Device and method for preparing paper and plastic composite plate for steel roll package

A preparation device and packaging technology, applied in the directions of lamination devices, chemical instruments and methods, lamination auxiliary operations, etc., can solve the problems of high cost, easy rust and damage of steel coil packaging materials, and achieve low production cost, Easy recovery and recycling, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

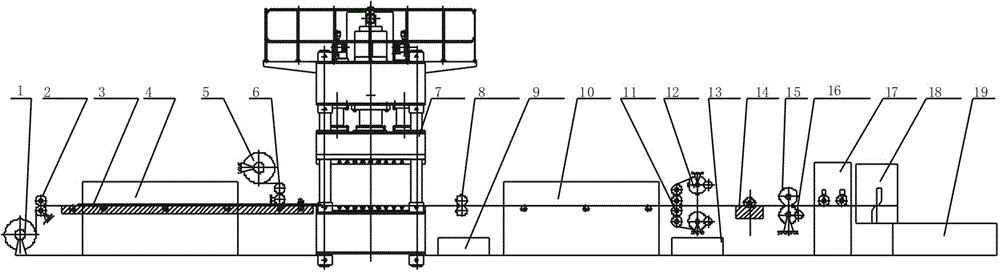

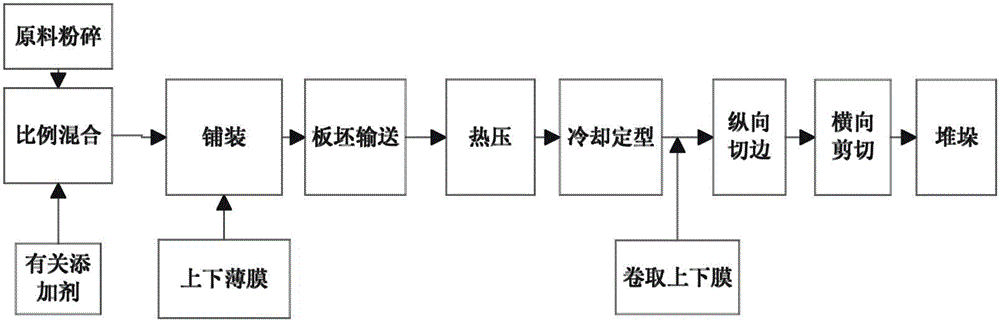

[0037] The schematic diagram of the structure of the paper-plastic composite board preparation device for steel coil packaging implemented according to the present invention is as follows: figure 1 , mainly including: the lower film uncoiler 1, the laying machine 4, the upper film uncoiler 5, the hot press machine 7, the cooling box 10, the lower winding device 11, the upper winding device 12, the moving Material trolley 13, edge shearing device 14, sheet material pulling device 15, shearing machine 18, stacking platform 19.

[0038]The lower film uncoiler 1 and the upper film uncoiler 5 have the same structure, and are mainly composed of lower base, follower bracket assembly, material shaft, roller device, magnetic powder brake device, deviation correcting machine (oil cylinder follower) and other components; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com