Truss type servo-transfer guide rail assembly

A technology of truss and guide rail, which is applied in the field of truss servo handling guide rail assembly, which can solve the problems of unsafe use, loss of control, waste of resources, etc., and achieve the effects of reduced loss of manpower and material resources, high construction safety, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

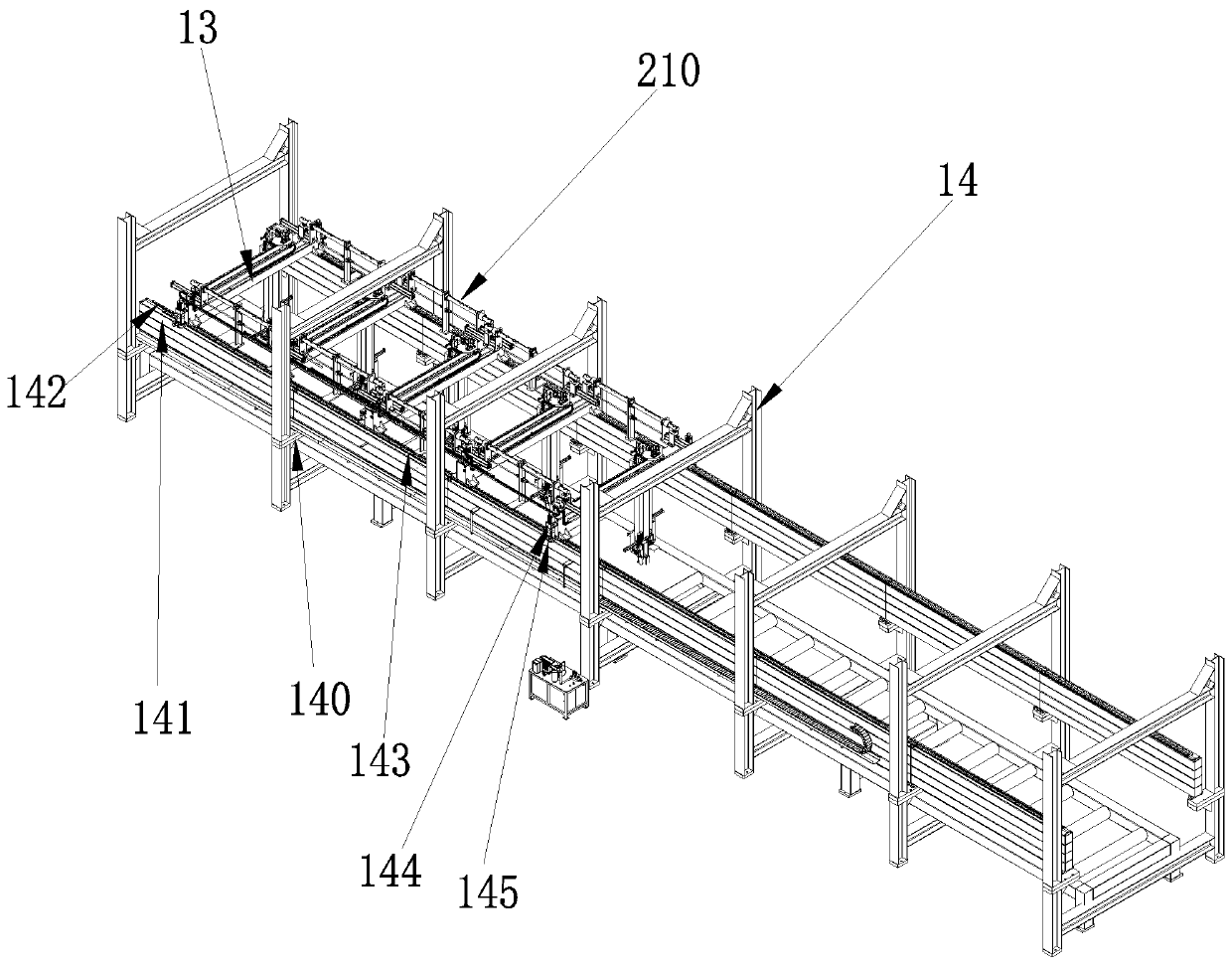

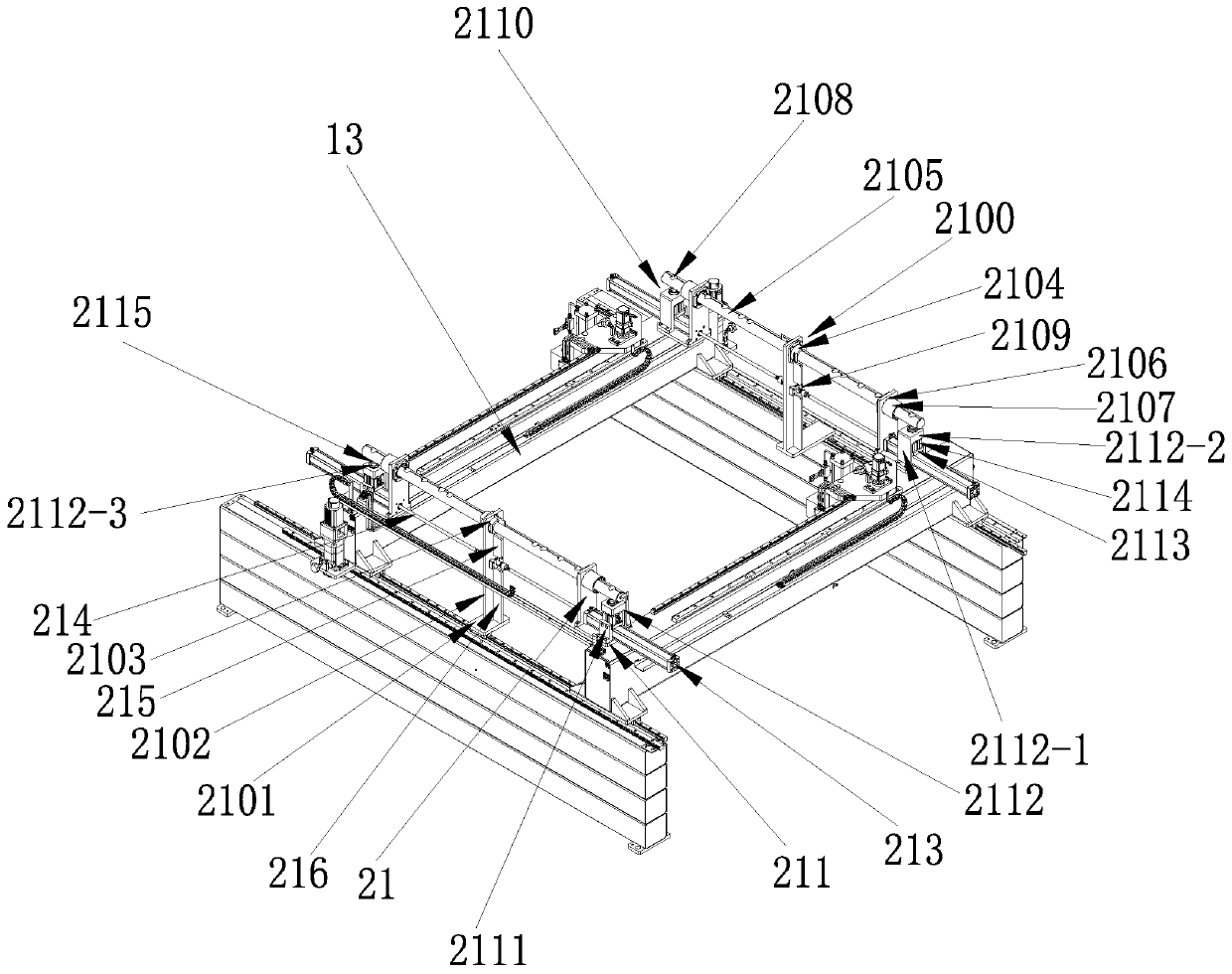

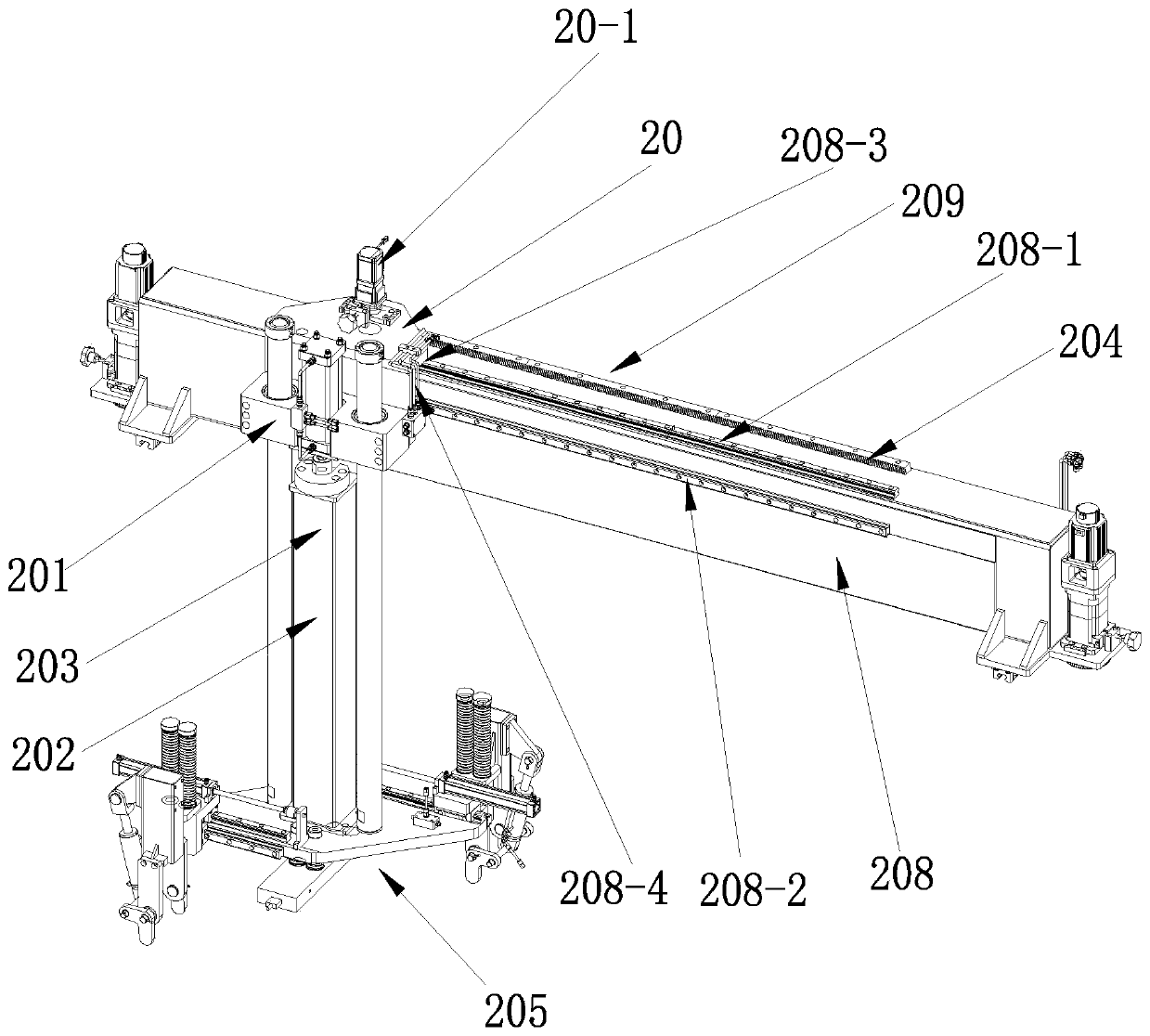

[0032] Example: such as figure 1 As shown, a truss servo transport rail assembly includes several trusses 14 and several grasping and conveying devices 13; truss support bases 140 are installed on both sides of the bottom of the truss 14, and truss support blocks 141 are installed on the truss support bases 140, Several trusses 14 are connected by truss support blocks 141, and transverse slide rails 142 are installed on the truss support blocks 141, and several grasping conveying devices 13 are slidably connected on the transverse slide rails 142; Mechanism 210, a first rack 143 is provided on one side of the horizontal slide rail 142; a driving motor 144 is installed on one side of the grasping and conveying device 13, and a first gear 145 is connected to the lower side of the bottom of the driving motor 144, and the first The gear 145 is set in mesh with the first rack 143; the present invention is simple in structure, convenient and practical, and can carry out material loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com