Design method and production process of antique Chinese type long door decorative fabric

A design method and production process technology, applied in the field of fabric weaving, can solve the problems of complex flower shape of Chinese-style long door decorative fabrics, complex jacquard loom process, low production efficiency, etc. head effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

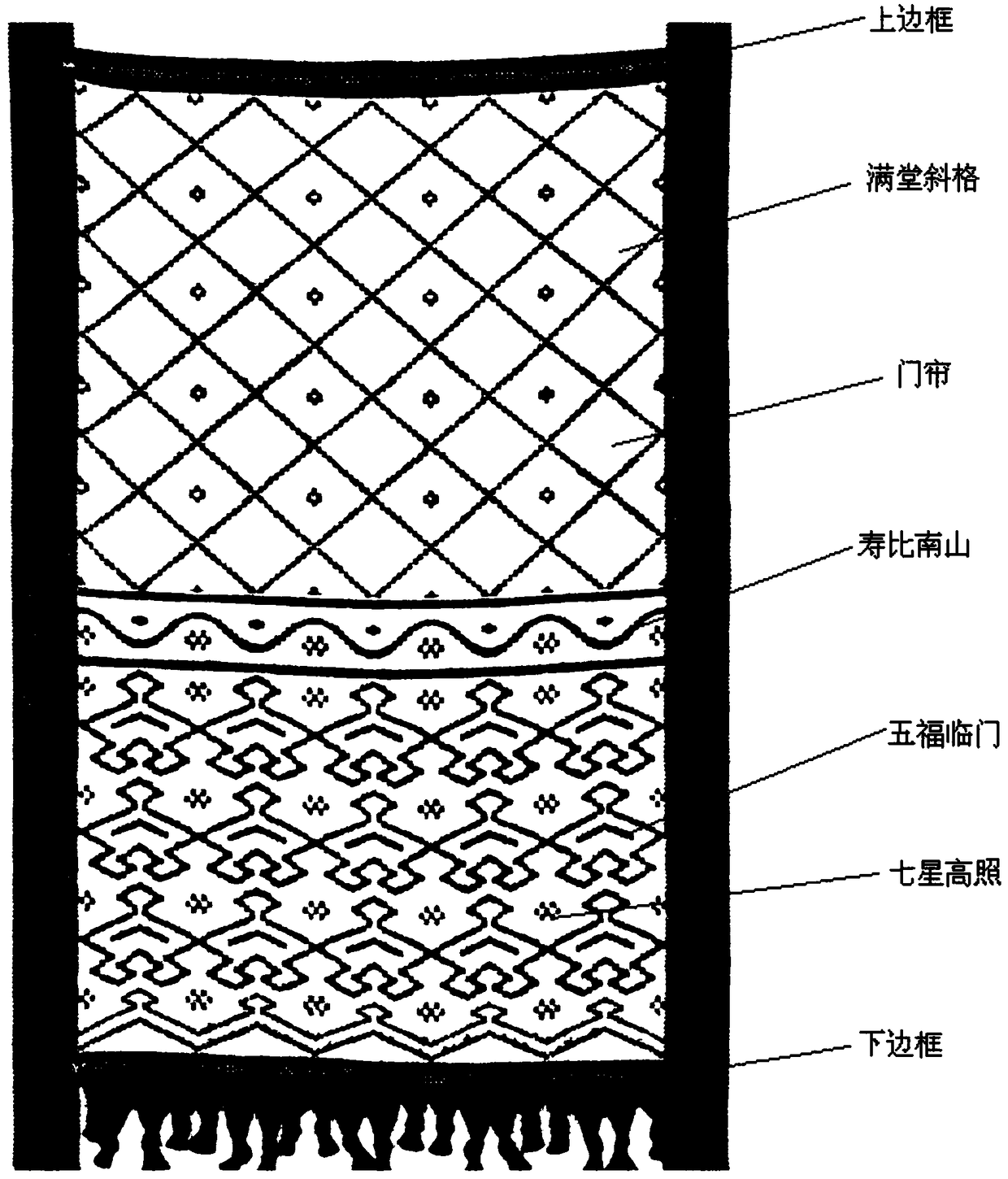

[0051] 1. Product Design Specifications

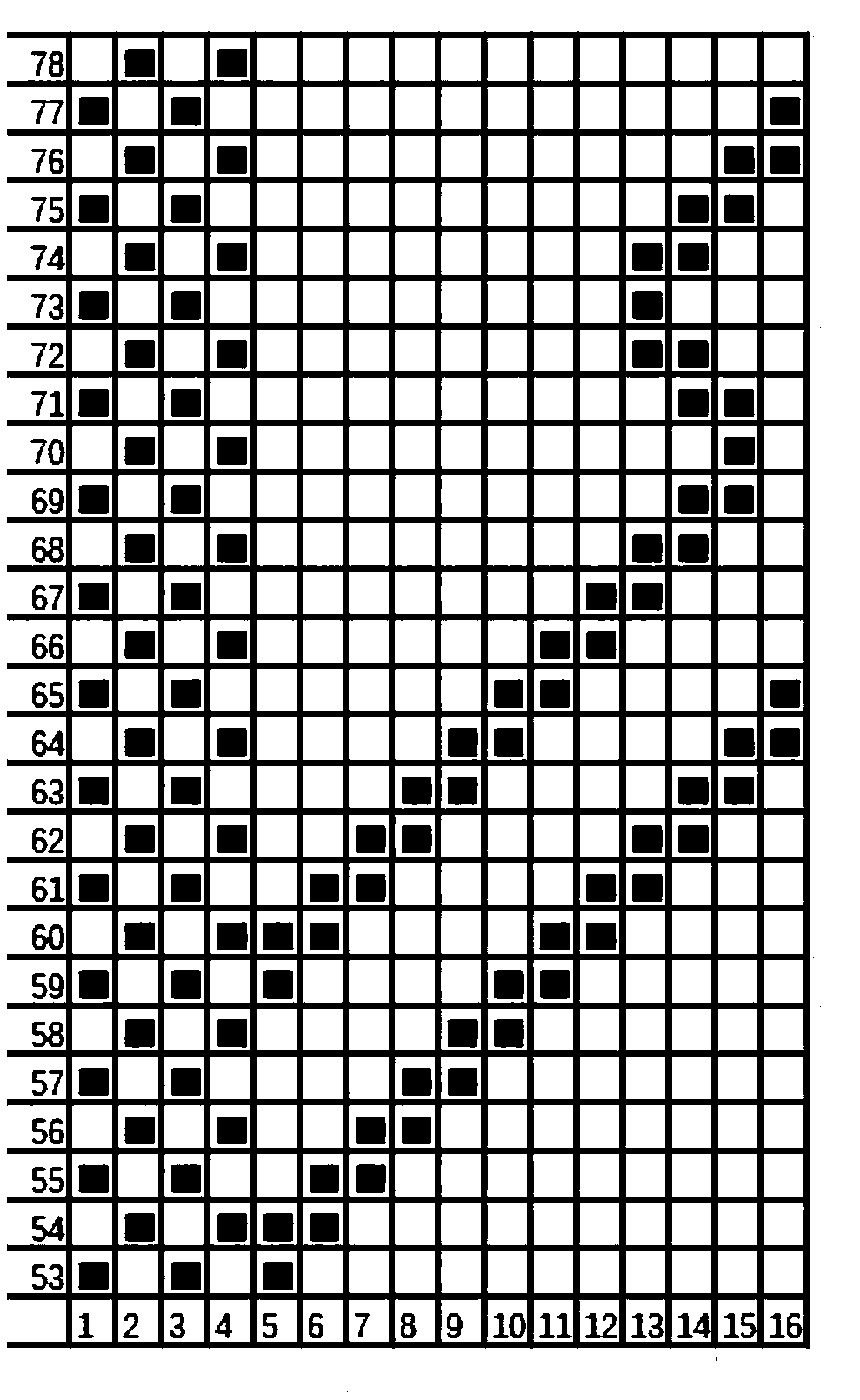

[0052] The fabric weave is plain weave + flower weave + dobby weave. The whole fabric consists of six large pieces.

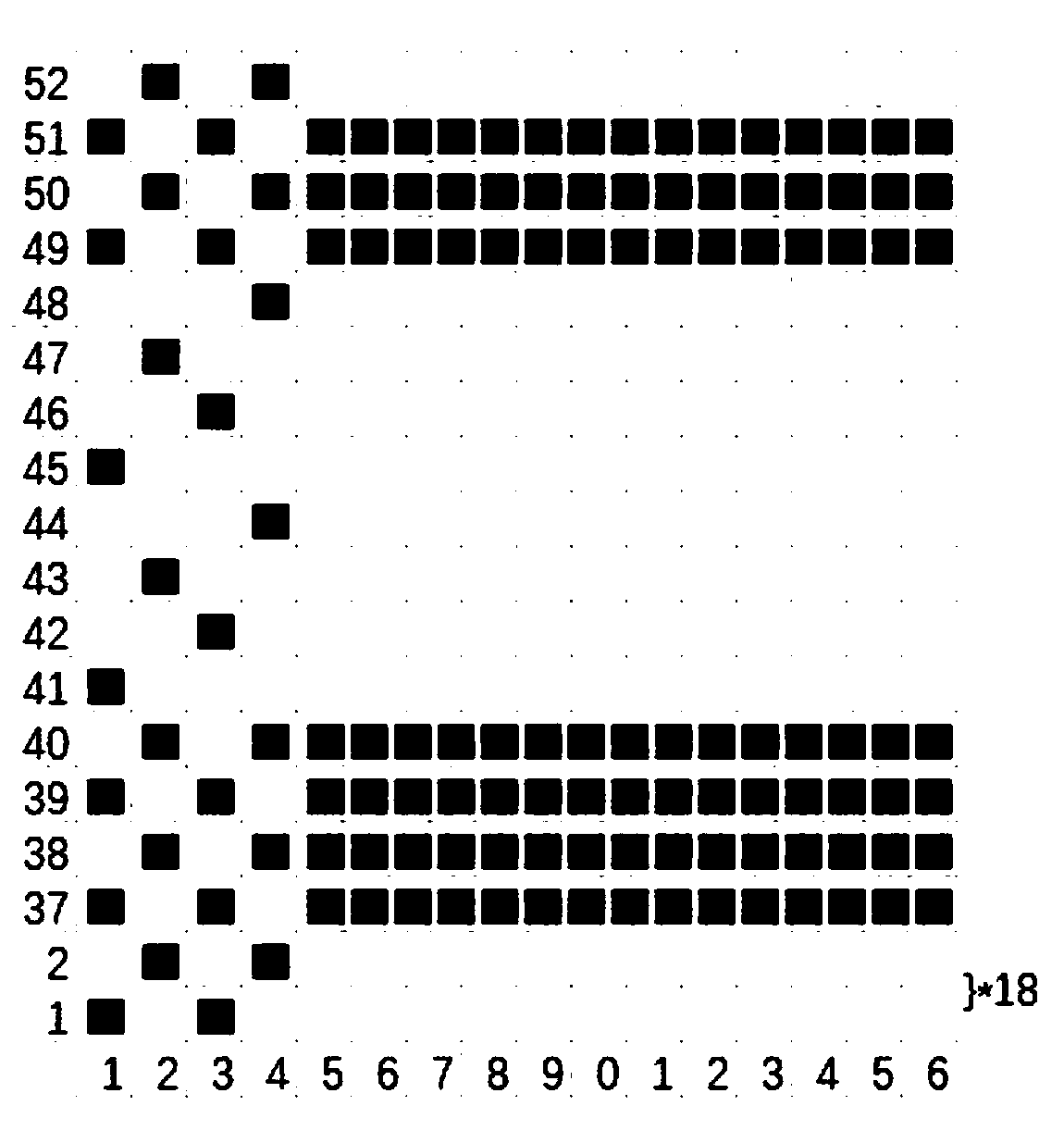

[0053] The first block is the lower frame of the Chinese-style Nagato. The lower frame is made of plain weave woven with ground warp yarn as the main color, and 36 weft yarns are used. The lower frame of the Chinese-style Nagato is formed by the warp floating length of the red warp yarn. In the middle of the lower frame, double weft weaving is used, and 4 dark blue yarns are woven into the fabric surface by using the change of the weft floating length. The Kesi effect makes the door frame structure clear. The use of weft double weave forms the traditional Kesi effect, and it is an innovative point of this fabric to be used in modern mass production. The pattern of the lower frame fabric is as follows figure 2 shown.

[0054] A total of 52 weft yarns are used in the lower frame, among which the 1st-36th weft forms ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com