A belt online adjusting device capable of preventing belt deviation

A technology for adjusting devices and belts, used in transportation and packaging, conveyors, winding strips, etc., can solve problems such as fatigue damage, affecting belt tension, belt edge deformation, etc., to improve service life and prevent belt deviation. , to ensure a good rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

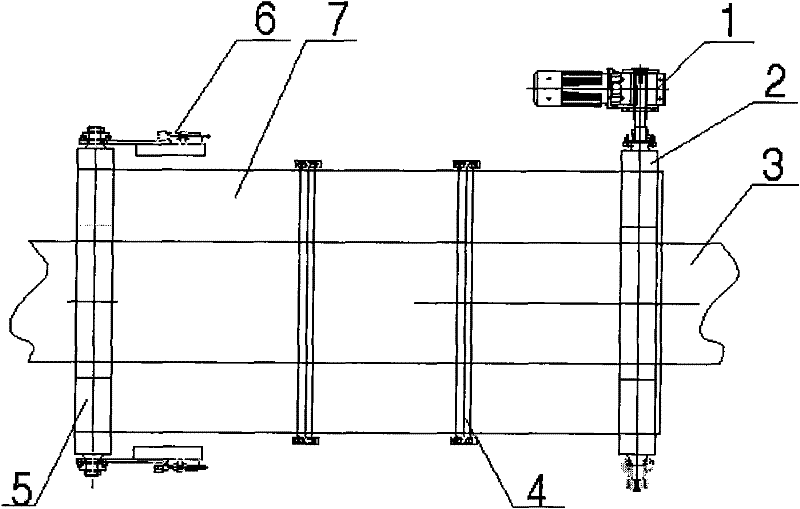

[0062] The device of the present invention is put into use in the outlet section of the five-cold-rolling unit finishing unit of a certain cold-rolling plant.

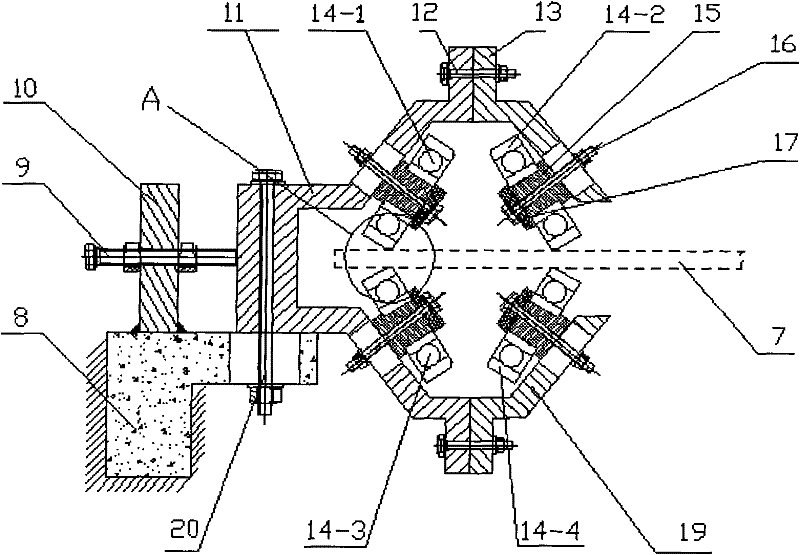

[0063] The utility model relates to an on-line belt adjustment device for preventing belt deviation, which is arranged at the upper and lower positions of the sides of the belt, and includes a pressure roller for exerting pressure on the belt, a pressure roller bracket part and a pressure roller angle adjustment part. The pressure wheel bracket part includes a fixed bracket and a side movable bracket that can move along the belt surface, and its pressure wheel is arranged obliquely above and below the upper and lower belts relative to the belt surface. The pressure wheel angle adjustment part is installed on the mobile bracket, and can adjust the belt pressure angle of the pressure wheel.

[0064] The fixed bracket is fixed on the basic equipment by welding, and the position of the left mobile bracket is adjusted throu...

Embodiment 2

[0074] Except for the following differences, others are the same as Example 1.

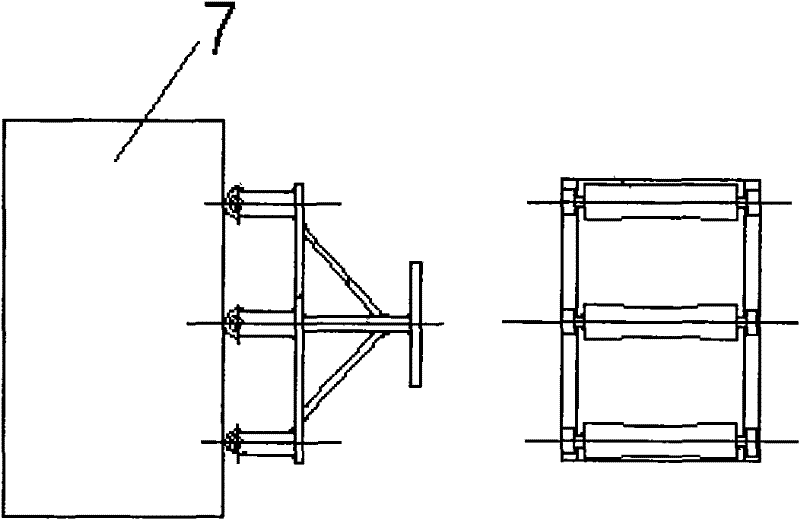

[0075] The belt on-line adjustment device for preventing belt deviation in this embodiment is used in pairs, that is, the side moving bracket that can move along the belt surface of the pressure wheel bracket part is connected with a symmetrical opposite side moving bracket, and the pair The same pressure wheels and pressure wheel angle adjustment parts are arranged symmetrically on the side moving support, so that the symmetrically arranged pressure wheels and pressure wheel angle adjustment parts on the moving support are arranged in a "V" shape.

[0076] The four sets of pressure rollers are respectively fixed on the left and right brackets, and the brackets can make the four sets of pressure rollers be symmetrically arranged on the upper and lower sides of the belt in a "V shape", and at the same time, the position can be adjusted up, down, left, and right to find out and adjust the belt deviat...

Embodiment 3

[0078] Except for the following differences, others are the same as Example 1.

[0079] The adjusting device of this embodiment is divided into left and right symmetrical structures, such as Figure 8, the left and right symmetrical structure of the adjustment device can be symmetrically arranged on both sides of the belt, the schematic diagram of its online use is shown in Figure 12. The integral adjustment device is generally used on narrow belts, and the adjustment device split into left and right symmetrical structures is generally used on wide belts.

[0080] The pressure roller is arranged obliquely above and below the upper and lower belts at an angle of 25-45° (β) relative to the belt surface, and the oblique wedge-shaped shaft surface is arranged obliquely at an angle (α) of 15-20° relative to the shaft centerline .

[0081] According to the belt on-line adjustment device for preventing belt deviation in the present invention, product quality problems such as strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com