Jet type oil injector

An oil injector and jet technology, which is used in lubricating oil control valves, machines/engines, liquid variable capacity machines, etc., can solve problems such as component tolerances and difficulty in batching, and reduce manufacturing costs and tolerances. , the effect of simplifying the orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

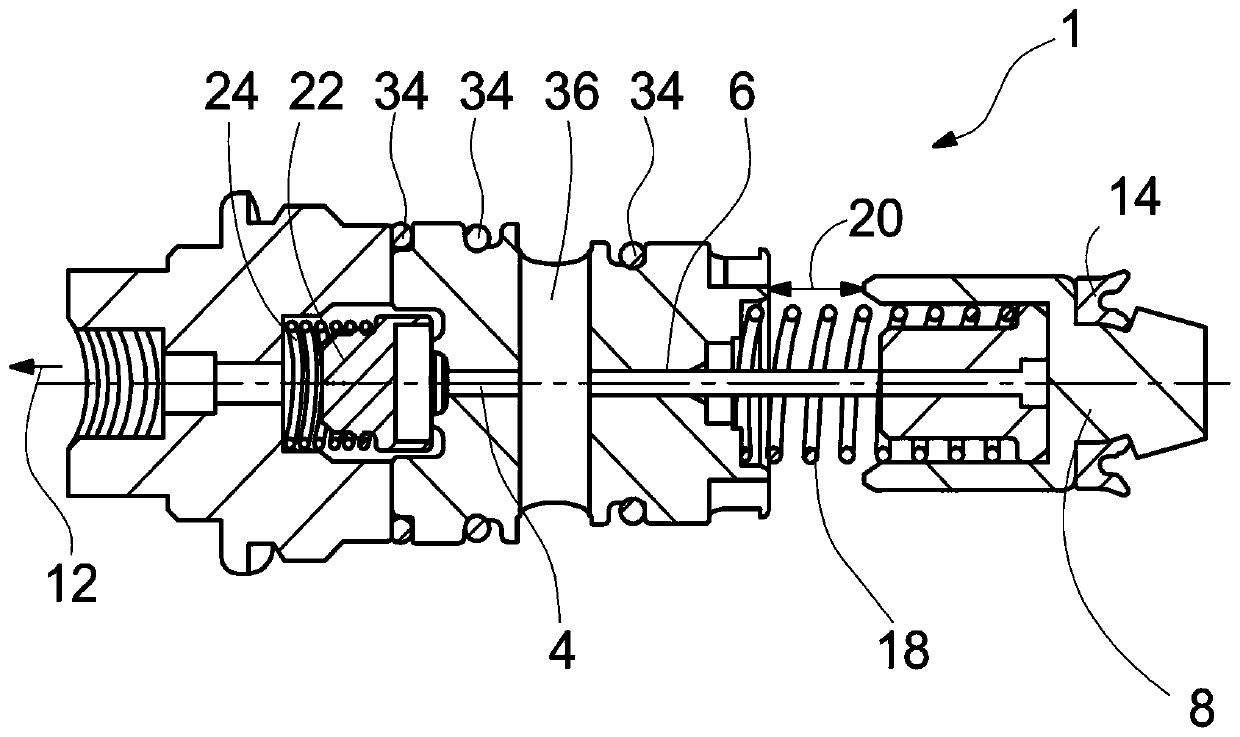

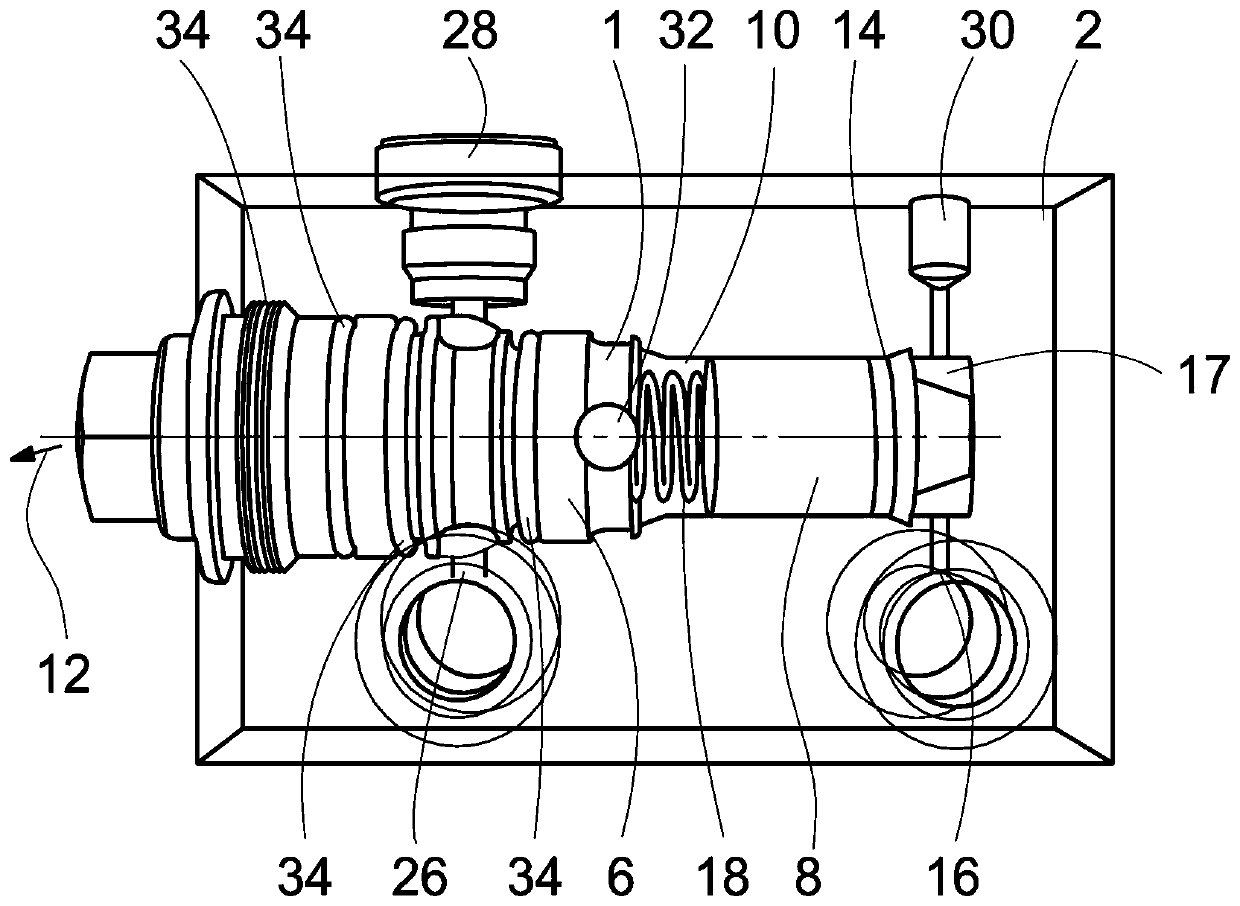

[0021] figure 1 and 2 A sectional view and a perspective view of the jet lubricator 1 , which is installed in the housing 2 , are shown. The jet lubricator 1 has a cavity 4 for containing a quantity of lubricant. The jet oiler 1 also has a dosing piston 6 and an actuating piston 8 . The cavity 4 , the dosing piston 6 and the actuating piston 8 are arranged in a stepped bore 10 in the housing 2 , which is designed as a blind bore.

[0022] During operation, the dosing piston 6 is actuated by the actuating piston 8 in order to transfer the lubricant to the lubrication points, so that the dosing piston 6 moves into the cavity 4 and thus discharges the lubricant present in the cavity 4 from the jet lubricator. The lubricant discharge direction is indicated by arrow 12 .

[0023] In the region of the actuating piston 8 , radial openings 16 are provided in the stepped bore, which can be connected to a fluid delivery unit (not shown). Through the radial openings 16 it is possibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com