Seal baiting valve

A discharge valve and sealing seat technology, applied in shaft seals, lifting valves, valve details, etc., can solve problems such as easy leakage of material liquid, human injury, and safety, and achieve improved sealing performance, convenient operation, and increased service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings and embodiments.

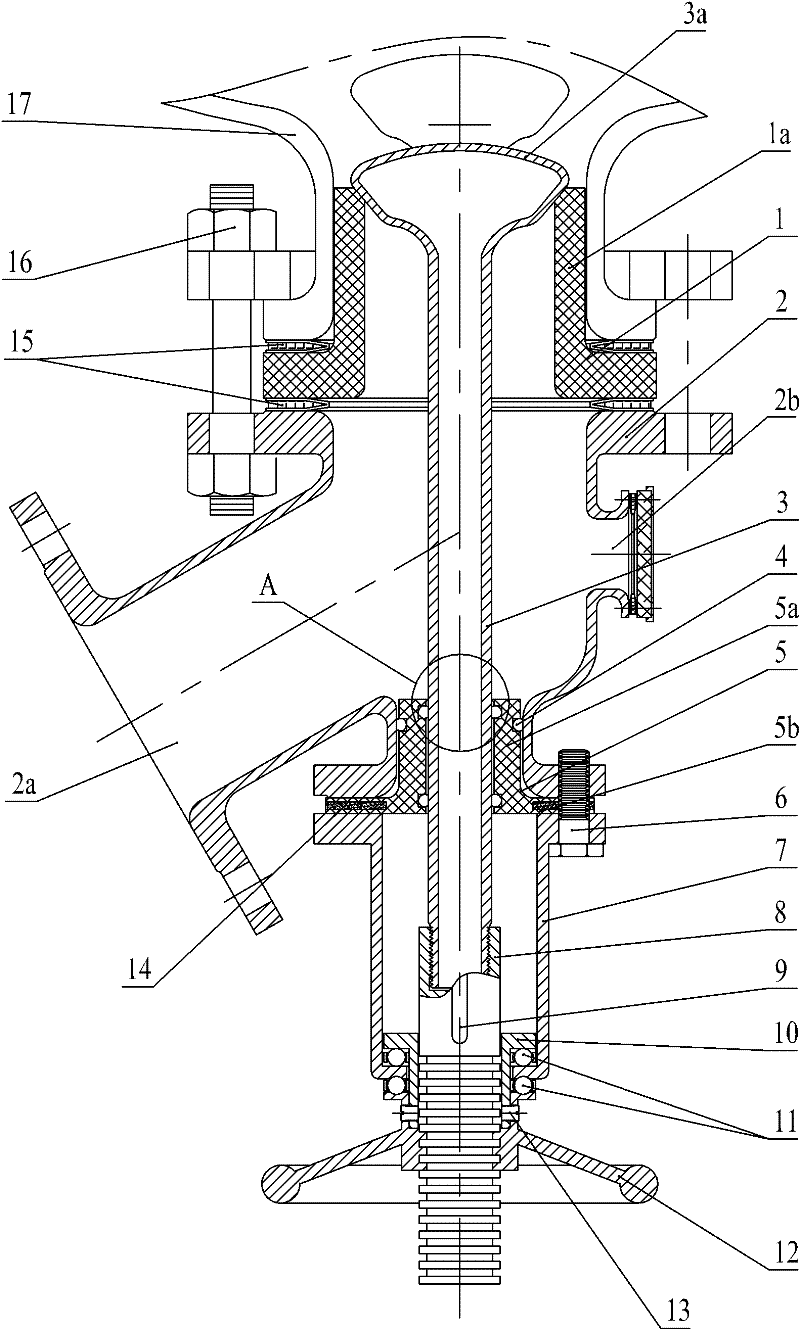

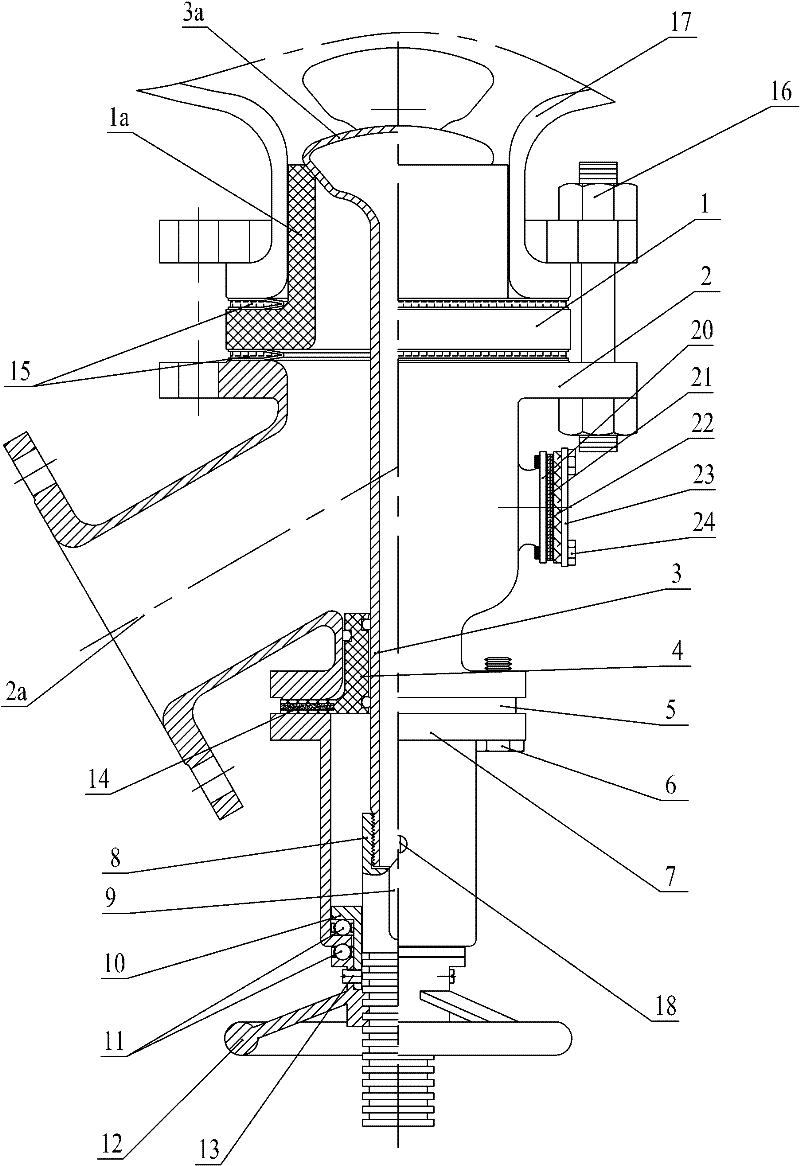

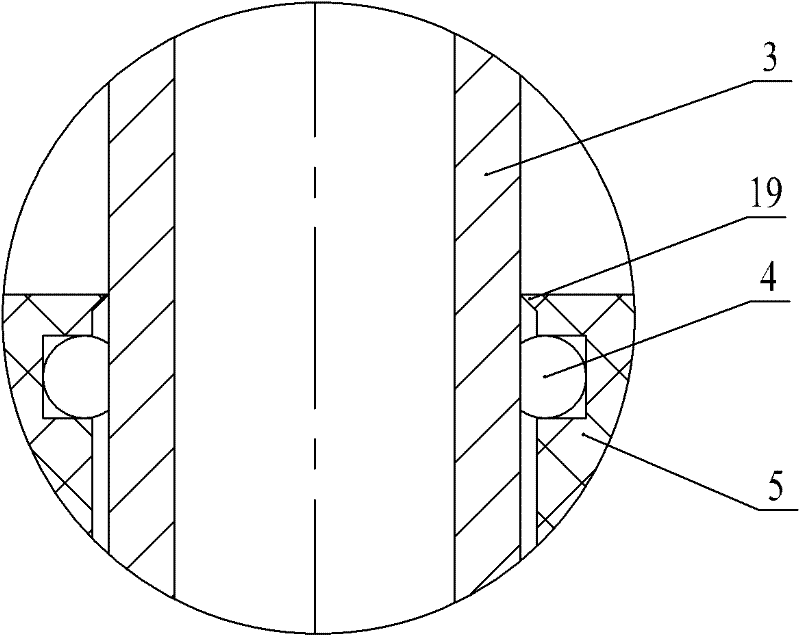

[0020] As shown in the figure, the sealed discharge valve in the embodiment is mainly composed of a valve seat 1, a valve body 2, a valve core 3, a sealing ring 4, a sealing seat 5, a hexagon head bolt 6, a bracket 7, a screw rod 8, and a connecting sleeve 10 , flat bottom thrust ball bearing 11, hand wheel 12, set screw 13, gasket 15, limit pin 18, tetrafluoroasbestos washer 21, transparent tempered glass 22, cover plate 23 and hexagonal screw 24 and other components.

[0021] Such as figure 1 , figure 2 As shown, the valve body 2 is connected to the discharge port at the bottom of the container 17 by a looper flange 16, and the side of the valve body 2 has a discharge port 2a; the valve seat 1 is sandwiched between the upper end of the valve body 2 and Between the containers 17; the bracket 7 is connected to the lower end of the valve body 2 by means of he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com