A fixture and compensation method for avoiding extrusion scratches of sealing rubber rings and retaining rings

A sealing rubber ring and compensation method technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as extrusion or scratches, and achieve the goals of reducing faults, easy orientation, and eliminating irregular extrusion deformation and scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be further described in connection with the examples, but the embodiments of the present invention are not limited thereto.

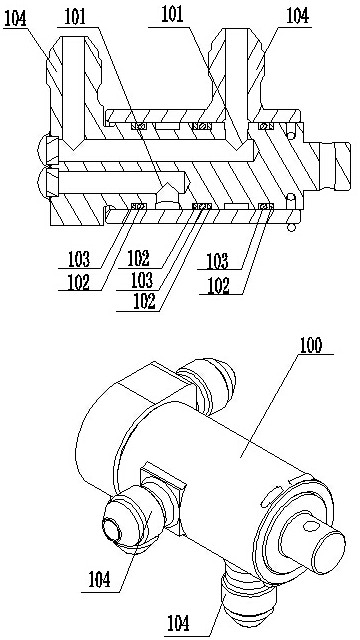

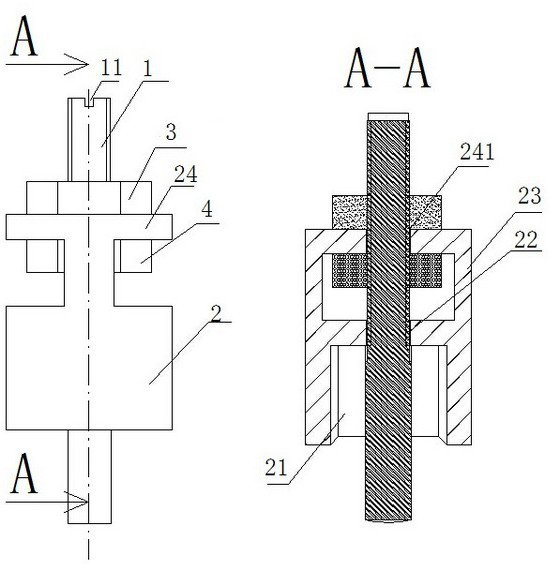

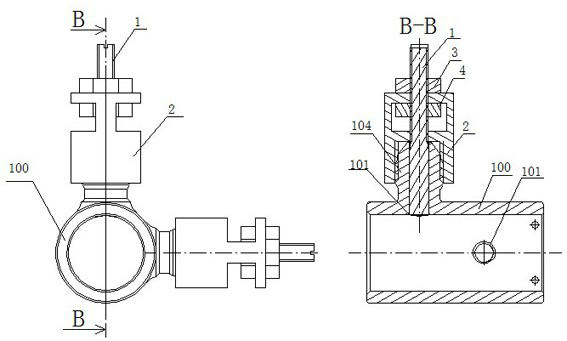

[0036]Such asfigure 2 ,image 3As shown, a clamp for avoiding sealed rubber rings, retaining rings, and a housing part 100 with associated apertures 101 and nozzles 104, including a compensation core. Rod 1, the outer diameter of the compensation mandrel 1 matches the nozzle 104 and the inner diameter; the compensation mandrel 1 extends into the end surface of the nozzle 104 is an arcuate surface that is consistent with the inner surface of the housing part 100.

[0037]The size of the compensation core rod 1 is designed according to the inner diameter of the associated hole 101 on the housing part 100, and the outer diameter of the core rod 1 and the inner diameter tolerance of the core rod 1, the curved surface of the correlation hole 101 are combined. The shape is consistent with the shape of the inner surface of the housing part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com