Preparation method of self-oxygen-supply type biomass fuel

A biomass fuel and self-oxygenation technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low calorific value, large ash, and insufficient combustion, so as to improve fuel efficiency, complete combustion, The effect of improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

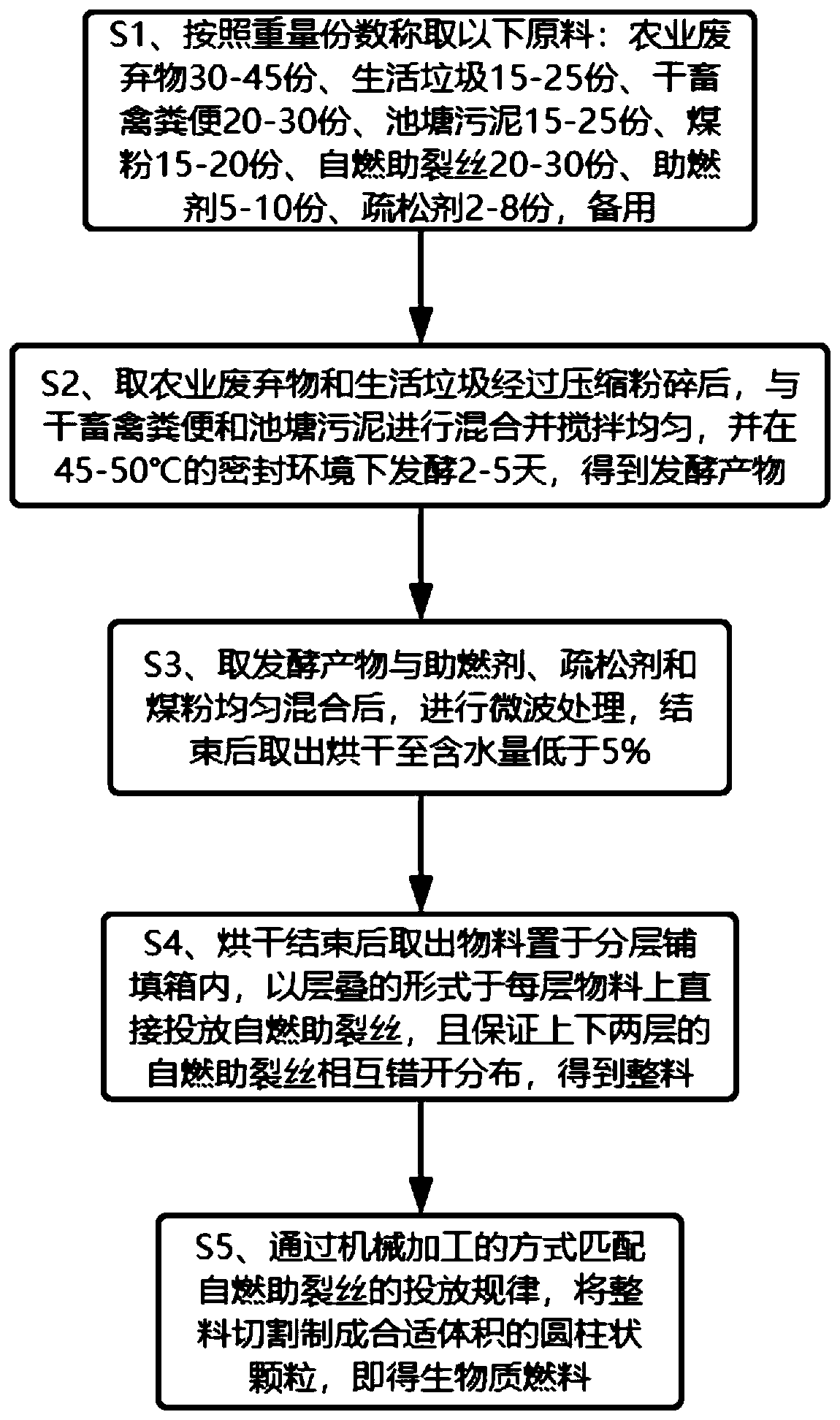

[0044] see figure 1 , a method for preparing self-oxygenated biomass fuel, comprising the following steps:

[0045] S1. Weigh the following raw materials according to parts by weight: 30 parts of agricultural waste, 15 parts of domestic garbage, 20 parts of dry livestock and poultry manure, 15 parts of pond sludge, 15 parts of coal powder, 20 parts of spontaneous combustion aided cracking, 5 parts of combustion aid 2 parts, loosening agent, spare;

[0046] S2. After compressing and pulverizing the agricultural waste and domestic waste, mix them with dry livestock and poultry manure and pond sludge and stir evenly, and ferment in a sealed environment at 45°C for 2 days to obtain a fermentation product;

[0047] S3. After the fermentation product is uniformly mixed with the combustion aid, loosening agent and coal powder, microwave treatment is carried out. The microwave treatment temperature is 80 ° C and the time is 60 minutes. After the end, it is taken out and dried until t...

Embodiment 2

[0056] see figure 1 , a method for preparing self-oxygenated biomass fuel, comprising the following steps:

[0057] S1. Weigh the following raw materials according to parts by weight: 40 parts of agricultural waste, 20 parts of domestic garbage, 25 parts of dry livestock and poultry manure, 20 parts of pond sludge, 18 parts of coal powder, 25 parts of spontaneous combustion aided cracking, 8 parts of combustion aid 5 parts, 5 parts of loosening agent, spare;

[0058] S2. After compressing and pulverizing the agricultural waste and domestic waste, mix them with dry livestock and poultry manure and pond sludge and stir evenly, and ferment in a sealed environment at 48°C for 4 days to obtain a fermentation product;

[0059] S3. After the fermentation product is evenly mixed with the combustion aid, loosening agent and coal powder, microwave treatment is carried out. The microwave treatment temperature is 100°C and the time is 75min. After the end, take it out and dry it until th...

Embodiment 3

[0064] see figure 1 , a method for preparing self-oxygenated biomass fuel, comprising the following steps:

[0065] S1. Weigh the following raw materials according to parts by weight: 45 parts of agricultural waste, 25 parts of domestic garbage, 30 parts of dry livestock and poultry manure, 25 parts of pond sludge, 20 parts of coal powder, 30 parts of spontaneous combustion aided cracking, 10 parts of combustion aid 8 parts, 8 parts of loosening agent, spare;

[0066] S2. After compressing and pulverizing the agricultural waste and domestic waste, mix them with dry livestock and poultry manure and pond sludge and stir evenly, and ferment in a sealed environment at 50°C for 5 days to obtain a fermentation product;

[0067] S3. After the fermentation product is evenly mixed with the combustion aid, loosening agent and coal powder, microwave treatment is carried out. The microwave treatment temperature is 120 ° C and the time is 90 minutes. After the end, it is taken out and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com