Table-type cutting machine and cutting work table thereof

A desktop cutting machine and workbench technology, applied in work accessories, manufacturing tools, metal sawing equipment, etc., can solve problems such as potential safety hazards and achieve the effect of preventing miscuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

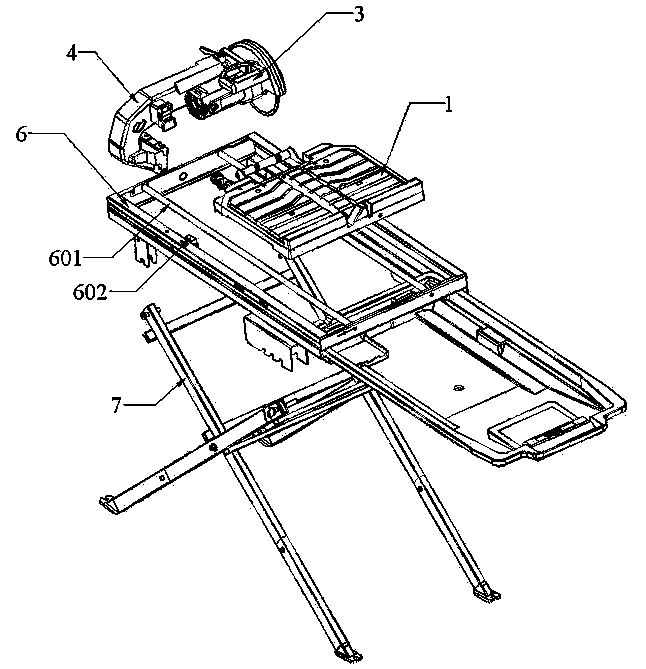

[0033] refer to Figure 3 to Figure 5 As shown, the desktop cutting machine of the present invention mainly includes: a cutting head assembly 3, a cantilever assembly 4, a machine base, a cutting workbench, a workbench bracket 5, and an accommodation cavity; wherein, the machine base includes: a frame 6, a folding bracket 7 , the cantilever rotating shaft 203, the driving end 204, and the installation notch 105.

[0034] Wherein, the cutting head assembly 3 and the cantilever assembly 4 form an integral body, the cantilever assembly 4 is used to support the cutting head assembly 3, and the whole they constitute is fixed on the top of the frame 6, and the frame 6 is provided with a slide rail 601, and the cutting table and The workbench bracket 5 constitutes a whole and forms a sliding connection with the frame 6 through the slide rail 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com