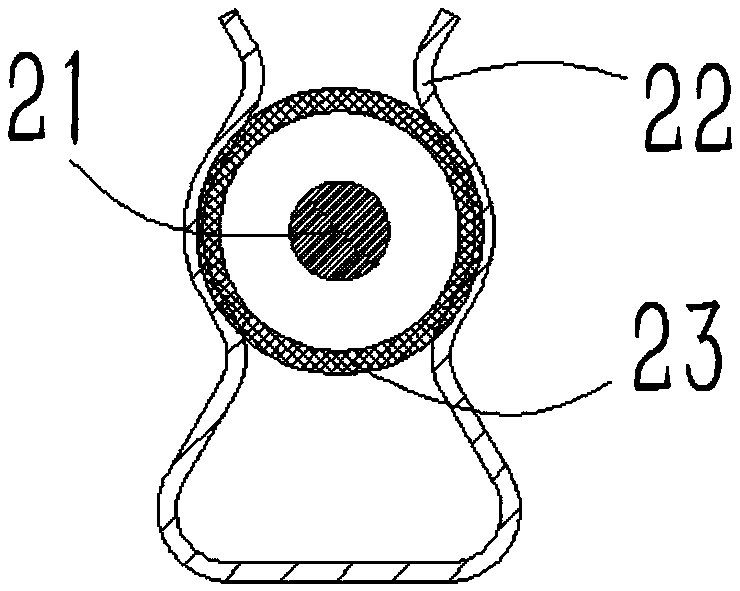

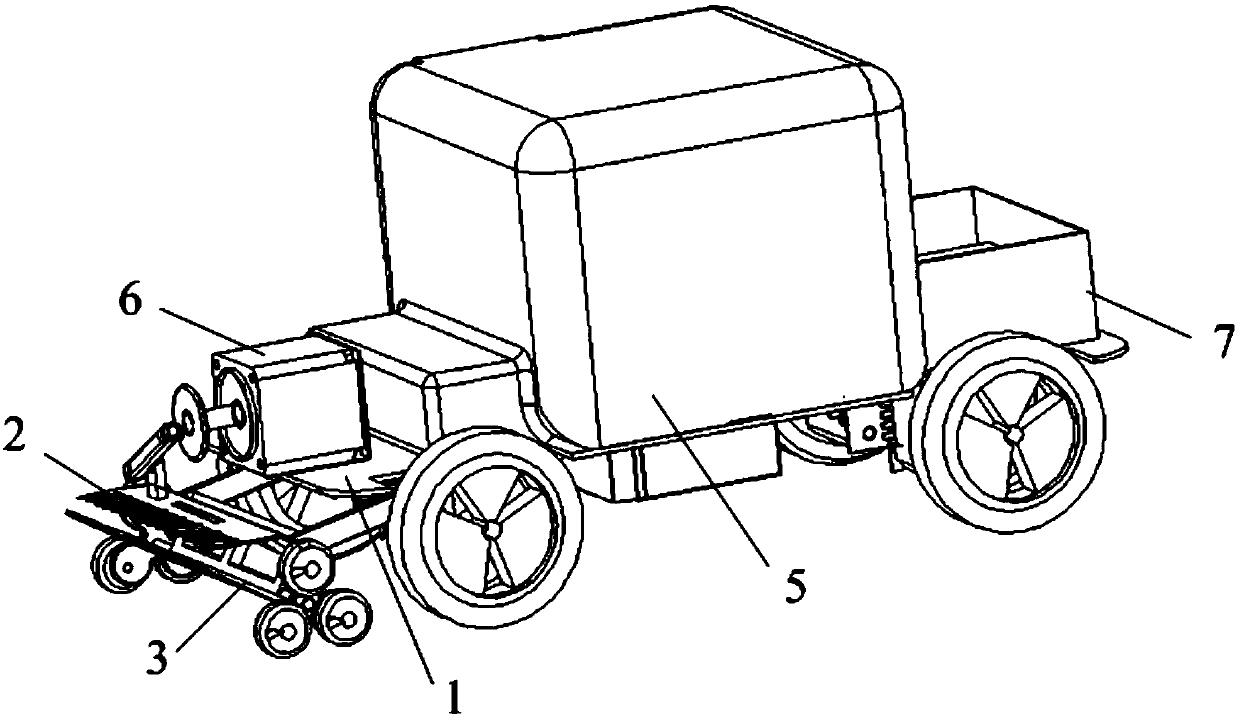

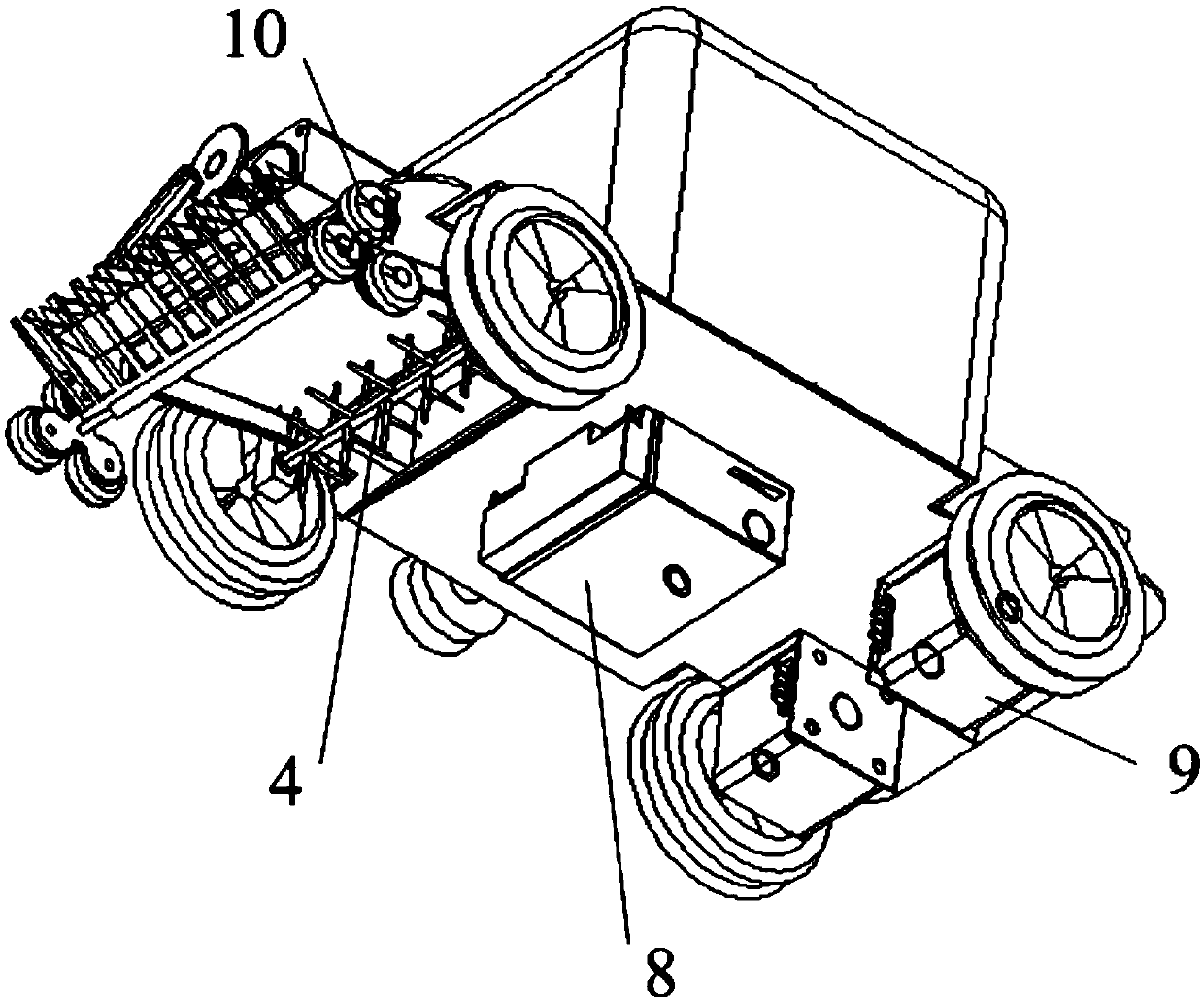

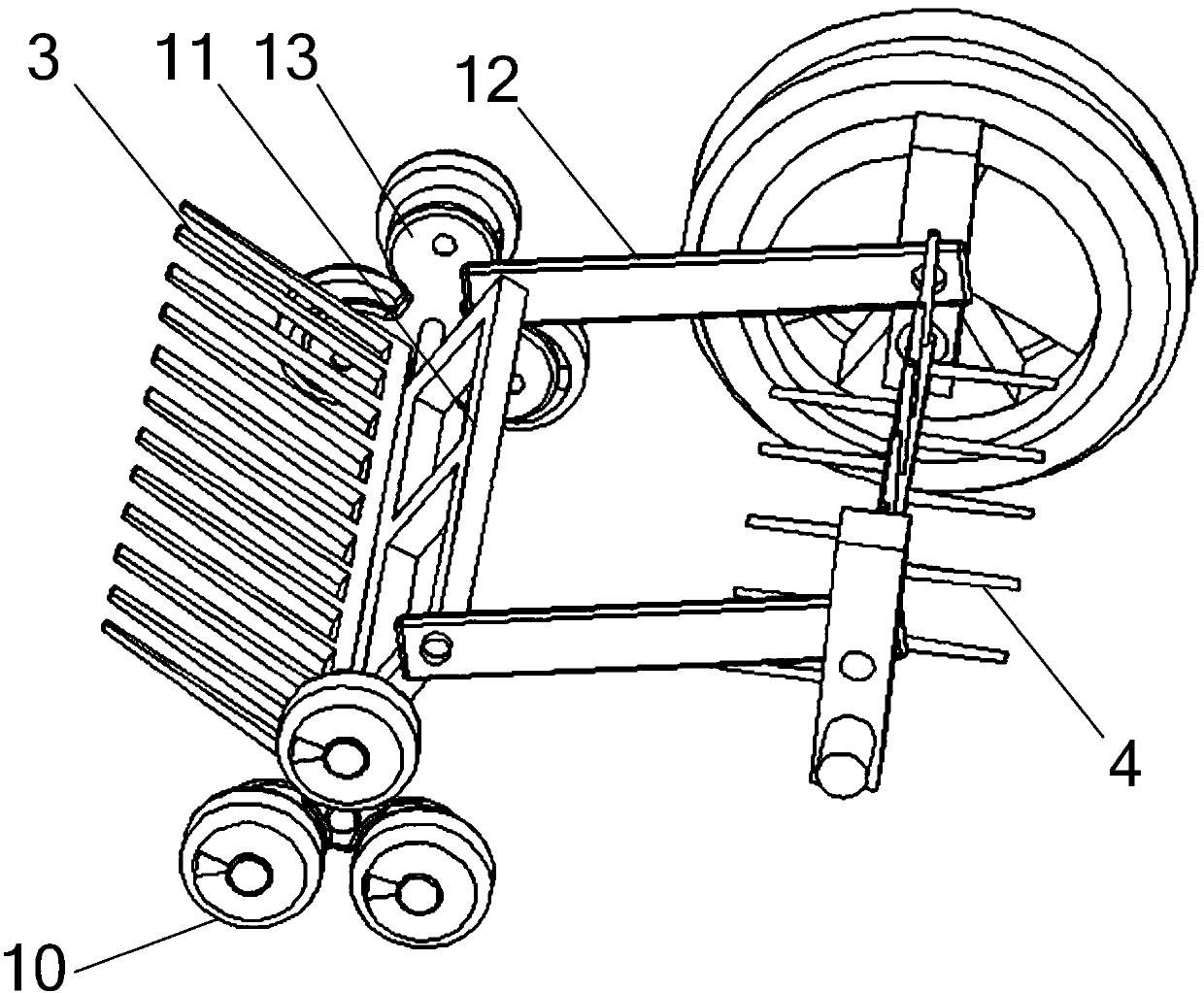

Cutter front-loaded round bundled household mowing grass catcher and method thereof

ActiveCN109511358AUniform mowing heightReduces the problem of mismanagementMowersMotor driveEngineering

The invention discloses a cutter front-loaded round bundled household mowing grass catcher and a method thereof. Existing hay mowers are not suitable for home courtyard lawns. The device of the invention comprises a chassis, a cutter assembly, a drive assembly, a lawn comber frame, a pickup, a collection chamber, a mounting rack and a connecting plate. A cutter motor drives an upper blade to moverelative to a lower blade through a disk and a connecting rod; when the chassis advances or veers, the lawn comber frame lifts grass before the cutting work of the cutter, and then the grass is cut during the movement of the upper blade relative to the lower blade; when the ground changes, an auxiliary wheel always fits the ground, and heights of the lawn comber frame and the cutter keep unchangedrelative to the ground through the mounting rack; when front two wheels rotate, the pickup behind the cutter is driven to rotate such that cut grass scrolls into the collection chamber; and the broken grass which scrolls into the collection chamber is bundled and formed under the action of the round bundling device. By adaptive adjustment of mowing height, neat trimming is ensured by firstly mowing and then trimming, and broken grass is independently processed.

Owner:NINGBO UNIV

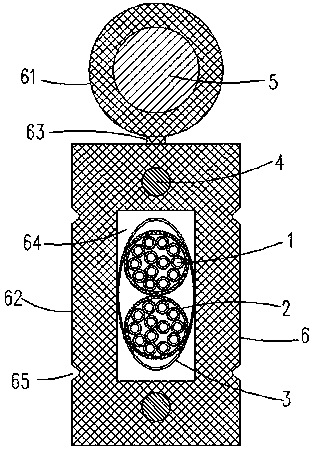

Overhead optical cable for splicing

InactiveCN108121041AAffect light transmission functionPrevents affecting optical transmission performanceFibre mechanical structuresEngineeringMicro cluster

The invention discloses an overhead optical cable for splicing. A sheath comprises a circular sleeve part, a rectangular sleeve part and a connecting part which are molded integrally. A micro-tube packages a coloring optical fiber and forms a micro-cluster pipe unit. Two micro-cluster pipe units parallelly penetrate a second packaging chamber. A packaging pipe wraps the two micro-cluster pipe units. A reinforcing member is arranged in a first packaging chamber of the circular sleeve part. Two reinforcements penetrate through the rectangular sleeve part. Furthermore the two reinforcements are symmetrically arranged at the upper side and the lower side of the second packaging chamber. The left side wall and the right side wall of the rectangular sleeve part are respectively provided with twostripping grooves symmetrically. Two stripping grooves on the left side wall of the rectangular sleeve part are arranged symmetrically with the two stripping grooves on the right side wall. Two stripping grooves on each side wall of the rectangular sleeve part are correspondingly arranged outside the two micro-cluster pipe units, and are correspondingly arranged at inside of the upper side wall and the lower side wall of the second packaging chamber. The overhead optical cable is advantages in that a compact structure is realized; a multi-core micro-pipe structure is utilized for reducing thedimension of the cable as possible, reducing the external diameter of the cable, reducing weight of the cable and realizing easy stripping.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

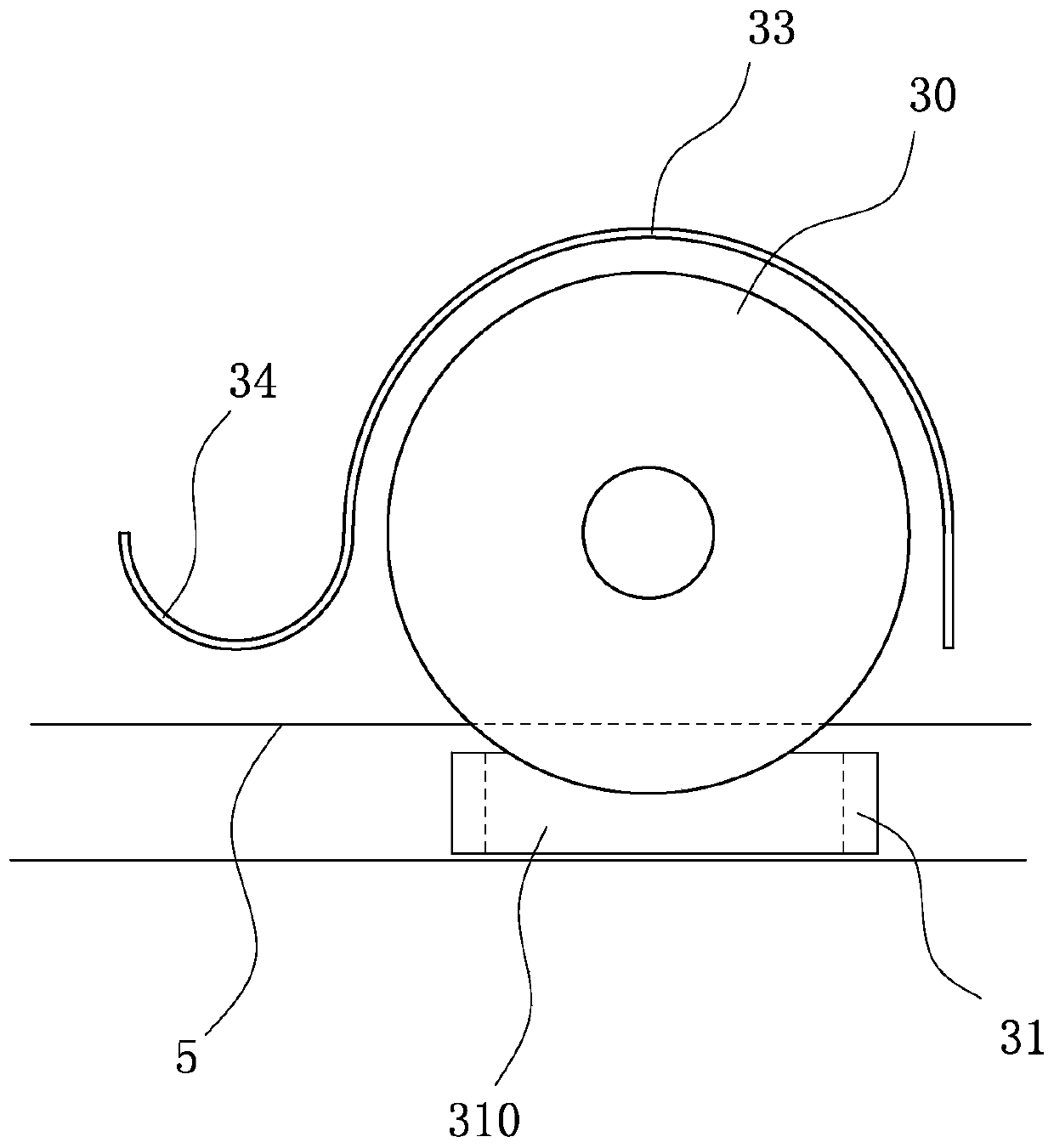

Rotary cutter

InactiveCN110405823ASimple structureLow costMetal working apparatusArticle deliveryBiomedical engineeringEngineering

The invention discloses a rotary cutter, and relates to the technical field of tube membrane rotary cutting. The rotary cutter comprises an unreeling device, a guiding mechanism, a cutting mechanism and a reeling device. A reeled tube membrane is rotationally output through the unreeling device. The guiding mechanism penetrates into the tube membrane to horizontally expand the tube membrane. The cutting mechanism obliquely cuts the tube membrane horizontally expanded on the guiding mechanism into a slice membrane on a single layer. The slice membrane is pulled and reeled through the reeling device. The discharging direction of the unreeling device and the guiding direction of the guiding mechanism are identical, and the reeling direction of the reeling device and the cutting direction of the cutting mechanism are identical. The technical problem that in the prior art, the quality of tube membrane rotary-cut finished products is not stable is solved, the smoothness of conveying and cutting of the tube membrane and pulling and reeling of the slice membrane is greatly improved, cutting of the cutting mechanism on the horizontally expanded tube membrane is more stable, the cutting quality is higher, finally, the quality of the formed slice membrane is more stable, and the yield is remarkably increased. The rotary cutter is simple in structure and low in cost, and matching of all the composition devices is diverse.

Owner:山东海王塑业科技有限公司

Laser cutting machine for automobile lamp lens

InactiveCN105215557AAvoid miscuttingProtect the working environmentLaser beam welding apparatusEngineeringMechanical engineering

The invention provides a laser cutting machine for an automobile lamp lens. The laser cutting machine comprises a machine body. A rail is arranged in the machine body and provided with a moving carrying plate. The moving carrying plate transversely moves through the rail. The moving carrying plate longitudinally moves through a longitudinal moving device arranged at the bottom of the moving carrying plate. The moving carrying plate is provided with carrying blocks. A laser cutting device is arranged above the middle of the rail. The moving carrying plate and the laser cutting device are provided with corresponding infrared position determining devices respectively, and the cutting position of the laser cutting device is determined through the infrared position determining devices. The lens is driven by the moving carrying plate to move and cut through the laser cutting device, the cutting position is determined through the infrared position determining devices, and mistaken cutting is prevented. Blowing sprayers are arranged to cool the cutting position, air suction pipes are used for recycling smoke generated through cutting, and the work environment is protected.

Owner:MAGNETI MARELLI AUTOMOTIVE COMPONENTS WUHU

Automatic cutting apparatus of overedger

InactiveCN101676468BIncrease profitReduce labor intensityNeedle severing devicesKey pressingElectricity

The invention discloses an automatic tangent apparatus of an overedger, which comprises a centre controller, a first cloth detection apparatus, a handwheel detection device, an electromagnetic cutting knife, a suction fan, a display circuit and a button input circuit. The centre controller electrically connects with the first cloth detection apparatus, the handwheel detection device, the electromagnetic cutting knife, the display circuit and the button input circuit respectively; wherein, the first cloth detection apparatus is arranged on a feeding cloth side of a feeding cloth table of the overedger, the handwheel detection apparatus is used for detecting a turning circle number of the handwheel of the overedger. A cutting-line work can be automatically completed by the apparatus provided by the invention, which can reduce labor intensity of operators, simultaneously, a cutting-line length can be controlled accurately which can increase utilization ratio of the line, thereby, increase production efficiency greatly.

Owner:SHANGHAI AKITA ELECTRICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com