Paper cutting cutter

A technology of paper cutter and cutter body, which is applied in metal processing and other directions, can solve the problems of improper cutting, uneven paper, and affecting the use effect of paper cutter, so as to achieve the effect of convenient cutting, avoiding incorrect cutting and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

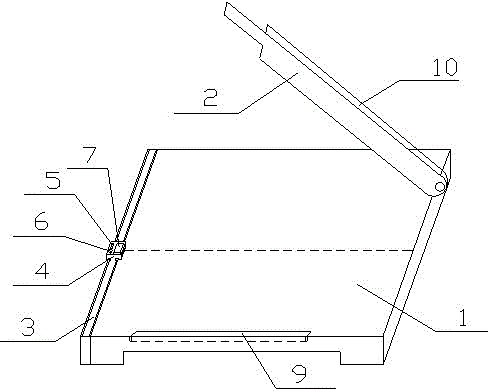

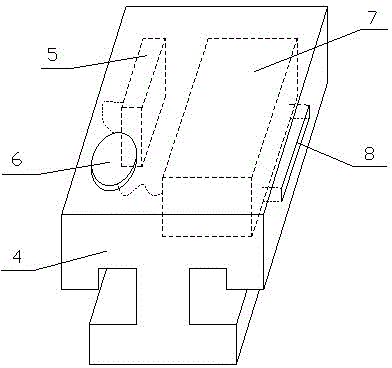

[0022] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0023] like figure 1 As shown, the present invention designs a paper cutter, including a base plate 1 and a knife body 2 arranged on the base plate 1, at least one slide rail 3 is fixedly arranged on the base plate 1, and each slide rail 3 A slider 4 with an opening 8 is clamped inside; an irradiation mechanism is provided on the slider 4, and the irradiation mechanism includes a battery 5, a switch 6, and a laser emitter 7 connected in sequence, wherein the laser emitter 7 The emission port of the laser emitter protrudes from the opening 8 and fits with the horizontal surface of the base plate 1, so that the emission port of the laser emitter 7 can transmit radiation; the switch 6 can be turned on or off to control the laser emitter 7 to emit laser light, When the switch 6 is turned on, the laser emitted by the laser emitter 7 forms a linear radiation on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com