Pressure booster and diecasting arrangement

A converter and pressure technology, applied in the direction of fluid pressure converter, fluid pressure actuating device, servo meter circuit, etc., can solve the problems of failure of spring preloading device, obstructed flow cross section, high production cost, etc., and achieve operation capacity. Strong, simple structure principle, the effect of improving operational safety and mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

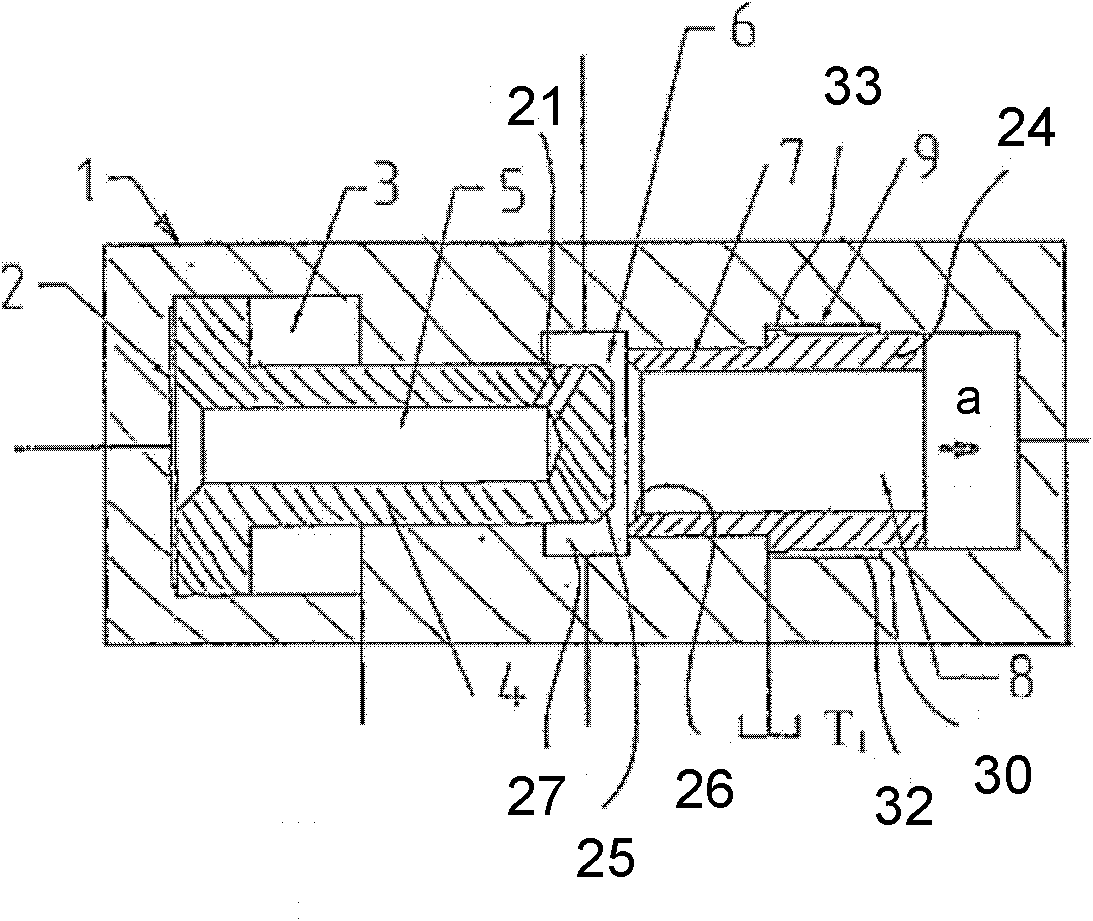

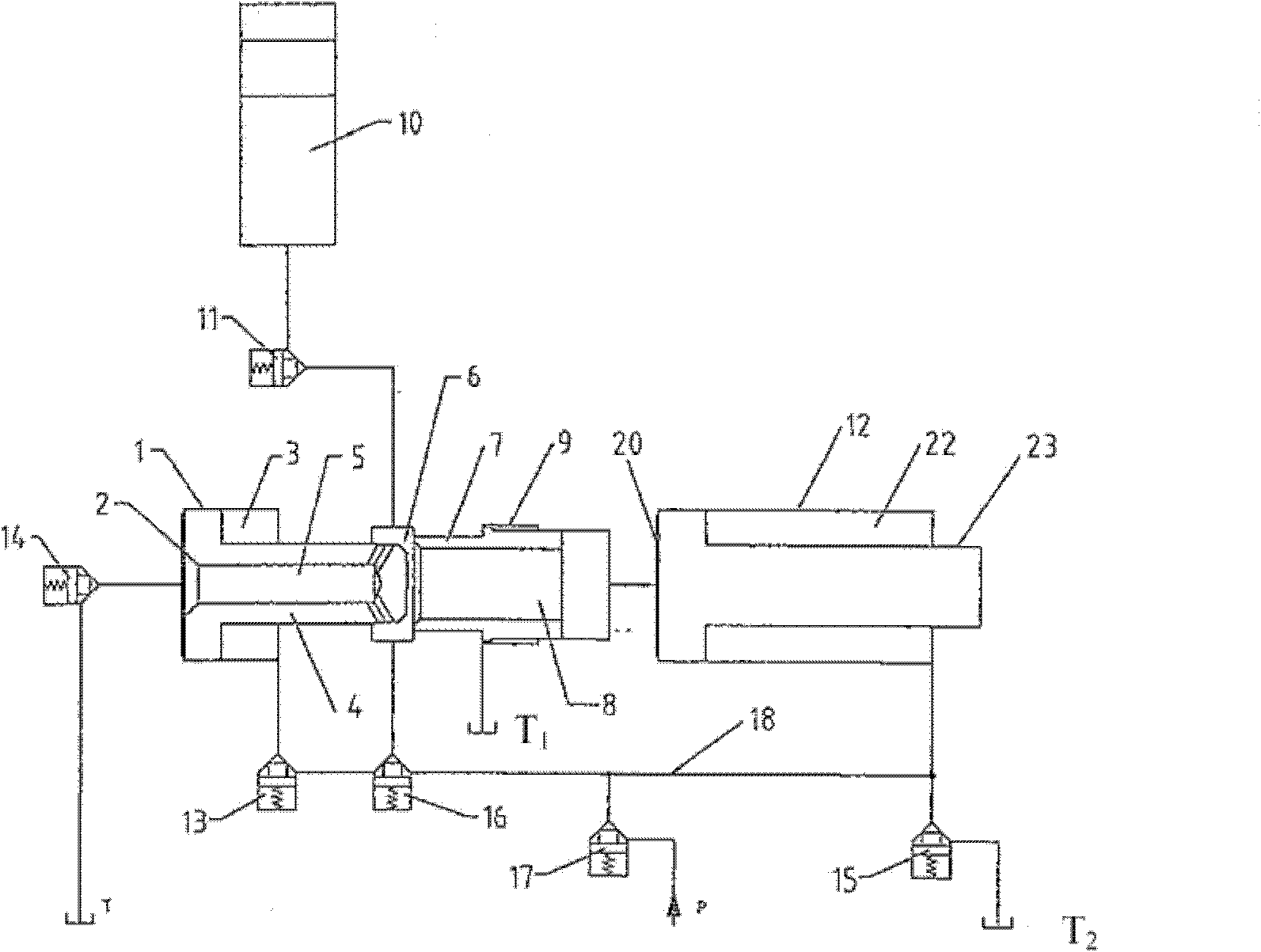

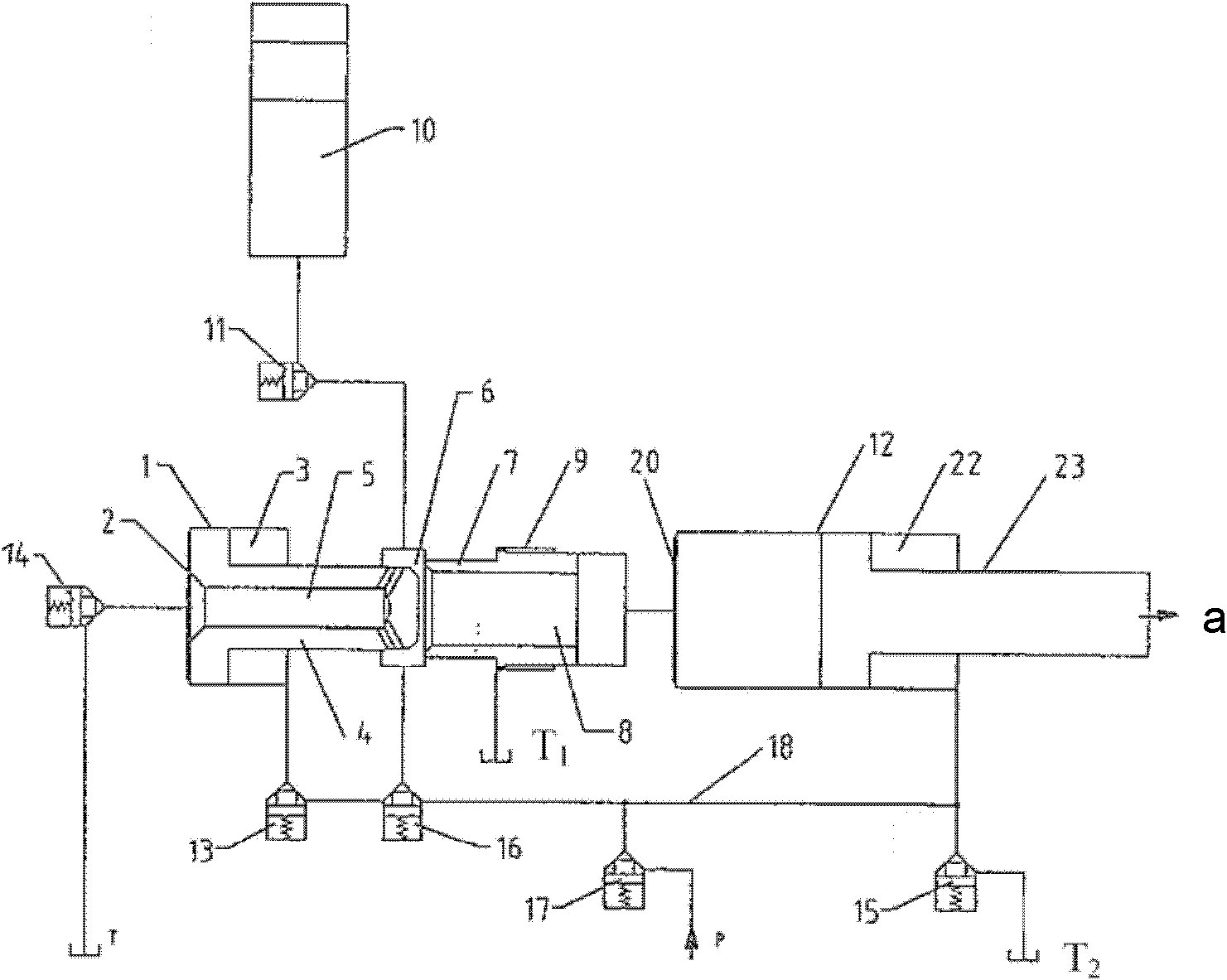

[0035] figure 1 Shows a pressure converter labeled 1, which can be used to increase the pressure in the piston chamber of a working fluid cylinder (not shown here). A pressure converter of this kind can be installed in an injection machine or press, for example.

[0036] In order to be integrated in a device of the injection machine, different pipelines can be provided. in figure 1 The simplification of the interface for the input and output of hydraulic medium is shown with thin lines. In relation to the substantially annular liquid inlet chamber arranged in the middle, for example, two ports can be seen to the pressure medium supply device. Each interface and the parts connected to it are shown in the following appendix Figure 2 to 6 Inside and explained. The pressure converter 1 has a pressure converter piston 4, which consists of a piston part and a piston rod coaxially connected to it. Visibly, the diameter of the piston part is larger than the diameter of the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com