Secondary structure concrete transportation tool capable of being manufactured on site

A secondary structure and transportation technology, applied in the field of construction tools, can solve problems such as waste, low efficiency, unfavorable construction of high-rise buildings, etc., and achieve the effect of improving work efficiency and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

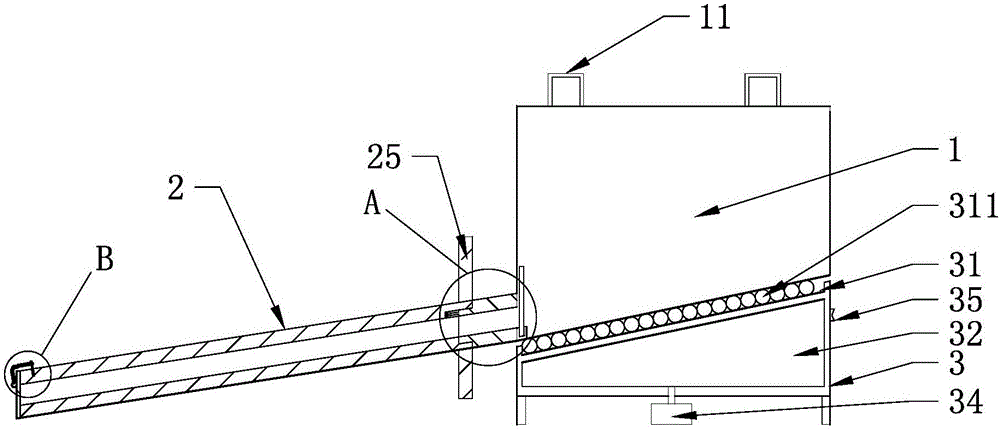

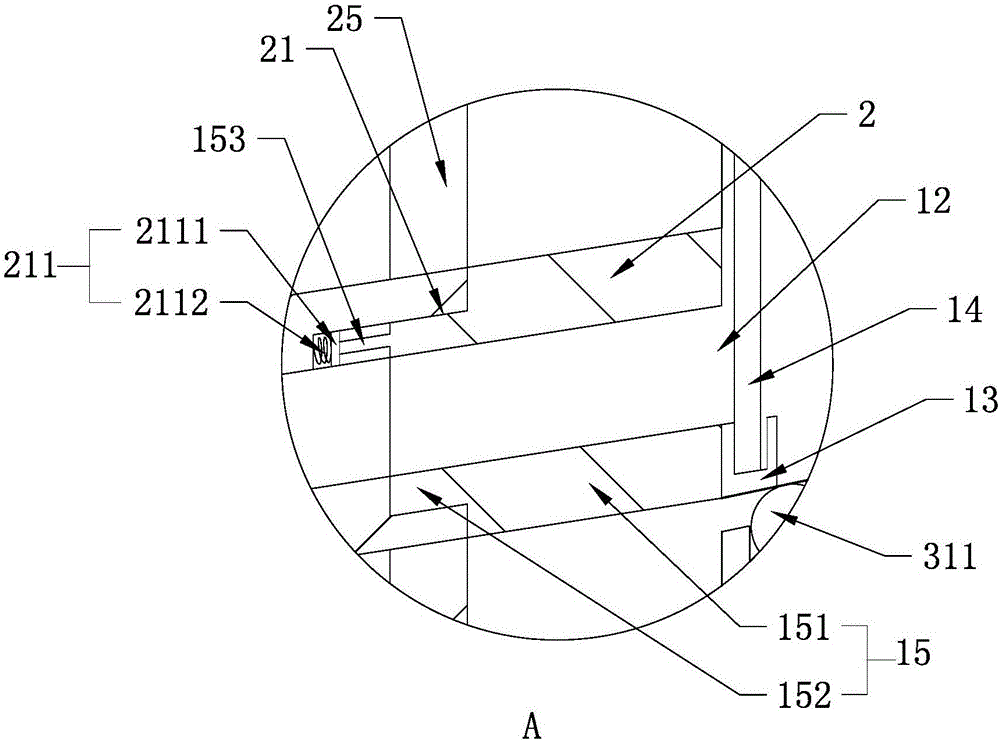

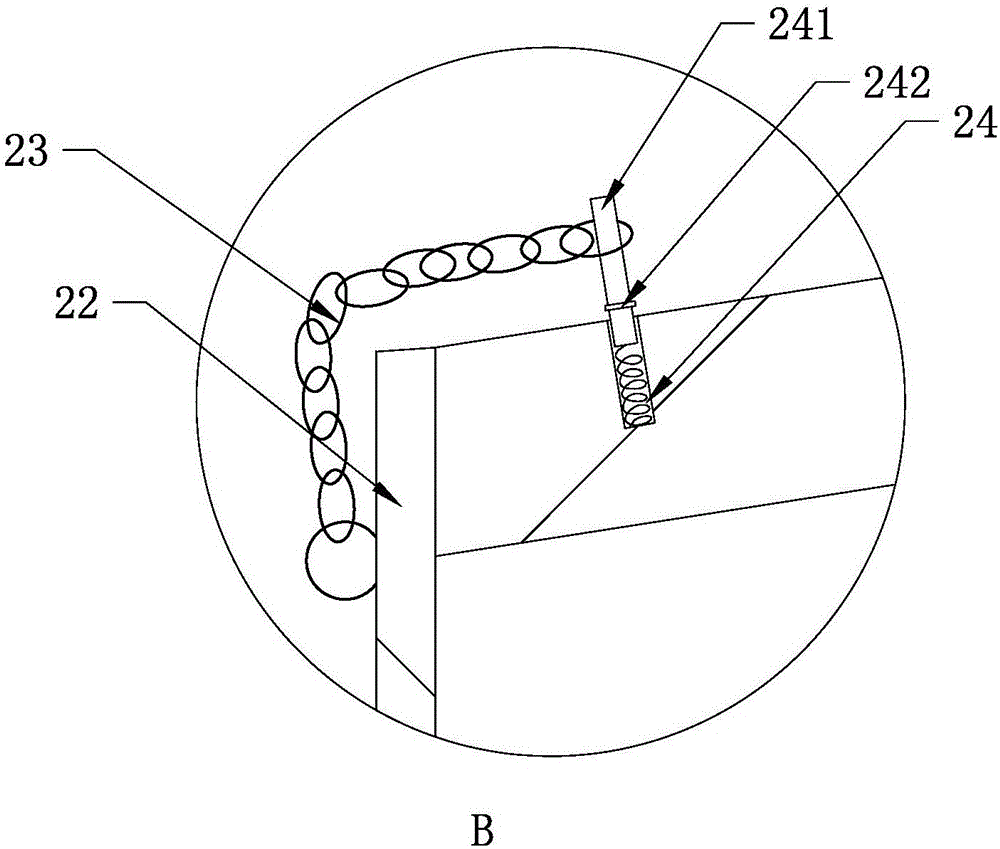

[0021] refer to Figure 1 to Figure 4 Further description will be given to an embodiment of a secondary structure concrete transportation tool that can be fabricated on site in the present invention.

[0022] A secondary structure concrete transportation tool that can be made on site, including a hopper 1, a pump pipe 2, and a base 3. The top of the hopper 1 is provided with four lifting rings 11 for tower cranes, and the lower part of the hopper 1 is provided with a discharge port for discharging concrete. 12. A slide rail 13 is provided in the hopper 1, and a material baffle plate 14 is provided on the slide rail 13 to block the discharge port 12. The discharge port 12 is connected with a discharge pipe 15, which includes the discharge pipe 15 and the discharge port 12. The connected fixed section 151 and the discharge section 152 for discharging, the pipe diameter of the discharge section 152 is smaller than the pipe diameter of the fixed section 151, the discharge pipe 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com