Plate positioning device for laser cutting

A laser cutting and positioning device technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems affecting the production efficiency and progress of enterprises, large workload, poor alignment effect, etc., to improve cutting Efficiency and effect of cutting progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

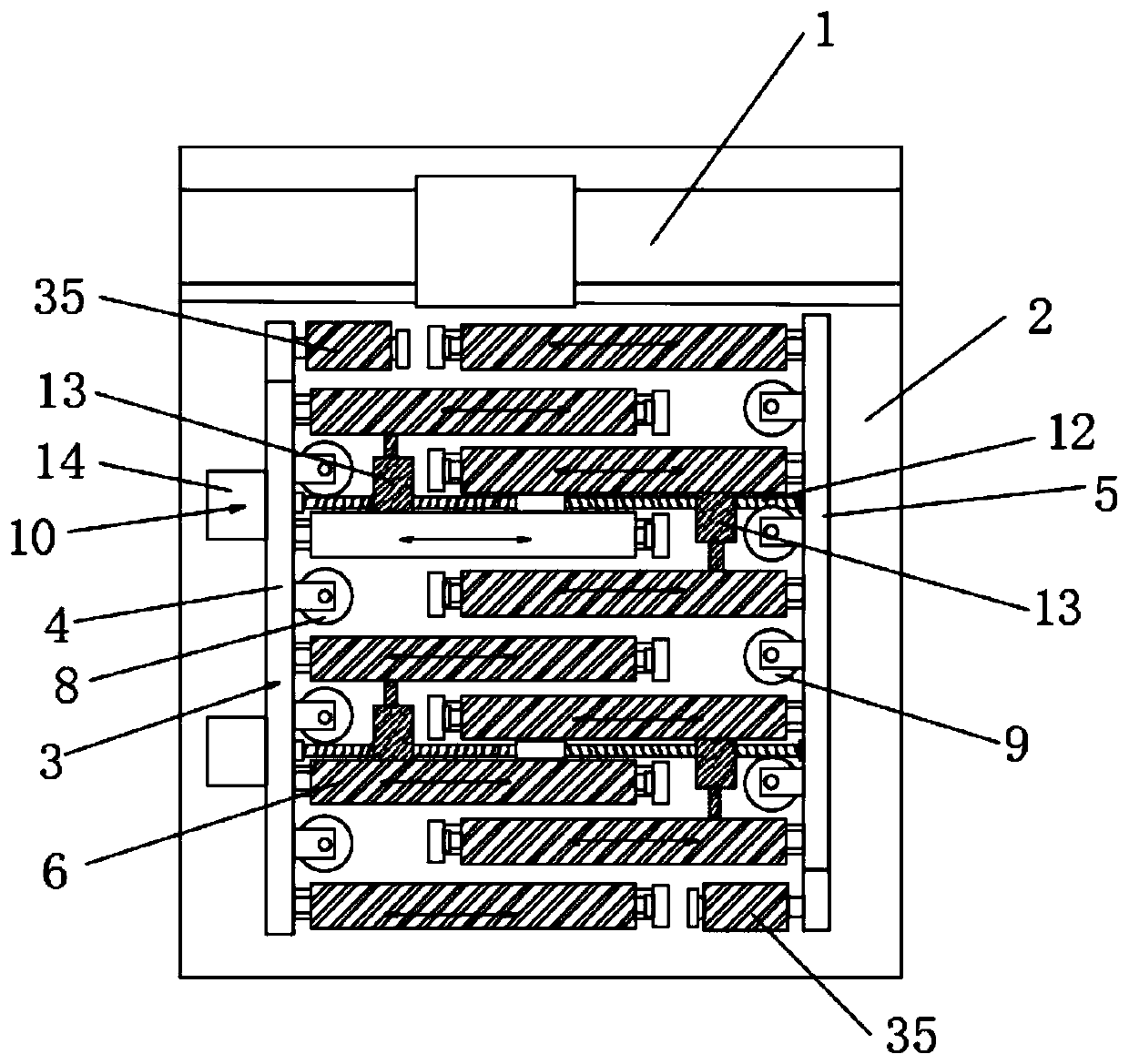

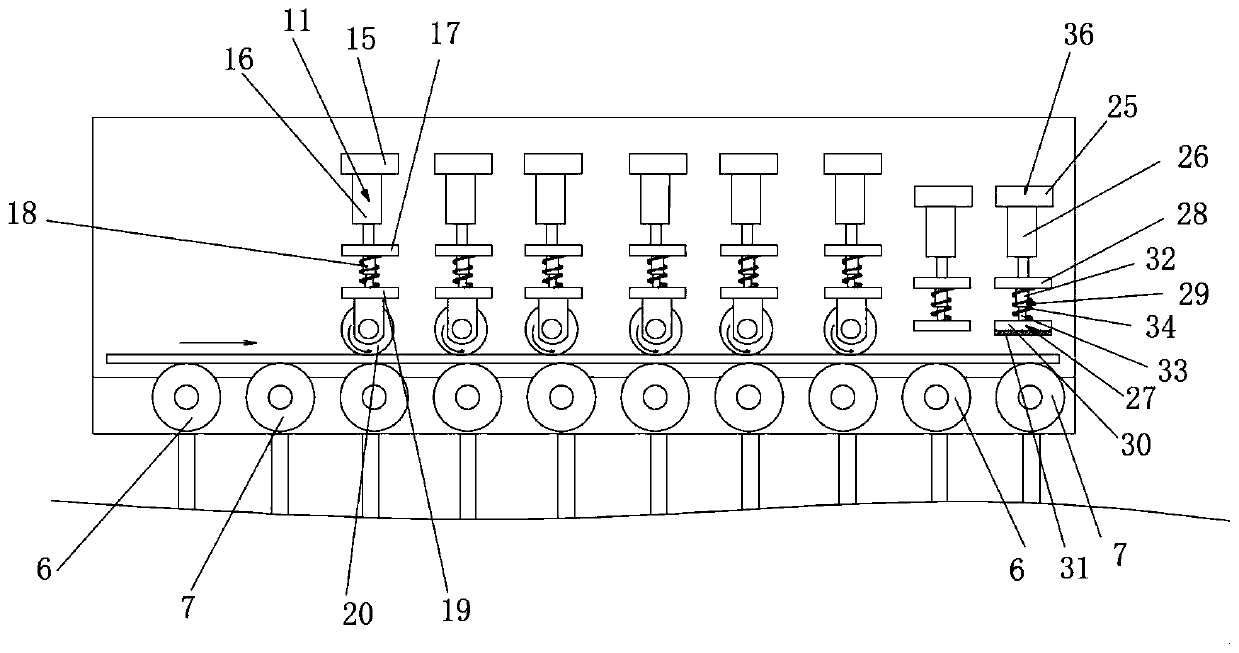

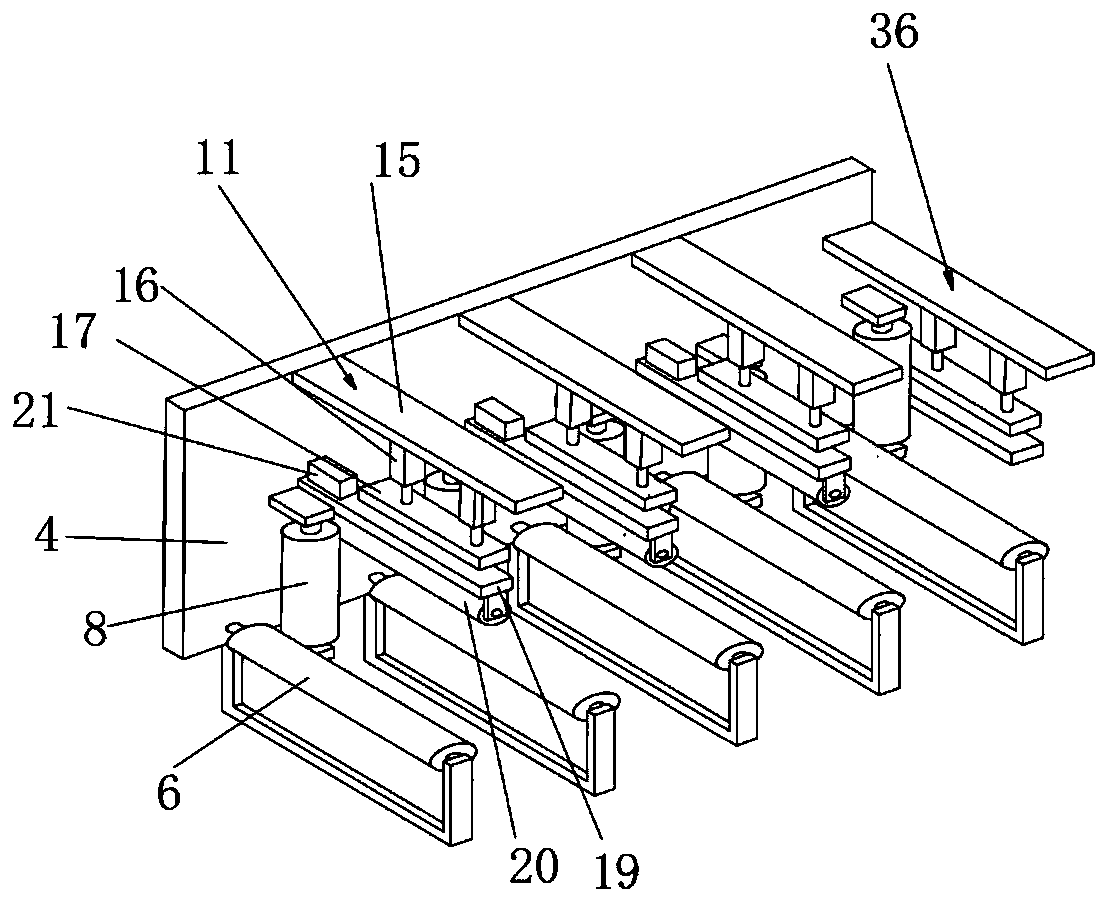

[0025] Embodiment: a kind of plate positioning device for laser cutting, such as Figure 1-6As shown, it includes a base frame 2 docked with the laser cutting device 1, and the base frame 2 is provided with a plate centering positioning frame 3, and the plate centering positioning frame 3 includes a first moving frame 4 and a second moving frame oppositely arranged 5. The first moving frame 4 is provided with a plurality of first rotating rollers 6, and the second moving frame 5 is provided with a plurality of second rotating rollers 7 set at the same height as the first rotating rollers 6, adjacent to the first rotating rollers Insertion gaps are respectively provided between a turning roller 6 and between adjacent second turning rollers 7, and the first turning roller 6 and the second turning roller 7 are arranged in a staggered manner and form a conveying roller table; the first moving The inner side of the frame 4 is provided with a plurality of vertically arranged first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com