Angle bracket installation riveting point seat and riveting point device of photovoltaic module frame

A photovoltaic module and frame technology, applied in the production tooling field of photovoltaic module frame, can solve problems such as failure to meet the use requirements, low pass rate of finished products of photovoltaic module frame, corner code cannot be effectively locked, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

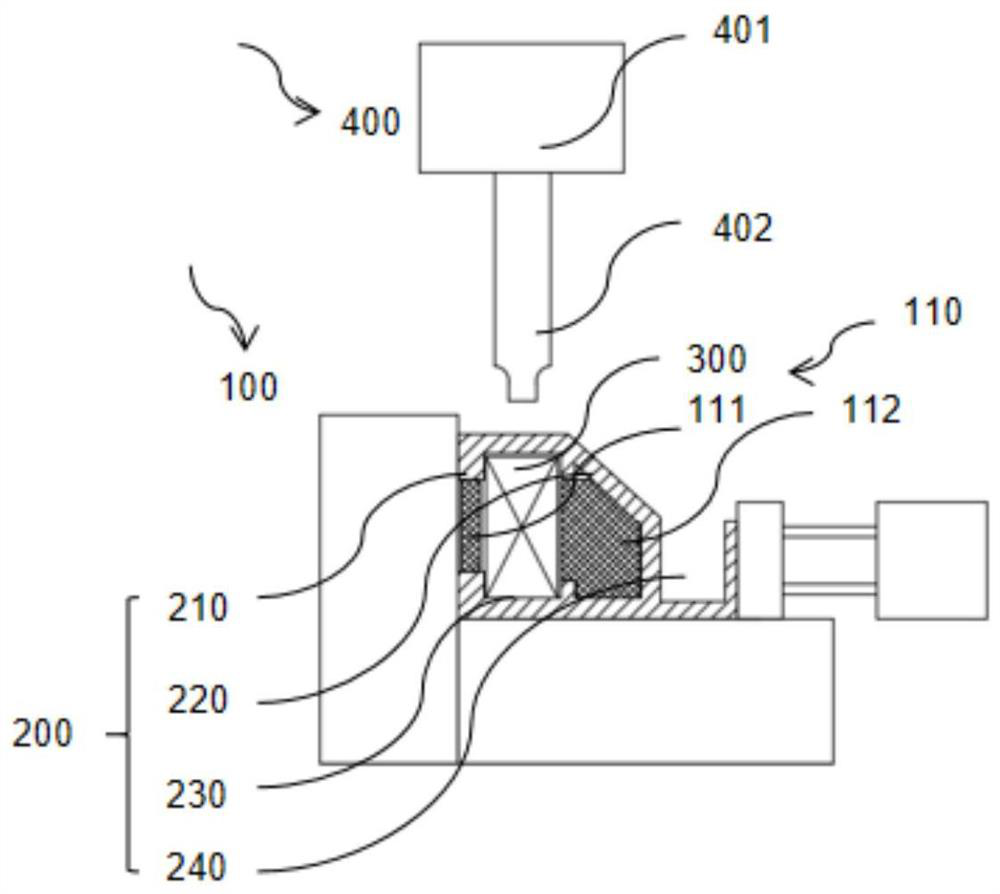

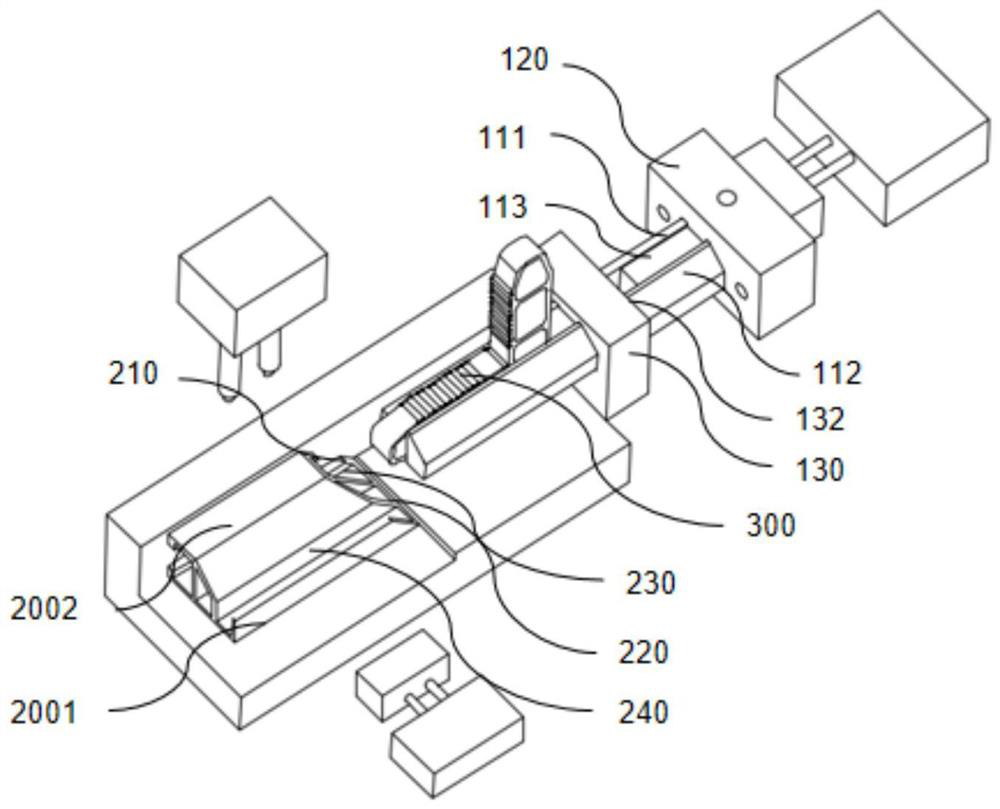

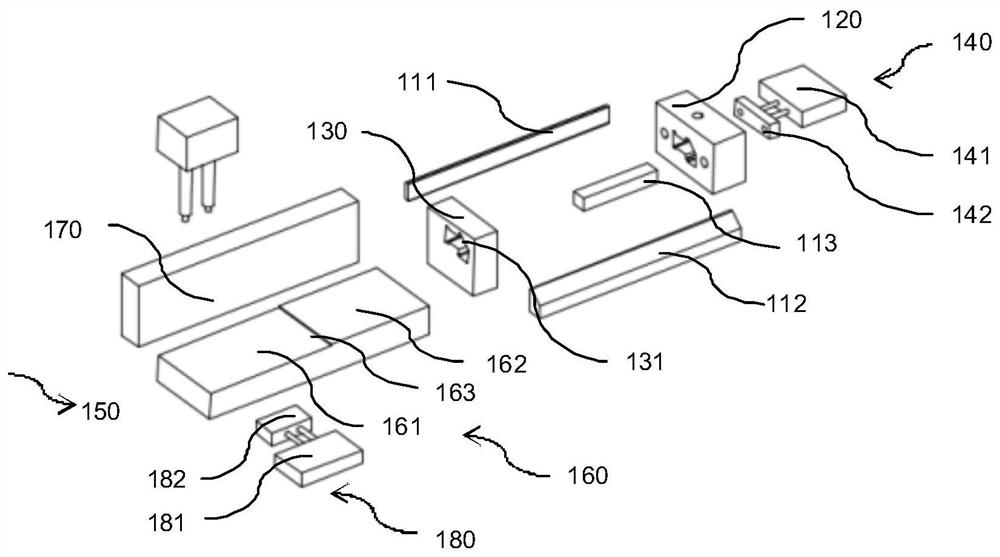

[0032] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the following in conjunction with the attached Figure 1-3 Specific embodiments of the present invention are described in detail.

[0033] See attached figure 1 , a photovoltaic module frame 200, including an opening fastening part 210, a corner connection cavity 230, a cavity 220 and a clamping part 240, the opening fastening part 210 is used to fix the photovoltaic module frame 200 on the base, and the corner connection The cavity 230 is used to cooperate with the corner bracket 300 , the cavity 220 communicates with the corner bracket connection cavity 230 , the cavity 220 is located between the corner bracket connection cavity 230 and the clamping part 240 , and the clamping part 240 is used for clamping the laminate.

[0034] See attached figure 1 , the first aspect of this embodiment provides a corner code installation riveting point s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com