Special machine for fine boring of pin holes in crankshafts

A crank shaft and pin hole technology, which is applied in the field of crank shaft fine boring pin hole special machine, can solve the problems of low production efficiency and complicated processing procedures, and achieve the effects of stable pressure, guaranteed processing quality, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

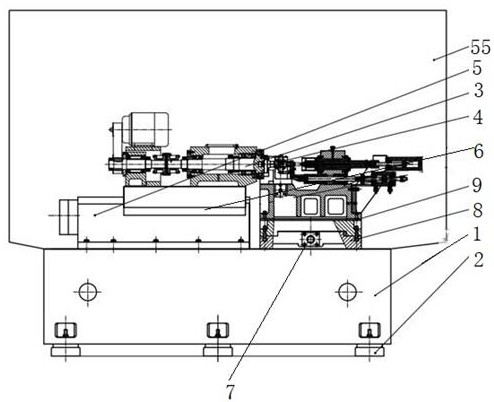

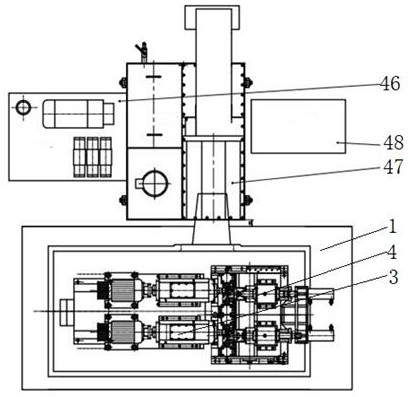

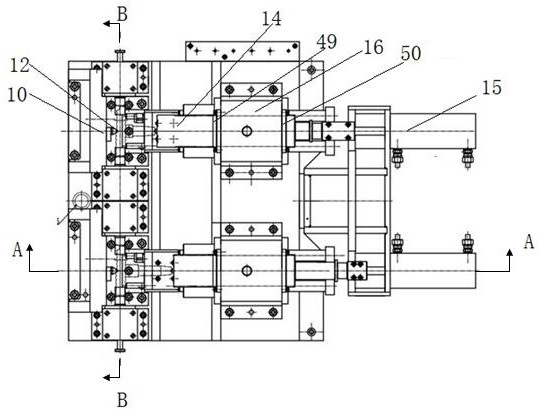

[0035] Such as figure 1 , figure 2Shown is a crankshaft precision boring pin hole special machine provided by the present invention, including a bed 1, the bed is made of gray cast iron as a whole, and a shock absorber 2 is arranged at the bottom of the bed 1, and the shock absorber is adjusted through the shock absorber. The upper surface of the bed is kept horizontal, and the upper part of the bed 1 is provided along the length direction with a boring mechanism 3 for driving the tool to feed for boring and a fixture 4 for pre-positioning, feeding, positioning and clamping of the crank shaft. The bottom of the boring mechanism 3 is provided with a hydraulic sliding table 5, and the saddle 6 on the hydraulic sliding table 5 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com