Overhead optical cable for splicing

A technology for overhead optical cables and connecting parts, which is applied in the field of aerial optical cables for splicing, which can solve the problems of increasing splicing points, increasing the complexity of splicing loss, construction difficulty, and difficult opening and stripping of optical cables, and achieves reduced outer diameter, light weight, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

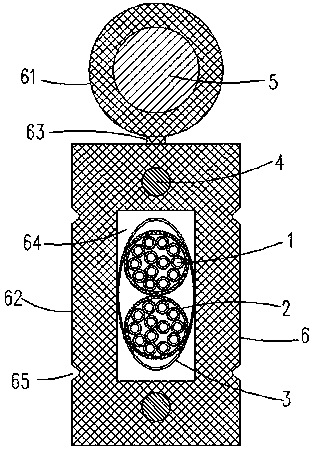

[0022] Such as figure 1 As shown, the present invention is a kind of aerial optical cable for splicing, including colored optical fiber 1, microtube 2, wrapping tape 3, reinforcement 4, reinforcement 5 and sheath 6, and sheath 6 includes integrally formed round sleeve part 61, The rectangular sleeve part 62 and the connecting part 63, the connecting part 63 is placed between the circular sleeve part 61 and the rectangular sleeve part 62, and a first wrapping cavity is provided in the axial direction (ie, the length direction) of the circular sleeve part 61. A second wrapping cavity 64 is provided in the center direction of the sleeve portion 62 . The microtubes 2 are wrapped on the colored optical fiber 1 to form a micro-tuft unit, and the two micro-tuft units are arranged parallel to each other. The wrapping tape 3 is wrapped around the two micro-tuft units and passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com