Cylinder-shaped speed-changing box

A technology of gearbox and circular body, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc. problem, to achieve the effect of strong wear resistance, small footprint and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

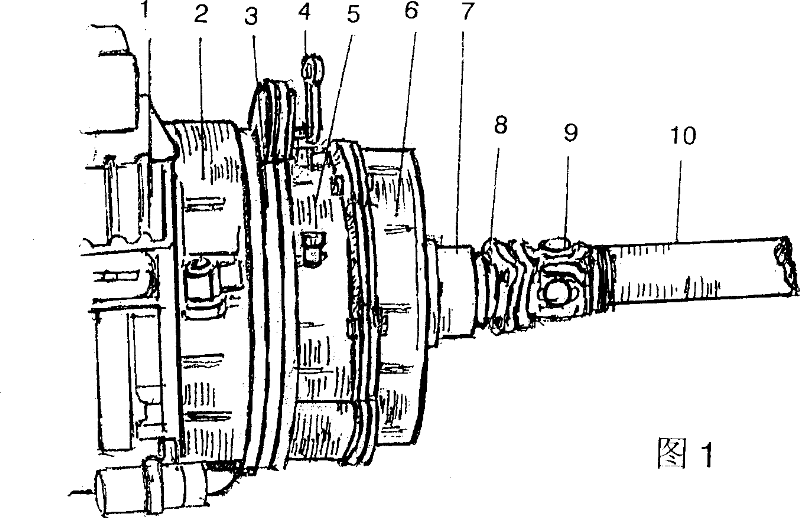

[0084] Figure 1 is the appearance of the circular gearbox

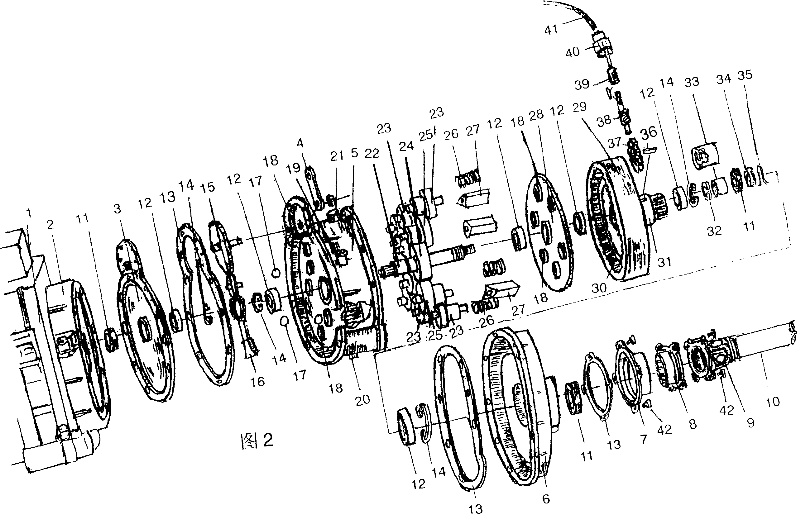

[0085] Fig. 2 is a diagram of the parts of the circular gearbox as shown in Fig. 6, Fig. 7, Fig. 13 and Fig. 31:

[0086] A kind of circular gearbox, which is connected with the engine with a cover plate 3, the cover plate is connected to the H-shaped plate 5, the inner plane of the H-shaped plate is connected with the fixed plate 28 by the fixed frame 27, and the outer side of the fixed plate is provided with a rotating plate 29, which rotates The inner ring sleeve of the disk has internal teeth 30 on the periphery of the fixed flat disk, the output shaft skin 31 outside the center of the rotating disk, the output shaft skin passes through the inner circle of the shell 6, and the input shaft 22 passes through the cover disk, the H-shaped disk, and the center of the rotating disk. There are bearings 12, oil seals 11 in the cover plate, bearings in the H-shaped plate and the fixed flat plate, bearings, worm gear 37, wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com