Cutting device

A technology of cutting device and cutting equipment, which is applied in the field of metal cutting, and can solve the problems of unguaranteed quality of metal shell, low cutting precision, and easy miscutting of product segments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

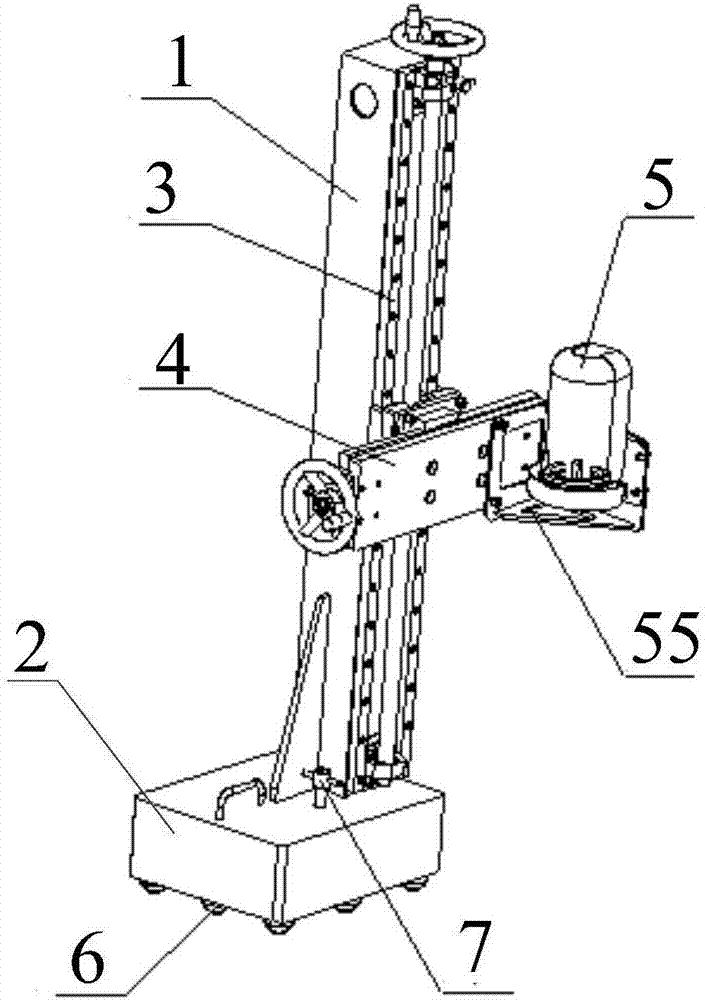

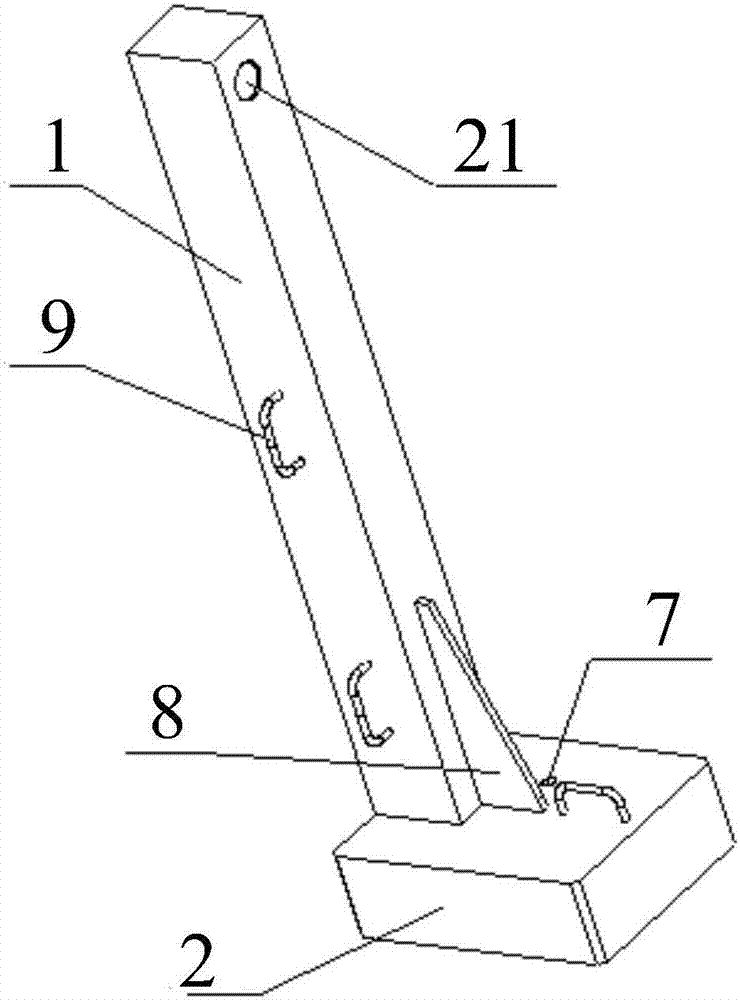

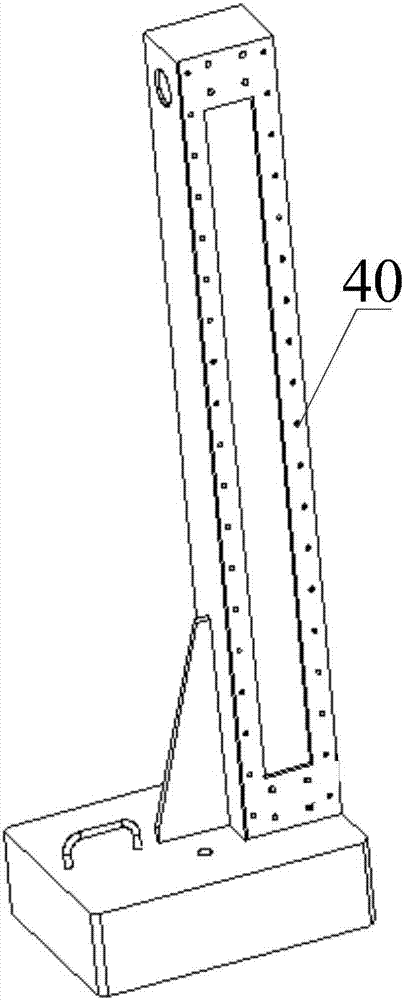

[0056] In order to solve the technical problems in the prior art that when the redundant heat-proof layer on the metal shell is cut by manual cutting, the cutting precision is low, and the product section is easily cut by mistake, which leads to the unguaranteed quality of the metal shell. The invention provides a cutting device, which comprises: a first pillar, one end of the first pillar is connected with one end of the base, and a vertical movement mechanism is installed on one side of the first pillar; the vertical movement mechanism Used to adjust the position of the cutting device in the vertical direction; a horizontal movement mechanism, the horizontal movement mechanism is connected to the vertical movement mechanism through a drive plate; the horizontal movement mechanism is used to adjust the position of the cutting device in the horizontal direction; Cutting equipment, the cutting equipment is connected to one end of the horizontal movement mechanism through the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com