Red and green composite fluorescence glass for white-light LED (light-emitting diode) and preparation method of fluorescence glass

A technology of composite fluorescent and red fluorescent powder, which is applied in the field of red-green composite fluorescent glass for white LEDs and its preparation, which can solve the problems of easy change, co-fired crystal lattice environment, poor heat resistance, aging resistance and moisture resistance, etc. problem, to achieve the effect of improving performance, reducing process cost and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of red-green composite fluorescent glass for white light LED, said method comprising the following steps:

[0033] (1) Weigh according to the following mole fraction: R 2 O 5-20% mole fraction, ZnO 10-30% mole fraction, B 2 o 3 20-50% mole fraction, SiO 2 0-20% mole fraction, R'O 0-20% mole fraction, where, R 2 O, ZnO, B 2 o 3 , SiO 2 and R'O are derived from raw material R 2 CO 3 , ZnO, H 3 BO 3 , SiO 2 , R'CO 3 ;

[0034] (2) the raw material R 2 CO 3 , ZnO, H 3 BO 3 , SiO 2 , R'CO 3 After mixing evenly, melt it, the melting temperature is 900°C-1200°C, keep it warm for 1-3 hours, and obtain glass liquid;

[0035] (3) Pour the molten glass into cold water, and perform water quenching to obtain a transparent matrix glass;

[0036] (4) Grinding the glass into powder, uniformly mixing with the composite phosphor composed of the red phosphor and the green phosphor according to the mass ratio, and sintering in a muffle furnace at ...

Embodiment 1

[0039]A kind of red-green composite fluorescent glass for white light LED, it comprises matrix glass, red fluorescent powder and green fluorescent powder; Described matrix glass is mainly made of R 2 O, ZnO, B 2 o 3 , SiO 2 and R'O components are prepared from raw materials, where R 2 O is Na 2 O, R'O is BaO; specific glass components (mole fraction):

[0040]

[0041] The red phosphor is Ca1-xSrxAlSiN 3 :Eu 2+ and (Ca1-xSrx) 2 Si 5 N 8 :Eu 2+ , 0≤x≤1, the green phosphor is Lu3-xYxAl 5 o 12 : Ce 3+ , 0≤x≤1;

[0042] Wherein, the mass ratio of the matrix glass, the red phosphor powder and the green phosphor powder is glass powder:red phosphor powder:green phosphor powder=1:0.05:0.003.

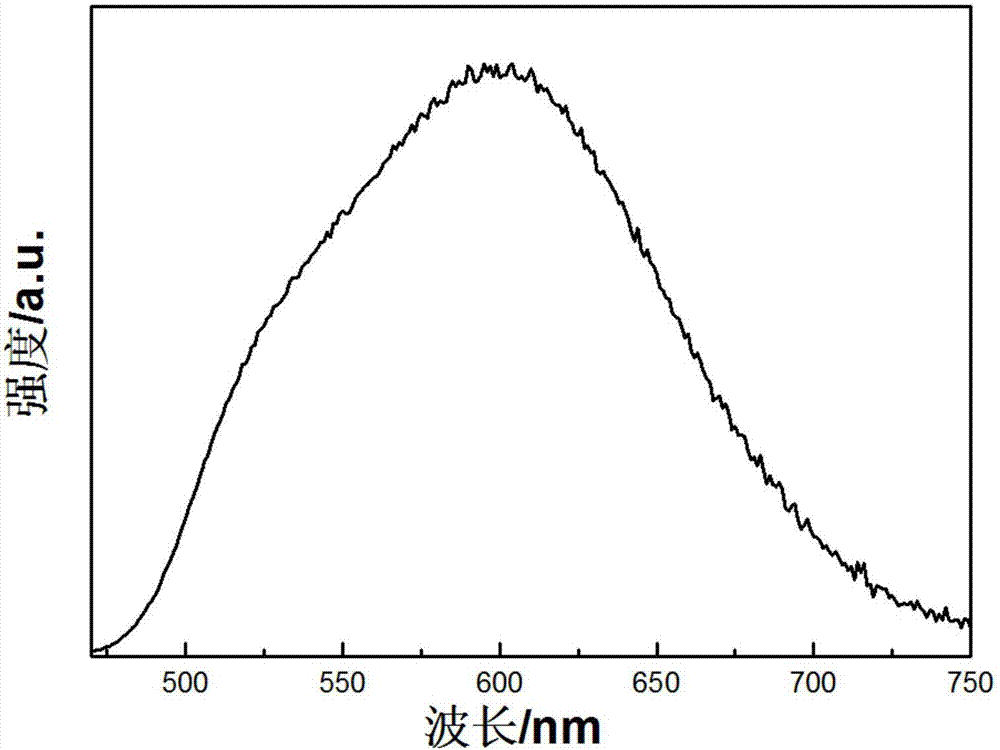

[0043] Adopt fluorescence spectrometer (FLS8900, British Edinburgh Instruments company) to measure the red-green composite fluorescent glass of above-mentioned gained, the emission spectrogram of gained is as follows figure 2 Shown; The physical figure of the obtained red-gree...

Embodiment 2

[0045] A kind of red-green composite fluorescent glass for white light LED, it comprises matrix glass, red fluorescent powder and green fluorescent powder; Described matrix glass is mainly made of R 2 O, ZnO, B 2 o 3 , SiO 2 and R'O components are prepared from raw materials, where R 2 O is Na 2 O, R'O is BaO; specific glass components (mole fraction):

[0046]

[0047] The red phosphor is Ca1-xSrxAlSiN 3 :Eu 2+ and (Ca1-xSrx) 2 Si 5 N 8 :Eu 2+ , 0≤x≤1, the green phosphor is Lu3-xYxAl 5 o 12 : Ce 3+ , 0≤x≤1;

[0048] Wherein, the mass ratio of the matrix glass, the red phosphor powder and the green phosphor powder is glass powder:red phosphor powder:green phosphor powder=1:0.05:0.001.

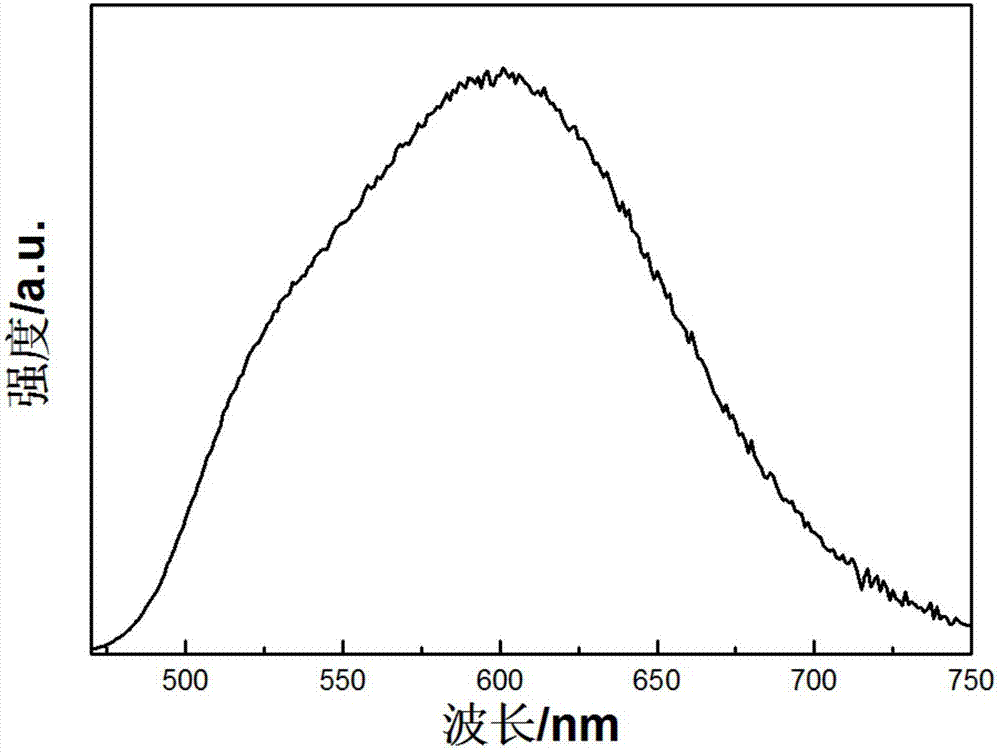

[0049] Adopt fluorescence spectrometer (FLS8900, British Edinburgh Instruments company) to measure the red-green composite fluorescent glass of above-mentioned gained, the emission spectrogram of gained is as follows image 3 shown. The fluorescence test results of Example 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com