Installation hole detection device

A detection device and mounting hole technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of technical personnel providing reference data to improve production quality, cost increase, etc., to achieve low cost, improve stability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

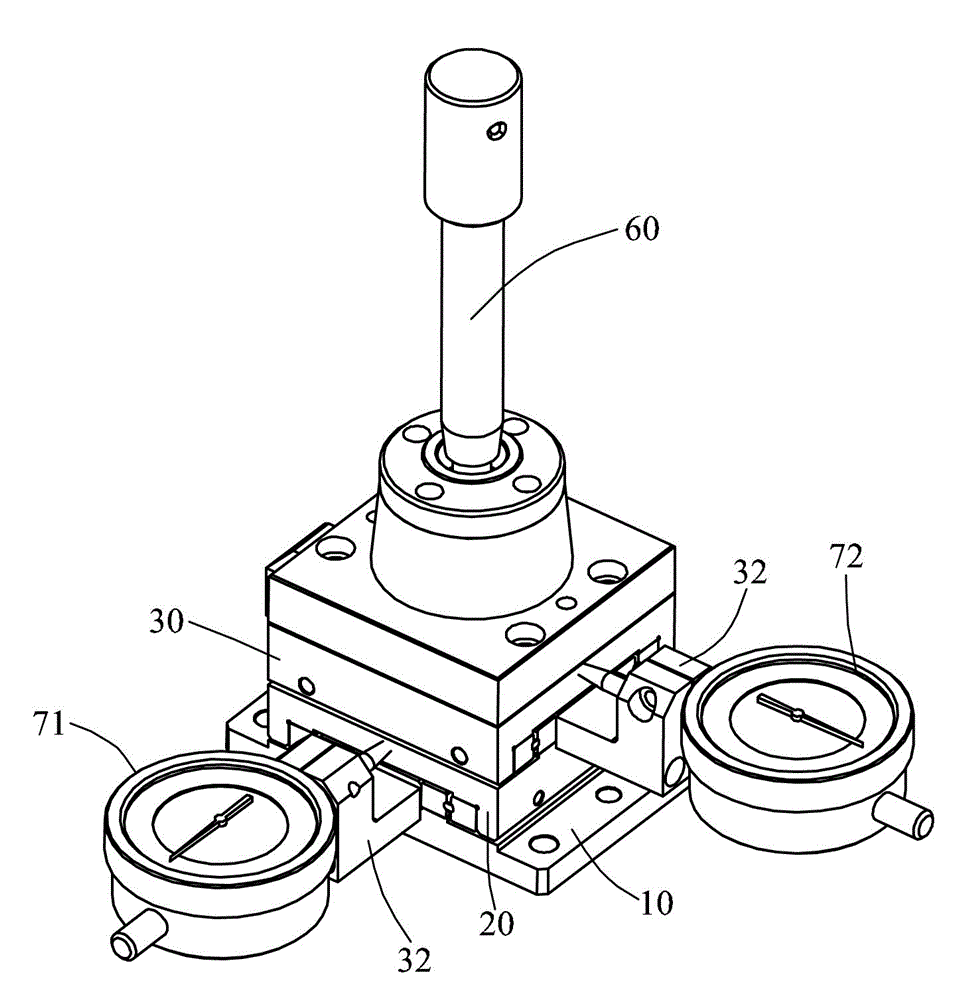

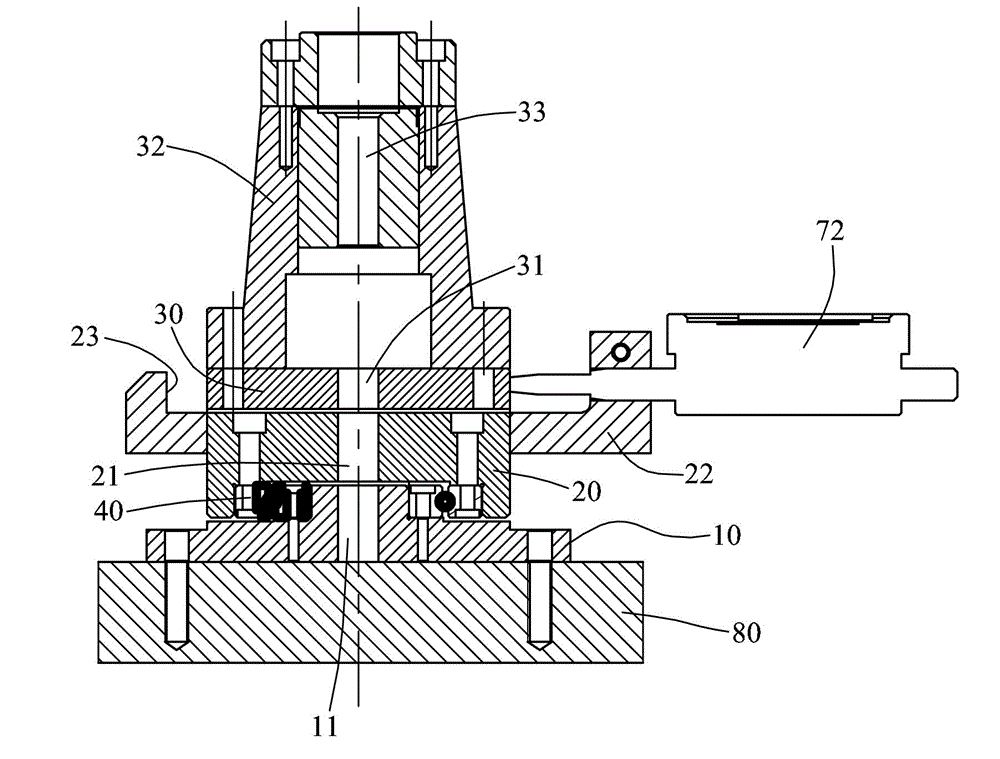

[0020] Such as Figure 1 to Figure 3 As shown, the installation hole detection device of the present invention has a base 10, which can be fixedly connected on the base 80 for supporting and positioning the detected piece, and has a reference hole 11 on the base 10, and the base 10 When it is fixedly connected to the base 80, the position of the reference hole 11 is made to coincide with the theoretical position of the installation hole of the tested part. A detection part 32 is connected on the base 10, and the detection part 32 can slide freely in the horizontal direction relative to the base 10, and an insertion hole 33 is set on the detection part 32, and when the detection part 32 is slid, it can be adjusted. The insertion hole 33 is positioned such that it coincides with the axis of the reference hole 11 .

[0021] The detection part 32 is specifically connected on the base 10 by a sliding assembly, the sliding assembly includes a horizontal slider 20 arranged above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com