Cloth cutting device

A cutting device and fabric technology, applied in the cutting of textile materials, fabric surface trimming, textiles and papermaking, etc., can solve the problems of unusable, heavy sewing workload, long fabric length, etc., to avoid unusable, reduce The effect of reducing workload and reducing yarn slipping points

Active Publication Date: 2018-05-08

NINGBO WENZE TEXTILE CO LTD

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the cloth is cut before storage. During the storage process, the cut part of the cloth is easy to slip, and the slipped cloth cannot be used any more. It is easy to cause waste of cloth, but the length of the cloth is long, and the workload of locking the cloth is one by one. Big

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

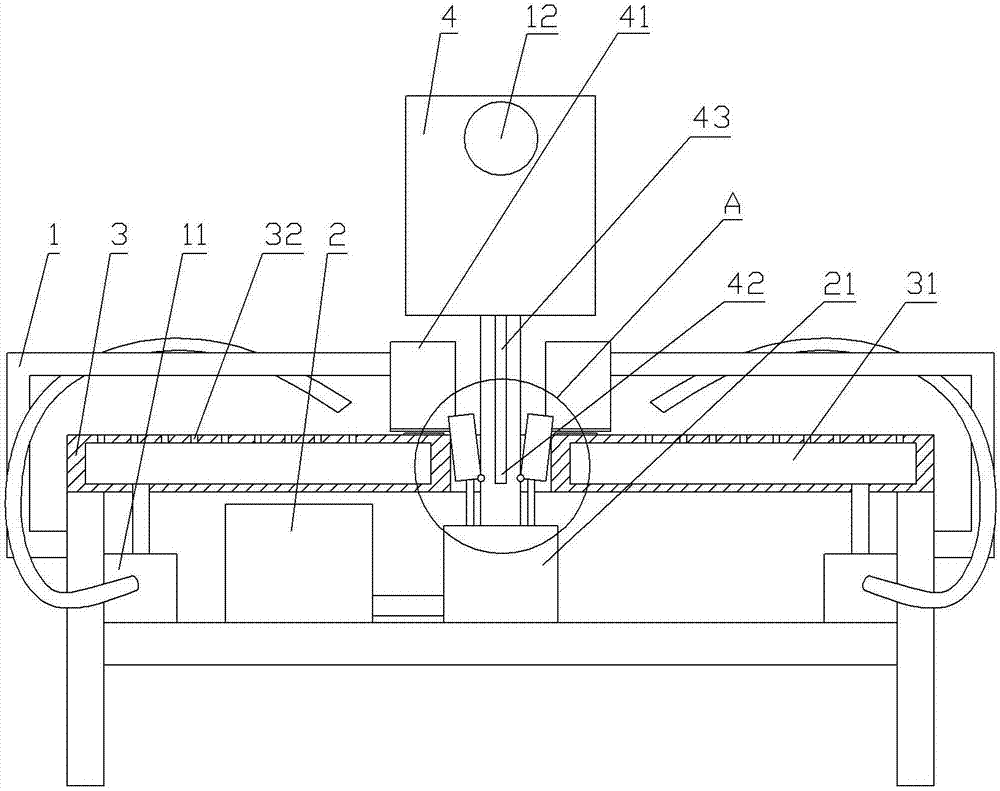

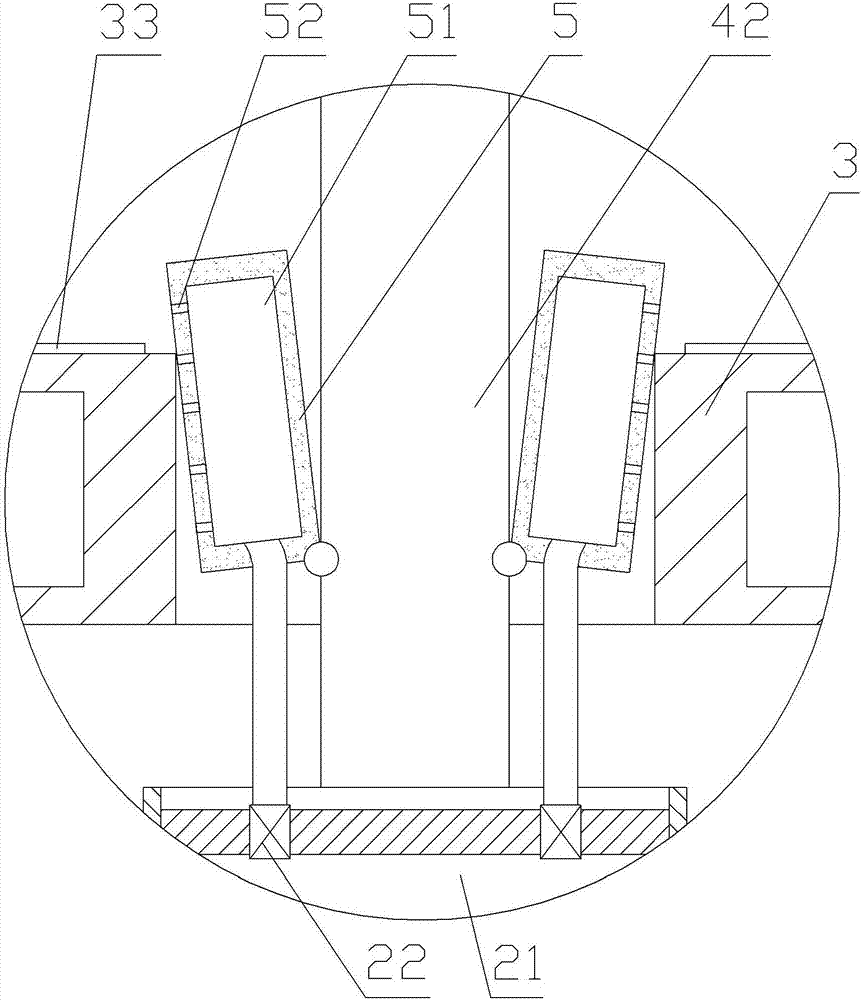

The invention relates to the field of textile and particularly discloses a cloth cutting device. The cloth cutting device comprises a frame, a hydraulic cylinder, a cutter, a worktable and a glue applying mechanism, wherein the frame is fixedly provided with a guide bar and a spring; the piston rod of the hydraulic cylinder is fixedly provided with a sliding bar; the cutter is fixed onto the sliding bar; the worktable is provided with a sliding groove; a rotating block is hinged to the sliding bar, and the hinge point of the rotating block and the sliding bar is arranged at the bottom of the rotating block; the hydraulic cylinder is provided with an L-shaped separating blade; the glue applying mechanism comprises a glue storage tank and an air cylinder, the glue storage tank is provided with a glue inlet, the air cylinder is provided with a glue inlet check valve, and the glue storage tank is communicated with the glue inlet check valve; the piston of the air cylinder is fixedly provided with a glue outlet check valve, the inside of the air cylinder is provided with a pressure spring, the inside of the rotating block is provided with a cavity, and the side wall of the cavity is provided with a through hole. The cloth cutting device can avoid yarn slippage after cloth is cut.

Description

technical field [0001] The invention relates to the field of textiles, in particular to the field of cloth cutting. Background technique [0002] Clothes are indispensable in people's daily life. Clothing is cut and sewn from cloth, and the quality of cloth directly affects the warmth retention and service life of clothing. In order to improve the aesthetics of clothes, cloths of different colors and shapes need to be used in the production process of clothes, so it is necessary to cut the filling materials; after cutting, the cloths are combined into complete clothes with needle and thread. In the clothing production process, after the fabric is cut, it is generally necessary to fold the sides of the fabric, and then lock the edges with needles and threads, so that the fabric is not easy to slip after being folded. [0003] The newly produced cloth is larger in size, and requires a larger space to be placed during storage, and takes up a larger space. However, the cloth i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06H7/02D06C25/00

CPCD06C25/00D06H7/02

Inventor 孙文清

Owner NINGBO WENZE TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com