Pick-blowing nozzle for fluid jet loom

A technology of fluid jetting and looms, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as loss of function, weft yarn damage, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

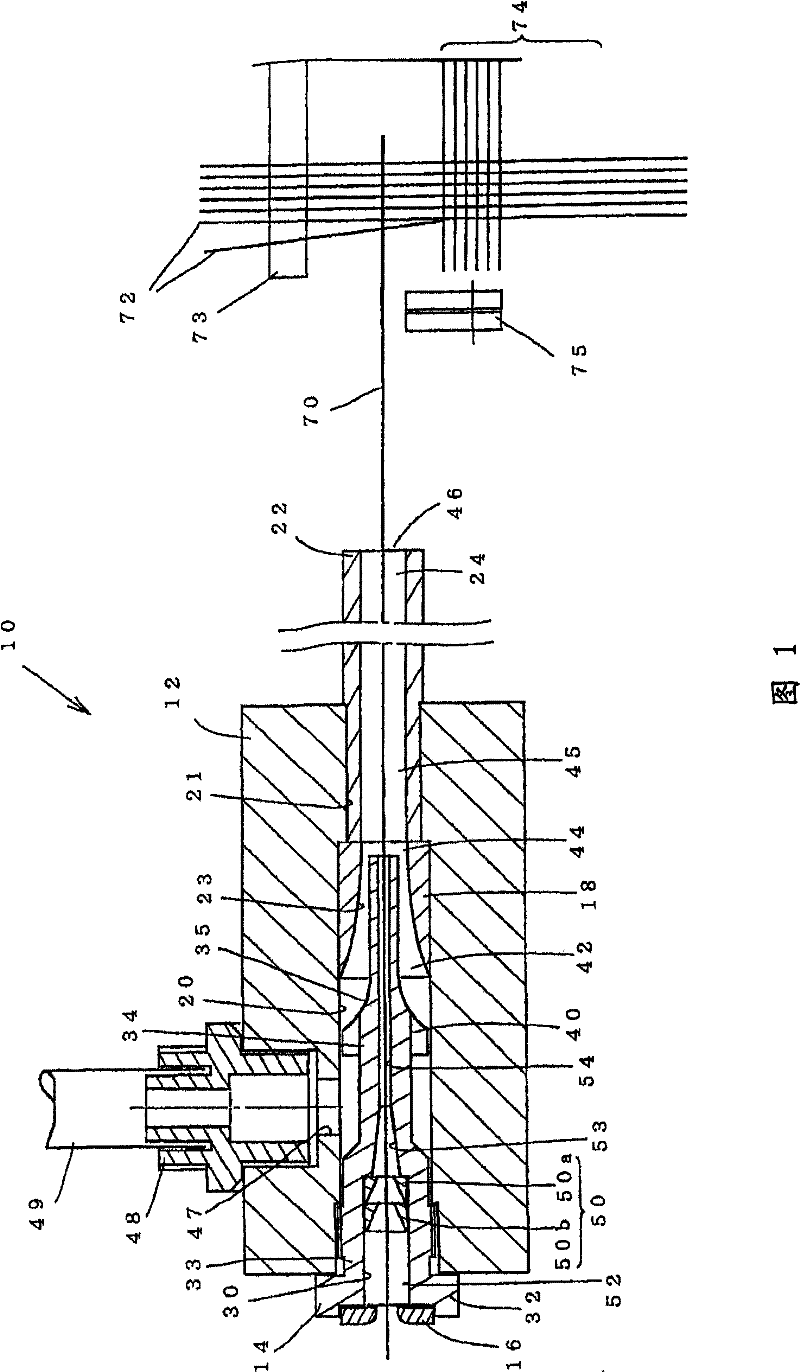

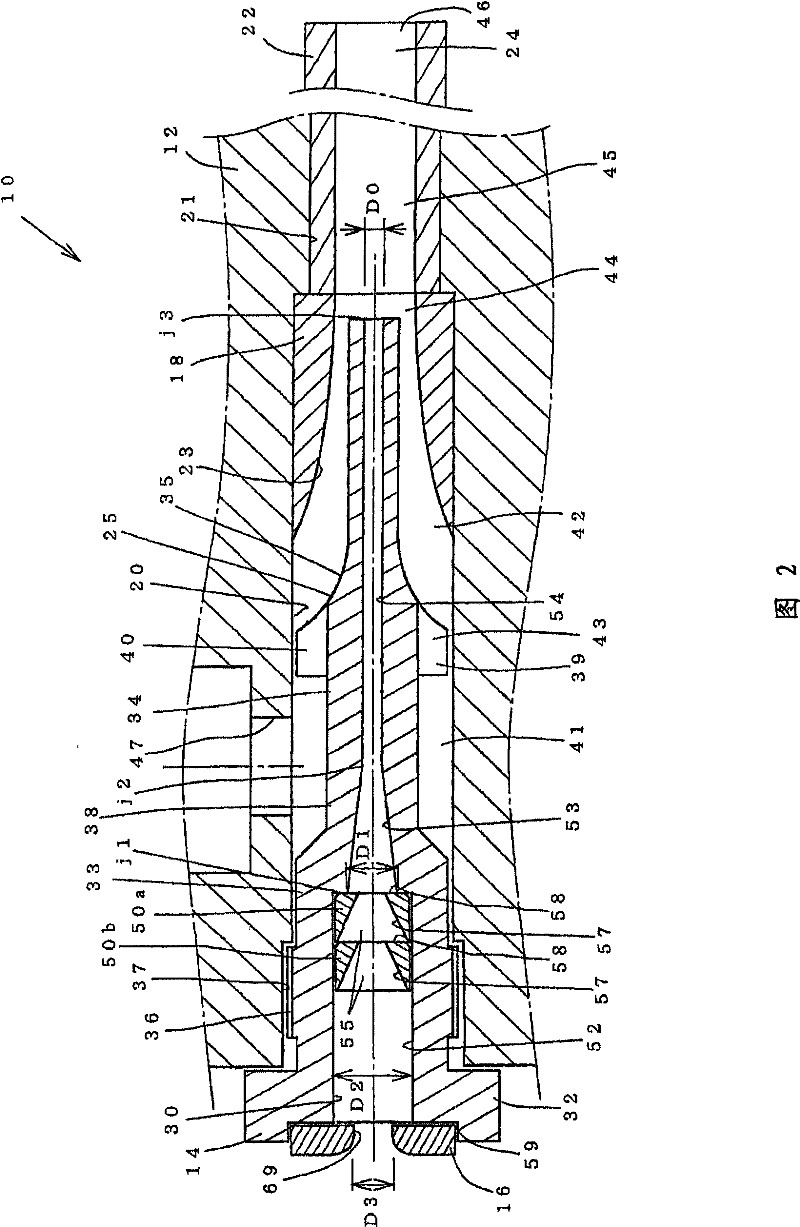

[0028] As the weft insertion nozzle 10 that can specifically implement the present invention, the main nozzle used by the air-jet loom is taken as an example, and the following uses Figure 1 ~ Figure 2 Be explained. refer to Figure 1 ~ Figure 2 The weft insertion nozzle 10 mainly includes: for example, its outer diameter forms a cylindrical shape, a nozzle body 12 having a through insertion hole 20 in its center; Yarn guide 14 in 20.

[0029] The nozzle main body 12 coaxially has a first insertion hole 20 opened on one end (rear end) side and a second insertion hole 21 communicated with the first insertion hole 20 and opened on the other end (front end) side. Both the first insertion hole 20 and the second insertion hole 21 have a circular cross-sectional shape, and the diameter of the former is larger than that of the latter.

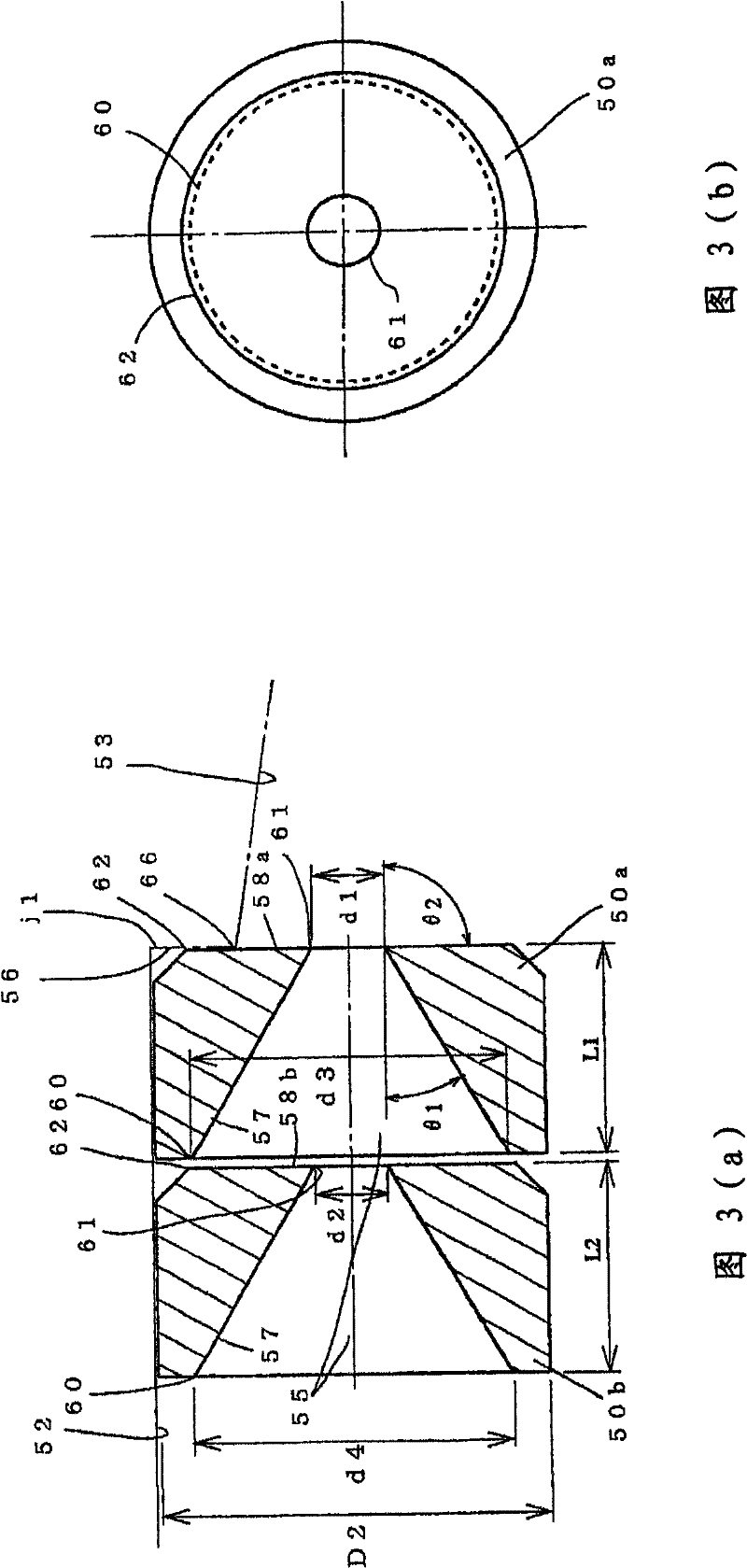

[0030] A throttling member 18 having a through hole is coaxially inserted into the first insertion hole 20 from one end (rear end) side, and a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com